Escolar Documentos

Profissional Documentos

Cultura Documentos

Air Conditioning Plant Marine

Enviado por

krishnaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Air Conditioning Plant Marine

Enviado por

krishnaDireitos autorais:

Formatos disponíveis

G.E.

Q.

Make diagrammatic sketch of an air condition plant and system for

cooling accommodation and how to regulate in individual room

control.

Thermostatic expansion valve control.

Condenser

in

Cabins

Cooling water

out

Compressor

Steam

Humidifier

Flat valve

Fresh

Air

Blower fan

Recirculation

Air

Air Filter

Coolin g

coil

Heater

coil

The human body's sensation of comfort influenced by: (a) Surrounding air temperature.

(b) Surrounding air humidity.

(c) Surrounding air velocity.

(d) Surrounding air freshness.

The cooling function of an air conditioning system reduces both the

temperature and humidity of hot humid air. Passing the air over a

cooler takes out both heat and moisture.

Comfort zone is between 40% to 70% relative humidity at 20 to 29C

dry bulb temperature.

Humidification: To increase moisture content, a fine water spray

controlled by solenoid valve can be introduced. This action can be

initiated by HUMIDISTAT.

Dehumidification: Extraction of moisture is achieved by cooling the

atmosphere below its DEW POINT and being initiated by HUMIDISTAT.

The single duct air condition system can provide both HEATING and

COOLING with control of HUMIDITY.

The sketch shown is a single air duct system. The cooling coil is

direct expansion and a separate steam heating coil is fitted in the

unit for winter heating.

About 25% of outside air is drawn in so as to balance the system

circulation. Extra moisture added to the air by Humidifier reduces its

drying effect. Humidifier must be installed after the steam heaters to

prevent dryness of nasal passage, mouth and throat causing discomfort.

G.E.K

INDIVIDUAL ROOM CONTROL

The all zones' temperature control can be manipulated by the use of

compressor suction pressure via the solenoid valves as step

controlling and capacity unloading of compressor units as required.

The last step controlling has been done by capacity unloader and to

save the workload of the compressor by means of thermostat placed at

some accommodation space and it actuates the Master solenoid valve of

the Refrigeration plant which will stop the compressor when the preset temperature has been reached.

The particular Zone's temperature can be controlled by the flap

valve provided at each loop of the Zone ducts.

Local cabin temperature can be adjusted by volume controlled at the

delivery point air duct controller.

Thermostatic expansion valve control

The thermostatic expansion valve controls the flow of liquid

refrigerant to the evaporator, in such a way as to keep practically

that (1) entire coil filled with evaporating refrigerant and also to

keep (2) a constant super heat in the refrigerant vapour leaving the

evaporator.

The opening of valve is control by pressure variation on the top of

the diaphragm. The pressure on the diaphragm is form a closed system

of heat sensitive fluid (charge with the same refrigerant used in the

system) in the bulb; fasten to the evaporator out let, in the

capillary connected to the top of the diaphragm.

If the evaporator is operating with no super heat the pressure above

and below the diaphragm are equal. The diaphragm is also spring loaded

so that the refrigerant gas on the evaporator out let obtained super

heat temperature of about 6.6C.

{Not for exam: In passing through the valve there is the certain drop in pressure and

temperature, and a proportion of the refrigerant liquid flashes into gas. The

expansion valves have small orifice in order to effect the desire pressure reduction.

They are therefore prone to choke from any dirt in the system and so are always

protected by fine filters, which should be cleaned if any blockage is suspected. As

this valve is the first in the refrigerating circuit at which the temperature falls,

and if the plant is operating temperature below 0C, then any moisture in the circuit

will freeze out and ice may choke the expansion valve.}

When a valve is functioning correctly frost form on the outlet side of the valve,

and if the inlet side thus show frosting then this is a sign of blockage.

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Latvia Marine Engineering Test PaperDocumento90 páginasLatvia Marine Engineering Test PaperkrishnaAinda não há avaliações

- Marine Survey Practice - Notes Relative To Shell and Deck Plate RepairsDocumento2 páginasMarine Survey Practice - Notes Relative To Shell and Deck Plate RepairskrishnaAinda não há avaliações

- A Family History of Alladi Jagannat (Ebooksread - Com) PDFDocumento274 páginasA Family History of Alladi Jagannat (Ebooksread - Com) PDFkrishnaAinda não há avaliações

- Marine Survey Practice - Surveyor Guide Notes For Bilge Keels SurveyDocumento2 páginasMarine Survey Practice - Surveyor Guide Notes For Bilge Keels SurveykrishnaAinda não há avaliações

- Boiler Uptake Fire All NotesDocumento2 páginasBoiler Uptake Fire All NoteskrishnaAinda não há avaliações

- Boiler Uptake Fire 3Documento1 páginaBoiler Uptake Fire 3krishnaAinda não há avaliações

- Inspection On EconomiserDocumento2 páginasInspection On Economiserkrishna50% (2)

- Inspections and Survey Procedures in Auxiliary BoilerDocumento16 páginasInspections and Survey Procedures in Auxiliary BoilerkrishnaAinda não há avaliações

- Power Plant Interview Questions & AnswersDocumento1 páginaPower Plant Interview Questions & AnswerskrishnaAinda não há avaliações

- Boiler Inspection in FurnaceDocumento4 páginasBoiler Inspection in FurnacekrishnaAinda não há avaliações

- Safety Valve Floating MrthodDocumento4 páginasSafety Valve Floating MrthodSanjay ChakrabortyAinda não há avaliações

- Crankshaft SlippageDocumento3 páginasCrankshaft SlippagekrishnaAinda não há avaliações

- Safety Valve Setting BoilerDocumento2 páginasSafety Valve Setting BoilerkrishnaAinda não há avaliações

- Oil Whip and Oil WhirlDocumento1 páginaOil Whip and Oil WhirlkrishnaAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Dividido Trane 30 TonsDocumento23 páginasDividido Trane 30 TonsairemexAinda não há avaliações

- HVAC Basics Lunch & LearnDocumento64 páginasHVAC Basics Lunch & LearnTerry BuddAinda não há avaliações

- Armstrong - All Products Catalog PDFDocumento528 páginasArmstrong - All Products Catalog PDFsabotaaageAinda não há avaliações

- Air Cycle RefrigerationDocumento15 páginasAir Cycle RefrigerationSyed Wajih Ul HassanAinda não há avaliações

- Sypox Methane To h2 29-07 - GPDocumento14 páginasSypox Methane To h2 29-07 - GPDiegoAinda não há avaliações

- Heat Pump HandbookDocumento6 páginasHeat Pump Handbookmayank3478100% (1)

- P&Id Area 47 - Sulphidiser Plant Dehumidifier and Co2 SystemDocumento1 páginaP&Id Area 47 - Sulphidiser Plant Dehumidifier and Co2 SystemGoulet KostAinda não há avaliações

- Commercial Product CatalogDocumento44 páginasCommercial Product CatalogSavad AlwyeAinda não há avaliações

- Task 3: Liquid CoolingDocumento4 páginasTask 3: Liquid CoolinghabibullaAinda não há avaliações

- Absorb WaterDocumento5 páginasAbsorb WaterMonday VerdejoAinda não há avaliações

- Lab Manual-Aircon System-Level 2-TrendlineDocumento2 páginasLab Manual-Aircon System-Level 2-TrendlinetashaAinda não há avaliações

- Grzanie DodatkoweDocumento104 páginasGrzanie DodatkowemorusAinda não há avaliações

- Converted 277031216Documento57 páginasConverted 277031216Daniel SoseAinda não há avaliações

- Air DryerDocumento14 páginasAir DryerIhsan Habib AbikAinda não há avaliações

- Termostato Robertsaw AnsalDocumento7 páginasTermostato Robertsaw Ansalcapacitacion bomberos voluntarios sarmientoAinda não há avaliações

- Coupling The Multizone Airflow and Contaminant Transport Software Contam With Energyplus Using Co-SimulationDocumento2 páginasCoupling The Multizone Airflow and Contaminant Transport Software Contam With Energyplus Using Co-SimulationBv BvAinda não há avaliações

- Suzlon Pune Case Study Green BuildingDocumento10 páginasSuzlon Pune Case Study Green BuildingAnand Chavan Projects-Quality100% (1)

- Tax SlabsDocumento2 páginasTax SlabsFurqan HasanAinda não há avaliações

- Temperature Mapping Study and Qualification - Vacker UAEDocumento15 páginasTemperature Mapping Study and Qualification - Vacker UAEVacker Group UAE100% (3)

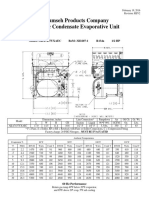

- Tecumseh Products Company Hermetic Condensate Evaporative UnitDocumento2 páginasTecumseh Products Company Hermetic Condensate Evaporative UnitAlexisAinda não há avaliações

- Dd2 (Detailed) Station - The White Palace Chilled Water Systems Schematic (East)Documento1 páginaDd2 (Detailed) Station - The White Palace Chilled Water Systems Schematic (East)Muhammad IshtiaqueAinda não há avaliações

- H2 Type Direct Fire Chiller Operation Manual PDFDocumento79 páginasH2 Type Direct Fire Chiller Operation Manual PDFUmar Majeed100% (2)

- Reporte VRF Lennox Group Engineering Diether 2020-09-03Documento7 páginasReporte VRF Lennox Group Engineering Diether 2020-09-03Felipe ElielAinda não há avaliações

- PM Utility: Manufacturing Department PT Indo Tirta AbadiDocumento10 páginasPM Utility: Manufacturing Department PT Indo Tirta Abadisetyo agungAinda não há avaliações

- BarrisolDocumento8 páginasBarrisolZh KaAinda não há avaliações

- A Check Valve in The Chiller BypassDocumento5 páginasA Check Valve in The Chiller BypassGaye KanalAinda não há avaliações

- Cooling Tower PDFDocumento7 páginasCooling Tower PDFShahid HussainAinda não há avaliações

- MullerDocumento5 páginasMullerTafadzwa MurunguAinda não há avaliações

- Ghanshyam Vaidya CompressedDocumento208 páginasGhanshyam Vaidya CompressedVenkatesh DharavathAinda não há avaliações

- Refrigerator: Model: SR-L676EV SR-L678EV SR-L626EV SR-L628EVDocumento59 páginasRefrigerator: Model: SR-L676EV SR-L678EV SR-L626EV SR-L628EVMiguel Alejandro RondonAinda não há avaliações