Escolar Documentos

Profissional Documentos

Cultura Documentos

Pebd Film Lupolen 2420d

Enviado por

Jonathan Guadalupe ChacónDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pebd Film Lupolen 2420d

Enviado por

Jonathan Guadalupe ChacónDireitos autorais:

Formatos disponíveis

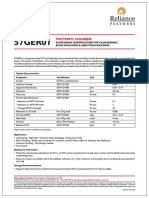

Basell - Lupolen 2420 D - Polyethylene, Low Density

Page 1 of 2

Lupolen 2420 D

Polyethylene, Low Density

Product Description

It is a low density Polyethylene with the following features:

Product Characteristics

Status

Commercial: Active

Test Method used

ISO

Availability

Europe, North America, Asia-Pacific, Australia/NZ, AfricaMiddle East, Latin America

Processing Method

Injection Blow Moulding, Blown film, Extrusion Blow

Moulding

Features

Processability, Good, Tear Strength, Good, Toughness,

Good

Typical Customer Applications

Bags & Pouches, Film, Shrink Film, Bottles For Consumer

Goods, Blown Film

ASTM

Typical Properties

Method

Value Unit

Density

ISO 1183

0.923 g/cm

Melt flow rate (MFR) (190C/2.16kg)

ISO 1133

Physical

0.25 g/10 min

Mechanical

Tensile Modulus

ISO 527-1, -2

240 MPa

Tensile Stress at Yield

ISO 527-1, -2

10.0 MPa

Tensile Strength

ISO 527-1, -3

27.0 MPa

Note: MD

20.0 MPa

Note: TD

Tensile Strain at Break

ISO 527-1, -3

200 %

Note: MD

600 %

Note: TD

Hardness

Shore hardness (Shore D)

ISO 868

48

Ball indentation hardness (H 49/30)

ISO 2039-1

17.0 MPa

Vicat softening temperature (A50 (50C/h 10N))

ISO 306

94.0 C

Melting Temperature

ISO 3146

Thermal

109 C

Film

Melt Temperature

170 to 220 C

Notes

Typical properties; not to be construed as specifications.

http://www.basell.com/portal/binary/com.vignette.vps.basell.productgrade.ProductGra...

3/18/2008

Basell - Lupolen 2420 D - Polyethylene, Low Density

Page 2 of 2

Additional Properties

Film properties tested using 70 m thickness blown film extruded at a melt temperature of 180C

and a blow-up ratio of 2:1.

Failure Energy, DIN 53373, 70m: 6.5 J/mm

Coefficient of Friction, ISO 8295: 70%

Recommended Thickness: 70 to 220 m

2003 Basell Service Company B.V.

For the contact details of the LyondellBasell company selling this product in your country, please visit

http://www.basell.com/.

Before using a LyondellBasell product, customers and other users should make their own independent

determination that the product is suitable for the intended use. They should also ensure that they can

use the LyondellBasell product safely and legally. This document does not constitute a warranty, express

or implied, including a warranty of merchantability or fitness for a particular purpose. In addition, no

immunity under LyondellBasell's or third parties' intellectual property rights shall be implied from this

document. No one is authorized to make any warranties, issue any immunities or assume any liabilities

on behalf of LyondellBasell except in a writing signed by an authorized LyondellBasell employee. Unless

otherwise agreed in writing, the exclusive remedy for all claims is replacement of the product or refund of

the purchase price at LyondellBasells option, and in no event shall LyondellBasell be liable for special,

consequential, incidental, punitive or exemplary damages.

CRP, Adflex, Adstif, Adsyl, Akoalit, Akoafloor, Avant, Catalloy, Clyrell, Entegrity, Get in touch with, Hifax,

Higran, Histif, Hostacom, Hostalen, LIPP, Lucalen, Luflexen, Lupocomp, Lupolen, Lupolex, Luposim,

Lupostress, Lupotech, Metocene, Moplen, Purell, Pro-fax, Sholybox, Softell, Spherilene, Spheripol,

Spherizone, Stretchene, Toppyl and Valtec are trademarks owned or used by LyondellBasell group

companies.

Adflex, Adstif, Adsyl, Clyrell, CRP, Hifax, Hostacom, Hostalen, Lucalen, Luflexen, Lupolen, Lupotech,

Moplen and Pro-fax are registered in the U.S. Patent and Trademark Office.

Unless specifically indicated, the grades mentioned are not suitable for applications in the

pharmaceutical/medical sector.

Release Date: 09 Jan 2008

http://www.basell.com/portal/binary/com.vignette.vps.basell.productgrade.ProductGra...

3/18/2008

Você também pode gostar

- Technical Data SheetDocumento4 páginasTechnical Data SheetJohn P. BandoquilloAinda não há avaliações

- Data SheetDocumento3 páginasData Sheetashv1972Ainda não há avaliações

- PPH 2150 BasellDocumento3 páginasPPH 2150 Basellkeyur1109Ainda não há avaliações

- Delrin500pnc010 PDFDocumento4 páginasDelrin500pnc010 PDFtushar7000Ainda não há avaliações

- 010F18SDocumento1 página010F18SJignesh PatelAinda não há avaliações

- High Density Polyethylene HMW Film Grade Melt Index 0.06 Density 0.949Documento1 páginaHigh Density Polyethylene HMW Film Grade Melt Index 0.06 Density 0.949Ing Ipn VbaAinda não há avaliações

- Adsyl 7623 XCP: Advanced Polyolefin Product DescriptionDocumento2 páginasAdsyl 7623 XCP: Advanced Polyolefin Product DescriptionLâm Quốc CườngAinda não há avaliações

- 3M MATERIAL SAFETY DATA SHEET 3M (TM) Transpore (TM) White Surgical Tape - 1534Documento7 páginas3M MATERIAL SAFETY DATA SHEET 3M (TM) Transpore (TM) White Surgical Tape - 1534Sri Wahyuni HandayaniAinda não há avaliações

- Lyondell Basell Moplen EP548PDocumento4 páginasLyondell Basell Moplen EP548PIndrajit SahaAinda não há avaliações

- Technical Data Sheet - IsODocumento2 páginasTechnical Data Sheet - IsOAsrilAinda não há avaliações

- Basell - Moplen HP561R - Po..Documento2 páginasBasell - Moplen HP561R - Po..samiviamAinda não há avaliações

- Ucon 50-HB-58 SDS - 230822 - 152418Documento10 páginasUcon 50-HB-58 SDS - 230822 - 152418alfa_ohmAinda não há avaliações

- 3m Scotch Glue StickDocumento7 páginas3m Scotch Glue StickSirhc ZialcitaAinda não há avaliações

- Desmodur N 3300Documento4 páginasDesmodur N 3300Cesar Martinez50% (2)

- Worbla - MSDS-Worblas-Black-Art-Trade-name-BlackartflexDocumento6 páginasWorbla - MSDS-Worblas-Black-Art-Trade-name-BlackartflexLeonardo RodriguesAinda não há avaliações

- Dupont Zytel: Zytel 73G15Hsl Bk363Documento2 páginasDupont Zytel: Zytel 73G15Hsl Bk363Roberto HernandezAinda não há avaliações

- Basell - Hifax CB 1128 A - Compounded PolyolefinDocumento2 páginasBasell - Hifax CB 1128 A - Compounded Polyolefindins_28Ainda não há avaliações

- Pearlthane 11T93Documento2 páginasPearlthane 11T93Gabriel SalomonAinda não há avaliações

- Basell PP Homo Rafia Hp456j Mi 3 4Documento2 páginasBasell PP Homo Rafia Hp456j Mi 3 4crawn06Ainda não há avaliações

- Article Information Sheet: 3M Brand 1860 Teal Medical RespiratorDocumento4 páginasArticle Information Sheet: 3M Brand 1860 Teal Medical RespiratorDedy patreszAinda não há avaliações

- Zytel 103HSL BKB080Documento3 páginasZytel 103HSL BKB080Parag NambiarAinda não há avaliações

- Borclear RB707CF: PolypropyleneDocumento3 páginasBorclear RB707CF: PolypropylenesamiviamAinda não há avaliações

- Acticell UDocumento1 páginaActicell UAndrek QueckAinda não há avaliações

- LD-PE LyondellBasell Purell 2410TDocumento3 páginasLD-PE LyondellBasell Purell 2410TNeagu MariusAinda não há avaliações

- Technical Data Sheet - PE Granules-BasellDocumento3 páginasTechnical Data Sheet - PE Granules-Basellbtv.mylepham.208Ainda não há avaliações

- 3M 8210 MSDS-2015Documento4 páginas3M 8210 MSDS-2015Michael TadrosAinda não há avaliações

- Material Safety Data SheetDocumento7 páginasMaterial Safety Data SheetАндрей МошкинAinda não há avaliações

- Y77G33LKDocumento1 páginaY77G33LKrenebbAinda não há avaliações

- Optitemp HT 2 EP: DescriptionDocumento2 páginasOptitemp HT 2 EP: DescriptionWirawan Adi Setya RAinda não há avaliações

- FORTRON® 1120L4 - PPS - Specialty: DescriptionDocumento2 páginasFORTRON® 1120L4 - PPS - Specialty: DescriptionAdam GordonAinda não há avaliações

- Datasheet Moplen EP340K 3288 - 1531149020Documento4 páginasDatasheet Moplen EP340K 3288 - 1531149020afidyusufAinda não há avaliações

- Article Information Sheet: 3M™ Silicone Acrylic Double Coated Tape 9119-50Documento4 páginasArticle Information Sheet: 3M™ Silicone Acrylic Double Coated Tape 9119-50douglareAinda não há avaliações

- SDS Petrifilm EB 3MDocumento9 páginasSDS Petrifilm EB 3MDebrina AAinda não há avaliações

- Safety Data Sheet: 1. Product and Company IdentificationDocumento11 páginasSafety Data Sheet: 1. Product and Company IdentificationZhan FangAinda não há avaliações

- Technical Data: Three Bond 1207CDocumento3 páginasTechnical Data: Three Bond 1207CVictorEkaSetiawanAinda não há avaliações

- 3M 200MP Att AisDocumento5 páginas3M 200MP Att AisNerissa CastilloAinda não há avaliações

- Desmopan 487 ISODocumento2 páginasDesmopan 487 ISOMohammad Doost MohammadiAinda não há avaliações

- Safety Data Sheet: 1. Product and Company IdentificationDocumento11 páginasSafety Data Sheet: 1. Product and Company IdentificationZhan FangAinda não há avaliações

- PVC 57ger01Documento1 páginaPVC 57ger01rajesh patelAinda não há avaliações

- Oxygen and Walter Vapour Barrier Properties of Flex Pack FilmsDocumento1 páginaOxygen and Walter Vapour Barrier Properties of Flex Pack FilmsconturmediaAinda não há avaliações

- Licowax® C PowderDocumento2 páginasLicowax® C Powder王偉仲Ainda não há avaliações

- Bondller-Double Coated Tape-MSDS-Safety Data SheetDocumento7 páginasBondller-Double Coated Tape-MSDS-Safety Data Sheeteurope toyotapeAinda não há avaliações

- Basell Moplen HP500N (MI 12)Documento1 páginaBasell Moplen HP500N (MI 12)qshakimAinda não há avaliações

- Material Safety Data SheetDocumento7 páginasMaterial Safety Data SheetАндрей МошкинAinda não há avaliações

- PSF 1,000Cst Pure Silicone Fluid: Safety Data SheetDocumento8 páginasPSF 1,000Cst Pure Silicone Fluid: Safety Data SheetPearl JamAinda não há avaliações

- Craybond 85-22 (PIR) - 18-03-23Documento3 páginasCraybond 85-22 (PIR) - 18-03-23YASHICA VAITTIANATHANAinda não há avaliações

- Safety Data Sheet: 1. IdentificationDocumento9 páginasSafety Data Sheet: 1. IdentificationShiva NAinda não há avaliações

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingDocumento12 páginasSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingCelbargzAinda não há avaliações

- Lotrène FE8000 2014 04 16 PDFDocumento2 páginasLotrène FE8000 2014 04 16 PDFHameer SattarAinda não há avaliações

- Tinuvin 292Documento3 páginasTinuvin 292Mohammad Doost Mohammadi100% (1)

- Flexible Packaging For ChemicalsDocumento12 páginasFlexible Packaging For ChemicalsAgus WidadiAinda não há avaliações

- DK15 0934Documento1 páginaDK15 0934Dileep SettyAinda não há avaliações

- Desmopan 192 ISODocumento2 páginasDesmopan 192 ISOaakashlakhanpal9830Ainda não há avaliações

- MSDS 90033400 MolykoteDocumento12 páginasMSDS 90033400 Molykotejaysx5Ainda não há avaliações

- Dykem Hi-Spot BlueDocumento3 páginasDykem Hi-Spot BlueMark Evan SalutinAinda não há avaliações

- 3M MATERIAL SAFETY DATA SHEET 3M Paper Masking Tape, 2214Documento7 páginas3M MATERIAL SAFETY DATA SHEET 3M Paper Masking Tape, 2214Manmohan ThakurAinda não há avaliações

- Lupolen: Technical Data SheetDocumento3 páginasLupolen: Technical Data SheetJaime222Ainda não há avaliações

- Safety Data Sheet Bulk BagsDocumento4 páginasSafety Data Sheet Bulk BagsLaboratory Plant 7Ainda não há avaliações

- The Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderNo EverandThe Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderAinda não há avaliações

- Achieving a Safe and Reliable Product: A Guide to Liability PreventionNo EverandAchieving a Safe and Reliable Product: A Guide to Liability PreventionAinda não há avaliações

- RR 2017 Annual ReportDocumento208 páginasRR 2017 Annual ReportYangAinda não há avaliações

- Hitachi Excavator ZX200-3G & ZX200-3GDocumento11 páginasHitachi Excavator ZX200-3G & ZX200-3GJi Uvex83% (6)

- SPMO FRM 006 Pre Inspection ReportDocumento2 páginasSPMO FRM 006 Pre Inspection ReportDawnAinda não há avaliações

- Global Report Construction Equipment 2017Documento76 páginasGlobal Report Construction Equipment 2017FirasAlnaimiAinda não há avaliações

- Load Carrying Electric Vehicle: Market AnalysisDocumento32 páginasLoad Carrying Electric Vehicle: Market AnalysisSarbani MishraAinda não há avaliações

- The Nature of Industrial BuyingDocumento40 páginasThe Nature of Industrial Buying99862123780% (1)

- Porsche Financial Services BrochureDocumento8 páginasPorsche Financial Services BrochureAndre BarnesAinda não há avaliações

- Hydro Plant Risk Assessment GuideDocumento24 páginasHydro Plant Risk Assessment GuideWan Mohd FatahAinda não há avaliações

- Finished SurreyDocumento2.210 páginasFinished SurreySale LeadsAinda não há avaliações

- Global Partner Program - Training and Certification - Learning Path OptionsDocumento51 páginasGlobal Partner Program - Training and Certification - Learning Path OptionsFabioAinda não há avaliações

- 5 HV Substation Design Feb 17 18Documento254 páginas5 HV Substation Design Feb 17 18HassenLAinda não há avaliações

- Is 458 2003Documento68 páginasIs 458 2003Yazer ArafathAinda não há avaliações

- 148NK08 BridonDocumento15 páginas148NK08 BridonTara SnyderAinda não há avaliações

- Unit - V Security in The CloudDocumento40 páginasUnit - V Security in The CloudArunkumar PanneerselvamAinda não há avaliações

- HobbsDocumento41 páginasHobbsganeshanAinda não há avaliações

- Intro To ScrumDocumento40 páginasIntro To ScrumAvay KumarAinda não há avaliações

- PATROL Getting StartedDocumento112 páginasPATROL Getting Startedmajumder_subhrajitAinda não há avaliações

- Ebookk GROHE Kitchen Brochure 2009Documento28 páginasEbookk GROHE Kitchen Brochure 2009Ikhsanul HakimAinda não há avaliações

- ES350 Setting InstructiojnDocumento5 páginasES350 Setting Instructiojnjade5jadeAinda não há avaliações

- Project Final (Hariharan.K)Documento87 páginasProject Final (Hariharan.K)KaileshwarenAinda não há avaliações

- CSR GBDocumento160 páginasCSR GBPrespective innovationAinda não há avaliações

- Jascon 55 SpecificationDocumento2 páginasJascon 55 SpecificationRaymundo AlarconAinda não há avaliações

- Cloud ComputingDocumento29 páginasCloud Computingtanishq_5774371100% (2)

- ScrumAssessment Paper1Documento26 páginasScrumAssessment Paper1Dianna Tivadar100% (2)

- B2TBSPF102: All Dimension in Charts and Drawing Are in MillimetersDocumento3 páginasB2TBSPF102: All Dimension in Charts and Drawing Are in Millimeterskhaled aliAinda não há avaliações

- Quality Assurance in Textile EducationDocumento7 páginasQuality Assurance in Textile Educationandrei_bertea7771Ainda não há avaliações

- BOOK Technical English Vocabulary and GrammarDocumento148 páginasBOOK Technical English Vocabulary and GrammarErica FemeniaAinda não há avaliações

- Mail-Room-Workflow PDFDocumento49 páginasMail-Room-Workflow PDFahmedAinda não há avaliações

- Exercise StudentDocumento3 páginasExercise StudentHazim RahmanAinda não há avaliações