Escolar Documentos

Profissional Documentos

Cultura Documentos

A 312 PDF

Enviado por

Joao Osmar Correa0 notas0% acharam este documento útil (0 voto)

24 visualizações7 páginasTítulo original

A 312.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

24 visualizações7 páginasA 312 PDF

Enviado por

Joao Osmar CorreaDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 7

aa Designation: A 312/A 312M - 93

Standard Specification for

seen YEO NE standards

Seamless and Welded Austenitic Stainless Steel Pipes’

“This tandad is insued under the feed designation A 312/A 312Mé the number imine folowing the designation indicates the

year of orginal adoption or, inthe case of revsos, the year of last revision. A number in pareatheses indies the year of lat

reapproval A superscript epson () indicates an edifoial change sce the last revsin or reapproval

This standard has been approved for use by agencis ofthe Deparment of Defense. Cansul the DoD Index of Specifications and

Standard forthe specie ear of isue which has been adoped by the Deparment of Defnse

‘Note—Footoie A of Table 2 and 13 of were added eitoally ta Oniaber 1993

1, Scope

1.1 This specification? covers seamless and straight-seam

welded austenitic steel pipe intended for high-temperature

nd general corrosive service,

Nore (—When the impact test criterion for a low-temperature

service would be 15 ft-bf[20J] energy absorption or 15 mils (0.38 ma]

fferal expansion, some ofthe austenitic sales steel grades covered by

ths specification ae accepted by certain pressure vest or Ding codes,

‘Btnoat the necesity of making the actual tes. For example, Grades

‘Feu04, TPROSL. and TP347 are accepted bythe ASME Pressure Vessel

Tose, Section VIII Division I, and by the Chemical Plant and Refinery

Piping Code, ANSI B33, for service at temperatures as lw as ~425°F

230°C] without qualification by impact ets, Other AISI stainless steel

ae usually aovepted for Service temperatures as low 35 ~125°F

Fr00rCh without impact testing. Impact testing may, under certain

{eumsiance, be required. For example, materials with chromium oF

nickel content outside the AISI ranges, and for material with carbon

Content exceeding 0.10 8, are required to be impact tested under the

tues of ASME Section VII} Division 1 when service temperautes a7€

inet than ~S0°F (45°C).

1.2 Grades TP304H, TP309H, TP309HCb, TP3IOH,

TPIIOHCb, TP31GH, TP321H, TP347H, and TP343H

are modifications of Grades TP304, TP309Cb, TP309S,

‘TP310Cb, TP310S, TP316, TP321, TP347, and TP348, and

ae intended for

1.3 Optional supplementary requirements are provided

for pipe where a greater degree of testing is desired. These

supplementary requirements call for additional tests to be

made and, when desired, one of more of these may be

specified in the order.

1.4 The Appendix of this specification lists the dimen-

sions of welded and searaless stainless steel pipe as shovea in

ANSI 36.19. Pipe having other dimensions may be fur-

rished provided such pipe complies with all other require-

ments of this specification,

1.5 Grades TP 323 and TP 323M have lower strength

requirements for pipe manufactured by the seamless process

in nominal wall thicknesses greater than ¥ in. (9.5 mm).

1.6 The values stated in either inck-pound units or SI

units are to be regarded separately as standard. Within the

text, the SI units are shown in brackets. The values stated in

"This specification is under be friticion of ASTM Commitee 4-1 00 Stee,

Sain Se a Rete! Als ana te ect openly of Sebati

‘01.10 on Tubing.

Curt edtion approved Oct. 25, 1993. Pablshed December 1993. Originally

‘blshed a5 A 312 = 48 T. Last previous editon A 312/A 312M -923.

2 For ASME Boies and Pressure Veil Code applications see related Specif-

cation $4312 in Seri I f that Code.

163

each system are not exact equivalents; therefore, each system

‘must be used independently of the other. Combining values

from the two systems may result in nonconformance with

the specification. The inch-pound units shall apply unless the

“M" designation of this specification is specified in the order.

Nore 2—The dimensionless designator NPS (nominal pipe size) bas

been subtitued in this standard for such traditional terms a¢ “nomial

diameter,” “Sze,” and “nominal siz.”

2, Referenced Documents

2.1 ASTM Standards:

‘A262 Practices for Detecting Susceptibility

Intergranular Attack in Austenitic Stainless Steels?

‘A370 Test Methods and Definitions for Mechanical

Testing of Steel Products?

‘A 430/A 450M Specification for General Requirements

for Carbon, Ferritic Alloy, and Austenitic Alloy Steel

Tubes*

‘A S30/A 530M Specification for General Requirements

for Specialized Carbon and Alloy Stee! Pipe*

E 112 Test Methods for Determining the Average Grain

Size

E381 Method of Macroctch Testing, Inspection, and

Rating Stee} Products, Comprising Bars, Billets, Blooms,

and Forgings*

E 527 Practice for Numbering Metals aid Alloys (UNS)*

2.2 ANSI Standards

B1.20.1 Pipe Threads, General Purpose

36.10 Welded and Searniess Wrought Steel Pipe

1B36.19 Stainless Steel Pipe

23 AWS Standard:

‘859 Corrosion-Resisting Chromium and Chromium-

Nickel Stee! Welding Rods and Electrodes”

24 Other Standard:

SAE 11086 Practice for Numbering Metals and Alloys

(UNS)

3. General Requirements

3.1. Material furnished under this specification shall con-

to

2 Annual Book of ASTM Standards, ol 01.03.

‘+ Anraal Book of ASTM Standards, VO. 9

$ Annual Book of ASTM Standards, Vol 03.0)

‘Available from American National Sundarés Insitute, 11 Wert 2nd St,

1th Floor, New York, NY” 10036.

aaah fom the Ameron Walking Soe, $50 MW. Leeune Re

(FL 33138

Warrendale, PA 15096,

' Available rom Society of Automotive Engineers, 409 Commonwealth Driv,

Gh 4 312/A 312M

form to the applicable requirements of the current edition of

Specification A 530/A 530M unless otherwise provided

herein,

4. Ordering Information

4.1 Orders for material to this specification should include

the following, as required, to describe the desired material

adequately:

4.1.1 Quantity (feet, centimetres, or number of lengths),

4.1.2 Name of material (austenitic steel pipe),

4.1.3 Process (seamless or welded),

4.1.4 Grade (Table 1),

4.1.5 Size (NPS or outside diameter and schedule number

or average wall thickness),

4.1.6 Length (specific or random) (Section 10),

4.1.7 End finish (Section on Ends of Specification A $30/

‘A530M),

4.1.8 Optional requirements (Section 7),

4.1.9 Test report required (Certification Section of Speci~

fication A 530/A 530M),

4.1.10 Specification number, and

4.1.11 Special requirements or any supplementary re-

quirements selected, or both.

5. Materials and Manufacture

$1 Manufacture:

S.l.1 The pipe shall be made by the seamless or an

automatic welding process, with no addition of filler metal in

the welding operation.

5.1.2 “Welded pipe NPS 14 and smaller shall have a

single longitudinal weld, Welded pipe of a size larger than

NPS 14 may be produced by forming and welding two

longitudinal sections of fat stock when approved by the

purchaser. All weld tests, examinations, inspections, or

treatments are to be performed on each weld seam.”

5.1.3 At the manufacturer's option, pipe may be either

hot finished or cold finished.

5.1.4 The pipe shall be free of scale and contaminating

iron particles. Pickling, blasting or surface finishing is not

mandatory when pipe is bright annealed. The purchaser may

request that a passivating treatment be applied.

5.2 Heat Treatment:

1 All_pipe shall be furnished in the heat-treated

condition. The heat-treatment procedure, except for “H”

grades, $30815, $31272, and $31254, shall consist of heating

the pipe to a minimum temperature of 1900°F (1040°C] and,

‘quenching in water or rapidly cooling by other means.

5.22 All H grades shall be furnished in the solution

treated condition. If cold working is involved in processing,

the minimum solution treating temperature for Grades

‘TP321H, TP347H, and TP348H shall be 2000°F {2 100°C]

and for Grades TP304H, and TP316H, 1900°F [1040°C]. If

the H Grade is hot rolled, the minimum solution treating

temperatures for Grades TP321H, TP347H, and TP348H

shall be 1925°F [1050°C], and for Grades TP304H, and

‘TP316H, 1900°F [1040°C]. The minimum solution treating

temperature for S30815 and $31272 shall be 1920°F

[1050°C}. The minimum solution treating temperature for

‘TP309H, TP309HCb, TP3IOH, and TP3IOHCo shall be

1900°F [1040°C]

5.2.3 The heat-treatment procedure for S31254 shall con-

sist of heating the pipe to a minimum temperature of 2100°F

164

}

{1150°C] and quenching in water or rapidly cooling by other

means.

5.3,A solution annealing temperature above 1950°F |

[1065°C} may impair the resistance to intergrantstar corro-

sion after subsequent exposure to sensitizing conditions in

‘TP309HCb, TP310HCb, TP321, TP321H, TP347, TP347H, ©

TP38, and TP348H. When specified by the purchaser, a

lower temperature stabilization or resolution anneal shall be

used subsequent to the initial high temperature solution

anneal (see Supplementary Requirement 6).

5.3.4 The heat-treatment procedure for $24S65 shall con-

sist of heating the pipe to the range of temperatures 2050°F +

(1121°C) to 2140°F (170°C) and quenching in water or

rapidly cooling by other means, 7

5.4 Grain Size

5.4.1. The grain size of Grade UNS $32615, as determined 5

in accordance with Test Methods E 112, shall be No. 3 or

finer. *

5.4.2 The grain size of TP309H, TP309HC, TP310H

and TP310HCo, as determined in accordance with Test +

Methods E 112, shall be No. 6 or coarser. 4

5.4.3 The grain size of TP321H, as determined in accor-

dance with Test Methods E 112, shall be No. 7 ot coarser.

6. Chemical Composition

6.1. The steel shall conform to the requirements as to:

chemical composition prescribed in Table 1.

17. Product Analysis

7.1 At the request of the purchaser, am analysis of one’

billet or one length of flatrolied stock from cach heat, or wo

pipes from each lot shall be made by the manufacturer. Alot,

of pipe shall consist ofthe following number of lengths of the

same size and wall thickness from any one heat of steel:

‘|

[NPS Designator Leng of Pein Lot

Under 2 400 or tacion thecal

Dios 200 or fraction thereat ;

6 and over 100 0 faction thereat

7.2 The results of these analyses shall be reported to the ;

purchaser or the purchaser's representative, and shall con-. 5

form to the requirements specified in Section 6. i

7.3 If the analysis of one of the tests specified in 7.1 does

not conform to the requirements specified in Section 6, an

analysis of each billet or pipe from the same heat or lot may =

bbe made, and all billets or pipe conforming fo the require |

ments shall be accepted. {

t

'

8. Tensile Requirements z

8.1 The tensile properties of the material shall conform to

the requirements prescribed in Table 2.

9. Mechanical Tests and Grain Size Determinations Re-

quired

9.1 Transverse or Longitudinal Tension Test—One ten-

sion test shall be made on a specimen for lots of not more

than 100 pipes. Tension tests shall be made on specimens

from two tubes for lots of more chan 100 pipes.

Nore 3—The term “lot for mechanical tess, applies to all pipe of

the same diameter and wall thickness (or schedule) which are produced

fom the sume heat of steel and subjected to the same finishing

treatment: (J) in @ continuous heat-treatment furnace, or (2) in a

batch-type heat-treatment furnace, equipped with recording pyrometers

iene atamarenen terse deta are

hb A312/A 312M

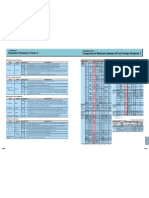

TABLE 1 Chemical Requirements

Ganpeson ©

ons ear

co ange | roe ian ts

cae | ro: | Caton. rare, rar | Seon} Nes leoramien| Sete |e | axe [ium | Mire | Yee | copper [cern | eran

or ae [ee ot | ms

Hin. 70 (485) 25 (170)

raz saz

votes rspsis) 502051

Seems:

Fan. s1si5) 301208)

> Hint 70 (488) 25 (170)

wer sumo sists] S028)

Teaern Suro) 7sists)_———S0 8)

PHB $34800_ 75515) 30205)

Trace soumme 731515) S051

pmo Seco S0(ez0)—S0(31

Thaw Srioot Soles] —S0Lss)

Texts Soro Tststs] ©3015)

Tone szicco —s00(e00] S510)

TPXMA9. $20910 100 (690) ‘55 {380}

TP304N s3045t ‘80 (580) 35 (240)

‘Teaten (s31651 80 (550) 35 (240)

‘TP304LN ‘$0453, 75 (515) (30 (205)

Treo Sess Fetes] © Sts)

. $31254 ‘94 (650) 44 [300]

Sons evieoo) as 810

Sie Toso] 35 (20)

enves sists] 025)

ses cote] 20)

sme

isoasn ese) so

Doze miso ass)

: sums owls) aay

Seas —_ieiresl eau

Smowonn 2 ersomm rao. Tae

Gade capt STO wna SSTE 35 7%

Sito: soese Es

“Pot to the issuance of A SI2/ASIOM

valves were 76 [515] and 90 (205), respectively, fr nominal wal greater han

n,m,

and automatically controled within a SO°F [30°C] range, the lager of

(2) Eack 200 & (60 m] or faction thereof or, (6) That pipe heat treated

‘im the same batch furnace charg.

9.2. Flattening Test—For material heat treated in a batch-

type furnace, flattening tests shall be made on 5 % of the pipe

from each heat-treated lot. For materia! heat treated by the

continuous process, this test shall be made on a sufficient

‘number of pipe to constitute 5% of the lot, but in no case

less than two lengths of pipe.

9.2.1 For welded pipe a transverse-guided face bend test of

Pe Filer Mata

aS rye

Grade gy —e UNS Designation

Troe S20400 Roo ‘$0800, wa08e0

Tea. $3040 RSet Seosss, wo08es

Troon 580451 F908 ‘Se0se0, w508e0

Troan $30453 RSet. 50883, W083

Trap 536409 F908 'S90860, 90840

‘Teaoec> — $30840 2 i

Teooes— $30908 g 3 :

Tsiocs— S31040 i

Tess 831008,

so1a72

qesie 831500 ERare sste80, wsis40

Trove. 91003 ERSEL 31683, W51643

Trove S31651 ERG Sor6s0, w31840

TROON 531853, ERSV6L 31653, W583

TRai6H 831809 enaien Sain. wareia

RQ21 180, W240

TES ee een ERAT Sacred wared

eur 38700 ERa7 4760, woa7e0

Tema $34800 ERSA7 $4780, w94740

TPxw.t9 — $22100 R200 ‘S2n960, w32240

TPxM20 __ §28300 R20 ‘523960, Wa2440

the weld may be conducted instead of a flattening test in

accordance with the method outlined in the steel tubular

product supplement of Test Methods and Definitions A 370,

‘The ductility of the weld shall be considered acceptable when

there is no evidence of cracks in the weld or between the

weld and the base metal after bending. Test specimens from

5 % of the lot shall be taken from the pipe or test plates of the

same Taterial as the pipe, the test plates being attached to |

the end of the cylinder and welded as a prolongation of the

pipe loagitudinal seam.

9.3 Hydrostatic Test—Each length of finished pipe shall: ¢

be subjected to the hydrostatic test in accordance with |

Specification A 530/A 530M, unless specifically exempted

under the provisions of 9.4.

94 For pipe whose dimensions equal or exceed NPSIO,

the purchaser with the agreement of the manufacturer may!

waive the hydrostatic test requirement when in lieu of such

test the purchaser performs a system test. Each length of pipe

furnished without the completed manufactures's hydrostatic”

test shaif include with the mandatory markings the letters q

“NH”

9.5 Grain Size—Grain size determinations on grades

TP309H, TP309HCb, TP310H, TP310HCb, and UNS

$32615 shall be made on the same number of tubes as

prescribed for the flattening test.

10. Lengths

10.1 Pipe lengths shall be in accordance with the fol-

lowing regular practice:

10.1.1 Unless otherwise agreed upon, all sizes from NPS.

Yo to and including NPS 8 are available in a length up to 24

‘(Note 4] with the permissible range of 15 to 24 ft [Note 4].

Short lengths are acceptable and the number and minimum

fength shall be agreed upon between the manufacturer and

the purchaser.

Note 4—This values) applies when the inch-pound designation of

‘this specification isthe basis of purchase. When the “M" designation of

this specification is tbe basis of purchas:, the corresponding m

166

pb A312/A 312M

saluels) shall be agreed upon between te manuBicturer and the

purchaser.

10.1.2 If definite cur lengths are desired, the lengths

required shall be specified in the order. No pipe shall be

acer the specified length ard not more than ¥ in. (5 mm]

ves that specified. -

10.1.3 No jointers are permitted unless otherwise speci-

fied.

11. Workmanship, Finish, and Appearance

11.1 The finished pipes shall be reasonably straight and

gyall have a workmanlike finish. Imperfections may be

femoved by grinding, provided the wall thicknesses are not

Georeased t0 less than that permitted in Section 8 of

‘Specification A 530/A 530M.

12, Repair by Welding

12.1 For welded pipe whose diameter equals or exceeds

NPS 6, and whose nominal wall thickness equals or exceeds

0.200, weld repairs made with the addition of compatible

filler metal may be made to the weld seam with the same

‘ocedures specified for plate defects in the section on Repair

by Welding of Specification A 530/A 530M.

12.2 Weld repairs of the weld seam shall not exceed 20 %

of the seam lengths.

123 Weld repairs shall be made only with the gas

tungsten-arc welding process using the same classification of

bare filles rod qualified to the most current AWS Specifica-

tion A5.9 as the grade of stainless steel pipe being repaired

and as shown in Table 3,

124 Pipes that have bad weld seam repairs with filler

metal shall be uniquely identified and shall be so stated and

identified on the certificate of tests.

13. Product Marking

13.1 In addition to the marking specified in Specification

A 530/A S30M, the marking shall include the manufactur-

ers private identifying mark, the marking requirement of

9.4, if applicable, and whether seamless or welded. For

Grades TP304H, TP316H, TP321H, TP347H, TP348H, and

30815, the marking shall also include the heat number and.

heat-treatment lot identification. If specified in the purchase

order, the marking for pipe larger than NPS 4 shall include

the weight,

14, Government Procurement

14.1 Scale Free Pipe jor Government Procurement:

14.1.1 When specified in the contract or order, the

following requirements shall be considered in the inquiry,

contract or order, for agencies of the U.S. Government

where scale free pipe or tube is required. These requirements

shall take precedence if there is a conflict between these

Tequirements and the product specifications.

14.1.2 The requirements of Specification A 530/A 530M

for pipe and Specification A 450/A 450M for tubes shall be

applicable when pipe or tube is ordered t0 this specification.

14.1.3 Pipe and tube shall be one of the following grades,

as specified herein:

Gate [UNS Designation

eso 0400

TPs, S30403,

TRON 30851

P36 31600

TEL, 31603

TP3GN 531651

PRT 331700

eHITL 31705

Ta ‘sani

eM? 34700

14.1.4 Part Number:

Example: ASTM A 312 Pipe 304 NPS 12 SCH 40S SMLS

Specification Number ASTM A312

Pie P

Grate 304

NPS 2

Wal 5 ors

SMLS OR WELDED SME

141.42

Specification Number -. ASTM ABIZ

Tate T

Grace 308

Oussice Diameter 0280

Wall 03s

SMLS OR WELDED wD

14.1.5 Ordering Information—Orders for material under

this specification shall include the following in addition to

the requirements of Section 4:

16.1.5.1 Pipe or tube,

14.152 Part number,

14.1.5.3 Ultrasonic inspection, if required,

14.154 If shear wave test is to be conducted in two

opposite circumferential directions,

14,1.5.5 Intergranular corrosion test, and

14.1.5.6 Level of preservation and packing required.

‘SUPPLEMENTARY REQUIREMENTS FOR PIPE REQUIRING

SPECIAL CONSIDERATION

One of more of the following supplementary requirements shall apply only when specified in the purchase

order. The purchaser may specify a different frequency of test or analysis than is provided in the

supplementary requirement. Subject to agreement between the purchaser and manufacturer, retest and

‘etceatment provisions of these supplementary requirements may also be modified,

SI. Product Analysis

SL.1 For all pipe NPS $ and larger in nominal size there

shall be one product analysis made of a representative

sample ftom one piece for each ten lengths or fraction

167

thereof from each heat of steel.

$1.2 For pipe smaller than NPS 5 there shall be one

product analysis made from ten lengths per heat of steel or

from 10% of the number of lengths per heat of steel,

hb A312/A 312M

whichever number is smaller.

1.3. Individual lengths failing to conform to the chemical

requirements specified in Section 6 shall be rejected.

'S2. Transverse Tension Tests

$2.1 There shall be one transverse tension test made from

‘one end of 10 % of the lengths furnished per heat of steel

This applies only to pipe NPS 8 and larger.

‘$2.2 Ifa specimen from any length fails to conform to the

tensile properties specified that length shall be rejected.

3. Flattening Test

$3.1 The flattening test of Specification A 530/A 530M

shall be made on a specimen from one end or both ends of

each pipe. Crop ends may be used. If this supplementary

Tequirement is specified, the number of tests per pipe shail

also be specified. Ifa specimen from any length fails because

of lack of ductility prior to satisfactory completion of the first

step of the flattening test requirement, that pipe shall be

rejected subject to retreatment in accordance with Specifica-

m_ A 530/A 30M and satisfactory retest. If a specimen

ym any length of pipe fails because of a lack of soundness,

that length shall be rejected, unless subsequent retesting

indicates that the remaining length is sound.

S4, Etching Tests

S4.1. The steel shall be homogeneous as shown by etching

tests conducted in accordance with the appropriate portions

of Method E 381. Etching tests shall be made on a cross

section from one end or both ends of each pipe and shall

show sound and reasonably uniform material free of inju-

rious laminations, cracks, and similar objectionable defects.

If this supplementary requirement is specified, the number of

‘tests per pipe required shall also be specified. If 2 specimen

from any length shows objectionable defects, the length shall

be rejected, subject to removal of the defective end and

subsequent retests indicating the remainder of the length to

168

be sound and reasonably uniform material.

SS. Radiographic Examination

$5.1 The entire length of weld in each double welded pipe

‘Shall be radiographically examined, using X-radiation, in

accordance with Paragraph UW-S51 of Section VIII Division

1 of the ASME Boiler and Pressure Vessel Code. In addition

to the marking required by Section 13 each pipe shall be

marked “RT” after the specification and grade. Require-

ments of $5 shall be required in the certification.

$6. Stabilizing Heat Treatment

$6.1 Subsequent to the solution anneal required in 5.3,

Grades TP309HCb, TP310HCb, TP321, TP321H, TP347,

‘TP347H, TP348, and TP348H shall be given a stabilization,

heat treatment at a temperature lower than that used for the

initial solution annealing heat treatment. The temperature of

stabilization heat treatment shall be at 2 temperature as

agreed upon between the purchaser and vendor.

7. Intergranular Corrosion Test

S7.1 When specified, material shall pass intergranular

corrosion tests conducted by the manufacturer in accordance

with Practices A 262, Practice E.

Nore s—Practice E requires testing oo the sensitized condition for

low carbon or stabilized grades, and on the ai-hipped condition for

other grads.

$7.2 A stabilization heat treatment in accordance with

Supplementary Requirement S6 may be necessary 2nd is

permitted in order to meet this requirement for the grades

containing titanium or columbium, particularly in their H

versions.

8. Minimum Wall Pipe

$8.1 When specified by the purchaser, pipe shall be

furnished on a minimum wall basis. The wall of such pipe

shall not fall below the thickness specified. In addition to the

smarking required by Section 13, the pipe shall be marked $8.

Gh A 312/A 312M

APPENDIX

‘{Nonmandatory Information)

. TABLE X1.1 IS BASED ON TABLE 1 OF THE AMERICAN NATIONAL STANDARD FOR STAINLESS

STEEL PIPE (ANSI B36.19-1965)

TABLE X1.1 Dimensions at Welded and Seamless Stainless Stee! Pipe

nore —The decal hickness liste for the respective pipe sizes represents te noina x erage wall mensions.

Ouisice Dameter oranal Wall Tae

nee = ame Sereae 55 ‘Scheaule 109" Schedule 405 Secreta 29S

B = m om FY El |

ie D405 7028 ‘089 1280068 17 Bai

% 90540 1372 be é 0.065 16 ges 2a 302

* oss (1715 0.085 1550031 2at 320

e 0880 2136 66s iis 2m 0309 27 am

% 1050 2587 0085 AS 2 ons 2a7 331

10 1315 3840 0.085 165 27 0383 338 455,

+e 1360 2216 0.085 185 2n — ai4o 338 435

‘ 1.900 4825 0.065 165 27 OMS aR 508

2 2375 e033 085 155 27 ose 391 ry

i 2875 73.09 ooe 2a 305 0203 518 70

3 3.500 83.90 0.083 20 305 0216 543 782

3M 4000 101.60, 0.083 2H 305 0228 5% 308

2 450011430, 0.083 an 305 (Daa 02 038

5 Ss 14130 0.109 a4 0258 655 952

5 662518828, 0.108 340 0200 mM 1097

3 8825 218.08, 0.108 375 oaz2 B18 3270

0 10750 273.05 axa 4190965 927 y2708

2 12750 323.85, 0155 oa7se 9528 12708

16 1400035550, 0.188 2 z :

16 16000 408.40 0.365

8 1g000 457.20 165

2 20.000 50800 188

2 00 55880 0.188 478 soto

x 24000 608.60 0218 550 635

2 a000___762.00 0250 835 792

“Schedules 38 and 105 wat Pickresses donot permit treading in accordance with the Arercan National Standard for Pipe Threads (ANSI B3.20.9,

‘These 60 not conform tothe Amencan National Stanger tr Wiliad and Searsoss Wrought Stvel Pipe (ANS! 536,10-1979)

‘The American Socey for Testing and Matrias takes 2 positon respecting tha vast ct any saan ights assorted connection

wit any tam mentioned inthis stancard. Users of hs stand are expressly acvsed that detrmiacon ofthe vast Of any Such

‘atant rhs, and the risk ot ingemart of such rights are entraly ther own responsibly

‘his tancar is sje to revision af anytime by he resgonsbie occa! commie and must be reviewed every ve years anc

{net revised, eer reaporoved or wirawn. Your cormments are nite ether or rension ots standard oor agonal stardaras

ang should be adressed 1 ASTM Headquarters. Your comments wil feceive cartul consideration af mowing othe responsible

technical commis, when you may alent you fe! that your comerens Rave ne received a far hearing you should make yet

nme sown tote ASTM Commitee 2 Standarés, 1916 Race Se, Philpha, PA 19103.

169

Você também pode gostar

- A 192 PDFDocumento2 páginasA 192 PDFJoao Osmar CorreaAinda não há avaliações

- Electric-Resistance-Welded and Carbonamanganere Boiler Tuôes'Documento3 páginasElectric-Resistance-Welded and Carbonamanganere Boiler Tuôes'Joao Osmar CorreaAinda não há avaliações

- TCC - Estudo Medição de EngrenagensDocumento132 páginasTCC - Estudo Medição de EngrenagensIdentinet2Ainda não há avaliações

- Abnt NBR 15417Documento59 páginasAbnt NBR 15417Joao Osmar CorreaAinda não há avaliações

- ASME VIII CalculationDocumento15 páginasASME VIII CalculationJoao Osmar Correa100% (1)

- TCC - Estudo Medição de EngrenagensDocumento132 páginasTCC - Estudo Medição de EngrenagensIdentinet2Ainda não há avaliações

- ASME VIII CalculationDocumento15 páginasASME VIII CalculationJoao Osmar Correa100% (1)

- Nova NR-13Documento22 páginasNova NR-13Joao Osmar CorreaAinda não há avaliações

- Dimensionamento de Equipamentos 1 - Vasos de PressãoDocumento104 páginasDimensionamento de Equipamentos 1 - Vasos de Pressãonosepe100% (63)

- Design Calculations For Pressure Vessels PDFDocumento24 páginasDesign Calculations For Pressure Vessels PDFJoao Osmar CorreaAinda não há avaliações

- Nova NR-13Documento22 páginasNova NR-13Joao Osmar CorreaAinda não há avaliações

- Ultrassom AsmeDocumento2 páginasUltrassom AsmeJoao Osmar CorreaAinda não há avaliações

- ZincagemDocumento5 páginasZincagemJoao Osmar CorreaAinda não há avaliações

- ZincagemDocumento7 páginasZincagemJoao Osmar CorreaAinda não há avaliações

- Trabalho de VasosDocumento27 páginasTrabalho de VasosJoao Osmar CorreaAinda não há avaliações

- Catalogo Ibombas ImbilDocumento15 páginasCatalogo Ibombas ImbilJoao Osmar CorreaAinda não há avaliações

- Trabalho de VasosDocumento27 páginasTrabalho de VasosJoao Osmar CorreaAinda não há avaliações

- PM - Ims 65 05 15Documento6 páginasPM - Ims 65 05 15Joao Osmar CorreaAinda não há avaliações

- Material ComparisonDocumento1 páginaMaterial ComparisonSheikh Yasir SaleemAinda não há avaliações

- Vaso Pressao CoteqDocumento31 páginasVaso Pressao CoteqEdimilson AlvesAinda não há avaliações

- Tabela de Conversao de Dureza 2Documento5 páginasTabela de Conversao de Dureza 2Jarbas MoraesAinda não há avaliações

- Ensaio ultrassom peças norma critério limpezaDocumento1 páginaEnsaio ultrassom peças norma critério limpezaJoao Osmar CorreaAinda não há avaliações

- Tabela de Equivalência de Dureza para AçosDocumento5 páginasTabela de Equivalência de Dureza para AçosJoao Osmar CorreaAinda não há avaliações

- Alinhamento de BombasDocumento65 páginasAlinhamento de BombasJoao Osmar Correa100% (1)

- Dissertacao EndDocumento126 páginasDissertacao EndMarcos SilvaAinda não há avaliações

- Catalogo Ibombas ImbilDocumento15 páginasCatalogo Ibombas ImbilJoao Osmar CorreaAinda não há avaliações

- To de GradeDocumento2 páginasTo de GradeJoao Osmar CorreaAinda não há avaliações

- Tabela3 Conversao MedidasDocumento2 páginasTabela3 Conversao MedidasJoao Osmar Correa100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)