Escolar Documentos

Profissional Documentos

Cultura Documentos

Jerad DLId 0618 Vol 002 Issue 004

Enviado por

parosicTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Jerad DLId 0618 Vol 002 Issue 004

Enviado por

parosicDireitos autorais:

Formatos disponíveis

Journal of Environmental Research And Development

Vol. 2 No. 4, April-June, 2008

PERFORMANCE ANALYSIS OF SINGLE SLOPED GREEN

HOUSE SOLAR STILL

B. Selvakumar*, R. Jayaprakash1 and Sanjay Kumar2

1. Department of Physics, Sri Ramakrishna Mission Vidyalaya, College of Arts and Science,

Coimbatore, Tamilnadu (INDIA)

2. Department of Physics, BR Ambedkar Bihar University, Muzaffarpur, Bihar (INDIA)

Received October 4, 2007

Accepted March 27, 2008

ABSTRACT

This paper presents the performance and distillate yield analysis of a single sloped

green house solar still for growing plants in cold climates through better utilization of the

available sunlight. A green house solar still of area 0.20m x 0.50m along with still water

storage area 0.50m x 0.50m is constructed using stainless steel. Sides of the basin are well

insulated to prevent heat losses. The still body consists of a step type basin insulated at the

bottom with glass wool. There is a parallel openening at base of the step for the circulation

of air to green house channel. Slits are closed to prevent the air flow for solar still study.

Key Words : Solar still, Water collection, Efficiency, Greenhouse, Fossil fuel

INTRODUCTION

The basic principles of solar water

distillation are simple, yet effective, as

distillation replicates the way nature purifies

water. The suns energy heats water to the point

of evaporation. As the water evaporates, water

vapor rises, condensing on the glass surface

for collection. This process removes impurities

such as salts and heavy metals, as well as

destroys microbiological organisms. The end

result is water cleaner than the purest rainwater.

Heating saline water can be done using fossil

fuels like oil. But fossil fuels are slowly declining

with time because of the rapid consumption

used in technology development.

Solar energy is the best alternative

heating energy source. It is inexhaustible, clean

and available in almost all parts of the world.

The use of solar energy is however more

economical than the use of fossil fuels in remote

areas having low population densities, low

rainfall and abundant available solar energy.

Solar stills can easily provide enough water for

family drinking and cooking needs. The most

commonly used device in solar desalination is

the solar distiller. In operation, the greenhouse

effect of the transparent cover during sunny

hours increases the water temperature, causing

some of it to evaporate and increase the relative

humidity of the air contained within the

enclosure.

Hamdan M.A.1 showed the productivity

of fresh water by solar distillation depends

drastically on the intensity of solar radiation and

the sunshine time interval during the day.

Distilled water productivity varies quite

dramatically with the geographical position, the

suns position, prevailing meteorological

*Author for correspondence

618

Journal of Environmental Research And Development

conditions, still design and operational

techniques by Malik et al.2. Bilal3 and Tiwari

and Madhuri4 found that other parameters such

as water depth, salinity, black dye, wind speed

and direction have an effect on the output of

the solar stills. Numerous efforts have been

made by them to enhance the system

efficiency, so that the distillate output is obtained

at a reasonable cost and utilizes a minimum

amount of land surface along integrated with a

panel of collectors through heat exchangers by

Tiwari et al.5. Efforts involved in the use of

active solar distillation, in which the basin of

the solar still is integrated with a panel

of collectors through heat exchangers by Tiwari

et al.6, enhancing the solar still performance by

cooling the glass cover with water film was

studied by Bassam and Abu-Hijleh 7 .

Experimental study of a single-compartment

model and a two compartment type had been

studied by Pierre Meukam et al.8 for alcohol

distillation.

Bapeshwararao et al9 and Lawrence

et al10 have been studied the effect of water

flowing over the upper glass cover of a basin

solar still on its transient performance.

Numerical simulations for Condensation

irrigation (CI) through shorter pipes result in a

higher mean production had been studied by

Jenny Lindblom and Bo Nordell11. Performance

evaluation of one-sided vertical solar still tested

under desert climatic conditions of Algeria, has

been studied by Boukar and Harmim12. Tiwari13

studied a straightforward transient analysis of

a double basin solar still. It is concluded that

for higher daily yield of the collector should be

disconnected from the still during off sunshine

hours. Taj and Tiwari14 have been presented

the transient performance of a single basin seder

still coupled with a flat plate collector. Umarou

and Varadiyashivili15 have been explained the

fact that the free and forced convection

in convector still, which ensures rapid

displacement of the vapor-air mixture over the

Vol. 2 No. 4, April-June 2008

surface of the evaporation mirror. Dhiman and

Tiwari16 have been given analytical model of a

multi-wick solar still with flowing water over

the glass cover.

Tiwari17 and Tiwari et al18 studied a

simple multiple wick solar still becomes

reasonably hot and hence the yield is not very

high. To increase the yield under this situation

a double condensing multiple wicks solar still

has been proposed. A tube-type solar still has

been investigated by Murase19 to integrate a

conventional still and a water distribution

network suitable for concept of desert

plantation. Desalting solar stills made from

waste materials had been studied by Toyama

and Murase 20 . An inclined solar water

distillation system was designed and tested

under actual environmental conditions of

northern Cyprus by Hikmet et al21. Lawrence

and Tiwari22 had studied thermal modeling

based heat and mass transfer relations of a

greenhouse integrated with a solar still. Syed

et al23 studied a commercial green house

system utilizing the solar pond-assisted heat

pump system. Ted et al24 studied the tomato

production with glam houer. Two similar glam

houses were used to study the influence of a

double-plastic cover an annual heat are, light

transmission and plant growth. Palacio et al25

have been investigated performance of green

house still with top cover slope of 60.

MATERIAL AND METHODS

The dimension of general setup of green

house solar still is 0.50m x 0.65m. There are

two step zones provided within the system. One

for water storage basin and other for placing

the green house plants. The pictures of single

sloped green house solar still is shown in Photo

plate 1 and Photo plate 2. Water storage

segment of the still is accommodated with

dimension 0.50m 0.50m 0.02m. One side

of the still zone is of height 0.30m and other

end of the still zone of 0.06m. The next zone

for green house is started and it is of dimension

619

Journal of Environmental Research And Development

Vol. 2 No. 4, April-June, 2008

Photo plate 1 : Green house solar still

Photo plate 2 : Plant growth inside still

0.05m 0.15m 0.15m and it is placed 0.15m

down to the still zone. It is clearly viewed

through Photo plate 2. Base and sides of the

experimental study is started from 9 A.M. The

basin is filled with water of 4 litre of saline

water. The pre-calibrated thermocouples are

fixed at the appropriate places and it is

connected to the digital thermometer.

A thermometer with an accuracy of 0.1

C is fixed near the still to the air temperature

(Ta), water temperature (Tw) inside the still.

Also to measure the ambient temperature

(Tamb), Acrylic cover temperature (Tg), total

solar insolation (H) and the amount of distilled

water collected at the outlet are recorded. A

measuring jar is kept at the distilled water outlet and the collection is recorded at the regular

intervals.

water storage basin is painted with black paint

for good absorption of solar radiation. Glass

cover of thickness 3 mm is used at top of the

system. It is having a slope of 12.

The outer box for the still is made up of

wood of thickness 3mm with the length and

breadth as 0.60m and 0.80m. Bushes are

placed at the base of the still for uniform landing

in the land. Grooves are provided in the outer

cover for the inlet pipe, outlet pipe, distilled

water collection pipes and waste water flow

pipes. The bottom of the outer box and sides

are filled with the sawdust. It is used to reduce

the conduction heat loss through the base and

sides of the system. Condensed water over

the bottom of glass surface is crosses over

the green house zone and collected in water

collection segment. A stainless steel water

collection segment of dimension 0.60m

0.03m 0.03m is provided to collect the distilled

water.

Experimental arrangement

The single sloped green house solar still

unit has been designed and is installed with an

orientation in the North South direction. The

performance of the still has been studied for

number of days and its readings on clear

sunshine days have been recorded. The

Thermophysical Properties

Thermophysical properties are estimated

using experimentally measured temperatures

of evaporation and condensation surfaces.

These values are given by Toyoma et al.26.

k = 0.0244 + (0.7673 10-4) Tav

...(1)

-5

-8

= (1.718 10 ) + (4.620 10 ) Tav ...(2)

= 353.44 / (273.35 + Tav)

...(3)

3

hv = 2324.6 [(1.0727 10 ) (1.0167Tav)

+ (1.4087 10-4) Tav2 (5.1462 10-6)

Tav3 ]

...(4)

The arithmetic mean of the temperatures

of evaporation and condensation surface can

be expressed as follows:

Tav = (Tw + Tg) / 2

620

Journal of Environmental Research And Development

Similarly the values of saturation vapour

pressure are predicted under the expression,

which is suggested by Brooker et al.27.

P = 6893.03 exp (54.63 12301.69/T

5.17 ln T)

...(5)

where T = (1.8T + 491.69)

The Performance Ratio is calculated

using the formula

PR = (me,i hv) / (Hs)

...(6)

The convective heat transfer is considered in terms of dimensionless parameters, viz.

the Nusselt number (Nu), the Grashof number

(Gr), the Reynolds number (Re) and the Prandtl

number (Pr); the expressions for these numbers are

Nu = (hci L / k)

...(7)

n

where

hci = C (Gr Pr) k / L

The values of constants C and n are

determined by the following conditions :

C = 0.21, n = for 104 < Gr < 2.51 105

C = 0.1255, n = for 2.51 105 < Gr < 107

Gr = (xi3 i2 g T) / i2

...(8)

Pr = (Cp / k)

...(9)

Heat transfer modes in a solar still

It is very important to know accurately

the heat and mass transfer processes in basin

type solar stills for improving their

performance. Many researchers have

conducted a great many experimental and

theoretical studies about them. For the most

normal range of operation for a conventional

solar still, the most commonly used relationship

to evaluate heat and mass transfer coefficients

and it is proposed by Dunkle.28 . The study

carried out by Adhikari et. al29 for verifying

the applicability of Dunkles relationships

over a wide range of operating temperatures

within a solar still reported that Dunkles

relationships behave well in the lower

Vol. 2 No. 4, April-June 2008

temperature ranges. So Dunkles relationship

needs the modification in the higher ranges of

temperatures. Thus they proposed a relationship

for evaluating heat and mass transfer

coefficients including higher temperature

ranges as follows :

Internal heat transfer modes

(a) Convection :

Heat is transported inside the still by

free convection of air. It releases its enthalpy

upon air, which is coming in contact with the

glass cover. The heat transfer per unit area per

unit time due to convection is

Qci =

0.884

...(10)

(b) Evaporation :

Dunkle connects convective and evaporation heat transfer coefficients as :

Qei = 16.273 x 10-3 hci. R1 (TwTg) ...(11)

(c) Radiation :

In the usual analyses of solar stills, the

water surface and the glass cover are considered as infinite parallel planes. Using Stefan

Boltzmanns constant, the heat transfer coefficient is given by,

Qri = [(Tw + 273)4 (Tg + 273)4] ...(12)

External heat transfer mode :

The external heat transfer modes are

convention and radiation. Due to the small

thickness of the glass cover, it is assumed that

the lamp of the cover is uniform. The external

convention loss from glass to the outside atmosphere is,

Qce = hca (Tg Ta)

...(13)

here, hca is a function of wind velocity

and is given by Duffie, 1974, as,

hca = 5.7 + 3.8 V

The external radiation loss from the

acrylic cover to the atmosphere is given by,

Qre= g [(Tg + 273)4 (Tsky + 273)4)]

...(14)

621

Journal of Environmental Research And Development

T sky = (T a 12) is the apparent sky

temperature for long wave radiation. g for glass

is 0.85

The value of conduction heat loss through

the base Qbe is given by

Qbe = hb (Tw Ta)

...(15)

Efficiency

The efficiency of the still is calculated

using the formula

= (M L) / (H A t)

...(16)

RESULTS AND DISCUSSION

Thermal performance of single sloped

solar still coupled with green house effect is

Vol. 2 No. 4, April-June, 2008

studied. The instantaneous efficiency and

overall efficiency are predicted. Night water

collection of the still is also observed. The

observations are recorded on clear sunny days.

Fig. 1 show the variation of solar

radiation with respect to time for still

performance study and combined with green

house effect. It rises to maximum and then

decreases to the minimum. Radiation received

is in the range of 386.46 W/m2 to 1014.46 W/

m2 for still analysis and 434.77 W/m2 to 1026.54

W/m2 for inbuilt green house and still combined

performance.

1200

1000

Radiation (W/m

800

600

400

200

S +

G.H

0

9:30 10:30 11:30 12:30 1:30 2:30 3:30 4:30

Time (min)

Fig . 1: Variation of radiation with respect to time

Fig. 2 and Fig. 3 show the variation of

water temperature, air temperature, glass

temperature and ambient temperature with

respect to time for still alone and combined

performance for additional feature of green

house within the same system. The rise in

temperature is observed in the range of 28C

to 54C for water, 29C to 58C for air, 29C

to 38C for to glass and 28C to 37 C for

ambient temperature. Similarly the rise in

temperature is observed in the range of 29C

to 52C for water, 28C to 50C for air, 29C

to 37 C for glass and 28C to 36.5C for

ambient temperature. The air temperature is

lesser than the water temperature because

natural air flow is occurring from outside of

622

Journal of Environmental Research And Development

60

Vol. 2 No. 4, April-June 2008

55

50

50

45

Temperature (C)

Temperature (C)

40

40

30

35

20

30

Glass (C)

Air (C)

Wat er (C)

Room (C)

10

Glass

Air

Water

Room

25

20

9:30 10:30 11:30 12:30 1:30 2:30 3:30 4:30

0

9:30 10:30 11:30 12:30 1:30

2:30

3:30

4:30

Time (min)

Time (mi n)

Fig. 2 : Variation of temperature with respect to

time for still study

Fig. 3 : Variation of temperature with respect to

time for still combined with green house study

the system. So it maintains the low temperature

in green house area of the still system but in

the case of still performance the air

temperature is greater than the water

temperature.

Fig. 4 shows the variation of instantaneous water collection with respect to time.

The water collection is increased to the

maximum of 92 ml and then decreased to 24

ml at 5 P.M. for still. Similarly the maximum

100

90

80

Water collection (ml)

70

60

50

40

30

20

S

10

S+G

0

9:00 10:00 11:00 12:00 1:00

2:00

3:00

4:00

5:00

Time (min )

Fig. 4 : Variation of water collection with respect to time

623

Journal of Environmental Research And Development

Vol. 2 No. 4, April-June, 2008

less because it takes more time for water

condensation as well as water collection. The

water collection is stopped when the radiation

fall over the system stops. Thus in this system

the still effect is observed only during the

irradiation period.

Fig. 5 shows the variation of

instantaneous efficiency with respect to time.

The instantaneous efficiency increases with

water collection is 64 ml and then decreased

to 18 ml at 5 P.M. for green house study with

solar still.

The distilled water collection at the outlet

is increased according to solar radiation. It

shows that maximum yield at noon (12 P.M to

2 P.M) and then decreases in the evening

(5 P.M to 6 P.M). But in the case of still with

green house study the water collection rate is

30

25

Instanateous efficiency (%)

20

15

10

S

S+G

0

9:30 10:30 11:30 12:30 1:30

2:30 3:30 4:30

Time (min)

Fig. 5 : Variation of instantaneous efficiency with respect to time

time. The instantaneous efficiency obtained is

in the range of 1.81% - 24.18% for still and

4.42% - 17.67% for still combined with green

house study. The efficiency of the green house

still is less than the solar still. It is due to the

free flow of air in the green house, even though

it increases the growth rate of plants. The overall efficiency of the still is 16.05% and still

combined with green house is 12.15%.

Fig. 6 shows the variation of humidity

with respect to time for the green house solar

still. The humidity value starts to increase form

21 % to 96 %. The humidity is inversely

proportional to the still temperature. So it

increases the moisture content at the green

house zone. So it is more suited for plants

growth.

624

Journal of Environmental Research And Development

Vol. 2 No. 4, April-June 2008

120

100

Humidity (%)

80

60

40

20

Time (min)

Fig. 6 : Variation of Humidity with respect to time

Fig. 7 shows the latent heat inside the

still. It shows that the latent heat decreases

initially with respect to time. It reaches low

value around 2:00 P.M and starts to increase

according to time because the temperature at

this region is more. So it shows that the latent

heat is decreased in this region at higher order

of temperature. But in case of combined green

house study latent heat value is comparatively

smaller than the still because of low air

temperature maintained in the system

2430000

2420000

2410000

Latent Heat (Jkg-

1)

2400000

2390000

2380000

2370000

S

S + G.H

2360000

Time (min)

Fig. 7 : Variation of latent heat with respect to time

625

Journal of Environmental Research And Development

Fig. 8 shows the variation of saturated

vapour pressure with respect to time.

Saturated vapour pressure starts to increase

as time progress and it reaches the peak value

Vol. 2 No. 4, April-June, 2008

around 1:30 P.M to 2:00 P.M. Saturated vapour

pressure reaches maximum value when water

collection is more and tend to decrease when

water collection less.

12000

10000

SVP (pa)

8000

6000

4000

2000

S

S + G.H

0

9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00

Time (mi n)

Fig. 8 : Variation of SVP with respect to time

200000

4.5

180000

160000

3.5

140000

3

120000

Nu

Gr

2.5

100000

2

80000

1.5

60000

1

40000

20000

0.5

S

S + G.H

S

S + G.H

0

9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00

9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00

Time (min)

Time(min)

Fig. 9 : Variation of Gr with respect to Time

Fig. 10 : Variation of Nu with respect to time

626

Journal of Environmental Research And Development

Fig. 9 and Fig. 10 show the Grashof

number and Nusselt number variation with

respect to time. Both Grashof and Nusselt

number increases as time increases. The

Vol. 2 No. 4, April-June 2008

Nusselt number value and Grashof number

value is almost nearer to each other for still

performance study as well as combined

performance study.

0.14

0.12

0.1

PR

0.08

0.06

0.04

0.02

S

S + G.H

0

9:00 10:0011:0012:0013:0014:0015:0016:0017:00

Time (mi n)

Fig. 11 : Variation of PR with respect to Time

Fig. 11 shows the variation of

performance ratio with respect to time for still

performance and combined performance

studies. This shows that the value of

performance ratio increases due to increase in

temperature inside the still. In the case of green

house solar still the temperature is reduced due

to the free flow convection. Thus performance

ratio is very much reduced.

Thermal conductivity and dynamic

viscosity of water is analyzed for all the studies

and thermal conductivity is in the range of

2.73744 10-2 Wm-2 C1 and 2.73067 10-2

Wm-2 C-1 for still performance and combined

performance studies. Similarly dynamic

viscosity is in the range of 1.8971 10-5 Nsm-2

and 1.8837 10-5 Nsm-2 for still performance

and combined performance studies. The

thermal conductivity and dynamic viscosity are

observed and it is almost same for both the

studies.

The density of water is predicted for the

still under these experiments and it is observed

as 1.1689 to 1.1084 Kgm-3 and 1.1689 to 1.1119

Kgm-3 for still and combined green house study.

It shows a small decrease in density due to the

increase of temperature.

Heat transfer coefficients predicted

under internal and external heat transfer modes

for still and combined green house is shown in

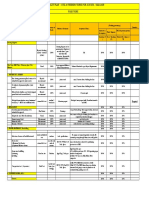

Table 1.

From the above table it is clear that

627

Journal of Environmental Research And Development

Vol. 2 No. 4, April-June, 2008

Table 1

Internal Heat Transfer Mode

2

External Heat Transfer Mode

2

Qri W/m

Qci W/m

Qei W/m

Qbe W/m

Qre W/m

Qce W/m

Still

52.25

15.90

124.67

3.93

104.11

64.54

Still combined with

Green House

48.59

14.46

106.62

3.52

111.87

80.47

evaporation rate.

A comparison chart for growth of plants

inside (G.H) and placed outside (O.G) the

green house solar still is listed in table 2.

evaporative heat transfer is less in still combined

with green house when compared to still study.

Which infers that lower evaporation rate is due

to air flow inside the still slow down the

Table 2

Day

G.Gram

G.H

1

2

3

4

5

6

7

8

10

11

12

B.Gram

O.G G.H

Cotton

F.Gram

Gingili

H.Gram

Paddy

O.G

G.H

O.G

G.H

O.G

G.H

O.G

G.H

O.G

G.H

O.G

.05

.15

.20

.50

.75

.925

1.30

2.00

2.60

3.30

3.90

5.15

5.90

6.50

6.95

7.80

8.50

9.15

10.20

.05

.08

.20

.300

.500

.825

1.00

1.55

2.10

3.00

3.90

4.65

5.10

5.90

6.45

7.25

7.90

8.50

8.90

.05

.75

.225

.50

.75

1.00

1.75

2.30

3.10

3.55

4.10

4.60

5.35

5.80

6.90

7.30

8.60

9.10

.05

.75

.125

.30

.65

.90

1.20

1.60

2.80

3.50

4.20

4.50

5.05

5.50

5.90

6.50

7.00

7.20

.05

.070

.100

.150

0.50

0.90

1.30

2.00

2.60

3.00

3.50

3.95

4.60

5.20

6.12

6.89

7.60

8.13

.05

.10

.225

.350

.500

.750

1.50

2.50

3.45

4.50

6.50

7.50

8.80

9.20

10.30

11.10

12.30

12.90

14.10

15.00

16.60

17.20

.02

.08

.125

.190

.750

1.15

2.00

2.80

4.00

4.90

6.50

7.25

9.10

9.80

10.25

10.40

11.00

11.30

11.50

12.10

12.30

12.45

.05

.125

.170

.275

.500

.700

1.10

2.75

3.15

5.50

6.25

7.50

8.25

9.10

9.80

10.45

11.15

12.36

13.59

15.00

15.50

.05

.10

.20

.275

.50

.700

1.10

2.75

3.15

5.50

6.25

7.50

8.25

8.75

9.10

9.45

10.15

10.56

10.95

11.30

11.90

.05

.03

.025

.075 .075

.05

.100 .100

.10

.125 .125

.15

.405 .375 .325

.700 .500 .625

1.00 0.90 .825

1.75 1.35 1.25

2.15 2.15 1.50

4.20 3.50 3.50

5.30 4..20 4.10

6.25 5.65 5.10

6.90 6.30 5.75

7.50 7.20 6.30

8.10 7.90 6.90

9.20 8.50 7.20

9.90 8.90 7.90

10.90 9.50 9.00

12.00 10.00 9.60

13.35 10.35 10.55

14.80 10.70 11.10

CONCLUSION

The results show that :

(1) the still daily average efficiency is

about 16.05% (0.5 m2 area) for still and

12.15% (0.5 m2 area) for green house study;

(2) total daily yield is about 838 ml

.025

.05

.07

.10

.225

.325

.725

1.05

1.80

2.75

3.50

4.20

4.95

5.60

6.10

6.80

7.35

8.00

8.60

9.15

9.60

.05

.10

.125

.750

1.00

1.50

2.00

2.50

3.10

3.60

4.20

4.60

5.00

5.45

5.90

6.20

(0.5 m2 area) for still and 536 ml (0.5 m2 area)

for combined performance of green house and

still study;

(3) The internal heat transfer and external heat transfer modes are studied for still

and ; and

628

Journal of Environmental Research And Development

(4) the growth rate of the green house

still is studied and it is compared with that of

plants growth outside the system.

11.

REFERENCES

1.

Hamdan M. A, Musa A.M and Jubran

B.A, Performance of solar still under

jordanian climate, Energy Conversion

and Management, 40(5), 495, (1999).

2. Malik M.A.S, Tiwari G.N, Kumar A and

Sodha M.S, Solar Distillation, Pergamon

Press, Oxford, (1982).

3. Bilal A. Akash, Mousa S. Mohsen and

Waleed Nayfeh, Experimental study of the

basin type solar still under local climate

conditions, Energy Conversion and

Management, 41(9), 883, (2000).

4. Tiwari G.N and Madhuri, Effect of water

depth on daily yield of the still,

Desalination, 61(1), 67, (1987).

5. Tiwari G.N, Saxena P and Thakur K,

Thermal analysis of active solar distillation

system, Energy Conversion and

Management, 35(1), 51, (1994).

6. Tiwari G.N, Saxena P and Thakur K,

Thermal analysis of active solar distillation system, Energy Conversion

Management, 35(1), 51, (1994).

7. Bassam A. K and Abu-Hijleh, Enhanced

solar still performance using water film

cooling of the glass cover, Desalination,

107(3), 235, (1996).

8. Meukam, Donatien Njomo, Aboudramane

Gbane and Siaka Toure, Experimental

optimization of a solar still: application to

alcohol

distillation,

Chemical

Engineering and Processing, 43, 1569,

(2004).

9. Bapeshwararao V.S.V, Singh U and

Tiwari G.N, Transient analysis of double

basin solar still, Energy Conversion

Management, 23(2), 83, (1983).

10. Lawrence S.A, Gupta S.P and Tiwari G.N,

Effect of heat capacity on the

performance of solar still with water flow

12.

13.

14.

15.

16.

17.

18.

19.

20.

629

Vol. 2 No. 4, April-June 2008

over the glass cover, Energy Conversion

Management, 30(3), 277, (1990).

Jenny Lindblom and Bo Nordell, Water

production by underground condensation

of humid air, Desalination, 189, 248,

(2006).

Boukar M and Harmim A, Performance

evaluation of a one-sided vertical solar

still tested in the desert of algeria,

Desalination, 183, 113, (2005).

Tiwari G.N, Enhancement of daily yield

in a double basin solar still, Energy

Conversion Management, 25(1), 49,

(1985).

Raj S.N and Tiwari G.N, Single basin solar

still coupled with flat plate collector,

Energy Conversion Management,

23(3), 145, (1983).

Umarov G. Ya and Vardiyashvili A.B,

Heat and mass transfer in convective

solar stills, Geliotekhnika, 6(1), 52,

(1970).

Dhiman N.K and Tiwari G.N, Effect

of water flowing over the glass cover of

a multi-wick solar still, Energy

Conversion Management, 30(3), 245,

(1990).

Tiwari G.N, Demonstration plant of a

multi wick solar still, Energy Conversion

Management, 24(4), 313, (1984).

Tiwari G.N, Sharma S,B and Sodha M.S,

Performance of a double condensing

multiple wick solar still, Energy

Conversion Management, 24(2), 155,

(1984).

Kazuo Murase, Hiroshi Tobata, Masayuki

Ishikawa and Shigeki Toyama

Experimental and numerical analysis of a

tube-type networked solar still for desert

technology, Desalination 190, 137,

(2006).

Toyama S and Murase K, Solar stills made

from waste materials, Desalination,

169(1), 61, (2004).

Journal of Environmental Research And Development

21. Hikmet S. Aybar, Fuat Egelioglu and U.

Atikol An experimental study on an

inclined solar water distillation system,

Desalination 180, 285, (2005).

22. Lawrence S.A and Tiwari G.N,

Performance of a greenhouse cum solar

still for the climatic condition of port

moresby,

Energy

Conversion

Management, 1(2), 249, (1991).

23. Syed A.Shah, Ted H.Short and Peter

Fynn R, A solar pond assisted heat pump

heating system for commercial green

houses, Solar Energy Society, Ohio

Agricultural Research and Development

Centre, Wooster, (1980).

24. Ted H.Short, A double plastic heat

conversion system for glass green houses,

J. American Society of Agricultural

Engineers, 77, 4528, (1997).

25. Palacio A and Fernandez J.L, Numerical

26.

27.

28.

29.

Vol. 2 No. 4, April-June, 2008

analysing of green house type solar still

with high inclination, Solar Energy, 50(6),

469, (1993).

Tayoma S, Aragoki T, Murase K and

Sumura T, Simulation of a multi-effect

solar distillers, Desalination, 45, 101,

(1983).

Brooker D.B, Bakker-Arkma F.W and

Hall C.W, Drying cereal grain, AVI West

Port, U.S.A, (1978).

Dunkle R.V, Solar water distillation: roof

type still and a multiple effect diffusion

still, International Development in Heat

Transfer, A.S.M.E., Proc. International

Heat Transfer, Part V, University of

Colorado, 895, (1961).

Adhikari S, Ashvini kumar and Sootha

G.D, Simulation studies on a multi-stage

staked solar still, Solar Energy, 54(5),

317, (1995).

Environment is Gods gift, preserve it

If U

Protect

NATURE

NATURE

will

Protect U

Grow tree, Feel the Environment free

630

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Reinforcing Details for Skewed and Angled Box CulvertsDocumento1 páginaReinforcing Details for Skewed and Angled Box Culvertsarif_rubin83% (6)

- Majestic Wood Fireplace MatrixDocumento11 páginasMajestic Wood Fireplace MatrixmarilynkcarlinAinda não há avaliações

- Sorry Re Alibi LtyDocumento1 páginaSorry Re Alibi LtyparosicAinda não há avaliações

- SuckerDocumento1 páginaSuckerparosicAinda não há avaliações

- Sucker RealiblityDocumento1 páginaSucker RealiblityparosicAinda não há avaliações

- Sucker RealiblityDocumento1 páginaSucker RealiblityparosicAinda não há avaliações

- LalaDocumento1 páginaLalaparosicAinda não há avaliações

- Electron Beam MachiningDocumento9 páginasElectron Beam MachiningYunitha RatnadillaAinda não há avaliações

- Final Report Task1Documento111 páginasFinal Report Task1Dejan KolarecAinda não há avaliações

- Rate AnalysisDocumento3 páginasRate AnalysisNiranjan Shrestha83% (12)

- Gutter DetailDocumento1 páginaGutter DetailarkikuAinda não há avaliações

- 3-0515.090 Rev 27 (515-2536) English Rotor-X Flow Sensor ManualDocumento12 páginas3-0515.090 Rev 27 (515-2536) English Rotor-X Flow Sensor Manualabbas dehghanAinda não há avaliações

- Baine Hospital Details Scope of Work 25082017Documento3 páginasBaine Hospital Details Scope of Work 25082017kumarjit kolayAinda não há avaliações

- Fosroc and Sika Concrete Admixture in JharkhandDocumento4 páginasFosroc and Sika Concrete Admixture in JharkhandsirfmeinAinda não há avaliações

- Point-Fixed Glass Wall Fitting Typical Product Catalog160PDocumento155 páginasPoint-Fixed Glass Wall Fitting Typical Product Catalog160PNajib Kiwan100% (1)

- Shalabny Buonocore - 2022 APSUSDocumento9 páginasShalabny Buonocore - 2022 APSUSFrankie GoodheartAinda não há avaliações

- NDT Certificate Inspection ReportsDocumento9 páginasNDT Certificate Inspection ReportsikponmwonsaAinda não há avaliações

- Steel - Incomplete PenetrationDocumento32 páginasSteel - Incomplete PenetrationAhora Con Todo PepitoAinda não há avaliações

- Jumbo structural hollow sections technical data and specificationsDocumento8 páginasJumbo structural hollow sections technical data and specificationsalextentwentyAinda não há avaliações

- Shear StrengthDocumento37 páginasShear Strengthahmed yehiaAinda não há avaliações

- Projek Solid Mechanics 1Documento3 páginasProjek Solid Mechanics 1Shaktivell Letchumanan0% (1)

- Vinavil 5406 enDocumento2 páginasVinavil 5406 enVladimir Delgado B.Ainda não há avaliações

- GCPAT Procor Composite Waterproofing System Us 1676Documento7 páginasGCPAT Procor Composite Waterproofing System Us 1676Saurav Negi EtherealAinda não há avaliações

- Thordon Rudder A4Documento8 páginasThordon Rudder A4Andrea NaranjoAinda não há avaliações

- Open Ended Structure LabDocumento24 páginasOpen Ended Structure LabIzzatul Syahira Binti ZakariaAinda não há avaliações

- SS400 Structural Steel - An OverviewDocumento3 páginasSS400 Structural Steel - An Overviewdie smansachiAinda não há avaliações

- Continuity TestingDocumento107 páginasContinuity TestingJohn Benedict MauricioAinda não há avaliações

- CIPP DesignDocumento6 páginasCIPP DesignkwesiwellsAinda não há avaliações

- Lecture Notes Conductors, Insulators, and SemiconductorsDocumento2 páginasLecture Notes Conductors, Insulators, and Semiconductorsoduleke davidAinda não há avaliações

- LG LWHD1006R Training ManualDocumento44 páginasLG LWHD1006R Training ManualGuillermo HernandezAinda não há avaliações

- Catalogue Price List - Adisa - EN PDFDocumento78 páginasCatalogue Price List - Adisa - EN PDFVlad BalanAinda não há avaliações

- SAP Manual HandbookDocumento21 páginasSAP Manual HandbookDennyzaAinda não há avaliações

- Viking Series 90 Operating & Maintenance Instructions: FiltersDocumento15 páginasViking Series 90 Operating & Maintenance Instructions: FiltersninatenaAinda não há avaliações

- Nonlinear Structural Analysis of A 2D Cut-And-Cover Tunnel Exposed To FireDocumento6 páginasNonlinear Structural Analysis of A 2D Cut-And-Cover Tunnel Exposed To Firebalamurugan25011990Ainda não há avaliações

- Field Quality Plan - 2022 RoadDocumento9 páginasField Quality Plan - 2022 RoadMozhi Moni100% (1)

- Structural Design I (Reinforced Concrete Design) : in CE 422Documento24 páginasStructural Design I (Reinforced Concrete Design) : in CE 422jereck loquisoAinda não há avaliações