Escolar Documentos

Profissional Documentos

Cultura Documentos

Dynamic Chainless Bicycle

Enviado por

Venkata RamuduDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Dynamic Chainless Bicycle

Enviado por

Venkata RamuduDireitos autorais:

Formatos disponíveis

International Journal of Advance Research in Engineering, Science & Technology(IJAREST),

ISSN(O):2393-9877, ISSN(P): 2394-2444,

Volume 2,Issue 5, May- 2015 , Impact Factor:2.125

DYNAMIC CHAINLESS BICYCLE

Mayur Linagariya1,Dignesh Savsani2

Mechanical Department, Noble Group Of Institute Junagadh, lunagaria.mayur93@yahoo.com

2

Mechanical Department, Noble Group Of Institute Junagadh, digneshks@gmail.com

Abstract

A shaft-driven bicycle is a bicycle that uses a driven shaft instead of a chain to transmit power from the pedals

to the wheel. Shaft drives were introduced over a century ago, but were mostly supplanted by chain-driven

bicycles due to the gear ranges possible with sprockets and derailleur. Recently, due to advancements in

internal gear technology, a small number of modern shaft-driven bicycles have been introduced. The shaft drive

only needs periodic lubrication using a grease gun to keep the gears running quiet and smooth. This

chainless drive system provides smooth, quite and efficient transfer of energy from the pedals to the rear

wheel. It is attractive in look compare with chain driven bicycle. It replaces the traditional method.

Keywords Bevel Gears, Shaft drive, Dynamometer, Chainless technology, Reliable and Durable

I.

INTRODUCTOIN

The shaft connected between the pair of

spiral bevel gears. The main application of the

spiral bevel gear is in a vehicle differential, where

the direction of drive from the drive shaft must be

turned 90 degrees to drive the wheels. The helical

design produces less vibration and noise than

convention straight-cut or spur-cut gear with

straight teeth.

If bevel-wheels could be accurately and cheaply cut

by machinery, it is possible

that gears of this description might supplant, to a

great extent, the chain-drive gear: but the fact that

the teeth of the bevel-wheels cannot be accurately

milled is a serious obstacle to their practical

success.

I.1

Objectives of dynamic bicycle

1.

2.

3.

4.

5.

II.

WORKING

The shaft connected between the pair of spiral

bevel gears. The main application of the spiral

bevel gear is in a vehicle differential, where the

direction of drive from the drive shaft must be

turned 90 degrees to drive the wheels.

Aim of our Project is to make new kind of

transmission system for bicycle for getting high

reliability system, and more safe system. A drive

shaft, driveshaft, driving shaft, propeller shaft, or

Cardin shaft is a mechanical component for

transmitting torque and rotation, usually used to

connect other components of a drive train that

cannot be connected directly because of

distance or the need to allow for relative

movement between them.

III.

COMPONENT OF BICYCLE

Increase durability of bicycle with the help

of shaft drive.

Reduce maintenance cost of bicycle.

Increase power transmission efficiency of

the bicycle.

Making system more reliable.

Reduce noise pollution using shaft drive

transmission system.

All Rights Reserved, @IJAREST-2015

International Journal of Advance Research in Engineering, Science & Technology(IJAREST),

ISSN(O):2393-9877, ISSN(P): 2394-2444,

Volume 2,Issue 5, May- 2015 , Impact Factor:2.125

III.1 Brake lever, Grip shift, Handlebar

Brake levers are usually mounted on the

handlebars within easy reach of the rider's hands.

They may be distinct or integrated into the shifting

mechanism. The brake lever transmits the force

applied by the rider through either a mechanical or

hydraulic mechanism.

Many people think that bicycle handlebars are

merely the means of steering a bike, and do not

give any more thought to the matter. The truth of

the matter is that the handlebars are very important

in determining your position on the bike.

III.2

Top tube, Down tube, Seat tube

III.2.1 Frame tubes

The diamond frame consists of two

triangles, a main triangle and a paired rear triangle.

The main triangle consists of the head tube, top

tube, down tube and seat tube. The rear triangle

consists of the seat tube, and paired chain stays and

seat stays.

III.2.2 Top tube

The top tube, cross-bar, connects the top of

the head tube to the top of the seat tube. Control

cables are routed along mounts on the top tube, or

sometimes inside the top tube. Most commonly,

this includes the cable for the rear brake, but some

mountain bikes and hybrid bicycles also route the

front and rear derailleur cables along the top tube.

III.2.3 Down tube

The down tube connects the head tube to the

bottom bracket shell. On racing bicycles and some

mountain and hybrid bikes, the derailleur cables

run along the down tube, or inside the down tube.

On older racing bicycles, the shift levers were

mounted on the down tube. On newer ones, they

are mounted with the brake levers on the

handlebars.

III.2.4 Seat tube

The seat tube contains the seat post of the

bike, which connects to the saddle. The saddle

height is adjustable by changing how far the seat

post is inserted into the seat tube. On some bikes,

this is achieved using a quick release lever. The

seat post must be inserted at least a certain length;

this is marked with a minimum insertionmark.

III.3 Pedal crank

Bicycles cranks are also known as the crank

set or chain set. The cranks are part of the drive

train, and as such, help convert the cyclist's energy

All Rights Reserved, @IJAREST-2015

into the movement of the bike. The crank set

consists of the crank arms, which are connected by

way of the bottom bracket (axle). Chain rings are

also connected to the right crank arm.

III.4 Pedal

Bicycle pedals have evolved, and now can

be found in all manner of shapes and sizes. This is

good news for you. it is quite easy to find the

perfect pedals for you. The pedals found on most

bikes are made from hard rubber or plastic. these

pedals are light and durable enough for casual

riding. More avid cyclists may want to consider a

more durable pedal made of aluminum alloys. For

those interested in maximum strength combined

with minimum weight, you can always pay more

for higher end bicycle pedals made of carbon or

titanium.

III.5 Rear hub

A hub is the center part of a bicycle wheel. It

consists of an axle, bearings and a hub shell. The

hub shell typically has 2 machined metal flanges to

which spokes can be attached. Hub shells can be

one-piece with press-in cartridge or free bearings

or, in the case of older designs, the flanges may be

affixed to a separate hub shell.

Hub gears or internal-gear hubs are gear ratio

changing systems commonly used on bicycles. Hub

gear systems generally have a long and largely

maintenance-free life though some are not suitable

for high-stress use in competitions or hilly, off-road

conditions.

Hub gears are sealed within the hub, which protects

them from water, grit, and impacts. Thus hub gears

usually require less maintenance and can be more

reliable over time than comparable external

derailleur gear systems, which may require more

adjustments and replacement of parts (front

chaining, rear cogs, narrow derailleur-chain).

Hub gears provide a means for shifting gear ratios

on drive trains incompatible with external

derailleur such as belt drives and shaft drives.

III.6 Wheel rim

The rim of a wheel is the outer circular

design of the metal on which the inside edge of the

tire is mounted on vehicles such as automobiles.

For example, on a bicycle wheel the rim is a large

hoop attached to the outer ends of the spokes of the

wheel that holds the tire and tube.

The rim is commonly a metal extrusion that is

butted into itself to form a hoop, though may also

be a structure of carbon fibre composite, and was

historically made of wood. Some wheels use both

International Journal of Advance Research in Engineering, Science & Technology(IJAREST),

ISSN(O):2393-9877, ISSN(P): 2394-2444,

Volume 2,Issue 5, May- 2015 , Impact Factor:2.125

an aerodynamic carbon hoop bonded to an

aluminium rim on which to mount conventional

bicycle tires.

the bicycle. It performs a similar role as a horse's

saddle, not bearing all the weight of the rider as the

other contact points also take some of the load.

III.7 Tire

A bicycle tire is a tire that fits on the

wheel of a bicycle, unicycle, tricycle, Quadra cycle,

bicycle trailer, or trailer bike. They may also be

used on wheelchairs and head cycles, especially for

racing. Bicycle tires provide an important source of

suspension, generate the lateral forces necessary for

balancing and turning, and generate the

longitudinal forces necessary for propulsion and

braking. They are the second largest source, after

air drag, of power consumption on a level road.

The modern detachable pneumatic bicycle tire

contributed to the popularity and eventual

dominance of the safety bicycle.

A bicycle seat post, seat pin, or saddle pole is a

tube that extends upwards from the bicycle frame

to the saddle. The amount that it extends out of the

frame can usually be adjusted, and there is usually

a mark that indicates the minimum insertion (or

maximum extension). Seat posts can be made of

steel, aluminium, titanium, carbon fibre, or

aluminium wrapped in carbon fibre.

Two main techniques for attaching a bicycle tire to

a rim have developed: clincher and tubular. In an

attempt to provide the best attributes of both

methods, tubular clinchers have also been offered.

III.8 Brake Arm

A bicycle brake is used to slow down or

stop a bicycle. There have been various types of

brake used throughout history, and several are still

in use today. The three main types are: rim brakes,

disc brakes, and drum brakes. Caliper (or rim)

bicycle brakes include side or center pull caliper

brakes, and v-brakes. Although these different

braking styles are slightly different, they all operate

by applying braking force to the rim of the wheel

via rubber brake pads.

In most cases, this is accomplished by

squeezing brake levers mounted on the bicycle

handlebars - thus contracting brake cables and

forcing the brake pads to press against the rim. Rim

brakes offer more modulation than pedal brakes,

but have the tendency to lose their power in overly

wet or muddily conditions.

III.9 Seat and seat post

A bicycle saddle, often called a seat, is one

of three contact points on an upright bicycle, the

others being the pedals and the handlebars. The

bicycle saddle has been known as such since the

bicycle evolved from the draisine, a forerunner of

the teeth are angled; however with spiral gears the

teeth are also curved.

IV.1.1 Shifting down

(to a lower gear) would result in the

pedalling becoming easier (more revolutions).

Pedalling at a lower resistance is perfect for steep

hills, or to train your legs to move quickly.

All Rights Reserved, @IJAREST-2015

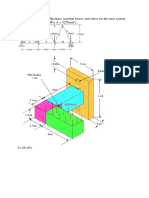

IV.

DESIGN OF BEVEL GEAR AND DRIVE

SHAFT

IV.1

BEVEL GEAR:Bevel gears are gears where the axes of the

two shafts intersect and the tooth-bearing faces of

the gears themselves are conically shaped. Bevel

gears are most often mounted on shafts that are 90

degrees apart, but can be designed to work at other

angles as well.

A spiral bevel gear is a bevel gear with helical

teeth. The main application of this is in a vehicle

differential, where the direction of drive from the

drive shaft must be turned 90 degrees to drive the

wheels. The purpose of gears is to transmit motion

and torque from one shaft to another.

That transmission normally has to occur with a

constant ratio, the lowest possible disturbances and

the highest possible efficiency.

Tooth profile, length hand shape are derived from

those requirements. Spiral bevel gears have their

teeth formed along spiral lines. They are somewhat

analogous to cylindrical type helical gears in that

IV.1.2 Shifting up

(To a higher gear) would result in pedaling

becoming more difficult (less revolutions). Cycling

in a higher gear is ideal for flat stretches, or

International Journal of Advance Research in Engineering, Science & Technology(IJAREST),

ISSN(O):2393-9877, ISSN(P): 2394-2444,

Volume 2,Issue 5, May- 2015 , Impact Factor:2.125

downhill

stretches.

The shaft drive is a patented, lightweight and

rugged aluminium alloy bevel gear drive system.

This chainless drive system provides smooth,

quiet and efficient transfer of energy from the

pedals to the rear wheel. The shaft drive is

designed and manufactured using the highest

quality parts to last for many years.

The shaft drive is combined with a multi-speed

internal rear gear hub to provide a wide range of

gearing for many types of terrain from city streets

to suburban paths to mountain trails.

IV.2

SHAFT DRIVE:In a chainless bike, a drive shaft takes over

the role of the chain. The pedals are connected to

the drive shaft by gears, allowing the drive shaft to

transfer power from the pedals to a gearbox on the

rear wheel. The power from the drive shaft then

spins a shaft rod that propels the rear wheel,

providing the bike with power.

The bearings used in the shaft are all sealed and

lubricated and do not require maintenance. The

shaft rod is a solid steel rod, attached at both ends

to the bevel gears.The drive shaft has served as an

alternative to a chain-drive in bicycles for the past

century, although never becoming very popular.

IV.2.1 Transmission

The drive shaft connects to a hub

transmission that replaces the stacked gears found

on a conventional bike. This transmission is

factory-lubricated and sealed permanently. Gear

changes occur inside the hub, protected from the

elements. This transmission is also known as a

planetary transmission, since "planet" gears cycle

around a central, fixed "sun" gear. Each gear has a

different number of teeth, and the various

combinations of gears provide a variety of gear

ratios, or speeds.

All Rights Reserved, @IJAREST-2015

International Journal of Advance Research in Engineering, Science & Technology(IJAREST),

ISSN(O):2393-9877, ISSN(P): 2394-2444,

Volume 2,Issue 5, May- 2015 , Impact Factor:2.125

V.

Features

Frame construction

Gear Components

Gear Changes

Maintenance

Durability

Resilience to Elements

Ground Clearance

(to drive system parts)

Safety

Efficiency

Gear Range

Noise

SHAFT DRIVEV/s CHAIN

Shaft Drive-Hub Bikes vs. Chain-Sprocket-Derailleur Bikes

Dynamic Bicycles ShaftDrive Bikes

Sprocket-Derailleur Bikes

Aluminium Alloy

Aluminium Alloy

Shimano internal Gear Hubs;

Sprockets, Derailleurs, Chains

Enclosed Shaft Drive

Single Shifter; Fast and seamless gear Multiple Shifters; must pedal to change gears;

changes; shifting independent of

no gear indicator

pedaling; easy-to-read gear indicator

No Scheduled Maintenance on Hub;

Periodic Grease added to Shaft Drive - Requires adjustment of derailleurs by trained

fast and easy

bike mechanic; periodic chain cleaning,

lubrication and tensioning

Hardened cromoly gears, cast

All moving parts fully exposed and susceptible

aluminium housings, sealed bearings.

to damage, misalignment and corrosion

All moving parts fully enclosed to

prevents damage and corrosion

Fully internal gearing sealed and

External gearing fully exposed and adversely

protected from rain, salt, dirt, and sand affected by rain, salt, sand and debris

13+ inches to shaft drive

~ 8 inches to derailleur, chain and sprocket

Gears fully enclosed in shaft-drive,

Chain, sprockets and derailleurs can tear and

nothing to catch on hands or clothing;

soil clothing and cut hands

no more "chain bite"

90%+ efficient (consistently with

75% - 95% efficient (varies depending on

minimal maintenance)

condition and upkeep)

8-speed = range of 21 gears of chain

21-gear or 24-gear

bike

7-speed = range of 18 gears of chain

bike

Low - runs virtually silent

Can vary depending on condition of chain and

alignment of derailleur

All Rights Reserved, @IJAREST-2015

International Journal of Advance Research in Engineering, Science & Technology(IJAREST),

ISSN(O):2393-9877, ISSN(P): 2394-2444,

Volume 2,Issue 5, May- 2015 , Impact Factor:2.125

IX.

References

Leonardo Caggiani, Michele Ottomanellia, 2012.

A dynamic simulation based model for optimal

fleet repositioning in bike-sharing systems

2. Rahul U. Urunkar et al Int. Journal of Engineering

Research and Applications, 2014. Study of Drive

Mechanisms of Bicycle, Tricycle or Like Vehicles to

Optimize Operating Performance

1.

VI.

Advantages

Drive system is less likely to become jammed, a

common problem with chain-driven bicycles

The rider cannot become dirtied from chain grease

or injured by the chain from "Chain bite", which

occurs when clothing or even a body part catches

between the chain and a sprocket

Lower maintenance than a chain system when the

drive shaft is enclosed in a tube

More consistent performance. Dynamic Bicycles

claims that a drive shaft bicycle can deliver 94%

efficiency, whereas a chain-driven bike can deliver

anywhere from 75-97% efficiency based on

condition

Greater clearance: with the absence of a derailleur

or other low-hanging machinery, the bicycle has

nearly twice the ground clearance

Another advantage that may be noticed about the

chainless bike is that it protects your clothes better.

Your footwear and your pants do not get

accidentally damaged, and you do not have the

same amount of cleaning to do. However, those

who are not so crazy about this alternative type of

bike say that it is enough to choose a bike with

encased chain, or with chain guards, and the

problem is solved.

https://www.e-book.com/bicycle-review.

https://www.mountainbikes.com/powerbikes.htm.

https://www.geartech.com/bewelgear-instruction.

http://www.all-about-bicycles.com/shaft-drivebicycles.html

VII.

Disadvantages

A drive shaft system weighs more than a chain

system, usually 1-2 pounds heavier

Many of the advantages claimed by drive shaft's

proponents can be achieved on a chain driven

bicycle, such as covering the chain and gears with a

metal or plastic cover

Use of lightweight derailleur gears with a high

number of ratios is impossible, although hub

Gears can be used

Wheel removal can be complicated in some designs

(as it is for some chain-driven bicycles with hub

gears).

VIII.

3. WEBSITES

Conclusion

In the beginning, chainless bikes were less efficient

than standard bikes, but the changes in technology

allowed them to reach a level of efficiency that

made them practical for day by day use.

The fact that the internal gears are protected against

any kind of damage, dirt, or debris, makes these

bikes quite a viable alternative. Keep in mind that a

shaft drive bicycle may not be as efficient as a good

quality well maintained classic model, but it still

has its fair share of advantages.

All Rights Reserved, @IJAREST-2015

6

Você também pode gostar

- Chainless BicycleDocumento66 páginasChainless BicycleRaghu Ram100% (1)

- Chainless CycleDocumento53 páginasChainless CycleKritisundar Garnayak89% (9)

- Design and Fabrication of Shaft Driven BicycleDocumento46 páginasDesign and Fabrication of Shaft Driven BicycleNishanth Krishnan80% (10)

- Project Report FINALDocumento24 páginasProject Report FINALViraj MhatreAinda não há avaliações

- Bike Frame Parts2Documento12 páginasBike Frame Parts2ali mortadaAinda não há avaliações

- Chain Less BicycleDocumento46 páginasChain Less BicycleShubham PatilAinda não há avaliações

- Design and Fabrication of Chainless BiycycleDocumento56 páginasDesign and Fabrication of Chainless BiycycleRinku Thomas100% (1)

- 2016 FSAE Electric Vehicle Pedal Assembly Design PDFDocumento40 páginas2016 FSAE Electric Vehicle Pedal Assembly Design PDFCarlos LLivisacaAinda não há avaliações

- A Project Report On Hydraulic BicycleDocumento4 páginasA Project Report On Hydraulic BicycleDevesh Yadav0% (1)

- Fabrication of Electric Folding Triscooter TricycleDocumento4 páginasFabrication of Electric Folding Triscooter TricycleEditor IJTSRDAinda não há avaliações

- Design and Fabriction of Chainless Bicycle AkeeraDocumento10 páginasDesign and Fabriction of Chainless Bicycle AkeeraAjay SilvinAinda não há avaliações

- Bicycle Crank AnalysisDocumento7 páginasBicycle Crank AnalysisrisirarocksAinda não há avaliações

- 2011 REV 3 PedalBox ScheitlinDocumento28 páginas2011 REV 3 PedalBox ScheitlinPaul BernalAinda não há avaliações

- Rocker BogieDocumento31 páginasRocker BogiePavan KumarAinda não há avaliações

- Staircase Climbing Trolley PDFDocumento7 páginasStaircase Climbing Trolley PDFSelvakumarAinda não há avaliações

- Design and Fabrication of Chainless BicycleDocumento19 páginasDesign and Fabrication of Chainless BicycleAr J Un67% (3)

- Mechanical Engineering Department, GCET JAMMUDocumento31 páginasMechanical Engineering Department, GCET JAMMUquant followerAinda não há avaliações

- Design and Analysis of ChassisDocumento8 páginasDesign and Analysis of ChassisSurya KaruturiAinda não há avaliações

- Go Kart Design ReportDocumento17 páginasGo Kart Design ReportabhayAinda não há avaliações

- Coconut Tree Climbing Robot Project ReportDocumento73 páginasCoconut Tree Climbing Robot Project ReportVinayaga ProjectinstituteAinda não há avaliações

- Solar Car Vehicle DesignDocumento224 páginasSolar Car Vehicle Designsheraaz8775% (4)

- Clutch and Types of Clutches (C)Documento11 páginasClutch and Types of Clutches (C)Rahul Kumar100% (1)

- Proteus FramebuildingDocumento114 páginasProteus FramebuildingMark JohanssonAinda não há avaliações

- PNEUMATIC BIKE: 3D PRINTING IN AGRICULTUREDocumento20 páginasPNEUMATIC BIKE: 3D PRINTING IN AGRICULTUREprajakta chaudhari100% (1)

- DTS-I Technology Seminar Report SummaryDocumento32 páginasDTS-I Technology Seminar Report SummarySaurabh SinghAinda não há avaliações

- Manual Treadmill Cycle": Minor Project Report ON " Submitted To Maharishi Markandeshwar Deemed To Be UniversityDocumento16 páginasManual Treadmill Cycle": Minor Project Report ON " Submitted To Maharishi Markandeshwar Deemed To Be UniversityShrwan GyawaliAinda não há avaliações

- Literature Review: Automatic Pneumatic Bumper and Braking SystemDocumento10 páginasLiterature Review: Automatic Pneumatic Bumper and Braking Systemkathir venkatachalamAinda não há avaliações

- 90 Degree Turning Motorized Steering MechanismDocumento62 páginas90 Degree Turning Motorized Steering MechanismMani Kandan100% (1)

- ReferencesDocumento6 páginasReferencesKaung KhantAinda não há avaliações

- Chassis Design Comparison of Two CarsDocumento6 páginasChassis Design Comparison of Two CarsheltaherAinda não há avaliações

- Modelling and Analysis of Dynamic Behavior of Tilting Vehicle PDFDocumento11 páginasModelling and Analysis of Dynamic Behavior of Tilting Vehicle PDFvhance7neil7allen7peAinda não há avaliações

- Treadmill BicycleDocumento4 páginasTreadmill BicycleAnonymous kw8Yrp0R5rAinda não há avaliações

- Presentation On AIR POWERED VEHICLEDocumento26 páginasPresentation On AIR POWERED VEHICLEVishal SrivastavaAinda não há avaliações

- Major Project Report EsvcDocumento34 páginasMajor Project Report EsvcJitesh WadhwaniAinda não há avaliações

- Chassis Design Report PDFDocumento8 páginasChassis Design Report PDFPrakhar YadavAinda não há avaliações

- Fabricating Reverse Gear for Two WheelersDocumento26 páginasFabricating Reverse Gear for Two WheelersSai RamAinda não há avaliações

- Mechanism For Electric MotorcycleDocumento2 páginasMechanism For Electric MotorcyclenomAinda não há avaliações

- Seminar Report VACCUM BRAKING SYSTEM (1sb16me042)Documento22 páginasSeminar Report VACCUM BRAKING SYSTEM (1sb16me042)Manasa100% (1)

- Designing Efficient Commuter Vehicle Using Finite Element Analysis and Computational Fluid DynamicsDocumento6 páginasDesigning Efficient Commuter Vehicle Using Finite Element Analysis and Computational Fluid DynamicsSyed Anas SohailAinda não há avaliações

- A Quick Guide To Motorcycle RakeDocumento11 páginasA Quick Guide To Motorcycle Rakesatria hiuAinda não há avaliações

- Thesis Final PDFDocumento32 páginasThesis Final PDFChan elvisAinda não há avaliações

- Electric Cycle Project ReportDocumento68 páginasElectric Cycle Project ReportARJUN S KAinda não há avaliações

- Design and Analysis of Go-Kart ChassisDocumento6 páginasDesign and Analysis of Go-Kart ChassisInternational Journal of Innovations in Engineering and ScienceAinda não há avaliações

- Design & Fabrication of Rocker-Bogie MechanismDocumento39 páginasDesign & Fabrication of Rocker-Bogie MechanismHarshal PatilAinda não há avaliações

- Automatic Side Stand Retreiving SystemDocumento49 páginasAutomatic Side Stand Retreiving SystemEtgsAinda não há avaliações

- Automatic Side Stand With Breaking Locking SystemDocumento44 páginasAutomatic Side Stand With Breaking Locking SystemSaravanan Viswakarma100% (2)

- BIKESTER Assembly Manual MTB - Fr.enDocumento23 páginasBIKESTER Assembly Manual MTB - Fr.enfuskjd dsdsdsdsAinda não há avaliações

- Mechanical Engineering Minor Project Report On Staircase Climber MAE IPUDocumento26 páginasMechanical Engineering Minor Project Report On Staircase Climber MAE IPUAakash SachdevaAinda não há avaliações

- Draft He SisDocumento31 páginasDraft He SisASIM RIAZAinda não há avaliações

- Electric Bicycle Project FileDocumento47 páginasElectric Bicycle Project FileSonu SainiAinda não há avaliações

- Sidecar BicycleDocumento15 páginasSidecar BicycleMarius DanilaAinda não há avaliações

- Seminar ReportDocumento45 páginasSeminar Reportmanaskollam0% (1)

- SYNOPSIS Solar Powered Mechanical HacksawDocumento10 páginasSYNOPSIS Solar Powered Mechanical HacksawEsteFan AjayAinda não há avaliações

- Economic Solution For Data Acquisition in A Formula SAE Race CarDocumento6 páginasEconomic Solution For Data Acquisition in A Formula SAE Race CarmclarenrulzAinda não há avaliações

- Design of An Energy Efficient High Performance Drive Train: Loek MarquenieDocumento116 páginasDesign of An Energy Efficient High Performance Drive Train: Loek MarqueniePratik PrakashAinda não há avaliações

- Analysis of Baja ChassisDocumento4 páginasAnalysis of Baja ChassisSunnel Daniel100% (2)

- Part1 Introducing AadlDocumento24 páginasPart1 Introducing AadlChoc CludAinda não há avaliações

- Pipe Climbing Robot DesignDocumento3 páginasPipe Climbing Robot DesignMectrosoft Creative technologyAinda não há avaliações

- Sidecar of BicycleDocumento20 páginasSidecar of BicyclePankaj KumarAinda não há avaliações

- PDFDocumento6 páginasPDFArjunAinda não há avaliações

- Ansys ExampleDocumento2 páginasAnsys ExampleVenkata RamuduAinda não há avaliações

- Rotational Moulding of PlasticsDocumento135 páginasRotational Moulding of PlasticsJulio Madero100% (2)

- Advance Excel SyllabusDocumento4 páginasAdvance Excel SyllabusVenkata RamuduAinda não há avaliações

- Plane Stress Bracket: Two Dimensional TrussDocumento7 páginasPlane Stress Bracket: Two Dimensional TrussVenkata RamuduAinda não há avaliações

- Condition MonitoringDocumento15 páginasCondition MonitoringVenkata RamuduAinda não há avaliações

- Questionnaire Re-Modified by Rvs On 7-4-17Documento14 páginasQuestionnaire Re-Modified by Rvs On 7-4-17Venkata RamuduAinda não há avaliações

- ThimmapuramDocumento3 páginasThimmapuramVenkata RamuduAinda não há avaliações

- SVSR Tech Computer Education Courses C++ C LanguageDocumento4 páginasSVSR Tech Computer Education Courses C++ C LanguageVenkata RamuduAinda não há avaliações

- DTPDocumento11 páginasDTPVenkata RamuduAinda não há avaliações

- Civil DiplomaDocumento9 páginasCivil Diplomavenkataramudu_magantiAinda não há avaliações

- Design of Plastic GearsDocumento15 páginasDesign of Plastic GearsVenkata RamuduAinda não há avaliações

- Section 8 Bevel Gearing DesignDocumento5 páginasSection 8 Bevel Gearing DesignLiniel de JesusAinda não há avaliações

- Indian Industry SCDocumento8 páginasIndian Industry SCVenkata RamuduAinda não há avaliações

- Intelligent Manufacturing SystemsDocumento5 páginasIntelligent Manufacturing SystemsVenkata RamuduAinda não há avaliações

- Development of A Student BicycleDocumento136 páginasDevelopment of A Student BicycleVenkata RamuduAinda não há avaliações

- Bicycle v2Documento30 páginasBicycle v2Ozi VolixAinda não há avaliações

- Bicycle v2Documento30 páginasBicycle v2Ozi VolixAinda não há avaliações

- CollegeDocumento11 páginasCollegeVenkata RamuduAinda não há avaliações

- Shimano XT M770 Shift Lever User ManualDocumento3 páginasShimano XT M770 Shift Lever User ManualNick SpeisAinda não há avaliações

- Park Tool Katalog 06Documento46 páginasPark Tool Katalog 06s3dbwAinda não há avaliações

- Campagnolo Catalogue 2014 TT-CX-Pista Range-EnGDocumento30 páginasCampagnolo Catalogue 2014 TT-CX-Pista Range-EnGKoutsoupisAinda não há avaliações

- Canyon MTB en 2016Documento91 páginasCanyon MTB en 2016josefm665699Ainda não há avaliações

- Bicycle History and TypesDocumento22 páginasBicycle History and TypesnilreoowAinda não há avaliações

- Shimano SLX HG81 Cassette Service ManualDocumento1 páginaShimano SLX HG81 Cassette Service ManualJose Luis GutierrezAinda não há avaliações

- Downhill Mountain Bike Gearbox: Josh Filgate, Jesse Kuhn, Morgan Misek Jay Seiter, Michael WitonisDocumento38 páginasDownhill Mountain Bike Gearbox: Josh Filgate, Jesse Kuhn, Morgan Misek Jay Seiter, Michael WitonisaddymailidAinda não há avaliações

- Human Power Using Bicycle Mechanism As An Alternative Energy Source: A Critical ReviewDocumento7 páginasHuman Power Using Bicycle Mechanism As An Alternative Energy Source: A Critical ReviewYogi dAinda não há avaliações

- Calculating Chain Length For Bicycle DrivesDocumento4 páginasCalculating Chain Length For Bicycle DrivesShauWilliamAinda não há avaliações

- Canyon MTB EN 2015Documento75 páginasCanyon MTB EN 2015William MendezAinda não há avaliações

- 2011 Trek Road CatalogueDocumento36 páginas2011 Trek Road CatalogueValerio ColettiAinda não há avaliações

- 2017 SRAM GX DH Components SicklinesDocumento15 páginas2017 SRAM GX DH Components SicklinesSickLinesAinda não há avaliações

- 2008 Marin XC120 Service ManualDocumento14 páginas2008 Marin XC120 Service Manualsastusbulbas100% (1)

- FocusBikes Catalog ROAD 2011 enDocumento39 páginasFocusBikes Catalog ROAD 2011 enTaufik JunaidiAinda não há avaliações

- Shimano 2020-2021 - Specifications - v032 - enDocumento267 páginasShimano 2020-2021 - Specifications - v032 - enbillAinda não há avaliações

- Be The Engine.: Bikes & Equipment 2009Documento17 páginasBe The Engine.: Bikes & Equipment 2009Rafael EscobarAinda não há avaliações

- Brochure Sport Uk 2008Documento10 páginasBrochure Sport Uk 2008Kurniawan DoankAinda não há avaliações

- 2012-2013 Specifications v010 enDocumento222 páginas2012-2013 Specifications v010 enMário CorreiaAinda não há avaliações

- Mongoose 2011 English Owners-Manual March2011Documento67 páginasMongoose 2011 English Owners-Manual March2011Ben Singleton Sr.100% (2)

- Gepida Electric Bikes 2017Documento61 páginasGepida Electric Bikes 2017Ravindra KempaiahAinda não há avaliações

- 05 Jamis CatalogDocumento38 páginas05 Jamis CatalogtspinnerAinda não há avaliações

- Dahon Mup8 Folding Bike Service InstructionsDocumento32 páginasDahon Mup8 Folding Bike Service Instructionsdexxx21Ainda não há avaliações

- The Ultimate Bicycle BookDocumento185 páginasThe Ultimate Bicycle BookMaria RusAinda não há avaliações

- Sun Rider Users ManualDocumento26 páginasSun Rider Users ManualMichael HudsonAinda não há avaliações

- Giant Talon 29er 2 MTB BikeDocumento4 páginasGiant Talon 29er 2 MTB BikeredcamilistaAinda não há avaliações

- Cycle AnatomyDocumento2 páginasCycle AnatomyAlvin RajAinda não há avaliações

- 2018-2019 Compatibility v026 en PDFDocumento47 páginas2018-2019 Compatibility v026 en PDFIsai Palacios SalgadoAinda não há avaliações

- Shimano 2016-2017 Line-Up Chart v017 enDocumento84 páginasShimano 2016-2017 Line-Up Chart v017 enFabio AtenógenesAinda não há avaliações

- Naskah Soal Ulangan Umum Semester Ganjil - Bahasa Inggris XII IPA& IPSDocumento4 páginasNaskah Soal Ulangan Umum Semester Ganjil - Bahasa Inggris XII IPA& IPSElisa Isandhyta81% (16)