Escolar Documentos

Profissional Documentos

Cultura Documentos

Installation: A.E Rre

Enviado por

sopian320Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Installation: A.E Rre

Enviado por

sopian320Direitos autorais:

Formatos disponíveis

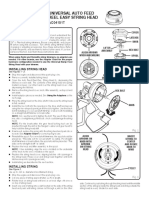

INSTALLATION Gear"abs rry oe cfranged in all reducers within each size

by seecting ttre proper pinion and gear of a common ratio.

Mking helical gear reducers a.e shapped completely A prni:n +yn rre -atic cannot be used with a gear from a

assembled and ready for installatbn exxat ror the addition difierent'aoo Ce.tain'B- and "C" reducers require additional

of lubricant. or dfe-ent parts besides the pinion and gear to make the

ratb crarqe See the chart below for changes required.

1. Fasten the pump secr:rely to the basepate

2. Mount the reducer on the reducer bracket finger tight. Sr7F RAT!O CHANGES REQUIRED

The breather cap should be located on the upper side of E.27 to 1 Snap ring for pinion and shaft

the reducer and drain plug m the bottom. 3 Two spacers ( A larger O.D. than is used

7.65 to

3. Place the coupling hatves trr tte hQh and low speed

1

on other ratios) and gear shaft

reducer shafts. Gear shaft and a longer key. also a snap

C 7.95 to 1

rino

4. Align the low speed shafl cotrplitg !'a'wtth the coupling

li0l=. S|AP RING lS FURNISHED WITH 'C" 7.95 TO 1 PINION AND

half on the pump or driver shafi. Use a straight edge to ss.{trT

align the coupling as in figure 6. A C4amp, clamped

over pieces of keystock. may be used to hold this Vften changing the reducer ratio, the nameplate should

alignment until the rnotrnting b.acket is securely bolted a,so be changed to new ratio reducer part number. After

to the base piate. lt may be necessary to shim the rnaking any output or input speed change (complete reducer

bracket to the extaci center heght of the pump or driven o. Eear ratio changes), a check should be made to ensure

shaft. For additional in'c,-rnabn on coupling alignment. the couplings are of sufficient size for the conditions which

refer to Engineering Se--e B- etin #ESB 61. recrcer will be operating. For ratios availabie see page 1 of

this manual, catalog specification sheet or consult factory or

USE STRAIGHT EDGE THESE S.RFA=.S U-:- 3E PARALLEL Viking representative.

: l-()

iL--1

I ll t

DISASSEMBLY

Before stafllng disassembly, stuoy the expodec view (see

t/ \S:E Fig. 7, 8 or 9) for the particular size reducer that is being

CHECK WIDTH BETWEEN THESE SURFACES WITH 3A- PERS -C BE

{! disassembled to help determine parts relationship. The parts

CERTAIN THE FACES ARE EQUAL DISTANCE APAR- =I,-.1_ =.

are indexed in a logical sequence of disassembly and will

FIGURE 6 prove to be a valuable aid in dismantling the reducer.

COUPLING ALIGNME}T

1. Disconnect the couplings and remove the capscrews

5. Rotate the reducer in the "banana' srots of the cracket holding the mounting bracket to the base. Remove the

until the high speed coupling ha= is at the exact center coupling halves and bracket from the reducer.

height of the motor coupling haf

2. Remove the breather and drain plugs. Drain all lubricant

6. Securely tighten the reduce. to the bracket . from the reducer.

7. Align the high speed shaft coupling and fasten the motor Remove the capscrews from the gear case halves.

securely to base plate. A

1. Tap firmly and alternately on the gear shaft and pinion

CAUTION ! :DO NOT EXCEED RECOMMENDED MAxtMUM shaft. This will separate the reducer halves.

HORSEPOWER, SEE CATALOG SPECIFICATION SHEE7.

With two screwdrivers at opposite sides, carefully pry

DO NOT OPERATE BEFORE ADDING LUBRICANT ^

the reducer cover loose from internal ball bearings. DO

NOf FORCE. Be careful not to damage the gasket or

OPERATION gasket surface.

After the first few hours of operation, inspect redi.rcer for Grasp the pinion and gear shafts and pull both

leaks. If leakage between gear case and cover cannot be assemblies simultaneously from the case or cover.

stopped by tightening of nuts or capscrews, the gasket

should be replaced. Leakage around either shaft indicates a Use a conventional gear or bearing puller to remover the

damaged lip seal which should be replaced. bearing from gear shaft. Remove the bevelled spacer

on "8" and "C" size reducers. Press the shaft from the

The operating temperature on the outside of the reducer gear.

case, after a few hours operation, should not be more than

approximately 750 F higher than surrounding air temperature. Use a puller and remove bearings from the pinion shaft.

The oil within the Reducer should never exceed 200o F. Remove the spacer from "8" size 7.65 to 1 ratio from the

pinion shaft.

Gear Ratios Remove the lip seals from the gear case halves (cover

Four different gear ratios are available for the "A" size and case) only if they show signs of deterioration

v Reducers. Eight ratios are available for "B" size reducers and

seven ratios for "C" size reducers. Complete reducers within

or damage. Lip seals must be pressed or driven out

from the inside of gear case and cover on "B" and "C"

a size may be interchanged on a Viking pump unit to obtain reducers. "A" size reducer may have lip seals pressed in

desired pump speeds and capacities. or out from either side of gear case half.

SECTION TSI\,4 6'10 ISSUE F PAGE 3 OF 8

Você também pode gostar

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementAinda não há avaliações

- Salsbury: Torque ConvertersDocumento19 páginasSalsbury: Torque Convertersvt133primAinda não há avaliações

- Syncro Trak Service ManualDocumento26 páginasSyncro Trak Service ManualMelina SbhAinda não há avaliações

- 1966 Comet Falcon Fairlane Mustang Manual-751-775Documento25 páginas1966 Comet Falcon Fairlane Mustang Manual-751-775shitAinda não há avaliações

- Single Speed Powershift Transmission Hyster H30-60H Repair ManualDocumento39 páginasSingle Speed Powershift Transmission Hyster H30-60H Repair ManualArmando OrtaAinda não há avaliações

- Lovejoy / Sier-Bath: Installation & Alignment InstructionsDocumento2 páginasLovejoy / Sier-Bath: Installation & Alignment Instructionsroyert80Ainda não há avaliações

- A2H Actuator CatalogDocumento6 páginasA2H Actuator CatalogahnafAinda não há avaliações

- Ford Engine Service Manual Fo S Eng 240 PDFDocumento6 páginasFord Engine Service Manual Fo S Eng 240 PDFDhanraj SinghAinda não há avaliações

- Rotating Beam Fatigue Test MachineDocumento13 páginasRotating Beam Fatigue Test MachineReAinda não há avaliações

- Valvula DireccionDocumento8 páginasValvula DireccionVictor Manuel Lozada ObessoAinda não há avaliações

- Parts Replacement Manual For Dodge® Torque-Arm ™: Speed Reducers Straight Bore & Taper BushedDocumento16 páginasParts Replacement Manual For Dodge® Torque-Arm ™: Speed Reducers Straight Bore & Taper BushedRomulo Davila GarciaAinda não há avaliações

- 261.marine Sample Pgs Low PDFDocumento2 páginas261.marine Sample Pgs Low PDFamanda benallyAinda não há avaliações

- Atlas Milling Machine PDFDocumento16 páginasAtlas Milling Machine PDFkkkaaa100% (3)

- VDO Fuel Level Sender - Install. Instruct. (220.003, 220.004, 220.005)Documento2 páginasVDO Fuel Level Sender - Install. Instruct. (220.003, 220.004, 220.005)Anonymous vqsuRyAinda não há avaliações

- 138-110 ManualDocumento16 páginas138-110 Manuall_aguilar_mAinda não há avaliações

- Er 063 2Documento4 páginasEr 063 2ariel.garayAinda não há avaliações

- 2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPDocumento17 páginas2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPPaco Caballero SaorinAinda não há avaliações

- Cummins Jake BrakeDocumento7 páginasCummins Jake BrakerowanAinda não há avaliações

- Main Bearing 'B & W'Documento5 páginasMain Bearing 'B & W'aliakbar tavafiAinda não há avaliações

- 07 1955 CAD-SteeringDocumento9 páginas07 1955 CAD-SteeringLuis Fernando ZampieriAinda não há avaliações

- Transmicion MerconvDocumento8 páginasTransmicion MerconvCesarAinda não há avaliações

- Cabezas de Biela 2Documento3 páginasCabezas de Biela 2Jose RamonAinda não há avaliações

- Actuator R431004010Documento6 páginasActuator R431004010dianAinda não há avaliações

- Scottoiler: Kawasaki ZZR 600: Scottoiler Esystem (The Electronic Scottoiler) Installation GuideDocumento1 páginaScottoiler: Kawasaki ZZR 600: Scottoiler Esystem (The Electronic Scottoiler) Installation GuidejitmarineAinda não há avaliações

- Section T Part 2 3l80 THM 400 t5 To t9-6042 PDFDocumento42 páginasSection T Part 2 3l80 THM 400 t5 To t9-6042 PDFcampollano14Ainda não há avaliações

- Reaction and Friction Units: Classroom Manual Objectives Shop Manual ObjectivesDocumento6 páginasReaction and Friction Units: Classroom Manual Objectives Shop Manual ObjectivesJerico LlovidoAinda não há avaliações

- Scott Bonnar 45 Operating InstructionsDocumento8 páginasScott Bonnar 45 Operating InstructionsnickAinda não há avaliações

- 1955 Seagrave Model 530-BH ManualsDocumento129 páginas1955 Seagrave Model 530-BH Manualsbones333100% (3)

- Logan Lathe Model 922 ManualDocumento16 páginasLogan Lathe Model 922 Manualnjsmith5Ainda não há avaliações

- Lawn-Boy F Series DriveDocumento13 páginasLawn-Boy F Series DrivefogdartAinda não há avaliações

- Manual Qs Rc5Documento1 páginaManual Qs Rc5Director Tecnico AdministrativoAinda não há avaliações

- MI - 5386 - Relays PDFDocumento4 páginasMI - 5386 - Relays PDFSudarshan DhumalAinda não há avaliações

- Universal Auto Feed Reel Easy String Head: WarningDocumento6 páginasUniversal Auto Feed Reel Easy String Head: WarningElena CMAinda não há avaliações

- Mikuni HSR Instructions Dkh1699Documento18 páginasMikuni HSR Instructions Dkh1699BrianCookAinda não há avaliações

- Suspension Mercedes 9Documento1 páginaSuspension Mercedes 9David RoberAinda não há avaliações

- 1953 Lucas Dynamos E3L E3LM E3NDocumento7 páginas1953 Lucas Dynamos E3L E3LM E3NedelapolloAinda não há avaliações

- Instruction Manual: Spring BalancerDocumento7 páginasInstruction Manual: Spring Balancerjaskaran singhAinda não há avaliações

- Bearing Mounting Procedure: (Page 1 of 6)Documento6 páginasBearing Mounting Procedure: (Page 1 of 6)JoséMiguelSánchezGAinda não há avaliações

- PrestoliteStarterAlternatorManual PDFDocumento155 páginasPrestoliteStarterAlternatorManual PDFElzo FreitasAinda não há avaliações

- Pneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionDocumento4 páginasPneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionreliableplacementAinda não há avaliações

- SECTION 4.05: Cylinder Head AssemblyDocumento8 páginasSECTION 4.05: Cylinder Head AssemblyLUISA FERNANDA TORRES MANOSALVAAinda não há avaliações

- Wood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsDocumento4 páginasWood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsPOUETAinda não há avaliações

- Manual - Rotary 3 Speed HubsDocumento2 páginasManual - Rotary 3 Speed Hubsbostin011Ainda não há avaliações

- 90 MM 1Documento6 páginas90 MM 1Pedro PgAinda não há avaliações

- De AnleitungDocumento42 páginasDe AnleitungLucas GabrielAinda não há avaliações

- Sensenich Composite Propeller Installation InstructionsDocumento4 páginasSensenich Composite Propeller Installation InstructionsrobertoAinda não há avaliações

- Yt 1000R 20081Documento2 páginasYt 1000R 20081Ion CimirinschiAinda não há avaliações

- Hosch Opearting Manual1 PDFDocumento13 páginasHosch Opearting Manual1 PDFZahoor AhmedAinda não há avaliações

- ER-63 Fastener Torques For Reciprocating CompressorsDocumento8 páginasER-63 Fastener Torques For Reciprocating CompressorsCarlos A. Mantilla J.Ainda não há avaliações

- Typical Install: InstructionsDocumento9 páginasTypical Install: InstructionsPrzemysław OstałowskiAinda não há avaliações

- WheelHorse Raider 12 Owners Manual 1-6231 - 357Documento12 páginasWheelHorse Raider 12 Owners Manual 1-6231 - 357Kevins Small Engine and Tractor Service50% (4)

- RTL Sleevoil Instruction Manual 499970Documento11 páginasRTL Sleevoil Instruction Manual 499970गुंजन सिन्हाAinda não há avaliações

- Yamaha TDM 850 Scottoiler VSystem English8!8!2012Documento1 páginaYamaha TDM 850 Scottoiler VSystem English8!8!2012kojot-bg2640Ainda não há avaliações

- Bravo Shift AdjustDocumento4 páginasBravo Shift AdjustLucasAinda não há avaliações

- W R H Main Manual PDFDocumento14 páginasW R H Main Manual PDFjaikolangaraparambilAinda não há avaliações

- G631/631 Series Installation and Operation Instruction: Electrohydraulic ServovalveDocumento4 páginasG631/631 Series Installation and Operation Instruction: Electrohydraulic ServovalvenoaservicesAinda não há avaliações

- Atlas 4350 Hacksaw ManualDocumento6 páginasAtlas 4350 Hacksaw Manualf4d711Ainda não há avaliações

- Bottom End Bearing 'B & W'Documento4 páginasBottom End Bearing 'B & W'aliakbar tavafiAinda não há avaliações

- MN3085 - 0222 (W)Documento12 páginasMN3085 - 0222 (W)mariamalloney1730Ainda não há avaliações

- Mounting Adjusting Pump UnitDocumento2 páginasMounting Adjusting Pump UnitRalf JonesAinda não há avaliações

- Swire Mini Containers Spec SheetDocumento2 páginasSwire Mini Containers Spec Sheetsopian320Ainda não há avaliações

- Burner CalculationDocumento29 páginasBurner Calculationjoshuadelapava50% (2)

- Pre-Commissioning Hot Water BoilersDocumento2 páginasPre-Commissioning Hot Water Boilerssopian320100% (1)

- Sample - Belt Bucket Elevator DesignDocumento7 páginasSample - Belt Bucket Elevator Designmfhasnain100% (1)

- Design - B16.34, OS&Y, BB, THD Per B1.20.1, SW Per B16.11, Flex Wedge, Body Materials - ASTM A351, A494, A890, A990, Others Upon RequestDocumento1 páginaDesign - B16.34, OS&Y, BB, THD Per B1.20.1, SW Per B16.11, Flex Wedge, Body Materials - ASTM A351, A494, A890, A990, Others Upon Requestsopian320Ainda não há avaliações

- Rotary Kilns For Cement PlantsDocumento6 páginasRotary Kilns For Cement PlantsAngshuman Dutta100% (3)

- Design - B16.34, OS&Y, BB, THD Per B1.20.1, SW Per B16.11, Flex Wedge, Body Materials - ASTM A351, A494, A890, A990, Others Upon RequestDocumento1 páginaDesign - B16.34, OS&Y, BB, THD Per B1.20.1, SW Per B16.11, Flex Wedge, Body Materials - ASTM A351, A494, A890, A990, Others Upon Requestsopian320Ainda não há avaliações

- Bobco Catalog New PDFDocumento188 páginasBobco Catalog New PDFsopian320Ainda não há avaliações

- AUCBMPRESENTATIONMarrakish Nov 2014Documento29 páginasAUCBMPRESENTATIONMarrakish Nov 2014sopian320100% (1)

- Tool and Material List-Girth Gear InstallDocumento2 páginasTool and Material List-Girth Gear InstallPeter RoseAinda não há avaliações

- How-Use-Conco-English (System Conco) PDFDocumento4 páginasHow-Use-Conco-English (System Conco) PDFsopian320Ainda não há avaliações

- Net Positive Suction Head Required by Viking PumpsDocumento1 páginaNet Positive Suction Head Required by Viking Pumpssopian320Ainda não há avaliações

- Cleaning Technology For Heat Exchangers PDFDocumento9 páginasCleaning Technology For Heat Exchangers PDFsopian320Ainda não há avaliações

- Learning Guide: Central Texas College Department of NursingDocumento26 páginasLearning Guide: Central Texas College Department of Nursingapi-3697326Ainda não há avaliações

- EclipseDocumento6 páginasEclipsetoncipAinda não há avaliações

- Bahir Dar NDP UDP - Final ReportDocumento188 páginasBahir Dar NDP UDP - Final ReportWorkuMamo100% (1)

- Power Stations Using Locally Available Energy Sources: Lucien Y. Bronicki EditorDocumento524 páginasPower Stations Using Locally Available Energy Sources: Lucien Y. Bronicki EditorAmat sapriAinda não há avaliações

- 8 Field Quality PlanDocumento18 páginas8 Field Quality PlanRamaKrishna AAinda não há avaliações

- Conversion Tables by Cafe Fernando Food BlogDocumento5 páginasConversion Tables by Cafe Fernando Food BlogElston FooAinda não há avaliações

- AD&D - Forgotten Realms - Menzoberranzan - EXTRAS - House Do'Urden RestrospectiveDocumento16 páginasAD&D - Forgotten Realms - Menzoberranzan - EXTRAS - House Do'Urden RestrospectiveThiago RaulinoAinda não há avaliações

- Agricultural Extension and CommunicationDocumento173 páginasAgricultural Extension and CommunicationAlfredo Conde100% (1)

- Paper 2 Phy 2019-2023Documento466 páginasPaper 2 Phy 2019-2023Rocco IbhAinda não há avaliações

- Omyacarb 1t TNDocumento1 páginaOmyacarb 1t TNGİZEM DEMİRAinda não há avaliações

- Soal Pat Bahasa Inggris Kelas 5Documento5 páginasSoal Pat Bahasa Inggris Kelas 5Tini Bastuti Joyolaksono100% (1)

- Driver DST-4812 For 7.2 KG CMDocumento5 páginasDriver DST-4812 For 7.2 KG CMWWW.150775.BUGME.PWAinda não há avaliações

- Electrical BOQ 07.12.2021 New Boq R4 05-01-2022 Final 16.02.2022Documento92 páginasElectrical BOQ 07.12.2021 New Boq R4 05-01-2022 Final 16.02.2022Upendra ChariAinda não há avaliações

- GEHC Service Manual CARESCAPE Monitor B850 v1 2011Documento172 páginasGEHC Service Manual CARESCAPE Monitor B850 v1 2011NguyễnCảnhBắcAinda não há avaliações

- Chapter 3 Deflection of Beams - Conjugate Beam MethodDocumento6 páginasChapter 3 Deflection of Beams - Conjugate Beam MethodMbali MagagulaAinda não há avaliações

- AT2H - Basics - Symbolism in HinduismDocumento28 páginasAT2H - Basics - Symbolism in Hinduismapi-3764210Ainda não há avaliações

- Servo Controlled FBW With Power Boost Control, Operations & Maint. ManualDocumento126 páginasServo Controlled FBW With Power Boost Control, Operations & Maint. ManualKota NatarajanAinda não há avaliações

- HorticultureDocumento168 páginasHorticultureagni sahanaAinda não há avaliações

- Linear Predictor: Nature of Linear PredictionDocumento9 páginasLinear Predictor: Nature of Linear PredictionkvAinda não há avaliações

- DattadasDocumento4 páginasDattadasJéssica NatáliaAinda não há avaliações

- LH514 - OkokDocumento6 páginasLH514 - OkokVictor Yañez Sepulveda100% (1)

- 300.91C - Fire Alarm System Pre-Test and Acceptance Test Checklist 3-27-14Documento2 páginas300.91C - Fire Alarm System Pre-Test and Acceptance Test Checklist 3-27-14mthuyaAinda não há avaliações

- Obs Inf Worksheet 2013Documento2 páginasObs Inf Worksheet 2013api-338002331Ainda não há avaliações

- 8Documento3 páginas8Anirban Dasgupta100% (1)

- Course For Loco Inspector Initial (Diesel)Documento239 páginasCourse For Loco Inspector Initial (Diesel)Hanuma Reddy93% (14)

- Rolling Bearings VRMDocumento2 páginasRolling Bearings VRMRollerJonnyAinda não há avaliações

- Modeling The Dynamic and Static Behavior of Chemical ProcessesDocumento4 páginasModeling The Dynamic and Static Behavior of Chemical ProcessesFatma CahyaniAinda não há avaliações

- List of Irc Publications Referred To in The Specifications: AppendicesDocumento17 páginasList of Irc Publications Referred To in The Specifications: AppendicesPrasad BoniAinda não há avaliações

- Iare Ece Aec012 DSP QB 0Documento20 páginasIare Ece Aec012 DSP QB 0projects allAinda não há avaliações

- 32lh250h Commercial Mode PDFDocumento46 páginas32lh250h Commercial Mode PDFcordero medusaAinda não há avaliações

- To Engineer Is Human: The Role of Failure in Successful DesignNo EverandTo Engineer Is Human: The Role of Failure in Successful DesignNota: 4 de 5 estrelas4/5 (138)

- Piping Engineering Leadership for Process Plant ProjectsNo EverandPiping Engineering Leadership for Process Plant ProjectsNota: 5 de 5 estrelas5/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresNo EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresNota: 1 de 5 estrelas1/5 (2)

- Well Control for Completions and InterventionsNo EverandWell Control for Completions and InterventionsNota: 4 de 5 estrelas4/5 (10)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsNo EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsNota: 4 de 5 estrelas4/5 (16)

- Asset Integrity Management for Offshore and Onshore StructuresNo EverandAsset Integrity Management for Offshore and Onshore StructuresAinda não há avaliações

- Advanced Production Decline Analysis and ApplicationNo EverandAdvanced Production Decline Analysis and ApplicationNota: 3.5 de 5 estrelas3.5/5 (4)

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsNo EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsAinda não há avaliações

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesNo EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesNota: 4.5 de 5 estrelas4.5/5 (13)

- Flow Analysis for Hydrocarbon Pipeline EngineeringNo EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAinda não há avaliações

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideNo EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideNota: 2 de 5 estrelas2/5 (1)

- Structural Cross Sections: Analysis and DesignNo EverandStructural Cross Sections: Analysis and DesignNota: 4.5 de 5 estrelas4.5/5 (19)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsAinda não há avaliações

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingNo EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingAinda não há avaliações

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesNo EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesNota: 4 de 5 estrelas4/5 (2)

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsNo EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsAinda não há avaliações