Escolar Documentos

Profissional Documentos

Cultura Documentos

United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0256911 A1

Enviado por

DANESITítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0256911 A1

Enviado por

DANESIDireitos autorais:

Formatos disponíveis

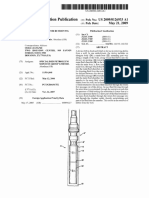

US 20070256911A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2007/0256911 A1

Legallais et al.

(43) Pub. Date:

(54) CONVEYOR DEVICE WITH AN IMPROVED

(30)

NOV. 8, 2007

Foreign Application Priority Data

TRANSFER ARM

Mar. 5, 2004

(75)

Inventors: Stephane Legallais, Octeville sur Mer

(FR); Vincent Brachet, Octeville sur

Mer (FR); Denis Gillet, Octeville sur

Mer (FR)

(FR) ............................................ .. 0450454

Publication Classi?cation

(51)

Int. Cl.

B65G 47/84

US. Cl. ........................................................ ..198/468.3

(2006.01)

Correspondence Address:

(52)

YOUNG & THOMPSON

745 SOUTH 23RD STREET

2ND FLOOR

(57)

ABSTRACT

Device for conveying objects, includes a rotating support

ARLINGTON, VA 22202 (US)

having a transfer arm Which consists of a plate and a gripper

head Which can hear at least one object and Which is

(73) Assignee: SIDEL

PARTICIPATIONS,

OCTEVILLE SUR MER (FR)

(21) Appl. No.:

10/591,400

(22)

PCT Filed:

Feb. 7, 2005

(86)

PCT No.:

PCT/EP05/50499

371(c)(1),

(2), (4) Date:

Jun. 18, 2007

76930

slidingly mounted in relation to the plate according to a

direction. The gripper head (20) is coupled to a slider sliding

in a slide rail ?xed to the plate, and including a ?rst and

second cam system in order to respectively slidingly drive

the gripper head and to pivotingly drive the plate, according

to the angular position of the arm around the axis of rotation

of the support. The slider is constructed as a single part

Which has an overall rail shape, and the pro?le of the slider

is complementary With respect to the pro?le of the slide rail.

The gripper head is ?xed such that it overhangs on the distal

end section of the slider.

Patent Application Publication Nov. 8, 2007 Sheet 1 0f 3

US 2007/0256911 A1

Patent Application Publication Nov. 8, 2007 Sheet 2 0f 3

US 2007/0256911 A1

Patent Application Publication Nov. 8, 2007 Sheet 3 0f 3

US 2007/0256911 A1

Nov. 8, 2007

US 2007/0256911 A1

CONVEYOR DEVICE WITH AN IMPROVED

TRANSFER ARM

[0001]

The present invention relates to a device for con

veying objects.

[0010] The purpose of the invention is, in particular, to

overcome these disadvantages by proposing a conveying

device comprising at least one more compact and lighter

transfer arm.

[0011]

[0002]

For this purpose, the invention proposes a convey

The present invention relates more particularly to a

ing device of the type previously described, characterized in

device for conveying objects such as preforms and bottles,

of the type comprising a rotating support Which is driven in

that the slider is produced in one piece With the overall shape

of a rail, the pro?le of the slider being complementary to the

pro?le of the slide, and in that the grasping head is ?xed in

rotation continuously about a substantially vertical axis of

rotation and Which carries a transfer arm, of the type in

Which the transfer arm comprises a supporting element

Which is mounted in a sWivelling manner With respect to the

a cantilevered manner to the distal end section of the slider.

rotating support, about a sWivelling spindle Which is sub

stantially parallel to the axis of rotation of the support, and

[0013] the ?rst cam system comprises a ?rst cam folloWer

element Which is ?xed to the distal end section of the slider;

a grasping head Which is able to support at last one object

and Which is mounted in a sliding manner With respect to the

[0014] the ?rst cam folloWer element is a roller called the

extension roller Which is mounted freely rotating on a roller

supporting element, in a direction approximately radial With

respect to the axis of rotation of the support, betWeen a

proximal retracted position and a distal extended position

With respect to the axis of rotation, of the type in Which the

grasping head is attached to a slider sliding in a slide ?xed

on the supporting element, and of the type comprising a ?rst

cam system and a second cam system for driving the

grasping head in its sliding and the supporting element in its

[0012] According to other features of the invention:

spindle substantially parallel With the axis of rotation of the

support, and the roller spindle is ?xed on the distal end

section of the slider through a portion of the grasping head,

in such a Way as to constitute a means of ?xing the grasping

head on the slider;

[0015]

the transfer arm comprises a return device Which is

interposed totally along the extension axis betWeen the distal

sWivelling respectively, according to the angular position of

end section of the slider and the supporting element in such

the arm about the axis of rotation of the support.

a Way as to return the grasping head to its retracted position;

[0003] Conveying devices of this type are found in con

tainer bloWing machines in Which the container is obtained

[0016]

the distal end of the return device is ?xed on the

by bloWing by inserting a preform previously produced by

spindle carrying the extension roller;

[0017] the supporting element comprises a main body

injection moulding into a bloWing mould. These machines

Which is provided With a sWivelling leg carrying at least one

are for example used for the manufacture of bottles made of

cam folloWer element Which is part of the second cam

polyethylene terephthalate (PET).

[0004]

The preform has the shape of a tube Which is closed

at one end and Whose other end already has the de?nitive

shape of the neck of the container.

[0005] The preform is therefore placed inside the mould

after having been brought to an appropriate temperature in

a heat conditioning oven. Once bloWn, each container is

removed from the mould to be taken to the output of the

machine.

[0006] Many container-bloWing machines are of the rotary

type. They therefore comprise a carrousel Which rotates

continuously about its axis and Which carries, at its periph

ery, a series of identical moulds.

[0007] Conveying devices With a transfer arm therefore

make it possible, on the one hand, to introduce preforms into

the moulds and, on the other hand, to WithdraW the contain

ers once formed, to and to do this Without having to stop the

carrousel. The transfer arms, because of their extension and

retraction capabilities on the one hand and their capability of

accelerating or sloWing doWn the head by means of sWiv

elling on the other hand, make it possible to avoid any

interference betWeen the moulds and the conveyed objects.

[0008] A conveying device of this type is described and

shoWn in the document WO-A-0l/44084.

[0009] This device, even though it has been satisfactory,

has certain limitations hoWever, in particular When it is made

to operate at high rates. The transfer arm can then prove to

be relatively bulky and heavy, Which results in high inertia

during movements.

system, and the proximal end of the return device is ?xed on

the sWivelling leg;

[0018] the return device is a spiral draW-spring Which

extends entirely under the loWer face of the slider;

[0019] the grasping head comprises a lug for ?xing it to

the distal end transverse face of the slider and a ?xing screW

Which is screWed into the distal end transverse face of the

slider through the lug;

[0020] the proximal end section of the slider comprises a

stop Which is able to cooperate With an associated surface of

the supporting element for determining the maximum exten

sion travel of the grasping head;

[0021] the supporting element comprises a ball bearing

Which receives the loWer axial end of the sWivelling spindle

such that the supporting element is mounted freely rotating

about the sWivelling spindle;

[0022] the sWivelling spindle comprises a threaded inter

mediate section Which is screWed into a spacer ?xed to the

rotating support to alloW height adjustment of the supporting

element With respect to the rotating support and means of

locking the sWivelling spindle in an adjusted position With

respect to the spacer;

[0023] the upper axial end of the sWivelling spindle com

prises a means of driving the sWivelling spindle in rotation

for the purpose of adjusting the height of the supporting

element.

[0024] Other features and advantages of the invention Will

appear on reading the folloWing detailed description, for the

understanding of Which reference is made to the appended

draWings in Which:

Nov. 8, 2007

US 2007/0256911 A1

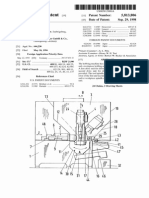

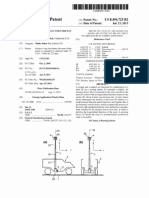

[0025]

FIG. 1 is a perspective vieW Which diagrammati

cally shows a conveying device equipped With a transfer arm

produced according to the disclosures of the invention;

[0026]

FIG. 2 is a perspective vieW Which diagrammati

cally shoWs the transfer arm of FIG. 1 in the retracted

position;

[0027] FIG. 3 is a cross-sectional vieW through the plane

3-3, Which diagrammatically shoWs the transfer arm of FIG.

1 in the retracted position;

[0028]

FIG. 4 is a plan vieW Which diagrammatically

shoWs the transfer arm of FIG. 1 in the retracted position.

[0029] In the folloWing description, identical, similar or

analogous elements Will be denoted by the same reference

numbers.

[0030] FIG. 1 shoWs a conveying device 10 ofthe type of

those that can be found in machines for manufacturing

containers made of PET by bloWing preforms, the preforms

being previously obtained by injection moulding and then

being heated above the vitreous transition temperature of

PET before being successively introduced into bloWing

moulds.

[0031] The conveying device 10 can be used in particular

for conveying the preforms or for conveying the containers.

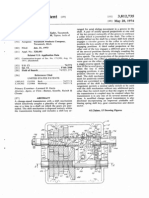

[0040]

The pro?le of the slider 22 is complementary to the

pro?le of the groove 25 of the slide 24 such that the slider

22 is held vertically doWnWards by the slide 24 and its

adapted pro?le.

[0041] The slider 22 is therefore constituted by a metal T

pro?le, in transverse cross-section With respect to the direc

tion of sliding BO, and the slider 22 is held vertically in the

slide 24 by the horiZontal branches of the T.

[0042]

It is noted that the slider 22 and the slide 24 can be

produced easily by machining.

[0043]

In a knoWn Way, the conveying device 10 com

prises a ?rst cam system and a second cam system for

driving the grasping head 20 in sliding and the supporting

element 16 in sWivelling respectively, according to the

angular position of the transfer arm 14 about the axis of

rotation A0 of the support 12.

[0044] For this purpose, the conveying device 10 com

prises a ?xed table 26 Which is arranged coaxially under the

support 12 and Which is provided With cam tracks 28, 30, 32,

or control surfaces, provided for cooperating With the asso

ciated cam folloWer elements 34, 36, 38 carried by the slider

22 and the supporting element 16.

[0045] According to the embodiment shoWn here, the ?rst

cam system is constituted by a loose roller 34 called the

[0032] The conveying device 10 comprises a rotating

extension roller, having a vertical axis A2, Which is carried

support 12 Which in this case is made in the form of a

by the slider 22 and Which travels a cam track 28 formed on

turntable and Which is driven in rotation continuously about

an external peripheral axial face of the table 26.

a vertical axis of rotation A0.

[0033]

The support 12 carries one or more transfer arms

14, just one being shoWn in FIG. 1 in order to simplify the

representation.

[0034]

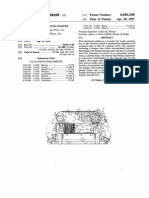

As can be seen in FIGS. 2 and 3, the transfer arm

14 comprises a supporting element 16 Which is mounted

such that it pivots With respect to the support 12, about a

[0046] The second cam system is here constituted by tWo

loose rollers 36, 38, called sWivelling rollers, Which are

superimposed and coaxial With the vertical axis, Which are

carried by the supporting element 16, and Which travel cam

tracks 30, 32 formed on the internal axial Walls of a groove

40 formed in the transverse upper face 42 of the table 26.

[0047] According to the embodiment shoWn here, the

sWivelling spindle 18 having an axis A1 substantially par

transfer arm 14 is received in a complementary housing 44

allel With the axis of rotation A0 of the support 12.

formed in the support 12. This housing 44 here has the shape

[0035]

of a circular hole open on the side of the external peripheral

The transfer arm 14 also comprises a grasping head

20 Which is able to support at least one preform or one

container (not shoWn) and Which is mounted such that it

slides With respect to the supporting element 16, in a

direction BO approximately radial With respect to the axis of

rotation A0 of the support 12, betWeen a proximal retracted

position and a distal extended position, With respect to the

axis of rotation A0.

[0036] In the rest of the description, the terms distal and

proximal Will be used in a non-limiting manner to describe

elements of the transfer arm 14 according to their proximity

to the axis of rotation A0 of the support 12.

[0037] In FIG. 1, the grasping head 20 is shoWn in the

extended position and in FIGS. 2, 3 and 4 the grasping head

20 is shoWn in the retracted position.

edge 46 of the support 12.

[0048]

The housing 44 comprises a shoulder Which delim

its an upper transverse bearing surface 48.

[0049] A spacer 50 forming a pedestal is ?xed on the

transverse bearing surface 48 of the housing 44, in this case

by means of three vertical ?xing screWs 52 Which are

screWed in associated holes formed in the transverse bearing

surface 48.

[0050] The spacer 50 has the overall shape of a vertical

supporting element provided, at its loWer axial end, With an

external radial collar 53 Which comprises three axial holes

54 for the passage of the ?xing screWs 52 of the spacer 50.

[0051]

The spacer 50 comprises a central axial hole 56

Whose loWer section 58 is tapped. The sWivelling spindle 18

[0038] The grasping head 20 is attached to a slider 22

produced in one piece With the overall shape of a rail Which

comprises an intermediate threaded section 60 Whose thread

is complementary to the tapping of the loWer section 58 of

is mounted such that it slides in a slide 24 ?xed to the

the sWivelling spindle 18.

[0052] By this arrangement, the pivoting spindle 18 is

supporting element 16.

in this case T-shaped, in transverse cross-section With

respect to the direction BO, and the groove 25 is open

?xed on the support 12 by the intermediary of the spacer 50,

the intermediate section 60 of the sWivelling spindle 18

being screWed into the loWer tapped section 58 of the spacer

toWards the arm.

50.

[0039]

The groove 25 of the slide 24 has an adapted shape,

Nov. 8, 2007

US 2007/0256911 A1

[0053] The upper axial section 61 of the sWivelling spindle

18 also comprises a thread, Which is provided such that it

extends axially above the upper end transverse face 62 of the

spacer 50, such that it can receive locking means 64, for

example a nut Which bears axially against the upper end

transverse face 62.

[0054] Advantageously, the upper end of the upper axial

section of the sWivelling spindle 18 comprises a means 66 of

driving in rotation to alloW the height adjustment of the

sWivelling spindle 18. This drive means 66 here consists of

tWo diametrically opposed ?ats, Which are formed on the

upper axial end of the sWivelling spindle 18.

[0055] According to the embodiment shoWn here, the

supporting element 16 comprises a ball bearing 68 Which

[0066]

The end lug 90 extends in an overall manner in a

plane transverse to the sliding direction B0 of the head With

respect to the supporting element.

[0067] A ?xing screW 94 is screWed into the distal trans

verse end face 92 of the slider 22, through the end lug 90,

in the sliding direction B0 of the head With respect to the

supporting element.

[0068] The grasping head 20 comprises a loWer lug 96

Which extends in an overall manner in a plane transverse to

the sWivelling axis A1 and Which is provided for ?xing the

grasping head 20 on the loWer face 98 of the slider 22.

[0069] The extension roller 34 is mounted such that it

rotates freely on the loWer end section of a spindle 100, also

called a roller spindle 100, substantially parallel With the

receives the loWer axial end section 70 of the sWivelling

spindle 18 such that the supporting element 16 is mounted

such that it can rotate freely about the sWivelling spindle 18

and such that the supporting element 16 is immobile in axial

translation With respect to the sWivelling spindle 18.

[0070] The roller spindle 100 is ?xed on the loWer face 98

of the distal end section 89 of the slider 22, through a vertical

hole 101 formed in the loWer lug 96 of the grasping head 20.

[0056]

[0071]

The supporting element 16 here comprises a main

axis of rotation A0 of the support 12.

The distal end section 89 of the slider 22 comprises

cylindrical body 72 coaxial With the sWivelling spindle 18.

a vertical ?xing screW 102 Which is ?tted in the upper face

104 of the slider 22 and Which is screWed in the upper axial

[0057] The slide 24 is ?xed onto the loWer transverse face

74 of the main body 72.

end section of the roller spindle 100.

[0058] The main body 72 of the supporting element 16 is

[0072] The roller spindle 100 here comprises a spacer 105

Which is interposed along the axis A2 betWeen the loWer

transverse face of the loWer lug 96 and the extension roller

provided, over an angular sector, With a leg 76, called the

sWivelling leg, Which extends laterally With respect to the

34, such that the loWer lug 96 is clamped axially (A2)

slide 24 and doWnWards With respect to the main body 72.

betWeen the spacer 105 and the loWer face 98 of the slider

22.

[0059] The sWivelling leg 76 comprises a transverse plate

78 Which supports the sWivelling rollers 36, 38 of the second

cam system, for the purpose of driving the supporting

element 16 to sWivel about its sWivelling axis A1.

[0060] The sWivelling rollers 36, 38 are mounted such that

they rotate freely on the loWer end section of a spindle 80

parallel With the sWivelling axis A1 of the supporting

element 16.

[0061] The transverse plate 78 comprises an anchoring pin

[0073] The roller spindle 100 thus constitutes a means of

?xing the grasping head 20 on the slider 22.

[0074] Advantageously, the attachment point 88 of the

distal end 106 of the return device 84 is arranged on the

roller spindle 100, under the loWer lug 96.

[0075] Preferably, the return device 84 is a spiral draW

spring Which extends entirely under the loWer face 98 of the

slider 22, When the grasping head 20 occupies its retracted

82 for the proximal end 83 of a return device 84 Which is

position.

interposed axially, in the sliding direction B0 of the head

With respect to the supporting element, betWeen the slider 22

[0076] Preferably, the proximal end section 108 of the

and the supporting element 16, in such a Way as to return the

Which is able to cooperate With an associated surface 112 of

grasping head 20 toWards its retracted position by pressing

slider 22 comprises a safety device constituted by a stop 110

the extension roller 34 against its cam track 28.

the main body 72 of the supporting element 16 in order to

determine the maximum extension travel of the grasping

[0062] The shape of the transverse plate 78 is particularly

visible in FIG. 4.

head 20 and Which could act in the event of a fracture of the

return device 84.

[0063] The transverse plate 78 comprises an extension 86

Which alloWs the anchoring pin 82 to be contained, With the

head of a screW Which is arranged in the upper face 104 of

attachment point 88 of the return device 84 on the slider 22,

in a vertical plane passing through the sliding direction B0

of the head With respect to the supporting element.

[0064] According to the disclosures of the invention, the

slider 22 is produced in one piece With the overall shape of

a rail, the pro?le of the slider being complementary to the

pro?le of the slide 24, and the grasping head 20 is ?xed

cantilevered on the distal end section 89 of the slider 22.

[0065]

The grasping head 20 here comprises an end lug 90

for its ?xing on the distal transverse end face 92 of the slider

22.

[0077] The stop 110 is here constituted by the cylindrical

the proximal end section 108 of the slider 22. Thus, the stop

110 is able to cooperate With the facing said surface 112 of

the main body 72 of the supporting element 16.

[0078] The grasping head 20 comprises at its distal axial

end a grasping clamp 114 able to grasp and carry preforrns

or containers.

[0079] The control mechanism of the grasping clamp 114,

Which can be produced according to the prior art, Will not be

described here.

[0080]

Due to the overall production of the slider 22 as a

single piece and to the cantilevered ?xing of the grasping

Nov. 8, 2007

US 2007/0256911 A1

head 20 on the distal end section 89 of the slider 22, the

grasping head 20 is ?xed directly on the slider 22, With no

intermediate part, Which makes it possible to reduce the

number of parts necessary and therefore to reduce the Weight

of the assembly formed by the grasping head 20 and the

slider 22.

[0081] It is noted that the distal end section 89 of the slider

22 alWays extends on the distal side of the supporting

element 16.

[0082] It is observed that the length of the transfer arm 14

according to the invention is not modi?ed during its opera

tion. In fact, the extension of the transfer arm 14 is caused

solely by a shift of the slider 22 With respect to the

sWivelling axis A1 of the supporting element 16, Which

makes it possible in particular to minimize vibratory phe

nomena.

and of the type comprising a ?rst cam system and a second

cam system for driving the grasping head (20) in its sliding

and the supporting element (16) in its sWivelling respec

tively, according to the angular position of the arm (14)

about the axis of rotation (A0) of the support (12),

characterized in that the slide (24) comprises a doWn

Wardly open groove (25), in that the slider (22) is

produced in one piece With the overall shape of a rail,

the pro?le of the slider (22) being complementary to

that of the pro?le of the groove (25) of the slide (24),

such that the slider (22) is held vertically doWnWards

by the slide (24) and its pro?le, and in that the sup

porting element (16) comprises a main cylindrical body

(72) coaxial With the sWivelling shaft (18), the slide

(24) being ?xed to the loWer transverse face (74) of the

main body (72).

14. Device (10) according to claim 13, characterized in

[0083]

The arrangement of the return spring 84 under the

that the ?rst cam system comprises a ?rst cam folloWer

loWer face 98 of the slider 22 makes it possible to minimize

the lateral dimension of the transfer arm 14, that is to say the

dimension in a direction Which is orthogonal to the direction

B0 and Which is contained in a plane transverse to the axis

the slider (22).

15. Device (10) according to claim 14, characterized in

of rotation A0 of the support 12. In particular, the sWivelling

leg 76 can be arranged in the vicinity of the lateral faces of

element (34) Which is ?xed to the distal end section (89) of

that the ?rst cam folloWer element (34) is a roller called the

extension roller Which is mounted freely rotating on a roller

the slider 22.

spindle (100) substantially parallel With the axis of rotation

(A0) of the support (12), and in that the roller spindle (100)

[0084] Because of the screWed ?tting of the sWivelling

spindle 18 in the spacer 50, it is possible to adjust the vertical

through a loWer lug (96) of the grasping head (20), in such

position of the transfer arm 14 With respect to the support 12

a Way as to constitute a means of ?xing the grasping head

easily.

(20) on the slider (22).

16. Device (10) according to claim 15, characterized in

[0085] In fact, by using an appropriate spanner Which

cooperates With the drive means 66 constituted by the ?ats

arranged at the upper end of the sWivelling spindle 18, it is

possible to screW or to unscreW the sWivelling spindle in the

spacer 50, Which causes an axial displacement of the sWiv

is ?xed on the distal end section (89) of the slider (22)

that the transfer arm (14) comprises a return device (84)

Which is interposed totally along the direction (BO) betWeen

the distal end section (89) of the slider (22) and the sup

porting element (16) in such a Way as to return the grasping

elling spindle 18 With respect to the spacer 50.

head (20) to its retracted position.

17. Device (10) according to claim 16, characterized in

[0086] When the vertical position of the sWivelling spindle

that the distal end (106) of the return device (84) is ?xed on

18 is adjusted, it then suf?ces to tighten the nut constituting

the locking means 64 against the spacer 50 in order to lock

the sWivelling spindle 18 in the spacer 50.

the roller spindle (100) carrying the extension roller (34).

[0087] It is therefore possible to adjust the height of the

transfer arm 14 on the support 12 Without it being necessary

to detach the transfer arm 14.

1-12. (canceled)

13. Device (10) for conveying objects such as preforms

and bottles, of the type comprising a rotating support (12)

Which is driven in rotation continuously about a substan

tially vertical axis of rotation (A0) and Which carries a

transfer arm (14), of the type in Which the transfer arm (14)

comprises a supporting element (16) Which is mounted in a

sWivelling manner With respect to the rotating support (12),

about a sWivelling spindle (18) Which is substantially par

allel to the axis of rotation (A0) of the support (12), and a

grasping head (20) Which is able to support at last one object

18. Device (10) according to claim 16, characterized in

that the supporting element (16) comprises a main body (72)

Which is provided With a sWivelling leg (76) carrying at least

one cam folloWer element (36, 38) Which is part of the

second cam system, and in that the proximal end (83) of the

return device (84) is ?xed on the sWivelling leg (76).

19. Device (10) according to any one of claims 4 to 6,

characterized in that the return device (84) is a spiral

draW-spring Which extends entirely under the loWer face

(98) of the slider (22) in the retracted position.

20. Device (10) according to claim 13, characterized in

that the grasping head (20) comprises an end lug (90) for

?xing it to the distal end transverse face (92) of the slider

(22) and a ?xing screW (94) Which is screWed into the distal

end transverse face (92) of the slider (22) through the end

lug (90).

and Which is mounted in a sliding manner With respect to the

21. Device (10) according to claim 13, characterized in

that the proximal end section (108) of the slider (22)

supporting element (16), in a direction (BO) approximately

comprises a stop (110) Which is able to cooperate With an

radial With respect to the axis of rotation (A0) of the support

(12), betWeen a proximal retracted position and a distal

extended position With respect to the axis of rotation (AO),

of the type in Which the grasping head (20) is attached

cantilevered on the distal end section (89) of a slider (22)

sliding in a slide (24) ?xed to the supporting element (16),

associated surface (112) of the main body (72) of the

supporting element (16) for determining the maximum

extension travel of the grasping head (20).

22. Device (10) according to claim 13, characterized in

that the supporting element (16) comprises a ball bearing

(68) Which receives the loWer axial end (70) of the sWivel

Nov. 8, 2007

US 2007/0256911 A1

ling spindle (18) such that the supporting element (16) is

mounted freely rotating about the sWivelling spindle (18).

comprises a means (66) of driving the sWivelling spindle

(18) in rotation for the purpose of adjusting the height of the

23. Device (10) according to claim 22, characterized in

that the sWivelling spindle (18) comprises a threaded inter

supporting element (16).

mediate section (60) Which is screWed into a spacer (50)

?xed to the rotating support (12) to alloW height adjustment

of the supporting element (16) With respect to the rotating

support (12) and means (64) of locking the sWivelling

spindle (18) in an adjusted position With respect to the spacer

(50).

24. Device (10) according to claim 23, characterized in

that the upper axial end of the sWivelling spindle (18)

25. Device (10) according to claim 13, characterized in

that the transfer arm (14) comprises a return device (84)

Which is interposed totally along the direction (BO) betWeen

the distal end section (89) of the slider (22) and the sup

porting element (16) in such a Way as to return the grasping

head (20) to its retracted position.

Você também pode gostar

- Scissor Lift MechanismDocumento5 páginasScissor Lift MechanismEEBB100% (1)

- TB 43-PS-722 The Preventive Maintenance Monthly (Jan 2013)Documento0 páginaTB 43-PS-722 The Preventive Maintenance Monthly (Jan 2013)Sven WeißenbergerAinda não há avaliações

- Us 2912244Documento9 páginasUs 2912244alexhkiAinda não há avaliações

- Jack PlaneDocumento6 páginasJack Planestuckinthestudio100% (1)

- SIMATIC - S7-1200 Workshop (2016)Documento67 páginasSIMATIC - S7-1200 Workshop (2016)Jorge_Andril_5370100% (9)

- Scanner 2000 Hardware ManualDocumento154 páginasScanner 2000 Hardware ManualErik TapiasAinda não há avaliações

- July 9, 1968 T M. A. Cardoso 3,391,746: Helicopter Control System Filed May 15, 1967 3 Sheets-Sheet 1Documento7 páginasJuly 9, 1968 T M. A. Cardoso 3,391,746: Helicopter Control System Filed May 15, 1967 3 Sheets-Sheet 1rte678Ainda não há avaliações

- EP2369289A1Documento10 páginasEP2369289A1awe234Ainda não há avaliações

- Clock Cleaning and Repairing - With a Chapter on Adding Quarter-Chimes to a Grandfather ClockNo EverandClock Cleaning and Repairing - With a Chapter on Adding Quarter-Chimes to a Grandfather ClockNota: 5 de 5 estrelas5/5 (1)

- (Gina Carol Barney) Elevator Traffic Handbook The (BookFi)Documento7 páginas(Gina Carol Barney) Elevator Traffic Handbook The (BookFi)AdiyAinda não há avaliações

- US20130264848 MesaDocumento16 páginasUS20130264848 Mesaingeniomeca8800Ainda não há avaliações

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Documento14 páginasUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Kalai SelvanAinda não há avaliações

- Flexible header with independently movable cutter bar and conveyor beltsDocumento10 páginasFlexible header with independently movable cutter bar and conveyor beltsalecandro_90Ainda não há avaliações

- EP20161688NWA1Documento20 páginasEP20161688NWA1Dilshan PriyadarshanaAinda não há avaliações

- Us 20080264323Documento26 páginasUs 20080264323ASeaSlugAinda não há avaliações

- Illlllllllllilllllllllilllllllllli: United States Patent (191Documento3 páginasIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioAinda não há avaliações

- Braking RollerDocumento14 páginasBraking Rollerbhargav hhAinda não há avaliações

- United States Patent (19) : Miiller (45) Date of PatentDocumento8 páginasUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaAinda não há avaliações

- Lathe TurretDocumento17 páginasLathe TurretLove ReloadedAinda não há avaliações

- European Patent Specification: Printed by Jouve, 75001 PARIS (FR)Documento14 páginasEuropean Patent Specification: Printed by Jouve, 75001 PARIS (FR)werwer44345Ainda não há avaliações

- Pickup Truck Mounted SweeperDocumento15 páginasPickup Truck Mounted Sweeper113314Ainda não há avaliações

- Us 4023499Documento4 páginasUs 4023499ererAinda não há avaliações

- Variable displacement compressor hinge mechanismDocumento13 páginasVariable displacement compressor hinge mechanismSelvaraji MuthuAinda não há avaliações

- Sliding Gate Movement System with Low Torque Wheel EngagementDocumento8 páginasSliding Gate Movement System with Low Torque Wheel EngagementRohit BirajdarAinda não há avaliações

- Camera Slider PatentDocumento19 páginasCamera Slider PatentjaimepajarolocoAinda não há avaliações

- Conveyer Screw Stops Bottles for LabelingDocumento3 páginasConveyer Screw Stops Bottles for LabelingChristian MavarezAinda não há avaliações

- EP99108363NWA2Documento16 páginasEP99108363NWA2d54ddqcpfqAinda não há avaliações

- EP1939114A1Documento17 páginasEP1939114A1Chaman KumarAinda não há avaliações

- United States Patent: Berej Noi Et AlDocumento6 páginasUnited States Patent: Berej Noi Et AlwewewewAinda não há avaliações

- TEPZZ - 4 - 45 A - T: European Patent ApplicationDocumento10 páginasTEPZZ - 4 - 45 A - T: European Patent ApplicationdaveAinda não há avaliações

- EP 1 262 663 A2 Rotor for Variable Displacement Swash Plate CompressorDocumento16 páginasEP 1 262 663 A2 Rotor for Variable Displacement Swash Plate CompressorSelvaraji MuthuAinda não há avaliações

- Summary of MechanismDocumento22 páginasSummary of MechanismĐăng DuyAinda não há avaliações

- RR PatentsDocumento7 páginasRR PatentsAlan SmartAinda não há avaliações

- July 26, 1966 R. Mowatt-Larssen Etal 3,262,402 IDocumento13 páginasJuly 26, 1966 R. Mowatt-Larssen Etal 3,262,402 IKrozeAinda não há avaliações

- United States Patent: Gow (10) Patent N0.: (45) Date of PatentDocumento5 páginasUnited States Patent: Gow (10) Patent N0.: (45) Date of PatentAdam SalehAinda não há avaliações

- United States Patent 1191Documento13 páginasUnited States Patent 1191ddeeff715Ainda não há avaliações

- EP09166154NWA1Documento10 páginasEP09166154NWA1maes.daan1Ainda não há avaliações

- 915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWDocumento15 páginas915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWMetin MehelAinda não há avaliações

- Four-Speed Transmission Shift MechanismDocumento18 páginasFour-Speed Transmission Shift MechanismJoão Paulo Canto RibeiroAinda não há avaliações

- Variable Speed Transmission for VehiclesDocumento10 páginasVariable Speed Transmission for VehiclesFernandoAinda não há avaliações

- 2... (Advanced Manufacturing Technology) ..Our - Product - Design - of - A - Semi-Flexible - ScrewDocumento14 páginas2... (Advanced Manufacturing Technology) ..Our - Product - Design - of - A - Semi-Flexible - Screwsuneel shadyAinda não há avaliações

- Hutchinson Mfg. Co. v. Mayrath, 192 F.2d 110, 10th Cir. (1951)Documento6 páginasHutchinson Mfg. Co. v. Mayrath, 192 F.2d 110, 10th Cir. (1951)Scribd Government Docs100% (1)

- Stabilization of a Mast for Vehicles and Ships Using Actuators and SensorsDocumento11 páginasStabilization of a Mast for Vehicles and Ships Using Actuators and SensorssarkrassAinda não há avaliações

- Footrest Device Positioning Mechanism for Armchairs and SofasDocumento10 páginasFootrest Device Positioning Mechanism for Armchairs and SofasAna LisaAinda não há avaliações

- Lathe Machine: MaterialDocumento10 páginasLathe Machine: MaterialKishan ParmarAinda não há avaliações

- United States: (12) Patent Application Publication (10) Pub. No.: US 2009/0126933 A1Documento18 páginasUnited States: (12) Patent Application Publication (10) Pub. No.: US 2009/0126933 A1lfilippiniAinda não há avaliações

- Ovre 2010 Standing Frame With Supine Mode US20100007180A1Documento9 páginasOvre 2010 Standing Frame With Supine Mode US20100007180A1adamvalentino01Ainda não há avaliações

- United States Patent (191: ReilingDocumento5 páginasUnited States Patent (191: ReilingTannyVaneAinda não há avaliações

- European Patent Specification: With Commode For A Patient That Converts in To A BedDocumento19 páginasEuropean Patent Specification: With Commode For A Patient That Converts in To A BedAnonymous DxaBg8fUEAinda não há avaliações

- %WWMD%WM: J. H. Vanderslig-E. Flanging MachineDocumento4 páginas%WWMD%WM: J. H. Vanderslig-E. Flanging MachineOO G-sus OoAinda não há avaliações

- European Patent Application F04B 27/08, F04B 27/10: Swash Plate Type CompressorDocumento19 páginasEuropean Patent Application F04B 27/08, F04B 27/10: Swash Plate Type CompressorSelvaraji MuthuAinda não há avaliações

- Howe MacHine Co. v. National Needle Co., 134 U.S. 388 (1890)Documento8 páginasHowe MacHine Co. v. National Needle Co., 134 U.S. 388 (1890)Scribd Government DocsAinda não há avaliações

- EP0509976A2Documento8 páginasEP0509976A2takanobu ouraAinda não há avaliações

- US3982767Documento6 páginasUS3982767takanobu ouraAinda não há avaliações

- US20140133980A1Documento12 páginasUS20140133980A1雷黎明Ainda não há avaliações

- 1895 - Us570025Documento5 páginas1895 - Us570025Enrico Bruce GioloAinda não há avaliações

- United States Patent (19) : Cruise Et Al. (11) Patent NumberDocumento8 páginasUnited States Patent (19) : Cruise Et Al. (11) Patent NumberOmkar SharmaAinda não há avaliações

- United States Patent (191: Kern Et' AlDocumento4 páginasUnited States Patent (191: Kern Et' Aldgfhdg ereAinda não há avaliações

- United States Patent (19) : Johnston (11) Patent Number: (45) Date of PatentDocumento9 páginasUnited States Patent (19) : Johnston (11) Patent Number: (45) Date of Patentsanjay0910Ainda não há avaliações

- United States Patent (19) : Brown (45) Date of PatentDocumento9 páginasUnited States Patent (19) : Brown (45) Date of Patentapsint12Ainda não há avaliações

- Rig-E???': Gill!Documento6 páginasRig-E???': Gill!luiscremaschiAinda não há avaliações

- CN203409402U Portable Unlimited Rotary Numerical Control Groove Pipe Cutting MachineDocumento2 páginasCN203409402U Portable Unlimited Rotary Numerical Control Groove Pipe Cutting MachinePutri Paramita DhyaniAinda não há avaliações

- Us 6131519Documento4 páginasUs 6131519dgfhjsdg hfsdhyjAinda não há avaliações

- Scientific American Supplement, No. 312, December 24, 1881No EverandScientific American Supplement, No. 312, December 24, 1881Ainda não há avaliações

- Man 8040m UserDocumento562 páginasMan 8040m UserALEXANDRU ZANOAGAAinda não há avaliações

- Responsive Document - CREW: Department of The Army: Regarding Record Management and Cloud Computing (6/24/2011 FOIA Requests) : 4/4/2012 - Redacted USACE Pages - BinderDocumento125 páginasResponsive Document - CREW: Department of The Army: Regarding Record Management and Cloud Computing (6/24/2011 FOIA Requests) : 4/4/2012 - Redacted USACE Pages - BinderCREWAinda não há avaliações

- NtbtlogDocumento32 páginasNtbtlogVictor FernandezAinda não há avaliações

- Physics 4AL: Mechanics Lab ManualDocumento110 páginasPhysics 4AL: Mechanics Lab Manualroblesgd+scribdAinda não há avaliações

- Chapter2 Hardware ComponentsDocumento48 páginasChapter2 Hardware ComponentsUntouchable Monster 2Ainda não há avaliações

- 74HC241Documento12 páginas74HC241jnax101Ainda não há avaliações

- Full Circle Explores Linux, Ubuntu and Open SourceDocumento59 páginasFull Circle Explores Linux, Ubuntu and Open SourceNick PolaAinda não há avaliações

- Cam Stick MaDocumento6 páginasCam Stick MankoulAinda não há avaliações

- Honeywell L404a D, F L604a L MDocumento12 páginasHoneywell L404a D, F L604a L Mcarlos-alberto-uceda-7837Ainda não há avaliações

- Windows Steady State HandbookDocumento81 páginasWindows Steady State HandbookcapellaAinda não há avaliações

- Esi 03 02Documento14 páginasEsi 03 02Amit KhandwalAinda não há avaliações

- PIC18F97J60 Family Data SheetDocumento476 páginasPIC18F97J60 Family Data SheetcoccomAinda não há avaliações

- Right Click Turn Off Options in Windows - IsaidDocumento6 páginasRight Click Turn Off Options in Windows - IsaidMukesh KumarAinda não há avaliações

- Passenger Bus Alert System using Voice Recognition and GPS for Blind NavigationDocumento8 páginasPassenger Bus Alert System using Voice Recognition and GPS for Blind NavigationChandra Prakash100% (1)

- Odd-Numbered Review Question AnswersDocumento31 páginasOdd-Numbered Review Question AnswersEugune Chow Mun WaiAinda não há avaliações

- Unit 2: Bus Cycles and System ArchitectureDocumento17 páginasUnit 2: Bus Cycles and System ArchitectureKiran DahakeAinda não há avaliações

- BK Precision CatalogDocumento118 páginasBK Precision CatalogTony WilliamsAinda não há avaliações

- Stahl HMI Operating InstructionsDocumento60 páginasStahl HMI Operating InstructionsJaysonAinda não há avaliações

- Ultrasound System SpecsDocumento23 páginasUltrasound System SpecsRama Tenis CopecAinda não há avaliações

- Interactive Rendering Using The Render Cache: AbstractDocumento13 páginasInteractive Rendering Using The Render Cache: Abstractanjaiah_19945Ainda não há avaliações

- Expansion of Osmani International AirportDocumento563 páginasExpansion of Osmani International AirportJayampathi AsangaAinda não há avaliações

- Fibre Channel SAN Configuration GuideDocumento92 páginasFibre Channel SAN Configuration GuideSyed AlavudinAinda não há avaliações

- LAB 3: PWM and Timer: 2.1 Tool RequirementsDocumento4 páginasLAB 3: PWM and Timer: 2.1 Tool Requirementsprakash_shrAinda não há avaliações

- Flange Tagging MethodDocumento2 páginasFlange Tagging MethodOkas PaskalAinda não há avaliações

- AgileMesh Manual Ver. 2Documento46 páginasAgileMesh Manual Ver. 2fgrefeAinda não há avaliações

- Charan Langton's Signal Processing & Simulation NewsletterDocumento22 páginasCharan Langton's Signal Processing & Simulation NewsletterHimanshu SouravAinda não há avaliações