Escolar Documentos

Profissional Documentos

Cultura Documentos

Thermal Performance and Nameplate Details of WEG Electric Motors

Enviado por

Pranay KharbeDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Thermal Performance and Nameplate Details of WEG Electric Motors

Enviado por

Pranay KharbeDireitos autorais:

Formatos disponíveis

www.weg.

net

3.8 Endshields

The drive end endshield (figure 15) is designed with fins for

better thermal heat dissipation, and to ensure low bearing

operating temperatures, resulting in extended lubrication

intervals.

For the frames 225S/M to 355A/B, where ventilation is critical

for thermal performance of the motor, the endshield fastening

screws are placed in such a way so as not to block airflow to

any fin, thus contributing to better thermal exchange.

Figure 17 - Fan cover

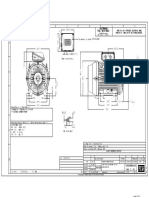

3.11 Nameplate

The nameplate supplies information determining motor

construction and performance characteristics. The line name

is given on the first line of the nameplate together with

nominal efficiency levels as required by IEC 60034-30-1.

Figure 15 - Drive and non-drive endshields

3.9 Drains

The endshields have holes for drainage of water that may

condense inside of the frame. These holes are supplied with

rubber drain plugs, in accordance with figure 16. These plugs

leave the factory in the closed position and must be opened

periodically to allow the exit of condensed water.

Figure 18 - Nameplate position of W22 motors

6

2

3

8 12

13

10

1

25

26

04AGO14

14

0000000000

15

16

27

11

19

20

21

22

17

18

Drain plug closed

Drain plug open

24

Figure 19 - Nameplate layout for frames 63 to 132

Figure 16 - Detail of the drain plug position on drive endshield.

3.10 Fan Cover

The fan cover is made of steel for frames 63 to 132 and

FC-200 (EN GJL 200) cast iron for frames 160 to 355. The

cast iron fan covers have an aerodynamic design, which

results in a significant reduction in noise level and optimized

airflow between frame fins for heat exchange improvement.

Figure 17 shows the aerodynamic design of the cast iron fan

cover.

24

6

2

3

8 12

25

10

13

04AGO14

14

26

0000000000

23

19

20

21

Figure 20 - Nameplate layout for frames 160 to 355

W22 Electric Motor

11

1

22

12

15

16

17

18

27

Você também pode gostar

- Refinery Cooling Plant SpecificationDocumento8 páginasRefinery Cooling Plant SpecificationHatem ShawkiAinda não há avaliações

- Compact Secondary Substations Technical CatalogueDocumento12 páginasCompact Secondary Substations Technical CatalogueHOFFERAinda não há avaliações

- GE Pegasus MHV MotorDocumento6 páginasGE Pegasus MHV MotoridontlikeebooksAinda não há avaliações

- Modul Air Fluid Coolers 1800Documento12 páginasModul Air Fluid Coolers 1800Roger AklAinda não há avaliações

- Wartsila O E W 38 TRDocumento12 páginasWartsila O E W 38 TRbunguiaoAinda não há avaliações

- Hermetically Sealed Compressors for Oil & GasDocumento2 páginasHermetically Sealed Compressors for Oil & GasSh.nasirpurAinda não há avaliações

- Grundfos NKDocumento121 páginasGrundfos NKSam Wang Chern PengAinda não há avaliações

- SB1012 Fresh Air Duct Sutrak AC 35 Rooftop UnitDocumento6 páginasSB1012 Fresh Air Duct Sutrak AC 35 Rooftop UnittchernserAinda não há avaliações

- SL98-358 B&W Service LetterDocumento3 páginasSL98-358 B&W Service LetterkamalAinda não há avaliações

- CSL 1060Documento6 páginasCSL 1060oscar horacio floresAinda não há avaliações

- Dual Seal TechnologyDocumento11 páginasDual Seal TechnologycuervohijoguachoAinda não há avaliações

- Efficient Screw Compressors for Dry Air DeliveryDocumento10 páginasEfficient Screw Compressors for Dry Air DeliverySaeedAkbarzadehAinda não há avaliações

- PMR v39 I3 117 126Documento10 páginasPMR v39 I3 117 126rezaeibehrouzAinda não há avaliações

- Ahmad Shahril Ashraf MohamedDocumento24 páginasAhmad Shahril Ashraf MohamedManoj BallaAinda não há avaliações

- The V8 Engine For McLaren's New MP4-12CDocumento6 páginasThe V8 Engine For McLaren's New MP4-12Cddi11Ainda não há avaliações

- Sketch ThriDocumento35 páginasSketch ThrisahilAinda não há avaliações

- 00643Documento9 páginas00643Sunilkumar ReddyAinda não há avaliações

- Alemite Carbon Shield - CatalogDocumento12 páginasAlemite Carbon Shield - CatalogAdolfo EirasAinda não há avaliações

- Special Applications: Compact Heat Exchangers Product InformationDocumento12 páginasSpecial Applications: Compact Heat Exchangers Product InformationEsteban Lopez ArboledaAinda não há avaliações

- MS6001FADocumento14 páginasMS6001FAsureshkumar908Ainda não há avaliações

- Unit10 - Modern Trends in DevelopmentDocumento33 páginasUnit10 - Modern Trends in DevelopmentMainak Paul100% (1)

- Space HeatersDocumento3 páginasSpace HeaterslimresAinda não há avaliações

- 3500BBDocumento156 páginas3500BBAna María AcostaAinda não há avaliações

- 314023114018VOLII SectionI TSpartVDocumento187 páginas314023114018VOLII SectionI TSpartVsaravananAinda não há avaliações

- 6gc Steering ManifoldDocumento4 páginas6gc Steering ManifoldThai NguyenAinda não há avaliações

- 0001Documento15 páginas0001Jhohan Franklin Meza LimaymantaAinda não há avaliações

- 6b Motor Nameplate Handout.325 PDFDocumento19 páginas6b Motor Nameplate Handout.325 PDFAntonius DickyAinda não há avaliações

- MOTOR NAMEPLATE DETAILSDocumento19 páginasMOTOR NAMEPLATE DETAILSSunil SinghAinda não há avaliações

- Api 23 02Documento4 páginasApi 23 02montsegranAinda não há avaliações

- Section 4 Air Handling Units - Double Skin ScopeDocumento4 páginasSection 4 Air Handling Units - Double Skin ScopematzoyekAinda não há avaliações

- 10-SEER Package Air Conditioners GuideDocumento43 páginas10-SEER Package Air Conditioners GuideGerardo ZamoranoAinda não há avaliações

- 30GBDocumento39 páginas30GBnay_lurAinda não há avaliações

- MotivairDocumento8 páginasMotivaircortezt0% (1)

- CFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarDocumento11 páginasCFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarGtatlisAinda não há avaliações

- CEB1053Documento30 páginasCEB1053oscar horacio floresAinda não há avaliações

- Boletin Non ClogDocumento12 páginasBoletin Non ClogulisesgeAinda não há avaliações

- Wartsila 200Documento24 páginasWartsila 200Carl Anthony Chamberlain100% (1)

- Copeland Zr90 300Documento21 páginasCopeland Zr90 300Wilson Javier CubaAinda não há avaliações

- Em 9S PDFDocumento6 páginasEm 9S PDFIvan DulicAinda não há avaliações

- Product 931153Documento9 páginasProduct 931153Juan Bayron Muñoz100% (1)

- Guide to Designing Jacketed Piping SystemsDocumento11 páginasGuide to Designing Jacketed Piping SystemsDhirendra Singh Rathore100% (7)

- Separator GazeDocumento4 páginasSeparator Gazestef11_127571Ainda não há avaliações

- Aircraft engine cooling system componentsDocumento4 páginasAircraft engine cooling system componentsSutanu MishraAinda não há avaliações

- SM 64800Documento63 páginasSM 64800HENKO7659Ainda não há avaliações

- Design Operation and Maintenance of CT PDFDocumento24 páginasDesign Operation and Maintenance of CT PDFHamid Ariz50% (2)

- Hoag 2015Documento30 páginasHoag 2015tahreem hussainAinda não há avaliações

- ROTARY SCREW COMPRESSORS ENCAPSULATED HP 7,5 - 10 - 15 20 - 25 - 30Documento6 páginasROTARY SCREW COMPRESSORS ENCAPSULATED HP 7,5 - 10 - 15 20 - 25 - 30Daniel Arbeláez0% (1)

- DLU TechDocumento20 páginasDLU Techqwerty_conanAinda não há avaliações

- Fabrication of Self Lubrication System For Complicated MachinesDocumento48 páginasFabrication of Self Lubrication System For Complicated MachinesKarthik Mayandy100% (2)

- 1 API 653 Memories Sept 2012Documento20 páginas1 API 653 Memories Sept 2012majid100% (1)

- Eyectors PDFDocumento110 páginasEyectors PDFDiego RinconAinda não há avaliações

- Combined Cycle Plants With Frame 9F Gas TurbinesDocumento8 páginasCombined Cycle Plants With Frame 9F Gas TurbinesNouman AhmedAinda não há avaliações

- Examples of Premature Stator Winding Failure in Recently Manufactured Motors and GeneratorsDocumento4 páginasExamples of Premature Stator Winding Failure in Recently Manufactured Motors and GeneratorsstarkopeteAinda não há avaliações

- MANUAL DezumidificatorDocumento98 páginasMANUAL DezumidificatorcivodulAinda não há avaliações

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAinda não há avaliações

- High-Performance GM LS-Series Cylinder Head GuideNo EverandHigh-Performance GM LS-Series Cylinder Head GuideNota: 4.5 de 5 estrelas4.5/5 (2)

- 77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016No Everand77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016S. K. SundaramAinda não há avaliações

- IMPORTANT QUESTION IN ELECTRICAL ENGG FOR ASSISTANT ENGINEER EXAMS OF UPRVUNL, UPPCL, MPPKVVNL, HPPSC, IES, GATE and Other State Psus.Documento223 páginasIMPORTANT QUESTION IN ELECTRICAL ENGG FOR ASSISTANT ENGINEER EXAMS OF UPRVUNL, UPPCL, MPPKVVNL, HPPSC, IES, GATE and Other State Psus.Rishi Kant Sharma100% (1)

- Scan 0023Documento16 páginasScan 0023Pranay KharbeAinda não há avaliações

- Locations ServicesDocumento3 páginasLocations ServicesszabeeAinda não há avaliações

- MCT 3Documento1 páginaMCT 3Pranay KharbeAinda não há avaliações

- Project ManagementDocumento2 páginasProject ManagementAmmiraju ChoudharyAinda não há avaliações

- Name Plate Title BlockDocumento1 páginaName Plate Title BlockPranay KharbeAinda não há avaliações

- PCMC B - ZoneDocumento1 páginaPCMC B - ZonePranay KharbeAinda não há avaliações

- Name Plate Title Block PDFDocumento1 páginaName Plate Title Block PDFPranay KharbeAinda não há avaliações

- Free and Public DNS Server List (Updated June 2015)Documento6 páginasFree and Public DNS Server List (Updated June 2015)Pranay KharbeAinda não há avaliações

- Mathematics Notes PDFDocumento89 páginasMathematics Notes PDFbalarajeAinda não há avaliações

- Sec 144 8-05screen PDFDocumento9 páginasSec 144 8-05screen PDFPranay KharbeAinda não há avaliações

- Name Plate WEG-w22 PDFDocumento1 páginaName Plate WEG-w22 PDFPranay KharbeAinda não há avaliações

- DetailsDocumento1 páginaDetailsPranay KharbeAinda não há avaliações

- Perkins Fans&BlowersDocumento12 páginasPerkins Fans&BlowersPranay KharbeAinda não há avaliações

- BITS Pilani WILP List of Textbooks 1-2014Documento8 páginasBITS Pilani WILP List of Textbooks 1-2014Vipul GoyalAinda não há avaliações

- BS en 1092Documento21 páginasBS en 1092Pranay Kharbe100% (5)

- Car Ent CatalogueDocumento21 páginasCar Ent CataloguePranay KharbeAinda não há avaliações

- (A) Transformer Specification SheetDocumento2 páginas(A) Transformer Specification SheetPranay KharbeAinda não há avaliações

- Trolley SpecificationsDocumento1 páginaTrolley SpecificationsPranay KharbeAinda não há avaliações

- BS en 1092Documento21 páginasBS en 1092Pranay Kharbe100% (5)

- Is:1239 Part 1 - Mild Steel Tube PipeDocumento17 páginasIs:1239 Part 1 - Mild Steel Tube PipeRathnakar Naik86% (36)

- GHGDocumento88 páginasGHGPranay KharbeAinda não há avaliações

- 1250GAS GA Cogen-ModelDocumento1 página1250GAS GA Cogen-ModelPranay KharbeAinda não há avaliações

- 70 1012 CDocumento1 página70 1012 CPranay KharbeAinda não há avaliações

- ACB MVS CatalougeDocumento59 páginasACB MVS CatalougePranay KharbeAinda não há avaliações

- Movie ListDocumento1 páginaMovie ListPranay KharbeAinda não há avaliações

- Higher Algebra - Hall & KnightDocumento593 páginasHigher Algebra - Hall & KnightRam Gollamudi100% (2)