Escolar Documentos

Profissional Documentos

Cultura Documentos

Fabrication of Air Brake System Using Exhaust Gas

Enviado por

Roopesh ReddyDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Fabrication of Air Brake System Using Exhaust Gas

Enviado por

Roopesh ReddyDireitos autorais:

Formatos disponíveis

FABRICATION OF AIR BRAKE SYSTEM USING ENGINE

EXHAUST GAS

SYNOPSIS

The aim is to design and develop a brake system based on exhaust gas is called AIR BRAKE

SYSTEM USING ENGINE EXHAUST GAS. The main aim of this project is to reduce the

work loads of the engine drive to operate the air compressor. In this project, we used exhaust gas

from the engine to rotate the generator turbine. Then the power is loaded to the D.C compressor

and it is used to the pneumatic cylinder to apply brake.

INTRODUCTION

This is an era of automation where it is broadly defined as replacement of manual effort by

mechanical power in all degrees of automation. The operation remains an essential part of the

system although with changing demands on physical input as the degree of mechanization is

increased.

Degrees of automation are of two types, viz.

Full automation.

Semi automation.

In semi automation a combination of manual effort and mechanical power is required whereas in

full automation human participation is very negligible.

At work as usual: 080-40969981 | Write to me: info@technofist.com, technofistprojects@gmail.com

|when u needs me the most: +91-9008001602, 080-40969981| On the

Web:www.technofist.com , www.itcdp.in

NEED FOR AUTOMATION:

Automation can be achieved through computers, hydraulics, pneumatics, robotics, etc., of these

sources, pneumatics form an attractive medium for low cost automation. The main advantages of

all pneumatic systems are economy and simplicity. Automation plays an important role in mass

production.

For mass production of the product, the machining operations decide the sequence of machining.

The machines designed for producing a particular product are called transfer machines. The

components must be moved automatically from the bins to various machines sequentially and the

final component can be placed separately for packaging. Materials can also be repeatedly

transferred from the moving conveyors to the work place and vice versa.

Nowadays almost all the manufacturing process is being atomized in order to deliver the

products at a faster rate. The manufacturing operation is being atomized for the following

reasons.

To achieve mass production

To increase the efficiency of the plant

To reduce the work load

To reduce the production cost

To reduce the production time

To reduce the material handling

To reduce the fatigue of workers

To achieve good product quality

Less Maintenance

At work as usual: 080-40969981 | Write to me: info@technofist.com, technofistprojects@gmail.com

|when u needs me the most: +91-9008001602, 080-40969981| On the

Web:www.technofist.com , www.itcdp.in

ADVANTAGES

1. It reduces the battery power

2. It increases the engine efficiency

3. It occupies less floor space

4. It reduces the air pollution

DISADVANTAGES

1. Initial cost is high

2. Need a separate compressor

3. Maintenance cost is high

APPLICATIONS

1. For automobile application

2. Industrial application

At work as usual: 080-40969981 | Write to me: info@technofist.com, technofistprojects@gmail.com

|when u needs me the most: +91-9008001602, 080-40969981| On the

Web:www.technofist.com , www.itcdp.in

At work as usual: 080-40969981 | Write

to me: info@technofist.com, technofistprojects@gmail.com |when u needs me the most: +91-9008001602, 080-40969981| On the

Web:www.technofist.com , www.itcdp.in

Você também pode gostar

- Introduction To M365 PresentationDocumento50 páginasIntroduction To M365 Presentationlasidoh0% (1)

- Air Brake System Using Exhaust GasDocumento5 páginasAir Brake System Using Exhaust GasAAinda não há avaliações

- Design and Fabrication of Pneumatic Can Crusher: Prepared byDocumento10 páginasDesign and Fabrication of Pneumatic Can Crusher: Prepared byDe SaravananAinda não há avaliações

- Pneumatic Auto Feed Sheet Cutting MachineDocumento5 páginasPneumatic Auto Feed Sheet Cutting MachineVigneshwaran Srinivasan100% (1)

- Automatic Pneumatic High Speed Sheet Cutting MachineDocumento3 páginasAutomatic Pneumatic High Speed Sheet Cutting Machineieee4mybusinessonly100% (1)

- Automatic Punching ConveyorDocumento5 páginasAutomatic Punching ConveyorMusthafa KadershaAinda não há avaliações

- Design and Fabrication of Pneumatic AutoDocumento17 páginasDesign and Fabrication of Pneumatic AutoDevarathAinda não há avaliações

- Automatic Power Saving ConveyorDocumento3 páginasAutomatic Power Saving Conveyorieee4mybusinessonly100% (1)

- Ctp016 Conveyor AutomationDocumento4 páginasCtp016 Conveyor AutomationANAND KRISHNANAinda não há avaliações

- Fabrication of Pneumatic Grinding MachineDocumento2 páginasFabrication of Pneumatic Grinding Machineieee4mybusinessonlyAinda não há avaliações

- 2.auto Indexing Drilling MachineDocumento7 páginas2.auto Indexing Drilling Machinesasitharan33Ainda não há avaliações

- Fabrication of Pneumatic Auto Feed Drilling MachineDocumento46 páginasFabrication of Pneumatic Auto Feed Drilling MachineDinesh Kumar100% (2)

- Internship ReportDocumento44 páginasInternship ReportPrajwal M AAinda não há avaliações

- Excavator PC210 8Documento24 páginasExcavator PC210 8Bálint Géza100% (2)

- Automatic Power Saving ConveyorDocumento3 páginasAutomatic Power Saving ConveyorPraveen KrishnaAinda não há avaliações

- A Project Report2Documento46 páginasA Project Report2Hemant RanaAinda não há avaliações

- 6 CNC Theory - GeneralDocumento20 páginas6 CNC Theory - GeneralManojAnandAinda não há avaliações

- Design and Development of Pneumatic Punching MachineDocumento5 páginasDesign and Development of Pneumatic Punching MachineSandeep MariAinda não há avaliações

- Fabrication of Pneumatic Fork LiftDocumento3 páginasFabrication of Pneumatic Fork Liftieee4mybusinessonly0% (1)

- IJERTV6IS120029Documento9 páginasIJERTV6IS120029RagavgloryfireAinda não há avaliações

- Pneumatic Slotting MachineDocumento5 páginasPneumatic Slotting MachinePaulAinda não há avaliações

- Jurnal MemeDocumento10 páginasJurnal MemeMamik Kumala SuwarnoAinda não há avaliações

- Latest 2017-2018 Mechanical Project List PDFDocumento19 páginasLatest 2017-2018 Mechanical Project List PDFVishwas ShettyAinda não há avaliações

- Automatic Sheet Metal Feeding and Cutting MachineDocumento5 páginasAutomatic Sheet Metal Feeding and Cutting MachineNivedhan GandhiAinda não há avaliações

- The Mid Way ReportDocumento15 páginasThe Mid Way ReportPreet ParmarAinda não há avaliações

- Automatic Musical Water FoundationDocumento4 páginasAutomatic Musical Water Foundationieee4mybusinessonlyAinda não há avaliações

- Ecway Technologies: Automatic Pneumatic Clutch and Braking System SynopsisDocumento5 páginasEcway Technologies: Automatic Pneumatic Clutch and Braking System SynopsisShankar GAinda não há avaliações

- Conveyor Operated RobotDocumento6 páginasConveyor Operated RobotIyappanAinda não há avaliações

- Gear Hobbing Dry Vs Wet Hobbing Manufacturing ProcessDocumento1 páginaGear Hobbing Dry Vs Wet Hobbing Manufacturing ProcessDhruv SutharAinda não há avaliações

- PC210 8M0Documento8 páginasPC210 8M0Vamshidhar Reddy KundurAinda não há avaliações

- Sensor Based Inspection ConveyorDocumento6 páginasSensor Based Inspection ConveyorPushpa Mohan RajAinda não há avaliações

- Pneumatic Slotting MachineDocumento4 páginasPneumatic Slotting MachinePatel NikhilAinda não há avaliações

- Pneumatic Auto Feed Drilling MachineDocumento4 páginasPneumatic Auto Feed Drilling MachineManiSubraManiAinda não há avaliações

- Pneumatic Mobile CraneDocumento21 páginasPneumatic Mobile CraneMayilai AshokAinda não há avaliações

- Microproject Microproject: Title of The Project Prepare Report On Autonomous RobotDocumento22 páginasMicroproject Microproject: Title of The Project Prepare Report On Autonomous RobotAkash MarkhaleAinda não há avaliações

- Automation FileDocumento56 páginasAutomation FileLoveable ShubhamAinda não há avaliações

- Seminar On Frictionless Compressor Technology - Mechanical Seminar Topic - Mechanical Engineering World - Project Ideas - Seminar Topics - E-Books (PDF) - New TrendsDocumento4 páginasSeminar On Frictionless Compressor Technology - Mechanical Seminar Topic - Mechanical Engineering World - Project Ideas - Seminar Topics - E-Books (PDF) - New TrendsMohammedKashifAinda não há avaliações

- Stampingmachine Published2017 PDFDocumento9 páginasStampingmachine Published2017 PDFSiddhasen PatilAinda não há avaliações

- Automatic Electro-Motorised JackDocumento7 páginasAutomatic Electro-Motorised JackMectrosoft Creative technologyAinda não há avaliações

- Energy Saving in Flour MillingDocumento4 páginasEnergy Saving in Flour MillingMilling and Grain magazine100% (1)

- Project Report On Industrial AutomationDocumento15 páginasProject Report On Industrial AutomationAtul KirtiAinda não há avaliações

- Course Material On CNC Turning and CNC MillingDocumento108 páginasCourse Material On CNC Turning and CNC MillingirinabesliuAinda não há avaliações

- 174-Article Text-315-1-10-20180122Documento6 páginas174-Article Text-315-1-10-20180122Thomas TamangAinda não há avaliações

- Latest Pneumatics and Hydraulics Based Projects PDFDocumento8 páginasLatest Pneumatics and Hydraulics Based Projects PDFMahe dude0% (1)

- Introduction of AutomationDocumento33 páginasIntroduction of AutomationDivya s SubramanyaAinda não há avaliações

- Design & Fabrication of Pneumatic Forging MachineDocumento39 páginasDesign & Fabrication of Pneumatic Forging MachineDinesh KumarAinda não há avaliações

- Project FileDocumento13 páginasProject FileAnasAhmedAinda não há avaliações

- Jurnal Bubut InternasionalDocumento6 páginasJurnal Bubut InternasionalrawitrahmatAinda não há avaliações

- Design and Fabrication Project: Fabrication of Pneumatic Vice With JackDocumento18 páginasDesign and Fabrication Project: Fabrication of Pneumatic Vice With JackTamil SelvanAinda não há avaliações

- Recent Development of Modern Spinning and WeavingDocumento20 páginasRecent Development of Modern Spinning and WeavingsuganAinda não há avaliações

- ASSIGNMENT in Control Eng'g. & LabDocumento5 páginasASSIGNMENT in Control Eng'g. & LabDECIPOLO, KENNETH JOHN E.Ainda não há avaliações

- Fabrication of Pneumatic Jack in Commerical VehicleDocumento28 páginasFabrication of Pneumatic Jack in Commerical VehicleSURESHAinda não há avaliações

- Seminar ReportDocumento31 páginasSeminar ReportAkku NandhuAinda não há avaliações

- Electromagnetic Embossing MachineDocumento12 páginasElectromagnetic Embossing Machinesubramanya1982Ainda não há avaliações

- D. Y. Patil College of Engineering & Technology, KolhapurDocumento62 páginasD. Y. Patil College of Engineering & Technology, KolhapurTushar KhorateAinda não há avaliações

- Thesis Oil PumpDocumento4 páginasThesis Oil PumpHelpWithWritingPapersUK100% (2)

- Fabrication of Pneumatic Auto Feed Drilling MachineDocumento37 páginasFabrication of Pneumatic Auto Feed Drilling Machinegnana muruganAinda não há avaliações

- Chapter - 1 1.1 PunchingDocumento53 páginasChapter - 1 1.1 PunchingKkkkAinda não há avaliações

- Himson Engg Training ReportDocumento27 páginasHimson Engg Training ReportrahulkumarmehtaAinda não há avaliações

- Basic Fundamentals of CNC Machine OperationDocumento20 páginasBasic Fundamentals of CNC Machine Operationnandusp1Ainda não há avaliações

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusNo EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusAinda não há avaliações

- Fundamentals of Paid AdvertisingDocumento36 páginasFundamentals of Paid AdvertisingRoopesh ReddyAinda não há avaliações

- French Assignment 2-Chadive Roopesh ReddyDocumento5 páginasFrench Assignment 2-Chadive Roopesh ReddyRoopesh ReddyAinda não há avaliações

- Moneycontrol 22Documento3 páginasMoneycontrol 22Roopesh ReddyAinda não há avaliações

- The Non-Obvious Takeaways From Zomato's IPO Prospectus: Sumanth RaghavendraDocumento11 páginasThe Non-Obvious Takeaways From Zomato's IPO Prospectus: Sumanth RaghavendraRoopesh ReddyAinda não há avaliações

- Lean Canvas: Problem Solution Unique Value Proposition Unfair Advantage Customer SegmentsDocumento1 páginaLean Canvas: Problem Solution Unique Value Proposition Unfair Advantage Customer SegmentsRoopesh ReddyAinda não há avaliações

- Digital Marketing Ads Campaign Report Group 8Documento17 páginasDigital Marketing Ads Campaign Report Group 8Roopesh ReddyAinda não há avaliações

- Grpahs MatterDocumento9 páginasGrpahs MatterRoopesh ReddyAinda não há avaliações

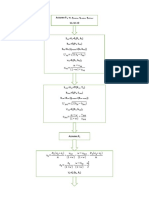

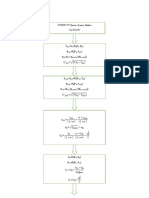

- Assume P, W, Ƞ, Ƞ, Ƞ U U 0: 5 Motive Suction DiffuserDocumento3 páginasAssume P, W, Ƞ, Ƞ, Ƞ U U 0: 5 Motive Suction DiffuserRoopesh ReddyAinda não há avaliações

- CNSNT PressureDocumento2 páginasCNSNT PressureRoopesh ReddyAinda não há avaliações

- CNSNT PressureDocumento2 páginasCNSNT PressureRoopesh ReddyAinda não há avaliações

- Internship FormDocumento2 páginasInternship FormRoopesh ReddyAinda não há avaliações

- Roopesh CVDocumento2 páginasRoopesh CVRoopesh Reddy100% (1)

- McMaster CarrDocumento30 páginasMcMaster CarrRoopesh ReddyAinda não há avaliações

- TRICARE Behavioral Health Care ServicesDocumento4 páginasTRICARE Behavioral Health Care ServicesMatthew X. HauserAinda não há avaliações

- Timetable - Alton - London Timetable May 2019 PDFDocumento35 páginasTimetable - Alton - London Timetable May 2019 PDFNicholas TuanAinda não há avaliações

- Ymrtc LogDocumento26 páginasYmrtc LogVinicius Silveira0% (1)

- Monitor Stryker 26 PLGDocumento28 páginasMonitor Stryker 26 PLGBrandon MendozaAinda não há avaliações

- Asim Kumar Manna - Business Mathematics and Statistics (2018, McGraw-Hill Education)Documento624 páginasAsim Kumar Manna - Business Mathematics and Statistics (2018, McGraw-Hill Education)rerr50% (2)

- 100 20210811 ICOPH 2021 Abstract BookDocumento186 páginas100 20210811 ICOPH 2021 Abstract Bookwafiq alibabaAinda não há avaliações

- 1 - Laminar and Turbulent Flow - MITWPU - HP - CDK PDFDocumento13 páginas1 - Laminar and Turbulent Flow - MITWPU - HP - CDK PDFAbhishek ChauhanAinda não há avaliações

- Ebops PDFDocumento2 páginasEbops PDFtuan nguyen duyAinda não há avaliações

- Taylor Et Al v. Acxiom Corporation Et Al - Document No. 91Documento40 páginasTaylor Et Al v. Acxiom Corporation Et Al - Document No. 91Justia.comAinda não há avaliações

- 1996 OKI LCD Driver Controller DatabookDocumento232 páginas1996 OKI LCD Driver Controller Databookpiptendo100% (1)

- LKG Math Question Paper: 1. Count and Write The Number in The BoxDocumento6 páginasLKG Math Question Paper: 1. Count and Write The Number in The BoxKunal Naidu60% (5)

- Health and Safety For The Meat Industry: Guidance NotesDocumento198 páginasHealth and Safety For The Meat Industry: Guidance NotesPredrag AndjelkovicAinda não há avaliações

- Buss40004 - Balance of PowerDocumento3 páginasBuss40004 - Balance of PowerVishwa NirmalaAinda não há avaliações

- LDSD GodseDocumento24 páginasLDSD GodseKiranmai SrinivasuluAinda não há avaliações

- Baxter - Heraeus Megafuge 1,2 - User ManualDocumento13 páginasBaxter - Heraeus Megafuge 1,2 - User ManualMarcos ZanelliAinda não há avaliações

- Resume NetezaDocumento5 páginasResume Netezahi4149Ainda não há avaliações

- Holiday AssignmentDocumento18 páginasHoliday AssignmentAadhitya PranavAinda não há avaliações

- Schneider Contactors DatasheetDocumento130 páginasSchneider Contactors DatasheetVishal JainAinda não há avaliações

- Settlement Report - 14feb17Documento10 páginasSettlement Report - 14feb17Abdul SalamAinda não há avaliações

- Conveyor Control Using Programmable Logic ControllerDocumento7 páginasConveyor Control Using Programmable Logic ControllerWann RexroAinda não há avaliações

- Topic Group Present (Week 8) Chapter 1:sociology and Learning ManagementDocumento2 páginasTopic Group Present (Week 8) Chapter 1:sociology and Learning ManagementLEE LEE LAUAinda não há avaliações

- Process Strategy: Powerpoint Slides by Jeff HeylDocumento13 páginasProcess Strategy: Powerpoint Slides by Jeff HeylMuizzAinda não há avaliações

- LicencesDocumento5 páginasLicencesstopnaggingmeAinda não há avaliações

- Specialty Coffee Association of Indonesia Cupping Form (ARABICA)Documento1 páginaSpecialty Coffee Association of Indonesia Cupping Form (ARABICA)Saiffullah RaisAinda não há avaliações

- Clash of Clans Hack Activation CodeDocumento2 páginasClash of Clans Hack Activation Codegrumpysadness7626Ainda não há avaliações

- Zahid Imran CVDocumento4 páginasZahid Imran CVDhia Hadj SassiAinda não há avaliações

- Unit 4Documento15 páginasUnit 4David Lopez LaraAinda não há avaliações

- The Grass Rink Summer Final 2019Documento9 páginasThe Grass Rink Summer Final 2019api-241553699Ainda não há avaliações

- TW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Documento3 páginasTW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Anonymous edvYngAinda não há avaliações