Escolar Documentos

Profissional Documentos

Cultura Documentos

LPT Procedure Rev.0 2014

Enviado por

Mohammad Rawoof0 notas0% acharam este documento útil (0 voto)

39 visualizações11 páginasBBBBBBBJ

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoBBBBBBBJ

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

39 visualizações11 páginasLPT Procedure Rev.0 2014

Enviado por

Mohammad RawoofBBBBBBBJ

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 11

( sogecnpT

LIQUID DYE PENETRANT TESTE

STANDARD PROCEDURE FOR No : PT-004

LIQUID DYE PENETRANT TESTING Issue: 2

I based on ASME Section-V Rev. : 0

RAJESHKUMAR | Ady esl Issue Date sumo

Approved by t

NDT Level IIE (188371) | Signature Page 1 of W

=

Prepared by | £0!8y Gamateldeen Issue Date [_3vizaors

pared BY [xr Lever m1.(183059) ‘Signature Poge 1 of I

( sogec-NDT STANDARD PROCEDURE FOR No : PT-004

1.0

2.0

3.0

40

5.0

60

20

8.0

LIQUID DYE PENETRANT TESTING Issue: 2

based on ASME Section-V Rev. : 0

TABLE OF CONTENTS

SCOP!

REFERENCE DOCUMENTS...

DEFINITIONS...

PROCEDURE.

4A Responsibilities.

4.2 Personnel Qualificat

43° Consumables,

44° Surface preparation..

45 Application of penetrant.

46 Dwell Time.

4.7 Removal of Excess Penetrant.

48 Drying After Excess Penetrant Removal,

4.9 Developer Application.

4.10 Observation.

4.11 Reporting

4.12 Post Cleaning.

ACCEPTANCE CRITERIA.

REPAIRS.

RECORDS.

REPORTING FORMAT.

Lotay Gamaleldeen Tsue Date |_s1za014

NDI Level HII (184049) ‘Signature Page 2 of i

Prepared by

“

§ sogeC-NDT STANDARD PROCEDURE FOR No : PT-004

LIQUID DYE PENETRANT TESTING Issue: 2

based on ASME Section-V Rev. : 0

1.0 SCOPE

1.1 This document describes the application of the non-desteuctive (esting method of

Penetrant Testing by Wet Visible Solvent Removable method

1.2. This procedure shall be demonstrated to the satisfaction of Authorised Inspector

per T 150, and the reports held on file,

8. | Requirement Paragraph Number in| Remarks

No this procedure

1 | Type or family group of penetrant | 4.3.

2. | Surface Preparation 44

3. | Method of peneirant application | 4.5

4 | Excess penetrant removal 47

5 | Method of applyingdeveloper | 4.9

6 | Minimum and Maximum times | 4.6,49

between steps and drying aids

7 | Decrease in penetrant dwell time | 4.6 Not allowed

8 | Increase in developer dwell time | 4.9.4 Not allowed

9 | Surface temperature outside 10 10 | 4.4.3

52 degrees C

10 | Performance Demonstration 12

11 | Personnel Qualification 42

Requirements

2.0 Reference Documents

2.1 ASME Section V- 2013

2.2 ASME Section VII Div. 1 2013

2.3. ASME/ ANS! B31.1, Power Piping- Edition 2014

Lo’ay Gamaleldeen

Tssue Date

30i2a014

[ Prepared by

NDI Level 11 (184059)

Signature

Page 3 of

i

¢ SOgeC-NDT STANDARD PROCEDURE FOR No : PT-004

3.0

40

LIQUID DYE PENETRANT TESTING Issue: 2

based on ASME Section-V Rev, : 0

2.4 ASME/ ANSI B31.3, Process Piping - Edition 2012

2.5 ASNT SNT-TC-IA, 2011, Recommended Practice for Personne! Qualification

and certification in Nondestructive Testing,

2.6 ASNT CP 189 ~ Edition 2011

2.7 QEA-OI NDI Written Practice of SOGEC Issue 3, Rev. 0

2,8 SAEP 1142—Edition 2014

2.9 SAEP 1145

2.40 ASME SE 1219

2.41 ASME SE 1220

DEFINITIONS

3.1 NDE inspector

A qualified and certified individual who conducts or evaluates the testing as

deseribed in this document, records test results and evaluates the same for

acceptance. He shall be certified (0 at least Level Il per SOGEC Written Practice

QEA 01 complying with CP 189 and with SAEP 1142,

3.2 Area of Interest

The actual test region and adjacent area of width at least 1 inch on cither side of it.

PROCEDURE

4.1 Responsibilities

4A The NDT Level II Inspector assigned for conducting the actual test is

responsible for following this procedure and reporting of test in approved

reporting formats.

42 Personnel Qualification

4.2.1 Personnel conducting the test or recording results shall be qualified and

certified to at least Level I (per SOGEC Written Practice, complying with

CP 189). The Level | operator is required to perform the test and record

Lo’ay Gamateldeen Issue Date 3un2AOLs

NDT Level 111 (184049) Signature | Page 4 of il

Prepared by

¢ SOgeC-NDT STANDARD PROCEDURE FOR No: PT-004

44

LIQUID DYE PENETRANT TESTING Issue: 2

based on ASME Section: Rey 9

test results in accordance with written instructions. He may be permitted to

make specific evaluation in accordance with written instruction. The Level

Toperator shall function under the supervision or direction of an individual

certified to at least Level I or level IIT.

PT level I shall only work under direct supervision of Level I] or Level IIL

4.2.2 Personnel involved in conducting the test recording results and evaluating

the same against applicable acceptance standards shall be certified to at

least Level Il in accordance with SOGEC Written Practice QEA 01,

complying with ANSI CP 189.

Consumables

4.3.1. The test consumables shall be in accordance with the applicable Client's,

specification. In the case of Saudi Aramco material used shall be from the

list provided in Appendix V of SAEP 1145. This procedure calls for the

use of a colour-contrast type solvent-removable dye in combination with a

wet solvent-suspended developer.

4.3.2 ‘The total sulphur, chlorine and fluorine contents of the test consumables

shall be controlled to the requirements specified in ASME Section V.

Batch test certificates of conformity shall kept on file as part of the quality

in the company.

4.3.3. Consumables shall be used in sets purchased from the manufacturer,

Intermixing of brands is not allowed. Manufacturers recommendations

will be followed .Brands approved for use, include.

1, Magnaflux (Spoteheck) and

2. Brent (Ardrox).

Surface Preparation

4.1 The test surface and an area least 25.4 mm (I inch) in width on either side

of the test surface shall be free of dirt, grease, rust, lint, weld spatter and

other extrancous matter which may interfere with the effectiveness of the

test. The Penetrant Remover may be used to finally clean the surface (see

4.3.3 above). Following pre-cleaning, evaporation time of cleaners shall be

5 minutes minimum. Where indications of retained moisture exist, the

evaporation time shall be increased until no evidence of moisture in the

area of test can be detected

Prepared by

Lo’ay Gamaleldeen Tsue Date [__ 31072004

NDT Level IN (184089) Signature Page 5 of u

¢ SOgeC-NDT [STANDARD PROCEDURE FOR |

No : PT-004

LIQUID DYE PENETRANT TESTING Issue: 2

based on ASME Section-V Rey, : 0

44.2 If the surface to be tesied is coated with paint it shall be thoroughly

cleaned off with paint thinner and solvent cleaner to ensure that the test

surface and at least 25.4 mm (1 inch) on either side is exposed for the test.

4.4.3. The temperature of the surfuce shall be between 10 and 52°C. If there is a

condition when the temperature of the test surface is beyond this range,

the effectiveness of the test shall be qualified as per ASME Section V

Article 6, Mandatory Appendix IIT.

4.5 Application of Penetrant

4.5.1. The dye penetrant shall be applied to the test surface to provide a thin

uniform coating over the entire area of interest ease shall be exercised to

ensure the test surface is fiee of cleaner after completion of pre-cleaning

operation before applying the penctrant dye. Following pre-cleaning,

evaporation time of cleaners shall be S minutes minimum. — Where

indications of retained moisture exist, the evaporation time shall be

increased until no evidence of moisture in the area of test can be detected.

4.5.2 Application may be done by means of spraying-on of the dye on the test

surface and area of interest, Alternatively application may be done by

brushing or dipping.

4.6 Dwell Time

4.6.1. A Dwell time of at least 10 minutes for welds and 20 minutes for wrought

produets like plate or forgings shall be permitted to allow for proper

penetration of the dye into the discontinuities sought to be identified.

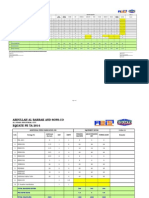

Minimum Dwell Times

Deed Times [ce OT

Mateta fee Hype cco ey

Sjesiany tal tras edlecae, Gangs aad ns Ea coy ef 5

sna tal gh Gonpertne ays aks (2 fess)

Wroogt eatets Usaats 10

leer apes Fe

Gide uppedtats fenedee veld Lxkit faa pocatycrads s

Fase Mies Gate 5

iss A bees Gat 5

Geese a Gat. s

nore

() Fertecpseatre rege fice SOF to 125°F(LOCLOS20) Fer tespertresta 10°F (°C) up $0'F(10"O, exiesepevetact

oil tos dba Deioastbe vdve ted

Prepared by

Lo'ay Gamaleldeen Issue Date SHA2DOLE

NDI Level 111 (184059) Signature Page 6 of i

¢ sogec-np1[- STANDARD PROCEDURE FOR No:PT-004

LIQUID DYE PENETRANT TESTING Issue: 2

based on ASME Section-V Rev. : 0

4.7 Removal of Exeess Penetrant

4.7.1 Affer elapse of the Dwell Time, the excess penetrant shall be removed

from the area of interest. This shall be achieved by means of dry wipes

‘until most traces of penetrant have been removed. The remaining traces of

penetrant shall be removed by wiping with solvent moistened cloth or

absorbent paper. For wet wipes, the cleaner shall not be applied directly to

the test surface.

4.8 — Drying After Excess Penetrant Removal

The surface may be dried by normal evaporation or by blotting, wiping. It is

recommended to wait at Ovo minutes fo ensure that the partis dry.

4.9 Developer Application

4.9.1 Non-Aqueous wet developer shall be used. The developer must be applied

only toa dry surface after drying (paragreph 4.8)

4.9.2 The maximum time between completion of excess dye removal and

application of the developer shall not exceed 15 minutes.

4.9.3 The developer shall be applied by spraying. Application shall aim towards

imparting a thin uniform of developer on the area of interest. Blotches and

drips shall be avoided, Heavy coating of the developer shall be avoided.

4.9.4. Development Time

Development time begins as soon as the wet developer coating is dry. This is

generally indicated by the disappearance of the wet shadow of the solvent carrier.

Development time shall be between 10 minutes and 30 minutes.

4.10 Observation

4.10.1 Development of indication shall be actively observed from the time of

application of the developer. Interpretation and evaluation shall be done

after the development time (see 4.9.4 above). If bleed-out does not alter

the examination results, longer periods are permitted. If the surface to be

examined is large enough to preclude complete examination within the

prescribed or established time, the examination shall be performed in

increments.

4.10.2. A minimum light intensity of 100 foot-candles (1000 Lox) is required on

the surface to be examined.

Lo’ay Gamaleldeen Tesue Date | _s1/i2aoid

Prepared by | Npy Level IN (184089) Signature | Page 7 of i

¢ sopec-NDT STANDARD PROCEDURE FOR No: PT-004

LIQUID DYE PENETRANT TESTING Issue: 2

based on ASME Section-V Rev. : 0

4.10.3 The light used, technique used and the measured light intensity shall be

measured and recorded in the Report form. The measurement shall be

done using a calibrated light meter. In the case of laboratories this may be

demonstrated onc time, documented and maintained on file.

The frequeney of measuring light at laboratory shall be one year.

4.10.4 Any indication which is believed to be non-relevant shall be regarded as

relevant until reexamined to verify whether or not an actual discontinuity

is present. Mechining merks, surface roughness, mechanical conditions

and other surface conditions could cause or produce false indications. If

interpretation of the ind s difficult for any reason, the examination

shall be repeated from the beginning,

441 Reporting

4.11.1 This shall be done on the latest revision of the format appended at the end

of this document. Other formats as may be approved or specified in

Contractual Specification may be used altemative but as a minimum, all

the specified by ASME as required on the report shall appear.

4.12 Post Cleaning

4.12.1. Post cleaning may be achieved by spraying on of cleaner and / or brushing

or wiping with clean cloth.

4.12.2 Water wash method (under pressure) may also be used for this purpose.

50 ACCEPTANCE

SL B313,and BSL

Indications > 1.6 mm (1/16") shall be considered as relevant. The following

relevant indications shall be considered un-acceptable,

1. Linear Indication: Any Crack or linear indication

2, Rounded Indications

Indications with dimensions > 4.8 mm (3/16")

Four or more rounded indication in a line separated by 16 mm (1/16") oF less

edge lo edge.

Prepared by |-E'ay Gamaleldesn Tesue Date | _anaot

spared NDT Level 111 (184089) Signature Page 8 of i

2

No : PT-004

¢ SOBEC-NDT[ STANDARD PROCEDURE FOR

LIQUID DYE PENETRANT TESTING Issu

l based on ASME Section-V Rev. : 0

Ten or more rounded indication in any 3870 mne (6 in?) of surface with the major

dimension of this area not to execed 150 mm (in)

5.2 ASME SEC VIII, Div. 1

Indications > 1.6 mm (1/16") shall be considered as relevant

The following Indications shall be rejectable:

1. Relevant linear indication > 1.6 mm (1/16")

2. Relevant rounded indications > 4.8 mm (3/16")

3. Four or more sounded indications in a line separated by 1.6 mm (1/16") or less

(edge to edge).

A Iinear indication is one in which the major dimension is equal to or exceeds

three times its least dimension. Rounded indications are those which cannot be

categorized as linear indication.

60 REPAIRS

6.1 Repairs in accordance with approval repeir procedure shall be conducted as

necessary.

6.2 After a defect is thought to have been removed, and prior to re-welding the

excavated area shall be examined by suitable methods to ensure that the defect is

completely removed or reduced to an acceptably sized discontinuity.

6.3 After completion of repairs, the repaired region and at least one inch on either end

of the repair region shall be subjected to inspection by the same test methods for

the original un-repaired area.

7.0 RECORDS

7A The NDE Test Reports shall form part of the Final Project Quality

Documentation.

8.0 — Reporting Format

8.1 The format used for reporting testing shall be as attached.

Lo’ay Gamaleldeen [Issue Date ‘MADDON

Prepared by T Np Level M1 (184049) Signature [_Page 9_ of in

¢ SOpeC-NDT STANDARD PROCEDURE FOR No : PT-001

>

LIQUID DYE PENETRANT TESTING Issue: 2

based on ASME Section-V Rev. : 0

iat 0.8 Pea os

LIQUID PENETRANT EXAMINATION REPORT

eet Pape

Pees Tew besten _—__—«______—

‘Coronel Bsningg_———__—_________i¢naticaten Wun,

ve wa Tre Burren wip

mew aut (om) ste Oreo

reeere Rocha Sanday

prtesetives —— Co]ttartranena — CoJwenwunb (J Patnaretie

Cie C)rewneet

Warstateee uration

Ins Liat ters nie Linh teen

Lid Metre Mot

Sbivaten and Sa

Tetra

feu

souanee —— eee

is PT Level Anapactor Chek

(rected B) tepeoved 0)

Kena:

Prepared by [-L2’ay Gamaleldeen Tesue Date [snore

i * NDT Level ILI (184049) Signature Page 10 of on

( SOfeC-NDI STANDARD PROCEDURE FOR No : PT-001

LIQUID DYE PENETRANT TESTING Issue: 2

based on ASME Section-V Rev. : 0

SUMMARY OF CHANGES

‘SUMMARY OF CHANGES - Issue: 2

RevisionNo. | PAGE | PARANUMBER CHANGES

0 All All New Issue

Lo’ay Gamaleldeen TIssueDate | _ai/i0i4

Prepared by

NDT Level IMI (184059) Signature Page II of u

Você também pode gostar

- API Individual Certification Programs: MD RawoofDocumento1 páginaAPI Individual Certification Programs: MD RawoofMohammad RawoofAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Eil-Piping NDT PDFDocumento19 páginasEil-Piping NDT PDFMohammad RawoofAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Musnell Colour SystemDocumento55 páginasMusnell Colour SystemMohammad RawoofAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Astm D2321 (2000) PDFDocumento10 páginasAstm D2321 (2000) PDFMohammad Rawoof100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- ANCC ProfileDocumento35 páginasANCC ProfileMohammad RawoofAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Astm D 2583Documento4 páginasAstm D 2583Mohammad Rawoof100% (4)

- AB4Documento14 páginasAB4Mohammad RawoofAinda não há avaliações

- BHN ProcedureDocumento13 páginasBHN ProcedureMohammad Rawoof100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- A1Documento13 páginasA1Mohammad RawoofAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Boilers - Water Treating 0Documento26 páginasBoilers - Water Treating 0Mohammad RawoofAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Additional FabricationDocumento7 páginasAdditional FabricationMohammad Rawoof100% (1)

- Api 570 - 02 Asme B 31.3Documento12 páginasApi 570 - 02 Asme B 31.3Mohammad RawoofAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Fuel Burner & Firebox Operation & ControlDocumento33 páginasFuel Burner & Firebox Operation & ControlMohammad Rawoof50% (2)

- Boiler Operation & ControlDocumento56 páginasBoiler Operation & ControlMohammad Rawoof100% (2)

- Furnaces - Equipment DescriptionDocumento23 páginasFurnaces - Equipment DescriptionMohammad RawoofAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Vents & Fire Protection System For Storage TanksDocumento24 páginasVents & Fire Protection System For Storage TanksMohammad Rawoof100% (2)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- 8 Inch Flange MTCDocumento8 páginas8 Inch Flange MTCMohammad Rawoof100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- PSV'S Job Completion Certificates: Saudi Kayan TurnaroundDocumento1 páginaPSV'S Job Completion Certificates: Saudi Kayan TurnaroundMohammad RawoofAinda não há avaliações

- TIAC Standards 2005 e PDFDocumento201 páginasTIAC Standards 2005 e PDFMohammad RawoofAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)