Escolar Documentos

Profissional Documentos

Cultura Documentos

Material Specification 594-Geomembrane Liner: 1. Scope

Enviado por

Danu WijayaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Material Specification 594-Geomembrane Liner: 1. Scope

Enviado por

Danu WijayaDireitos autorais:

Formatos disponíveis

Chapter 3

National Standard Material

Specifications

Part 642

National Engineering Handbook

Material Specification 594Geomembrane Liner

1. Scope

This specification covers the quality of High Density

Polyethylene (HDPE), Linear Low Density Polyethylene (LLDPE), Ethylene Propylene Diene Terpolymer

(EPDM), Poly Vinyl Chloride (PVC), Flexible Polypropylene (fPP), woven Polyethylene (PE-R) geomembrane liners, seams, gaskets, metal battens, bolts,

embed channels, clamps, and sealant.

2. Material

LinerThe liner shall have a nominal thickness as

specified. The liner shall be manufactured to be suitable for use in the specified exposed or buried conditions. It shall conform to the requirements of this

specification, Construction Specification 97, and the

requirements shown on the drawings.

Gaskets, metal battens, clamps, bolts, embed

channels, welding rod, adhesive, and sealant

Gasket material shall be neoprene, closed-cell medium,

0.25 inch thick, with adhesive on one side, or other

gasket material as approved by the liner manufacturer.

Metal battens shall be 0.25-inch-thick by 2-inch-wide

stainless steel. Clamps shall be 0.5-inch-wide stainless

steel. Bolts shall be stainless steel. The embed channel

and welding rod shall have the same properties as the

liner, as recommended by the manufacturer. Adhesive

shall be approved by the manufacturer and shall consist of material with a life expectancy similar to the

liner material. Sealant shall be as recommended by the

manufacturer. Silicone sealant shall not be used with

PVC liner materials.

Vents and pipe bootsVents and pipe boots shall

be compatible with the liner, as recommended by the

liner manufacturer.

3. Liner properties

The liner shall be manufactured from virgin polymers

and other compounding materials. Regrind, reworked,

or trim materials shall be from the same manufacturer

and the same formulation as the liner. Recycled materials shall not be allowed. The liner shall be uniform in

color, thickness, and surface texture. The liner shall be

resistant to fungal or bacterial attack and free of cuts,

abrasions, holes, blisters, contaminants, and other

imperfections.

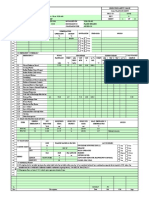

HDPE The HDPE liner shall meet the requirements

specified in Geosynthetics Research Institute (GRI)

Test Method GM13. Selected property values are

reproduced in tables 5941 and 5942 for smooth and

textured HDPE, respectively.

LLDPEThe LLDPE liner shall meet the requirements specified in GRI Test Method GM17 (smooth

and textured LLDPE) and GM25 (reinforced LLDPE).

Selected property values are reproduced in tables

5943 through 5945 for smooth, textured, and reinforced LLDPE, respectively.

A reinforced LLDPE liner shall consist of one ply of

reinforcing polyester (scrim) between two sheets of

LLDPE. The polyester scrim shall be of an open weave

that permits strike-through of the LLDPE.

EPDMThe EPDM liner shall meet the requirements

specified in GRI Test Method GM21. Selected property

values are reproduced in tables 5946 and 5947 for

nonreinforced and reinforced EPDM, respectively.

PVCThe PVC liner shall meet the requirements

specified in ASTM D7176. Selected property values are

reproduced in table 5948.

fPPThe fPP liner shall meet the requirements specified in GRI Standard GM18. Selected property values

are reproduced in tables 5949 and 59410 for nonreinforced and reinforced fPP, respectively.

A reinforced fPP liner shall consist of one ply of reinforcing polyester (scrim) between two sheets of fPP.

The polyester scrim shall be of an open weave that

permits strike-through of the fPP.

PE-RThe PE-R liner shall be manufactured from

woven HDPE scrim with a PE coating on both sides

and shall meet the property values specified in table

59411.

(210VINEH, January 2014)

5941

Chapter 3

National Standard Material

Specifications

Material Specification 594

Table 5941

Part 642

National Engineering Handbook

Geomembrane linercontinued

Requirements for smooth HDPE liner

Property

Test methods

Requirements*

- - - - - - - - - - nominal thickness - - - - - - - - - -

Density, g/cc

ASTM D1505/D792

Tensile properties

ASTM D6693

(Type IV)

yield strength, lb/in

break strength, lb/in

yield elongation, %

break elongation, %

30 mil

40 mil

60 mil

0.940

0.940

0.940

63

114

12

700

84

152

12

700

126

228

12

700

Tear resistance, lb

ASTM D1004

21

28

42

Puncture resistance, lb

ASTM D4833

54

72

108

Carbon black content, %

ASTM D1603

2.03.0

2.03.0

2.03.0

Seam properties

ASTM D6392

57

45**

80

60**

120

91**

shear strength, lb/in

peel strength, lb/in**

*

**

5942

All values, unless specified otherwise, are minimum average roll values as reported for the test method.

Break shall occur in a ductile mode in the geomembrane adjacent to the seam.

(210VINEH, January 2014)

Chapter 3

National Standard Material

Specifications

Material Specification 594

Table 5942

Part 642

National Engineering Handbook

Geomembrane linercontinued

Requirements for textured HDPE liner

Property

Test methods

Requirements*

- - - - - - - - nominal thickness - - - - - - - - - -

Density, g/cc

ASTM D1505/D792

Asperity height, mills

ASTM D7466

Tensile properties

ASTM D6693

Type IV

yield strength, lb/in

break strength, lb/in

yield elongation, %

break elongation, %

30 mil

40 mil

60 mil

0.940

0.940

0.940

10

10

10

63

45

12

100

84

60

12

100

126

90

12

100

Tear resistance, lb

ASTM D1004

21

28

42

Puncture resistance, lb

ASTM D4833

45

60

90

Carbon black content, %

ASTM D1603

2.03.0

2.03.0

2.03.0

Seam properties

ASTM D6392

57

45**

80

60**

120

91**

shear strength, lb/in

peel strength, lb/in

* All values, unless specified otherwise, are minimum average roll values as reported by the specified test method.

** Break shall occur in a ductile mode in the geomembrane adjacent to the seam.

(210VINEH, January 2014)

5943

Chapter 3

National Standard Material

Specifications

Material Specification 594

Table 5943

Part 642

National Engineering Handbook

Geomembrane linercontinued

Requirements for smooth LLDPE liner

Property

Test methods

Requirements*

- - - - - - - - - - nominal thickness - - - - - - - - - -

Density, g/cc

ASTM D1505/D792

Tensile properties

ASTM D6693

Type IV

break strength, lb/in

break elongation, %

30 mil

40 mil

60 mil

0.939

0.939

0.939

114

800

152

800

228

800

Tear resistance, lb

ASTM D1004

16

22

33

Puncture resistance, lb

ASTM D4833

42

56

84

Carbon black content, %

ASTM D1603

2.03.0

2.03.0

2.03.0

Seam properties

ASTM D6392

45

38**

58

50**

90

75**

shear strength, lb/in

peel strength, lb/in**

* All values, unless otherwise specified, are minimum average roll values as reported for each test method.

** Break shall occur in a ductile mode in the geomembrane adjacent to the seam.

5944

(210VINEH, January 2014)

Chapter 3

National Standard Material

Specifications

Material Specification 594

Table 5944

Part 642

National Engineering Handbook

Geomembrane linercontinued

Requirements for textured LLDPE liner

Property

Test methods

Requirements*

- - - - - - - - - - nominal thickness - - - - - - - - - 30 mil

40 mil

60 mil

Density, g/cc

ASTM D1505

0.939

0.939

0.939

Asperity height, mills

ASTM D7466

10

10

10

Tensile properties

ASTM D6693

Type IV

45

250

60

250

90

250

break strength, lb/in

break elongation, %

Tear resistance, lb

ASTM D1004

16

22

33

Puncture resistance, lb

ASTM D4833

33

44

66

Carbon black content, %

ASTM D1603

2.03.0

2.03.0

2.03.0

Seam properties

ASTM D6392

45

38**

60

50**

90

75**

shear strength, lb/in

peel strength, lb/in**

*

**

All values, unless otherwise specified, are minimum average roll values as reported for each test method.

Break shall occur in a ductile mode in the Geomembrane adjacent to the seam.

(210VINEH, January 2014)

5945

Chapter 3

National Standard Material

Specifications

Material Specification 594

Table 5945

Part 642

National Engineering Handbook

Geomembrane linercontinued

Requirements for textured LLDPE liner

Property

Test methods

Requirements*

- - - - - - - - - - nominal thickness - - - - - - - - - -

Mass per unit area,

lb/ft2

Grab tensile properties

ASTM D5261

24 mil

36 mil

45 mil

0.10

0.15

0.19

150

22

200

22

250

22

ASTM D7004

strength, lb (each direction)

elongation, % (each direction)

Tear resistance, lb (each direction)

ASTM D5884

55

55

55

Puncture resistance, lb

ASTM D4833

65

75

85

Ply adhesion, lb

ASTM D6636

20

20

20

Coating thickness over manufacturer's scrim, mil

Manufacturer's data

10

12

Seam properties

shear strength, lb/in

ASTM D751

45

60

90

peel strength, lb/in**

ASTM D413

38**

50**

75**

*

**

5946

All values, unless otherwise specified, are minimum average roll values as reported for each test method.

Break shall occur in a ductile mode in the geomembrane adjacent to the seam.

(210VINEH, January 2014)

Chapter 3

National Standard Material

Specifications

Material Specification 594

Table 5946

Part 642

National Engineering Handbook

Geomembrane linercontinued

Requirements for nonreinforced EPDM liner

Property

Test methods

Requirements*

- - nominal thickness - -

Tensile properties

break strength,

45 mil

60 mil

1200

1200

300

300

ASTM D412

lb/in2

break elongation, %

Tear resistance, lb

ASTM D1004

12

15

Puncture resistance, lb

ASTM D4833

30

40

Brittleness temperature, F

ASTM D2136

<49

<49

Seam properties

ASTM D7272

shear strength, lb/in

35

35

peel strength, lb/in

All values, unless specified otherwise, are minimum average roll values as reported for the test method.

(210VINEH, January 2014)

5947

Chapter 3

National Standard Material

Specifications

Material Specification 594

Table 5947

Part 642

National Engineering Handbook

Geombrane linercontinued

Requirements for reinforced EPDM liner

Property

Test methods

Requirements*

nominal thickness

45 mil

Tensile break strength, lb

ASTM D751

190

Tear resistance, lb

ASTM D5884

130

Puncture resistance, lb

ASTM D4833

60

Brittleness temperature, F

ASTM D2136

< 49

Seam properties:

ASTM D7272

shear strength, lb/in**

35

peel strength, lb/in***

5948

All values, unless specified otherwise, are minimum average roll values as reported for the test method.

(210VINEH, January 2014)

Chapter 3

National Standard Material

Specifications

Material Specification 594

Table 5948

Part 642

National Engineering Handbook

Geombrane linercontinued

Requirements for PVC liner

Property

Test methods

Requirements*

- - nominal thickness - 30 mil

Specific gravity

ASTM D792

Tensile properties:

ASTM D882

40 mil

1.2

1.2

Break strength, lb/in

73

97

Break elongation, %

380

430

Tear strength, lb

ASTM D1004

10

Low temperature impact, C

ASTM D1790

< 29

<-29

Dimensional stability, % (maximum)

ASTM D1204

Hydrostatic resistance, lb/in2

ASTM D751

100

120

Seam properties:

ASTM D 882

Shear strength, lb/in

58

77

Peel strength, lb/in

15

15

All values, unless specified otherwise, are minimum average roll values as reported for the test method.

(210VINEH, January 2014)

5949

Chapter 3

National Standard Material

Specifications

Material Specification 594

Table 5949

Part 642

National Engineering Handbook

Geombrane linercontinued

Requirements for nonreinforced fPP liner

Property

Test methods

Requirements*

- - nominal thickness - 30 mil

Mass per unit area, lb/ft2

ASTM D5261

Tensile properties:

ASTM D6693

Break strength, lb/in

(Type IV)

Break elongation, %

40 mil

0.12

0.16

60

72

700

700

Tear resistance, lb

ASTM D1004

10

12

Puncture resistance, lb

ASTM D4833

25

30

Carbon black content, %

ASTM D4218

23

23

Brittleness temperature, C

ASTM D2136

<40

<40

Seam properties:

ASTM D6392/D6214**

<40

<40

25

30

20***

25***

Shear strength, lb/in

Peel strength, lb/in

*

**

***

All values, unless specified otherwise, are minimum average roll values as reported for the test method.

ASTM D6392 shall be used for thermally welded seams and D6214 for chemically welded seams.

Break shall occur in a ductile mode in the geomembrane adjacent to the seam.

59410

(210VINEH, January 2014)

Chapter 3

Material Specification 594

National Standard Material

Specifications

Part 642

National Engineering Handbook

Geombrane linercontinued

Table 59410 Requirements for reinforced PP liner

Property

Test methods

Requirements*

- - - nominal thickness - - 36 mil

45 mil

ASTM D5261

0.15

0.18

Grab strength, lb

ASTM D7004

200

250

Break elongation, %

ASTM D751

22

22

Tear resistance, lb

ASTM D5884

55

55

Puncture resistance, lb

ASTM D 4833

75

85

Ply adhesion, lb

ASTM D 6636

15

15

Carbon black content, %

ASTM D4218

23

23

Brittleness temperature, C

ASTM D2136

< 40

< 40

Coating thickness over

scrim, mil

ASTM D7613

10

12

Mass per unit area, lb/ft2

Tensile properties:

(Annex A1)

Seam properties:

Shear strength, lb/in

ASTM D751

200

200

Peel strength, lb/in

ASTM D413

20**

20**

*

**

All values, unless specified otherwise, are minimum average roll values as reported for the test method.

Break shall occur in a ductile mode in the geomembrane adjacent to the seam.

(210VINEH, January 2014)

59411

Chapter 3

Material Specification 594

National Standard Material

Specifications

Part 642

National Engineering Handbook

Geombrane linercontinued

Table 59411 Requirements for reinforced, slit film, woven PE liner

Property

Test methods

Requirements*

nominal thickness

24 mil

Mass per unit area, oz/yd2

ASTM D1910

12

Grab strength, lb/in (either direction)

ASTM D751

330

Break elongation, % (either direction)

ASTM D751

29

Tear resistance, lb (either direction)

ASTM D751

74

Puncture resistance, lb/in2

ASTM D4833

182

Carbon black content, %

ASTM D1603

23

Brittleness temperature, C

ASTM D2136

-40

Hydrostatic resistance, lb/in2

ASTM D751A

310

Tensile properties:

Coating thickness over manufacturers data

scrim, mil

Seam properties:

Shear strength, lb/in

ASTM D 751

188**

Peel strength, lb/in

ASTM D 413

7**

*

**

All values, unless specified otherwise, are minimum average roll values as reported for the test method.

Break shall occur in a ductile mode in the geomembrane adjacent to the seam.

59412

(210VINEH, January 2014)

Você também pode gostar

- GRP and Buildings: A Design Guide for Architects and EngineersNo EverandGRP and Buildings: A Design Guide for Architects and EngineersAinda não há avaliações

- Geomemrane SpecificationDocumento12 páginasGeomemrane SpecificationZakir AliAinda não há avaliações

- Polyethylene GeomembranesDocumento18 páginasPolyethylene GeomembranesPalo DushiiAinda não há avaliações

- Concrete Protective Liners SpecsDocumento5 páginasConcrete Protective Liners SpecsengrfarhanAAAAinda não há avaliações

- E 1730 - 99 - Rte3mzatotkDocumento4 páginasE 1730 - 99 - Rte3mzatotkEric GozzerAinda não há avaliações

- Geotextile Non Woven SpecificationDocumento4 páginasGeotextile Non Woven SpecificationLow Kah ZhoyAinda não há avaliações

- Self-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectionDocumento5 páginasSelf-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectiondaovandongpktAinda não há avaliações

- Uniform Section US1000 - PET Specification (IU) - 5 20 15Documento11 páginasUniform Section US1000 - PET Specification (IU) - 5 20 15Felipe Strafite CusterAinda não há avaliações

- Uniform Section US2000 - PET Specification (IU) - 5 20 15Documento11 páginasUniform Section US2000 - PET Specification (IU) - 5 20 15Felipe Strafite CusterAinda não há avaliações

- E 1730 - 02 - Rte3mzaDocumento4 páginasE 1730 - 02 - Rte3mzaEric GozzerAinda não há avaliações

- gm19 - GEOMEMBRANASDocumento13 páginasgm19 - GEOMEMBRANASIsaias Quispe RuizAinda não há avaliações

- Test Methods, Test Properties and Testing Frequency For High Density Polyethylene (HDPE) Smooth and Textured GeomembranesDocumento11 páginasTest Methods, Test Properties and Testing Frequency For High Density Polyethylene (HDPE) Smooth and Textured Geomembranesgeo_unoAinda não há avaliações

- GM 13Documento11 páginasGM 13cubillosnelsonAinda não há avaliações

- Gri GM13Documento11 páginasGri GM13Mauricio PerezAinda não há avaliações

- Astm D 3542Documento4 páginasAstm D 3542manoj madurangaAinda não há avaliações

- Astm d2996 2001Documento5 páginasAstm d2996 2001Greg YeeAinda não há avaliações

- Gypsum Lath: Standard Specification ForDocumento2 páginasGypsum Lath: Standard Specification ForBehnamZBAinda não há avaliações

- GM19 Geosynthetic PDFDocumento13 páginasGM19 Geosynthetic PDFRicardo RodriguezAinda não há avaliações

- Ethylene Propylene Diene Terpolymer (EPDM) Sheet Used in Geomembrane ApplicationsDocumento4 páginasEthylene Propylene Diene Terpolymer (EPDM) Sheet Used in Geomembrane ApplicationsLupita RamirezAinda não há avaliações

- Rigid Cellular Polystyrene Geofoam: Standard Specification ForDocumento3 páginasRigid Cellular Polystyrene Geofoam: Standard Specification ForMohamed MamdohAinda não há avaliações

- Geosynthetic Institute: GRI Test Method GM13Documento11 páginasGeosynthetic Institute: GRI Test Method GM13Nolo Araya GaeteAinda não há avaliações

- Vulcanized Rubber Sheets Used in Waterproofing Systems: Standard Specification ForDocumento2 páginasVulcanized Rubber Sheets Used in Waterproofing Systems: Standard Specification ForMohammad YaseenAinda não há avaliações

- Mandrel Bend Test of Attached Organic Coatings: Standard Test Methods ForDocumento4 páginasMandrel Bend Test of Attached Organic Coatings: Standard Test Methods ForKarlos Albert Xukizuta100% (1)

- TxDoT 6200 Filter Fabric Specs PDFDocumento2 páginasTxDoT 6200 Filter Fabric Specs PDFthadikkaranAinda não há avaliações

- D 1330 - 85 R00 - Rdezmza - PDFDocumento2 páginasD 1330 - 85 R00 - Rdezmza - PDFCesar AlvarezAinda não há avaliações

- Styrene-Rubber (SR) Plastic Drain Pipe and Fittings: Standard Specification ForDocumento6 páginasStyrene-Rubber (SR) Plastic Drain Pipe and Fittings: Standard Specification ForLuizao CabeloAinda não há avaliações

- Astm D2996-01Documento6 páginasAstm D2996-01Gene DiJosephAinda não há avaliações

- ASTM D2628 (1998) - Preformed Polychloroprene Elastastomeric Joint Seals For Concrete PavingDocumento3 páginasASTM D2628 (1998) - Preformed Polychloroprene Elastastomeric Joint Seals For Concrete Pavingnoto SugiartoAinda não há avaliações

- TMP 1674627247 PDFDocumento14 páginasTMP 1674627247 PDFvivekAinda não há avaliações

- gm19b PDFDocumento11 páginasgm19b PDFJuan MansillaAinda não há avaliações

- Wwumrmmihmg - MVM''?L%: Tf$Twikl (Tm6Twt& - FF@F@Documento19 páginasWwumrmmihmg - MVM''?L%: Tf$Twikl (Tm6Twt& - FF@F@suryatejaAinda não há avaliações

- ASTM D3754 Tuberia de Fibra de VIdirio para Sistemas Industriales y A PresiónDocumento14 páginasASTM D3754 Tuberia de Fibra de VIdirio para Sistemas Industriales y A PresiónalexagoAinda não há avaliações

- Astm F-1962 PDFDocumento18 páginasAstm F-1962 PDFKenAinda não há avaliações

- Astm D3262-96Documento8 páginasAstm D3262-96anish_am2005Ainda não há avaliações

- ASTM C 37-C 37M Standard Specification For Gypsum LathDocumento3 páginasASTM C 37-C 37M Standard Specification For Gypsum Lathtraadel_320610041Ainda não há avaliações

- Astm d2310Documento3 páginasAstm d2310ashams492100% (1)

- Fiberglass (GRP) Pultruded Open-Weather Storm-And Guard-Square HandrailsDocumento10 páginasFiberglass (GRP) Pultruded Open-Weather Storm-And Guard-Square HandrailsDavid Drolet TremblayAinda não há avaliações

- Astm C 171 2007Documento2 páginasAstm C 171 2007sabruno100% (3)

- D 1970 - 00 Rde5nzatukveDocumento7 páginasD 1970 - 00 Rde5nzatukvedaovandongpktAinda não há avaliações

- Non-Reinforced Polyvinyl Chloride (PVC) Geomembranes Used in Buried ApplicationsDocumento5 páginasNon-Reinforced Polyvinyl Chloride (PVC) Geomembranes Used in Buried ApplicationsLito EstimosAinda não há avaliações

- Astm d6392Documento6 páginasAstm d6392Talca CalderónAinda não há avaliações

- Greige Woven Glass Tapes and Webbings': Standard Specification ForDocumento7 páginasGreige Woven Glass Tapes and Webbings': Standard Specification ForprateekAinda não há avaliações

- Geosynthetic Institute: GRI Test Method GM25Documento9 páginasGeosynthetic Institute: GRI Test Method GM25Григорий ЛевашовAinda não há avaliações

- D 522 - 93 Rduymi05m0eDocumento4 páginasD 522 - 93 Rduymi05m0ewpwmhatAinda não há avaliações

- Coal-Tar-Saturated Organic Felt Used in Roofing and WaterproofingDocumento3 páginasCoal-Tar-Saturated Organic Felt Used in Roofing and WaterproofingRufo CascoAinda não há avaliações

- Astm D 3517 - 04Documento12 páginasAstm D 3517 - 04148962Ainda não há avaliações

- D 3771 - 00 - Rdm3nzetukveDocumento5 páginasD 3771 - 00 - Rdm3nzetukvePrakash MakadiaAinda não há avaliações

- D522Documento5 páginasD522Jeremy TohAinda não há avaliações

- Astm F477-08Documento4 páginasAstm F477-08ALARCONISTAAinda não há avaliações

- Withdrawn: GRP Pipes and FritingsDocumento4 páginasWithdrawn: GRP Pipes and Fritingskhaledaj1977Ainda não há avaliações

- Fiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceDocumento3 páginasFiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceKevin Josue100% (1)

- Fiberglass (GRP) Pultruded Open-Weather Storm-And Guard-Square Handrails Guard, Square Railing SystemsDocumento10 páginasFiberglass (GRP) Pultruded Open-Weather Storm-And Guard-Square Handrails Guard, Square Railing SystemsDavid Drolet TremblayAinda não há avaliações

- C 582 - 95 - Qzu4mi1sruqDocumento8 páginasC 582 - 95 - Qzu4mi1sruqGovinda RajAinda não há avaliações

- Geosynthetic Institute: 475 Kedron Avenue Folsom, PA 19033-1208 USA TEL (610) 522-8440 FAX (610) 522-8441 GRI GII GEIDocumento12 páginasGeosynthetic Institute: 475 Kedron Avenue Folsom, PA 19033-1208 USA TEL (610) 522-8440 FAX (610) 522-8441 GRI GII GEIГригорий ЛевашовAinda não há avaliações

- D 228 - 03 Rdiyoc0wmwDocumento10 páginasD 228 - 03 Rdiyoc0wmwdaovandongpktAinda não há avaliações

- Greige Woven Glass Fabrics: Standard Specification ForDocumento17 páginasGreige Woven Glass Fabrics: Standard Specification ForTuyên RùaAinda não há avaliações

- Astm d6392Documento6 páginasAstm d6392Danilo Rojas MartinezAinda não há avaliações

- ISO-8573!3!1999 - Métodos de Prueba - HumedadDocumento4 páginasISO-8573!3!1999 - Métodos de Prueba - Humedadj_jjerfAinda não há avaliações

- PSV Calculation Sheet APIDocumento10 páginasPSV Calculation Sheet APIionutlaur86100% (2)

- 02sep OzturkDocumento237 páginas02sep OzturkJoel Morales PerezAinda não há avaliações

- Solver Setting in AnsysDocumento44 páginasSolver Setting in AnsysApurvAinda não há avaliações

- Surface & Coatings Technology: SciencedirectDocumento8 páginasSurface & Coatings Technology: SciencedirectVikrant Saumitra mm20d401Ainda não há avaliações

- Cylinder SequencingDocumento21 páginasCylinder Sequencingjoshi vivek0% (1)

- Asme PTC 1986Documento4 páginasAsme PTC 1986AmalAhmed0% (1)

- 973-SF Analyzer: Laboratory Precision - Field ReadyDocumento4 páginas973-SF Analyzer: Laboratory Precision - Field ReadymersiumAinda não há avaliações

- G2J122002 AdriawanDocumento3 páginasG2J122002 AdriawanHendy AdriawanAinda não há avaliações

- Lecture 11 - Introduction To Distributed Normal LoadsDocumento30 páginasLecture 11 - Introduction To Distributed Normal LoadsLantretz LaoAinda não há avaliações

- Plate Load Soil Test ReportDocumento5 páginasPlate Load Soil Test ReportJoseph Cloyd L. LamberteAinda não há avaliações

- Lecture 22 Thermal Engineering II (18.08.2020)Documento36 páginasLecture 22 Thermal Engineering II (18.08.2020)Dr. BIBIN CHIDAMBARANATHANAinda não há avaliações

- On The Resonances and Polarizabilities of Split Ring ResonatorsDocumento9 páginasOn The Resonances and Polarizabilities of Split Ring ResonatorsNabil DakhliAinda não há avaliações

- Chapter 8 (Bonding)Documento22 páginasChapter 8 (Bonding)Yossef AmrAinda não há avaliações

- RCM Flow Meter3Documento4 páginasRCM Flow Meter3Jairo FlechasAinda não há avaliações

- Influence of Heat Treatment On Microstructure and Properties of Gx12Crmovnbn9-1 Cast SteelDocumento6 páginasInfluence of Heat Treatment On Microstructure and Properties of Gx12Crmovnbn9-1 Cast SteelSankar GaneshAinda não há avaliações

- 2-Charge Formation in Clouds-1Documento26 páginas2-Charge Formation in Clouds-1Gokulraja GokulAinda não há avaliações

- HYDRODYNAMICSDocumento28 páginasHYDRODYNAMICSSysy monmonAinda não há avaliações

- Module 7Documento20 páginasModule 7Arlene OribelloAinda não há avaliações

- Firelite LWDocumento2 páginasFirelite LWgermanddAinda não há avaliações

- JNK Heaters Co - LTD: Ferrite Test ReportDocumento1 páginaJNK Heaters Co - LTD: Ferrite Test ReportUzorAinda não há avaliações

- 3rd Q Science 2022-2023Documento2 páginas3rd Q Science 2022-2023Richard CruzAinda não há avaliações

- WPS (Gtaw)Documento2 páginasWPS (Gtaw)Ramadhan AdityaAinda não há avaliações

- Testing Procedure UltrasoundDocumento6 páginasTesting Procedure UltrasoundMitecCenememAinda não há avaliações

- Interatomic DistanceDocumento3 páginasInteratomic DistanceisaacAinda não há avaliações

- Problems For PH1016: Chapter 31: 37, 41, 43, 45 (Op.), 57, 59, 61 (Op.) Chapter 32. 35 (Op.), 37, 39, 45, 47, 49, 51Documento9 páginasProblems For PH1016: Chapter 31: 37, 41, 43, 45 (Op.), 57, 59, 61 (Op.) Chapter 32. 35 (Op.), 37, 39, 45, 47, 49, 51Vũ Đức TuânAinda não há avaliações

- Chemical Equilibrium-2Documento13 páginasChemical Equilibrium-2MUHAMMAD YASEENAinda não há avaliações

- Defects - Solidification Cracking - TWIDocumento8 páginasDefects - Solidification Cracking - TWIJlkKumarAinda não há avaliações