Escolar Documentos

Profissional Documentos

Cultura Documentos

Jsa For Air Flushin & Mech. Cleaning of Pipes

Enviado por

Khuda BukshTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Jsa For Air Flushin & Mech. Cleaning of Pipes

Enviado por

Khuda BukshDireitos autorais:

Formatos disponíveis

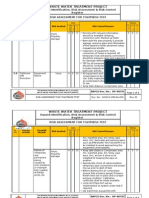

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Description of Activity to be carried out:

Work Location:

AIR FLUSHING / MECHANICAL CLEANING OF

UNDERGROUND & ABOVE GROUND PIPING

MC3

Risk Assessment Log Section:

Step

1.0

Critical Steps in this Activity:

JGC approve the use of this MSJSA :

Name:

Position: JGC HSE Manager

Signature:

Date:

Activity Guidelines used:

Potential Hazards:

Transportation of material/Equipment on site

(Loading / offloading of material manually on

vehicle and using Trailer, Crane, Forklift etc.)

HSE Controls to be Implemented:

Improper loading of material

Failure of lifting gears

Crane failure

Tool box talk will be conducted by Supervisor.

Supervisor will be responsible to complete safe activity

prechecklist sheet daily before start of work.

Loading of material will be done under proper supervision.

Ensure that overloading is prevented

Highlight any protruding load.

Use wooden wedges to prevent material from rolling.

Only Third party certified and color coded lifting gears will

be used

Daily inspection of crane and lifting gears to be done and

checklist to be filled.

For the lifting operation, wind speed should be less than

25 knots. The total lift weight should not exceed 75 % of

crane chart capacity (SWL)

Secure all material properly

Supervisor / Approved Riggers to assess each lift i.e.,

crane position, location away from edges of excavation or

weak ground

Third party certified operator will operate the crane / fork

lifter.

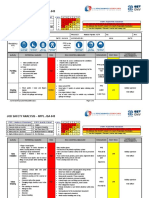

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

Potential Hazards:

HSE Controls to be Implemented:

Unsafe Crane Operation

Fire hazard

Falling down / Struck against / Struck

By

Road Traffic Accidents

Personnel Injury due to slip / trip,

Environmental Hazard due to leakage

of oil from equipment

Position the crane on solid and level ground,

Outriggers fully extended on approved pads

In case of sand storm / less visibility lifting operation

should be reviewed with HSE personnel.

Use proper signboards

Fork lifter and crane to be used as per size, shape and

weight of load.

Banksman will be third party certified and will wear high

visibility Vest for identification.

Barricade the loading / offloading area.

Double Tag line to be used to control load during lifting.

Banksman with vest to guide all vehicle maneuvering.

Safe access to be provided in case of requirement.

No un-authorized person allowed in the area

Check and protect any overhead or under ground

services.

Descon activities to be integrated into JGC transport and

traffic management plan.

Fire extinguisher to be available with crane and fork lifter.

No smoking in the crane cabin.

Good housekeeping to be maintained

Avoid standing at the edge of the trailer or vehicle while

loading / offloading

No passengers allowed traveling on the back of the

trailer/vehicle.

Ladder will be used to go up on trailer

Ensure nobody comes under the suspended load

Ensure reverse horn of fork lifter / crane working

No standing at the back of trailer /vehicle.

All drivers / operators to have valid driving license

Road traffic signs to be followed.

Speed limits to be followed

Proper House Keeping will be carried out to avoid slip /

trip hazards

Ensure use of drip tray

Management of spills will comply with the measures

stated in the Spill Contingency, Procedure RLO-0000FPR-50128.

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

Potential Hazards:

Back pain / Muscular skeletal

disease / Hand injury

HSE Controls to be Implemented:

2.0

Preparation for air flushing/cleaning

Unskilled / Untrained manpower

Defective equipment / tools

Inadequate PPES

Poor communication

Trained worker in (Manual handing ) will only be allowed

to do the job

Training for manual material handling.

Seek assistance whenever needed during manual lifting.

Use appropriate / suitable PPEs

Competent person to be appointed to supervise the job.

Tool box talk will be conducted by Supervisor.

Supervisor will be responsible to complete safe activity

pre checklist sheet daily before start of work.

Only trained and skilled manpower to do the job

Supervisor to ensure the Method Statement, Safe Work

Method Statement & Risk Assessment at job location

Use of proper and defect free tools / equipment

Safety device of equipment in functioning condition (e.g.

dead man switch)

Only JGC inspected and valid color coded equipment to

be used

Supervisor to ensure availability of proper and sufficient

quantity of PPES

Supervisor having good communication skills

Communication to manpower in the language they

understand

Proper communication means (e.g. radio) to be provided

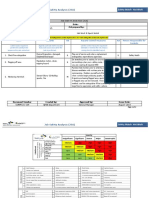

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

Potential Hazards:

No /Improper barricade & Safety

Signs

HSE Controls to be Implemented:

Improper supervision

Improper storage of material/ tools /

equipment

At appropriate distance & proper hard barricade

for above and under ground job points.

Use appropriate safety signboards for air flushing /

cleaning job

Full time supervision for air flushing job.

Supervisor to ensure walk down along whole length of

pipeline to be cleaned / flushed to ensure all fittings etc.

removed, holes blanked and barriers in place.

Material to be stored properly

Equipment to be parked properly

Proper and valid PTW to be obtained where applicable

Improper PTW

Heat Stress

Poor emergency response / 1st Aid

assistance

Ensure availability of cold water at job site in summer

Drink water frequently to avoid dehydration in summer

Ensure availability of heat stress shelter at job site in

summer

Act as per instructions against each flag color to prevent

yourself from heat stress in summer

Ensure availability of 1st aider, 1st aid kit and list of 1st

aiders at job site

List of emergency numbers to be made available

Immediately inform Descon Duty Manager on Descon

Hotline # 5228431 in case of any accident / injury /

incident.

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

Potential Hazards:

Use of defective air compressor

3.0

Use of Air Compressor for Air Flushing

HSE Controls to be Implemented:

Occupational Health problem due to

noisy atmosphere

Leakage of Lub. Oil

Fire hazard

Skin injury due to improper use of

compressed air.

Compressed air leakage due to

improper hose connection or

damaged hose

Improper earthing

All air compressors and other equipment will be JGC

Inspected, color coded.

Perform regular inspection on daily basis to identify

defects

Periodic maintenance to be done

Immediately report any defect/damage/malfunction or

missing part to supervisor

Ensure all moving parts of equipment are properly

guarded

Ensure all safety gadgets and gauges working properly

Wear hearing protection in noisy environment.

Ensure drip tray to avoid any spill due to leakage

Management of spills will comply with the measures

stated in the Spill Contingency, Procedure RLO-0000FPR-50128.

Provision of fire extinguisher with the air compressor.

Compressed air not to be used for personal cleaning

purpose i.e. removing dust from clothes using

compressed air

Inspection of air hose assembly and hose connections

before each use.

Wire checks will be used on hose joints

Hoses to be routed properly to prevent slip / trip hazard

Proper earthing of the air compressor to be done

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

4.0

Critical Steps in this Activity:

Air

Blowing

decompression)

(Continuous

Potential Hazards:

Quick

Improper planning

HSE Controls to be Implemented:

Improper isolation

Improper use of tools

Supervisor to make sure for Proper and valid PTW where

applicable

Supervisor to plan the job before starting activity.

Information to working groups in surrounding area about

this activity.

Supervisor to recheck isolation and lock out / tag out

before starting job

Use of proper tools for the job & no misuse of tools

Noise / Dust / Personal injury during

manual handling

Appropriate PPES will be worn as per job requirement

and job atmosphere / environment

Leakage / Burst of air hose due to

kinks formation

Maintain working area clean and tidy.

Route hose properly with no kinks

Hose, coupling, fittings will be checked visually to be well

in place. Hose joint will be provided with safety chain /

pin

Workers attending equipment will not leave the equipment

un-attended and wear applicable PPEs

Only calibrated gauges to be used

Periodic checks for leakage to be done

Faulty gauges

Leakage from blind / spade, valves

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

5.0

Critical Steps in this Activity:

Mechanical Cleaning

Potential Hazards:

Unsafe rigging / lifting

Slip/trip hazard

Unsafe use of compressed air

HSE Controls to be Implemented:

Follow safe rigging / lifting precautions as described in

Step # 1.0.

Critical lifting operation to be carried out in the presence

of rigging supervisor.

Rigging & lifting training for workers

Plan before start lifting.

Tools / material to be properly stacked / secured

Proper housekeeping and stacking of material to avoid

slip / trip hazards

Kinks free and proper routing of hose

If using compressor, follow precautions described in Step

# 3 regarding use of compressor for air flushing / blowing

Nozzle to be provided with dead-man switch if manually

doing air cleaning

Appropriate PPES to be used as per job nature and

working environment

Dust / Noise

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

6.0

Pipes at height (Air flushing / Mechanical

cleaning)

Potential Hazards:

Falling hazard / Falling Object

hazard

HSE Controls to be Implemented:

Slip/trip hazard due to improper hose

laying

Heat Stress

JGC Working at Height Procedure (S-000-1654-114

Section 4.22) to be used as guideline for working at

height.

Working at height training of workers

Provide full body harness and lanyards to be use and

anchored safely.

Material / tools properly secured on platforms during

working at height jobs

No tools or equipment will be thrown up or down

During working at height, area down side will be properly

barricaded and signs fro working at height will be posted.

Safe access & egress including ladder and scaffolding to

be provided and used by all workers

Side railings shall be ensured on open sides at height.

Ensure that the scaffolds are weekly inspected and

tagged and are safe as per the JGC Scaffolding

Procedure S-000-1654-125

Special care will be taken during windy conditions

Adequate lighting will be provided for night job.

No one walk along unguarded portions.

Any obstructions form the access and the walk way

platform shall be kept clear

Job at height to be stopped in case of high wind speed

(sandstorm etc.)

Air hose to be routed properly to avoid kinks formation

and slip /trip hazard

Ensure availability of cold water at job site in summer

Drink water frequently to avoid dehydration in summer

Ensure availability of heat stress shelter at job site in

summer

Act as per instructions against each flag color to prevent

yourself from heat stress in summer

Ensure availability of 1st aider, 1st aid kit and list of 1st

aiders at job site

List of emergency numbers to be made available

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

7.0

Critical Steps in this Activity:

Under ground pipes (Air flushing / Mechanical

cleaning of )

Potential Hazards:

HSE Controls to be Implemented:

Working on underground lines without

PTW

Fall into excavation

No/Unsafe access & egress

into excavation

Dust / Noise

Collapse / cave in of excavation / trench

Working without / invalid PTW

Unskilled Manpower

Improper access / egress

Poor communication with

inside Confined Space

workers

Oxygen deficiency / enrichment

Flammable gases accumulation / Too

much hot / humid During hot summer

Poor lighting inside confined space

Poor Emergency Response

Proper and valid PTW

Hard barricading around excavation / trench

Safe access & egress not more than 25 feet away from

job point

- Use of appropriate PPES as per job nature

- Proper supporting system for trench/excavation

- No storage of material and no parking of vehicle /

equipment within 2 meter from edge of excavation /

trench.

CONFINED SPACE ENTRY IN DEEP EXACAVATION

- JGC Confined Space Entry Procedure S-000-1654-124

will be used as a guideline for confined space jobs.

- Supervisor to ensure proper and valid PTW for confined

space entry

- Supervisor to ensure confined space training for himself

and workers involved in confined space job

- Trained hole watcher with high visibility vest for

identification to maintain in / out log

- Proper access and egress to be provided

- Pressure horn to be there with hole watcher

- Means of communication e.g. radio etc. to be arranged as

per requirement

- Gas testing to be done for Oxygen conc., flammable

gases and toxic gases in the confined space before start

of work and afterwards as per testing frequency

requirement

- Ensure for proper ventilation in the confined space.

Provide forced ventilation if natural ventilation is not

enough

- SCBA to be used if needed

- Work in groups and give interval (rest time) if required

- If hot summer day, try to do job during cooler part of the

day

- Supervisor to ensure proper lighting (preferably low

voltage) inside the confined space

- Ensure availability of 1st aider, 1st aid kit and list of 1st

aiders at job site

- List of emergency numbers to be made available

- Immediately inform Descon Duty Manager on Descon

-

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

Critical Steps in this Activity:

8.0

Refueling of Equipments e.g. Air Compressor,

welding generators etc

Potential Hazards:

Environmental hazard due to Spillage /

leakage of oil during refueling.

HSE Controls to be Implemented:

Fire Hazards during refueling.

Struck Against / Struck By / Damage to

structure etc

Stay near your equipments fueling point when refueling.

Never overstretch refueling hose

Never overfill or top the fuel tank

Refueling to be done at slow rate to reduce the potential

for spillage and static ignition buildup

Let the fuel dispenser shut off automatically and leave the

nozzle in the tank for six to eight seconds so the fuel can

settle down and any fuel in the nozzle can drip down into

fuel tank

Ensure drip tray under the equipment to be refueled.

Hose and refueling assembly should be in good condition

Refueling to be done only by refueling vehicle and trained

person.

If fuel is needed to be taken on site in cane, use the

recommended jerry cane

Ensure the availability of fire extinguisher near refueling

point

No ignition source /smoking near refueling point

Wearing of appropriate PPES at all time during refueling

Switch off equipment before starting refueling

Switch off mobile phone before starting refueling

Ensure proper access / egress to the equipment being

refueled

Driver to be guided by a banks man while reversing

through marrow access / egress

Audible reverse alarm to be fitted with refueling ehicle

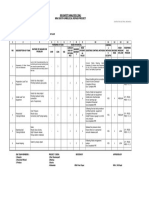

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

HSE Information / Requirements

Resources and Competency

Does the Work Team have the necessary capacity, capability, experience & authority to avoid, minimize, monitor and control the risks (Training / Awareness / Equipment, etc.)?

Detail minimum expected requirements:

Workforce has been trained relevant to the job they have to perform. Air Flushing, Confined Space entry, Working at Height,

Rigging Refueling and Heat stress training will be given to skilled workforce as per their job natures. Supervisor will conduct tool

box talk daily before start of work. Equipment has been inspected and certified by JGC

Communications / Workforce Consultation

Have all members of the Work Party attended the Toolbox Talk, and have they been made fully aware of the risks that they are taking (Residual risks)?

TBT Record No.

Yes

Supervisor to conduct tool box talk daily before start of work explaining the hazards involved in the job and preventive measures

To be taken.

External Risk

Has an assessment been conducted to identify all external (to the activity) hazards and potential risks (3rd parties such as other workforce teams or other adjacent parties)? What is the

result?

Risk Assess. No.

Job Safety Analysis has been carried out keeping in view all external Risks / Hazards. No simultaneous activities will be carried out

in the barricaded area

H&S Training

Employees should be trained in the proper interaction with equipment, and the proper response to incidents involving this equipment. List the training your employee(s) has received.

All employees attended JGC induction training and DESCON HSE trainings. Workforce will be trained relevant to the job they have to perform.

Air Flushing / Cleaning, Working at height, confined space entry, Refueling, Rigging and Heat stress training will be given to

workforce as per their job natures.

Specialist Training

Will the workforce require any specialist training?

YES

YES / NO (IF YES, list the specialist training required for the job):

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Workforce will be trained relevant to the job they have to perform. Air Flushing / Cleaning, Working at height, confined space

entry, Refueling, Rigging and Heat stress training will be given to workforce as per their job natures.

High Potential Risks

Does the task require special access / egress / heavy lifting / entry into confined spaces or work at height / in excavations?

(IF YES, a separate Risk Assessment needs to be completed).

YES

YES / NO

Risk Assess. No.

Working at height

Other Impacts

Are there any other ways in which the work will be affecting and/or protecting the Health and Safety of the team members?

YES / NO (If so, please describe below):

YES

Heat Stress

PTW / Isolations: Other Certificates / Permits

What other precautions (e.g. electrical isolation, permits to work) are required and who will authorize them?

PTW / Cert. Nos.

YES

Permit to work will be obtained wherever applicable.

Contingency / Emergency Response

Should special emergency procedures be instituted, e.g. Emergency Drill, providing Fire Wardens, extra First Aid cover, etc.?

YES / NO (If so, please describe below):

No

Air Emissions

Will the work you perform produce or cause the release of any air emissions?

No

YES / NO

(If YES, list air emissions and method for preventing impact to the environment):

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Water Discharges

Will the work you perform produce or cause the release of any wastewater?

YES / NO (IF YES, how will the wastewater be handled?):

No

Materials

What materials (chemicals, oils, etc.) and/or equipment will you be handling or bringing on-site to perform the contracted work?

NOT APPLICABLE.

Environmental Training

Have employees been trained in the proper handling of materials and equipment, and the proper response to incidents involving these materials? List the training your task employees

have received.

There is no hazardous material, so no need to get special training

Waste Generation

Will the work you perform result in any wastes? YES / NO (IF YES, list the disposal location, as well as amounts and types of wastes expected and the proposed disposal method):

YES

All waste will be disposed off as per JGC Waste Management Procedure RLO-0000-FPR-50126.

Energy

Will the work you perform consume energy (electricity, compressed air, natural gas, steam, etc.)? YES / NO (IF YES, explain what type of energy will be consumed, and how you will

minimize consumption):

Yes, Diesel fuel will be used in cranes, generators, air compressors etc. Equipment will be stopped if it is not needed to reduce fuel consumption

Other Impacts

Are there any other ways in which the work will be affecting and/or protecting the environment?

No

YES / NO (If YES, please describe below):

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Environmental Monitoring

Describe any environmental monitoring to be performed, including sampling methods, frequency, analytical requirements and laboratory to be used:

Not Applicable

Legal requirements

Identify environmental legal requirements applicable to the work that has not already been addressed by the Project.

Not Applicable

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Training modules required to complete Activity:

List Codes of Practice, Legislation, Standards which apply to this Activity:

JSA will be used as a training module

Standard

Codes

ASTM-1599

ASME B31.3

ASME B16.5

List Plant / Equipment / PPE required for this Activity:

Crane, power generator, welding machines,

compressor.

List Equipment / Maintenance

Checks required for this Activity:

Pre job equipment check

will be done before starting

the job

PPEs:

Safety Helmet

Engineering Certificates / Permits / Approvals required for this Activity

(e.g. RLC Permit Road closure, Utility isolation, Special Waste license, etc.)

No

Type

Reference/Documents

Safety Shoes

Safety Glasses

Coverall

As per job requirement:

Gloves , Ear Plugs, Dust Masks, Breathing

Aparatus, Safety Harness

Person(s) Responsible for Supervising / Inspecting Work:

Person(s) responsible for supervising the work, inspecting and approving work areas, work methods, protective measures, plant equipment and power / other tools:

NB: List of qualifications/experience is held in local JGC files see JGC HSE Group for details.

Name: .

Position:

Name: .

Position:

Signature: .................................................................

Signature: .................................................................

For a list of names and signatures of staff instructed in this Safe Work Method Statement and JSA, see JGC training records.

Copy 1 - To be posted at the Worksite / Supervisor at the Worksite

Copy 2 - To be retained by JGC HSE Group (24 months)

Copy 3 - To be held by the subcontractor (24 months)

SAFE ACTIVITY PRE-CHECK (SAP) SHEET

Company:

Date:

Foreman (print

name):

Location:

Task Description:

MUSTER / ASSEMBLY POINT LOCATION:

IS YOUR DESIGNATED PLACE OF WORK TIDY? - YES or NO (If "NO" housekeeping must be performed prior to work commencing).

PERMIT TO WORK REQUIREMENTS

YES

Key Task Related Hazards

(tick box)

NO

N/A

Excavations

Access Only

Plant & Equipment

Electrical

Key Preventative Control Measures

Confined Spaces

Isolations

Lock Out / Tag Out

Hot work

Instrumentation

Pre / Commissioning / START-UP

EXCAVATION

YES

NO

N/A

HOTWORK (Non PTW controlled)

SHORED / SLOPED / BENCHED

FIRE EXTINGUISHER

LADDERS PROVIDED

FIRE BLANKET

BURIED SERVICES IDENTIFIED

CYLINDERS UPRIGHT & SECURED

VEHICLE STOP BARRIERS / BOARDS

COMBUSTIBLES REMOVED

EXCAVATION INSPECTED

CONFINED SPACES

NO

N/A

EMERGENCY COMMUNICATIONS

WORK BELOW RESTRICTED

PERMIT to WORK

BARRIERS / SIGNS POSTED

GAS TEST COMPLETED

FLAME ARRESTORS FITTED

TALLY BOARD or similar

WELDING CABLES IN GOOD CONDITION

EMERGENCY ACCESS

CHEMICALS

COMMUNICATIONS

MSDS REVIEWED / AVAILABLE

SAFETY HARNESSES

SKIN / EYE / THROAT IRRITANT

SUITABLE (Ex.) LIGHTING

SHOWER or EYEWASH AVAILABLE

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

SPECIAL PPE AVAILABLE AS PER MSDS

SCAFFOLD INSPECTED

CONTAINERS LABELLED PROPERLY

INSPECTION SCAFTAG POSITIONED & IN DATE

SIGNS POSTED

SAFE ACCESS / EGRESS PROVIDED

RISK ASSESSMENT CONDUCTED

TOEBOARDS, KICKPLATES IN ORDER

HAZARDS COMMUNICATED

HANDRAILS SECURED

GROUNDING

HARNESS & LANYARDS INSPECTED

CONTAINMENT REQUIRED / PROVIDED

STATIC LINES - TIE OFF POINTS

ABSORBENT AVAILABLE IN SITU.

YES

NO

N/A

PORTABLE TOOLS

PLANT & EQUIPMENT INSPECTED

TOOLS, APPLIANCES INSPECTED

LIFTING GEAR, RIGGING INSPECTED & CERTS.

BANKSMAN / COMPETENT PERSON

IDENTIFIED

LIFTING PLAN / CALCS & M/S CHECKED

DEFECTS REPORTED

OPERATOR CERTIFIED

OPERATORS CERTIFIED

CABLES, HOSES INSPECTED

PPE REQUIREMENTS IDENTIFIED

PORTABLE APPLIANCES INSPECTED

EXTENSION CABLE CHECKED & TAGGED

FLAGMEN TRAINED / POSITIONED

OCCUPATIONAL HEALTH

N/A

SPECIAL PPE (VISORS, GLOVES, etc)

VENTILATION

PLANT & EQUIPMENT

NO

FIRE WATCH (Safety Passport check)

YES

STANDBY MAN

SCAFFOLDING

YES

GUARDS POSITIONED

YES

NO

N/A

PPE

SAFE ACTIVITY PRE-CHECK (SAP) SHEET

FIRST AIDER / FIRST AID KIT

HARD HAT

HEAT STRESS

BOOTS

DUST

GLASSES

HYGIENE (FOOD / WATER) CONTAINERS

COVERALLS / HIGH-VISIBILITY VESTS

NOISE

FACE MASKS

VIBRATION

GENERAL WORK GLOVES

YES

ELECTRICITY

NO

N/A

SPECIALIST PPE

PTW REVIEWED (COMPETENT PERSON)

WELDERS, FIRE RETARDANT GLOVES

SYSTEM LOCK OUT

ELECTRICAL RUBBER GLOVES

SYSTEM TAGGED OUT

EAR DEFENDERS / PLUGS

JSA / METHOD STATEMENT IN PLACE

HARNESSES / LANYARDS

SYSTEM DISCONNECTED

WELDERS SCREEN

SYSTEM TESTED

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

FACE MASK (DUST - FUMES)

MANUAL HANDLING

YES

NO

N/A

RESPIRATORS

WORKER(S) TRAINED (Safety Passport check)

SELF CONTAINED BREATHING APPARATUS

LIFTING, PULLING

FIRE RETARDENT CLOTHING

STRETCHING

ENVIRONMENTAL CONSTRAINTS

SHARP OBJECTS, PINCH POINTS

ENV. STUDY REPORT COMPLETED

(TROLLEYS, FORKLIFTS, etc) available

ENV. HAZARDS IDENTIFIED IN MS

SOUND GROUND / UNDERFOOT CONDITIONS

WORK AREA CHECKED (R&E SPECIES)

GENERAL

YES

NO

N/A

WASTE CONTAINERS / AREA IDENTIFIED

FLYING PARTICLES

SPILL CONTAINMENT

CABLES SECURED ABOVE HEAD HEIGHT

ENV. MONITOR INFORMED / AVAILABLE

VOIDS / HOLES COVERED & SECURED

SITE PLANT & VEHICLES

BARRIERS & TAPE PROVIDED

SAFE DISTANCE - VEHICLES & PEDESTRIANS

ALL HAZARDS COMMUNICATED

SIGNS ERECTED AND VISIBLE

OTHER WORKERS SAFETY CONSIDERED

NOISE / EXHAUST HAZARDS IDENTIFIED

Foreman

/ Supervisor: I have discussed the above potential hazards involved in the task, reviewed the SAFE

ACTIVITY PRECHECKLIST SHEET Card with the employees under my control, and implemented suitable and sufficient

controls to minimize the risks involved.

Name (print)

Signature

Employees: I / WE ACCEPT THE RESPONSIBILITY FOR THE SAFE BEHAVIOUR OF MYSELF AND MY CO-WORKERS

DURING THE TASKS IDENTIFIED ABOVE:

EMPLOYEE NAME

SIGNATURE

EMPLOYEE NAME

1.

10.

2.

11.

3.

12.

4.

13.

5.

14.

6.

15.

7.

16.

8.

17.

9.

18.

SIGNATURE

Você também pode gostar

- JSA - Sand Blasting & PaintingDocumento4 páginasJSA - Sand Blasting & Paintingsurendra behera100% (4)

- Appendix 18 Steam Blowing JSADocumento3 páginasAppendix 18 Steam Blowing JSAzhang75% (12)

- Confined Space JSADocumento1 páginaConfined Space JSADILAL B P100% (17)

- Risk Assessment For Air BlowingDocumento8 páginasRisk Assessment For Air BlowingAriel Dela Cruz100% (5)

- Risk Assessment For Tightness TestDocumento8 páginasRisk Assessment For Tightness TestAriel Dela Cruz100% (1)

- Job Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralDocumento2 páginasJob Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralNico Raharjo60% (5)

- JHA Pneumatic Test Using N2Documento4 páginasJHA Pneumatic Test Using N2Luqman Osman89% (9)

- Jsa For HydrotestDocumento10 páginasJsa For HydrotestAnonymous CcGYhZb080% (5)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocumento17 páginasSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh0% (1)

- Jsa For Civil Confined Space EntryDocumento11 páginasJsa For Civil Confined Space EntryKhuda BukshAinda não há avaliações

- Jsa For Drilling.Documento3 páginasJsa For Drilling.Belsyah Nofriyan75% (4)

- Hydro Test JSADocumento2 páginasHydro Test JSAEruse Okejero88% (17)

- Jsa For Piping and Erection RevisedDocumento1 páginaJsa For Piping and Erection RevisedAlvin Smith77% (26)

- JSA Installation of Equipment For Electrical and InstrumentDocumento3 páginasJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham75% (4)

- Risk Assess JSA Bolt Tightening 012Documento7 páginasRisk Assess JSA Bolt Tightening 012Abdeldjalil Ferhati100% (2)

- JSA Cable Laying PDFDocumento2 páginasJSA Cable Laying PDFManoj WaskelAinda não há avaliações

- Monthly HSE Performance ReportDocumento17 páginasMonthly HSE Performance ReportKhuda BukshAinda não há avaliações

- JSA-049 Valves & Support Installation and DismantlingDocumento4 páginasJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- Jha For HydrotestDocumento14 páginasJha For HydrotestnikAinda não há avaliações

- JSA Hydro TestingDocumento1 páginaJSA Hydro TestingZeyad RezkAinda não há avaliações

- JSA-020-Safety Watch-Hot WorkDocumento2 páginasJSA-020-Safety Watch-Hot WorkNishad MuhammedAinda não há avaliações

- JSA For WrappingDocumento6 páginasJSA For WrappingMohammed Minhaj100% (2)

- Manual Tig Welding (RRC) - Job ProcedureDocumento3 páginasManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- JSA For Holiday Testing PDFDocumento4 páginasJSA For Holiday Testing PDFMohammed Minhaj67% (3)

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocumento2 páginasJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- JSA For Fabrication WorksDocumento11 páginasJSA For Fabrication Workssurendra behera100% (3)

- Jsa For DG Operation PDFDocumento5 páginasJsa For DG Operation PDFajmalvk100% (4)

- JHA For Loop CheckDocumento8 páginasJHA For Loop CheckFrancis Enriquez Tan83% (6)

- Job Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewDocumento4 páginasJob Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewMoaatazz Nouisri100% (1)

- 12 JSA FlushingDocumento5 páginas12 JSA FlushingYosua SitumorangAinda não há avaliações

- JHA - Handrails and GratingsDocumento10 páginasJHA - Handrails and GratingsVidyesh Nair67% (3)

- JSA Tubing Leak TestDocumento1 páginaJSA Tubing Leak TestMuhammad Reza Gadran67% (3)

- Blinding and De-BlindingDocumento3 páginasBlinding and De-Blindingkaremkoko33% (3)

- Aboveground Piping Installation Works 2016Documento7 páginasAboveground Piping Installation Works 2016Aldrin75% (4)

- Example JSA Job Safety AnalysisDocumento13 páginasExample JSA Job Safety AnalysisPaulSwinbank100% (4)

- Jsa For Pre-Cast Column ErectionDocumento19 páginasJsa For Pre-Cast Column ErectionKhuda BukshAinda não há avaliações

- Grounding System Jsa 2008Documento4 páginasGrounding System Jsa 2008Aldrin100% (5)

- HSE Drilling and Well Control ProcedureDocumento5 páginasHSE Drilling and Well Control ProcedureKhuda Buksh100% (2)

- Permit To Work ProcedureDocumento42 páginasPermit To Work ProcedureKhuda Buksh100% (2)

- ISO 45001 Gap Analysis ChecklistDocumento7 páginasISO 45001 Gap Analysis ChecklistKhuda Buksh75% (12)

- Quality PlanDocumento21 páginasQuality PlanTAHER AMMAR88% (8)

- Ceramic-Disc-Brakes ReportDocumento17 páginasCeramic-Disc-Brakes ReportArjun Sagar.100% (2)

- Live SafersDocumento16 páginasLive SafersGabriel Zoratti100% (1)

- JSA - Chemical CleaningDocumento4 páginasJSA - Chemical CleaningkrshhAinda não há avaliações

- Hydro Testing On Piping System Utility and Plant Piping Jsa 2012Documento4 páginasHydro Testing On Piping System Utility and Plant Piping Jsa 2012AldrinAinda não há avaliações

- JSA For Hydro Test Activites (Generic)Documento4 páginasJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- JSA-055 Hydro-TestDocumento24 páginasJSA-055 Hydro-TestOmar Dhieb100% (7)

- Jsa-Hot Oil FlushingDocumento2 páginasJsa-Hot Oil Flushingyelsa otrebla100% (5)

- Jsa Pipe Cutting at Fire PumpDocumento5 páginasJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdAinda não há avaliações

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocumento15 páginasSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda BukshAinda não há avaliações

- Jsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementDocumento13 páginasJsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementKhuda Buksh100% (1)

- Jsa Nitrogen PurgingDocumento2 páginasJsa Nitrogen PurgingKanthimathinathan Krishnan100% (5)

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocumento7 páginasJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- Gas Cutting JsaDocumento4 páginasGas Cutting JsaMohammed Minhaj100% (1)

- Jsa For Confined SpaceDocumento5 páginasJsa For Confined Spacejithin shankar100% (3)

- Jsa For Blowing of Air in Underground PipesDocumento4 páginasJsa For Blowing of Air in Underground PipesMohammed MinhajAinda não há avaliações

- JHA General Maintenance Activity PDFDocumento5 páginasJHA General Maintenance Activity PDFdede SinbadAinda não há avaliações

- Tanks Confined Space JSADocumento5 páginasTanks Confined Space JSAkosoko100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Documento4 páginasThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaAinda não há avaliações

- JSA For Washing and Air BlowingDocumento3 páginasJSA For Washing and Air BlowingMohammed MinhajAinda não há avaliações

- JSA For HDPE SLEEVING DEL 89Documento3 páginasJSA For HDPE SLEEVING DEL 89Mohammed Minhaj100% (1)

- JSA For Installation of Fire PumpsDocumento2 páginasJSA For Installation of Fire Pumpsperquino oasan100% (3)

- JSA - Hydro-Testing of Pipe & EquipmentDocumento1 páginaJSA - Hydro-Testing of Pipe & EquipmentRajuAinda não há avaliações

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocumento16 páginasSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- Facility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3Documento8 páginasFacility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3AldrinAinda não há avaliações

- Lifting and HoistingDocumento4 páginasLifting and Hoistingfadhil AbdullahAinda não há avaliações

- Jsa For Steel Structure For Off PlotDocumento13 páginasJsa For Steel Structure For Off PlotKhuda BukshAinda não há avaliações

- Work at Heigh at Night SafetyDocumento49 páginasWork at Heigh at Night SafetyKhuda BukshAinda não há avaliações

- Toxic Gas Fact SheetDocumento15 páginasToxic Gas Fact SheetKhuda BukshAinda não há avaliações

- Materials Handling, Storage, Use, and DisposalDocumento54 páginasMaterials Handling, Storage, Use, and DisposalKhuda BukshAinda não há avaliações

- Work at Height Safety Question & AnswersDocumento34 páginasWork at Height Safety Question & AnswersKhuda BukshAinda não há avaliações

- Short Note For Safety OfficerDocumento24 páginasShort Note For Safety OfficerKhuda BukshAinda não há avaliações

- Safety GuideDocumento53 páginasSafety GuideKhuda BukshAinda não há avaliações

- HSE Procedure For Garbage DisposalDocumento4 páginasHSE Procedure For Garbage DisposalKhuda BukshAinda não há avaliações

- HSE Procedure For Planning & AuditingDocumento4 páginasHSE Procedure For Planning & AuditingKhuda Buksh100% (1)

- HSE PLAN by HTTPSDocumento52 páginasHSE PLAN by HTTPSKhuda BukshAinda não há avaliações

- 2 3 Programme Risk Assessment Template Oct 1 2007Documento6 páginas2 3 Programme Risk Assessment Template Oct 1 2007Khuda Buksh0% (1)

- Inspection Pass Inspection Pass Inspection PassDocumento6 páginasInspection Pass Inspection Pass Inspection PassKhuda BukshAinda não há avaliações

- HSE (Trainor Et Al) - 2006 - HSE Report No 426 ACUTEXDocumento106 páginasHSE (Trainor Et Al) - 2006 - HSE Report No 426 ACUTEXKhuda Buksh100% (1)

- Emergency ProceduresDocumento23 páginasEmergency ProceduresKhuda BukshAinda não há avaliações

- Terms and AbbreviationsDocumento166 páginasTerms and AbbreviationsKhuda Buksh100% (1)

- IRP 22 Risk Register 2015Documento30 páginasIRP 22 Risk Register 2015Jeya Kumar100% (1)

- Export Excel Dashboards ToDocumento19 páginasExport Excel Dashboards ToKhuda BukshAinda não há avaliações

- Cardiff Met Contracts ListDocumento3 páginasCardiff Met Contracts ListKhuda BukshAinda não há avaliações

- HSE Organization ChartDocumento1 páginaHSE Organization ChartKhuda BukshAinda não há avaliações

- Ppe Stop and ThinkDocumento3 páginasPpe Stop and ThinkKhuda BukshAinda não há avaliações

- WeldingDocumento16 páginasWeldingKhuda BukshAinda não há avaliações

- 50 Years of Double Ended Ferry DesignDocumento23 páginas50 Years of Double Ended Ferry Designyw_oulalaAinda não há avaliações

- Legal Method 1st DraftDocumento16 páginasLegal Method 1st DraftHardik BishnoiAinda não há avaliações

- Om90zv-2 Ex PDFDocumento223 páginasOm90zv-2 Ex PDFLe Du100% (2)

- Fault Tree AnalysisDocumento107 páginasFault Tree Analysisdoughstone100% (1)

- Automobile Inspection FormDocumento1 páginaAutomobile Inspection Formjohn3e8Ainda não há avaliações

- Green-Wave Traffic Theory Optimization and AnalysiDocumento6 páginasGreen-Wave Traffic Theory Optimization and AnalysiSimona NicoletaAinda não há avaliações

- SON Approves 80 Standards For CNG Vehicles and Related AppliancesDocumento1 páginaSON Approves 80 Standards For CNG Vehicles and Related Appliancesajeyetanemmanuel1Ainda não há avaliações

- Research Papers On Automotive Engineering PDFDocumento9 páginasResearch Papers On Automotive Engineering PDFafmcuvkjz100% (1)

- Company CatalogueDocumento36 páginasCompany CataloguekaushikAinda não há avaliações

- Vsa 17 ADocumento2 páginasVsa 17 AJustin WilliamsAinda não há avaliações

- S/N Offence Name Penalty 1 Penalty 2Documento5 páginasS/N Offence Name Penalty 1 Penalty 2balajiAinda não há avaliações

- 2012 Audi A6: ManualDocumento298 páginas2012 Audi A6: ManualTed ÖrkenrudAinda não há avaliações

- Unit 25 Essential Working Practices in Vehicle TechnologyDocumento10 páginasUnit 25 Essential Working Practices in Vehicle TechnologymariomatoAinda não há avaliações

- Ola0195171 722009 1 5693505 20230914-0903592202968Documento3 páginasOla0195171 722009 1 5693505 20230914-0903592202968Jade KayceeAinda não há avaliações

- CSC E-Governance Services India Limited - (CSC0002473)Documento2 páginasCSC E-Governance Services India Limited - (CSC0002473)CHELVASER100% (1)

- MACP AppealDocumento13 páginasMACP AppealSamirkumar P. LakhtariaAinda não há avaliações

- National Conference - NCAAT 2010Documento127 páginasNational Conference - NCAAT 2010mu_rajesh3415Ainda não há avaliações

- ArticleDocumento10 páginasArticlefawad.azeem14792Ainda não há avaliações

- 2016 Chevrolet TraxDocumento2 páginas2016 Chevrolet TraxjlnmeuserAinda não há avaliações

- Bucket Truck Safety-PioneerDocumento4 páginasBucket Truck Safety-PioneerhazopmanAinda não há avaliações

- YP 125 R Owner's Manual - enDocumento92 páginasYP 125 R Owner's Manual - enJonh DoeAinda não há avaliações

- Yantra Motors Quick IntroductionDocumento4 páginasYantra Motors Quick IntroductionrvsAinda não há avaliações

- Influence of The Tires Pressure in The Vehicle FuelDocumento11 páginasInfluence of The Tires Pressure in The Vehicle FuelAdobe IlAinda não há avaliações

- Regulations For The Use of Staff CarsDocumento7 páginasRegulations For The Use of Staff CarsIjaz HussainAinda não há avaliações

- Seat Belts Use Act of 1999 RA 8750Documento4 páginasSeat Belts Use Act of 1999 RA 8750Rudy Ortea100% (1)

- Ijrdet 0415 08 PDFDocumento4 páginasIjrdet 0415 08 PDFVenkatesh ReddyAinda não há avaliações

- TSB-Re-J24B-Cylinder-Head CracksDocumento3 páginasTSB-Re-J24B-Cylinder-Head Cracksspamail73887Ainda não há avaliações

- Agent/ Intermediary Name and Code:VAMAN RAO BALMURI AGD0000449Documento5 páginasAgent/ Intermediary Name and Code:VAMAN RAO BALMURI AGD0000449katta yadi reddyAinda não há avaliações