Escolar Documentos

Profissional Documentos

Cultura Documentos

12-01-16-Bump Integrator PDF

Enviado por

ashoknrTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

12-01-16-Bump Integrator PDF

Enviado por

ashoknrDireitos autorais:

Formatos disponíveis

For further informa on on the

ROMDAS road measurement system

please visit www.romdas.com

Email: info@romdas.com

Phone: + 64.9.87.7703

Bump Integrator

Fax: +64.9.87.7704

ROMDAS Overview

ROMDAS

Manufactured by ROMDAS (ROad Measurement Data Acquisi on System) has been developed by

Data Collec on Ltd. Data Collec on Ltd. (DCL) as a low cost modular system designed to collect road

New Zealand

and pavement data using any vehicle. ROMDAS oers great flexibility by allowing

providers of innova ve technology for users to add or remove modules depending on their specific data collec on

measuring and managing roads needs. Over the last several decades ROMDAS has been a leader of integra ng

new data collec on technology and

with over 200 units in use in over 60

countries, ROMDAS has a level of

refinement rarely found in compe ng

systems.

ROMDAS can be used for the

following:

Roughness surveys;

Transverse profile/ru ng

surveys;

Collec ng surface texture data

(MPD or SMTD)

Condi on ra ng surveys;

Loca on Referencing (spa al

GPS/GNSS data or linear LRP

data)

Video logging surveys (rightof

way and pavement view);

Road geometry surveys;

Automated crack detec on and

3D pavement modelling;

Travel me and conges on

surveys;

Inventory and asset surveys;

Recording loca ons with digital

photographs;

The DCL team has a wealth of

knowledge and experience available

to new users for customising systems

to meet specific needs and providing

ongoing technical support and

advice to exis ng users.

For further informa on on the

ROMDAS road measurement system

please visit www.romdas.com

Email: info@romdas.com

Phone: + 64.9.87.7703

Bump Integrator

Fax: +64.9.87.7704

Overview

ROMDAS

Manufactured by The ROMDAS Bump Integrator (BI) for measuring road roughness is a response

Data Collec on Ltd. type roughness meter. This is a mechanical instrument that measures the

New Zealand rela ve displacement of a vehicle's suspension in rela on to the body of the

vehicle. The concept behind Bump Integrator technology has long been

providers of innova ve technology for

measuring and managing roads established and proven worldwide. The BI readings are used to analyze the

linear profile and calculate the 'roughness' of a road's surface. Depending upon

2011 Data Collec on Ltd. the type of vehicle that the BI will be fi ed to either one or two BI's may be

used.

The raw roughness data from the BI can be recorded directly using either the

The ROMDAS system on a notebook computer or the miniROMDAS system

on a Pocket PC.

The raw roughness data can be converted into a calibrated roughness index

such as IRI using usersupplied roughness equa ons (which are determined

during roughness calibra on). A well calibrated Bump Integrator will easily rival

or exceed the accuracy of other Class 3 roughness profilers, including

accelerometer based equipment.

A ROMDAS system with Bump Integrator requires li letono operator

interac on during surveys and all readings are shown in real me on the survey

computer.

The Bump Integrator excels in rough, unpaved or wet condi ons where laser

based profiling equipment is unusable and thanks to its low minimum speed

(10km/h) it can also be operated areas of high conges on unlike accelerometer

based equipment.

Features and Benefits

FeaturesoftheBIinclude:

High resolu on, high reliability op cal encoder;

Designed for use in some of the most extreme and

rugged road condi ons;

Low minimum opera ng speed (10km/h);

Very low cost compared to vehicle mounted

accelerometer based equipment.

Simple design allows for quick and easy installa on

and full serviceability in the field.

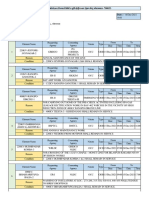

ROMDAS Survey Screen with Bump Integrator Module

For further informa on on the

ROMDAS road measurement system

please visit www.romdas.com

Email: info@romdas.com

Phone: + 64.9.87.7703

Bump Integrator

Fax: +64.9.87.7704

ROMDAS Installation

Manufactured by

Data Collec on Ltd. The BI is installed at the rear of the vehicle, above the rear suspension. The

New Zealand instrument is mounted on the floor of the vehicle and a cable is connected

to the suspension.

providers of innova ve technology for

measuring and managing roads There are three possible configura ons for installing the BI in a vehicle:

2011 Data Collec on Ltd. 1Solidrearaxle:

If the vehicle has a solid rear axle the BI should be installed over the centre

of the dieren al. This will measure what is termed a 'HalfCar' roughness

reading.

2Independentrearsuspension:

This installa on method u lises two BI units. If the vehicle has an

independent rear suspension it is recommended that two BI units be

installed; one for each wheel path. Each of these will measure a 'Quarter

Car' and the average of these two readings will give the overall roughness.

3Independentrearsuspension:

This installa on method u lises one BI unit. The use of one BI unit with an

independent rear suspension is possible, but not recommended. This is

because the vehicle will s ll measure a 'QuarterCar' reading but the

roughness measurements will be dominated by the roughness in a single

wheel path. It does not ma er which one is being monitored as it will prove

dicult to get a good calibra on of the meter because the roughness will

vary between wheel paths and test sec ons.

All moun ng accessories are supplied for ease of installa on.

Components

The BI kit comes complete with the

following components:

1 x Bump Integrator;

1 x base plate and cover;

1 x BI hook;

1 x BI wire (spare);

1 x BI spring (spare);

Technical Specifications

Encoderresolu on: 850 pulse per revolu on

Ver calresolu on: 1 pulse per 0.25 mm of suspension up movement

Weight: 2.5 kg

BIwirebreakingstrain: 95 kg

Você também pode gostar

- Biomediacal Waste Project FinalDocumento43 páginasBiomediacal Waste Project Finalashoknr100% (1)

- Alternator Technical Specification - ADocumento16 páginasAlternator Technical Specification - AMd.Jahangir alamAinda não há avaliações

- Direct Georeferencing 3D Points Cloud Map Based On SLAM and Robot Operating SystemDocumento5 páginasDirect Georeferencing 3D Points Cloud Map Based On SLAM and Robot Operating SystemFraj HarizAinda não há avaliações

- UML DIAGRAMS For Hospital ManagementDocumento8 páginasUML DIAGRAMS For Hospital ManagementDeepak M Krishna100% (4)

- 19-10-15 ROMDAS Video Logging PDFDocumento4 páginas19-10-15 ROMDAS Video Logging PDFSupriyo PAinda não há avaliações

- Chapter 1 ENT530Documento23 páginasChapter 1 ENT530MUHAMMAD KHAIROL BIN BINTAJOLAinda não há avaliações

- Swot Analysis Development of Batik BantulDocumento15 páginasSwot Analysis Development of Batik Bantulben besinAinda não há avaliações

- Roadroid Quick Start - Ver 1.2.1 Nov 13Documento6 páginasRoadroid Quick Start - Ver 1.2.1 Nov 133pivopijeAinda não há avaliações

- Apply Quality StandardsDocumento71 páginasApply Quality StandardsDavid PolaoAinda não há avaliações

- Cycle ProjekDocumento10 páginasCycle ProjekTyla Tylala ReginaAinda não há avaliações

- Quality Management Practices in BuildingDocumento14 páginasQuality Management Practices in Buildingyushma ghimireAinda não há avaliações

- 2001 Lake Mead Sedimentation SurveyDocumento212 páginas2001 Lake Mead Sedimentation SurveyAlexander Gilang Samudra RajasaAinda não há avaliações

- Road Asset Management Using GISDocumento25 páginasRoad Asset Management Using GISAgung PrabawaAinda não há avaliações

- Draft Letter For The Site VisitDocumento1 páginaDraft Letter For The Site VisitaenanrocksAinda não há avaliações

- Fuse SchneiderDocumento40 páginasFuse SchneiderAndalan Sumber UnggulAinda não há avaliações

- Construction Resource MGMTDocumento2 páginasConstruction Resource MGMTArshi KhanAinda não há avaliações

- National Institute of Construction Management and ResearchDocumento14 páginasNational Institute of Construction Management and Researchsimple_aniAinda não há avaliações

- #4 Project Integration: Pmbok 6 Ed. - DeiDocumento31 páginas#4 Project Integration: Pmbok 6 Ed. - DeiFandiAinda não há avaliações

- GM: 2021 Faqs: Section A: Timeline or Process RelatedDocumento12 páginasGM: 2021 Faqs: Section A: Timeline or Process RelatedpluslkAinda não há avaliações

- East Timor Labour CodeDocumento58 páginasEast Timor Labour CodeWarren Wright100% (1)

- The Control of Hazardous Energy (Lockout/Tagou T)Documento27 páginasThe Control of Hazardous Energy (Lockout/Tagou T)talhabctianAinda não há avaliações

- Ppes Works Corporate ProfileDocumento20 páginasPpes Works Corporate Profilebankrobber700% (1)

- Checklist Oil and Gas DevelopmentDocumento2 páginasChecklist Oil and Gas Developmentsailesh2u2000Ainda não há avaliações

- Scope ManagementDocumento35 páginasScope ManagementMuhammad Mubeen Khan100% (1)

- Global Market Segmentation and PositioningDocumento100 páginasGlobal Market Segmentation and PositioningKiara BaldeónAinda não há avaliações

- BPM Aris Part2Documento34 páginasBPM Aris Part2smallik3Ainda não há avaliações

- Cary Parking Study AnalysisDocumento25 páginasCary Parking Study Analysismatthewmourning100% (1)

- RoadVista 922 Retroreflectometer Data SheetDocumento4 páginasRoadVista 922 Retroreflectometer Data SheetNelson Julian BenavidesAinda não há avaliações

- Supervision Engineering Design Supply and Installation of 15kv Switching EIB CombinedDocumento25 páginasSupervision Engineering Design Supply and Installation of 15kv Switching EIB CombinedM. FakAinda não há avaliações

- 08 - Construction Projects Monitoring - Training ManualDocumento28 páginas08 - Construction Projects Monitoring - Training ManualGemechuAinda não há avaliações

- UNRA Updated Job Posting Jan 15 2016Documento184 páginasUNRA Updated Job Posting Jan 15 2016jadwongscribd100% (2)

- Appendix D Examples Users GuideDocumento205 páginasAppendix D Examples Users Guidejhocape100% (1)

- Perencanaan Waktu ProyekDocumento73 páginasPerencanaan Waktu Proyekapi-336212313Ainda não há avaliações

- Value EngineeringDocumento10 páginasValue EngineeringSudeep D'SouzaAinda não há avaliações

- Job Profile Logistic Officer Sep22Documento4 páginasJob Profile Logistic Officer Sep22Rizky AnandaAinda não há avaliações

- IRC Draft Specification For Cold Milling 14 April 2011Documento3 páginasIRC Draft Specification For Cold Milling 14 April 2011Sunil BoseAinda não há avaliações

- Qlassic StudiesDocumento14 páginasQlassic StudiesSyerifaizal Hj. MustaphaAinda não há avaliações

- Introduction To ProcurementDocumento29 páginasIntroduction To ProcurementghaziaAinda não há avaliações

- 19-10-14 How To Design A ROMDAS SystemDocumento12 páginas19-10-14 How To Design A ROMDAS SystemBayu KurniawanAinda não há avaliações

- 19-10-15 ROMDAS Bump IntegratorDocumento4 páginas19-10-15 ROMDAS Bump Integratorsazwan2Ainda não há avaliações

- Internship ReportDocumento15 páginasInternship ReportAravind KunchaeAinda não há avaliações

- 12-05-02 ROMDAS Product CatalogueDocumento31 páginas12-05-02 ROMDAS Product CatalogueМилош ШешлијаAinda não há avaliações

- Road Surface Profiler Mark III - A4 - WebDocumento2 páginasRoad Surface Profiler Mark III - A4 - WebErwin KohlerAinda não há avaliações

- LIDAR Based Detection of Road Boundaries Using The Dens - 2021 - Robotics and AuDocumento13 páginasLIDAR Based Detection of Road Boundaries Using The Dens - 2021 - Robotics and Aulihef14829Ainda não há avaliações

- LIO-SAM: Tightly-Coupled Lidar Inertial Odometry Via Smoothing and MappingDocumento8 páginasLIO-SAM: Tightly-Coupled Lidar Inertial Odometry Via Smoothing and Mappingpepepe123jkghjkhAinda não há avaliações

- Roughmeter PDFDocumento2 páginasRoughmeter PDFJean Bosco NtaganiraAinda não há avaliações

- Tata Elxsi - Submission - VJTI MechMindsDocumento2 páginasTata Elxsi - Submission - VJTI MechMindsShivraj ParleAinda não há avaliações

- LIO-SAM: Tightly-Coupled Lidar Inertial Odometry Via Smoothing and MappingDocumento8 páginasLIO-SAM: Tightly-Coupled Lidar Inertial Odometry Via Smoothing and MappingMetehan DoğanAinda não há avaliações

- Ali Real-Time Vehicle Distance Estimation Using Single View GeometryDocumento10 páginasAli Real-Time Vehicle Distance Estimation Using Single View GeometryGerman SolisAinda não há avaliações

- Flexible Low-Cost Data Capture Technology For Road NetworksDocumento9 páginasFlexible Low-Cost Data Capture Technology For Road NetworksNebojsa RadovicAinda não há avaliações

- 2020.01.10 - Airborne Testing of The Dss Test Results and AnalysisDocumento6 páginas2020.01.10 - Airborne Testing of The Dss Test Results and AnalysisarashAinda não há avaliações

- Roads and BridgesDocumento5 páginasRoads and BridgesFehr GrahamAinda não há avaliações

- Roadroid Smartphone ApplicationDocumento5 páginasRoadroid Smartphone ApplicationDoly ManurungAinda não há avaliações

- Gis Mapping Companies in IndiaDocumento15 páginasGis Mapping Companies in IndiadsmsoftAinda não há avaliações

- WP - Better and Faster Survey Data Through Technology - Get Geospatial AreadyDocumento10 páginasWP - Better and Faster Survey Data Through Technology - Get Geospatial Areadyraphael sermetAinda não há avaliações

- Embedded Mobile ROS Platform For SLAM Application With RGB-D CamerasDocumento5 páginasEmbedded Mobile ROS Platform For SLAM Application With RGB-D CamerasWa KaAinda não há avaliações

- Lidar Kadaster 3D KaltimDocumento74 páginasLidar Kadaster 3D KaltimIka Indah KarlinaAinda não há avaliações

- 3D Mapping DevelopmentDocumento62 páginas3D Mapping DevelopmentRey HenukAinda não há avaliações

- Roadroid: Continuous Road Condition Monitoring With Smart PhonesDocumento12 páginasRoadroid: Continuous Road Condition Monitoring With Smart PhonesPros Cons StatementAinda não há avaliações

- Integrated Radar Solution For MotorwaysDocumento2 páginasIntegrated Radar Solution For MotorwaysCORAL ALONSOAinda não há avaliações

- Dynamic Ramp Metering - Fact SheetDocumento2 páginasDynamic Ramp Metering - Fact SheetCouncilDistrict11Ainda não há avaliações

- An Occupancy Grid Mapping Enhanced Visual SLAM For Real-Time Locating Applications in Indoor GPS-denied Environments - 2019.04.011Documento16 páginasAn Occupancy Grid Mapping Enhanced Visual SLAM For Real-Time Locating Applications in Indoor GPS-denied Environments - 2019.04.011Yu Han LiAinda não há avaliações

- Presentation PDFDocumento15 páginasPresentation PDFBADRI VENKATESH0% (1)

- A Seminar Report On Self Sustainable BuildingDocumento32 páginasA Seminar Report On Self Sustainable BuildingashoknrAinda não há avaliações

- Certificate-12-"Hydrological Studies of Chandrabhaga River'Documento3 páginasCertificate-12-"Hydrological Studies of Chandrabhaga River'ashoknrAinda não há avaliações

- Certificate-11-"Hydrological Studies of Panchaganga River'Documento3 páginasCertificate-11-"Hydrological Studies of Panchaganga River'ashoknrAinda não há avaliações

- Certificate-9-"SUITABLE CONDITIONS FOR ROOTZONE-UbaleDocumento3 páginasCertificate-9-"SUITABLE CONDITIONS FOR ROOTZONE-UbaleashoknrAinda não há avaliações

- Certificate-10-"Hydrological Studies of Kishna RiverDocumento26 páginasCertificate-10-"Hydrological Studies of Kishna RiverashoknrAinda não há avaliações

- Mini Proj Sample Report BPPDocumento50 páginasMini Proj Sample Report BPPashoknrAinda não há avaliações

- PROJECT REPORT (ITS) - Mini Project-Bipin PatilDocumento51 páginasPROJECT REPORT (ITS) - Mini Project-Bipin PatilashoknrAinda não há avaliações

- Certificate 1 Biomedical Waste Management PVDDocumento3 páginasCertificate 1 Biomedical Waste Management PVDashoknrAinda não há avaliações

- Justifications 17.9.18Documento23 páginasJustifications 17.9.18ashoknrAinda não há avaliações

- Certificate 1 Biomedical Waste Management PVDDocumento3 páginasCertificate 1 Biomedical Waste Management PVDashoknrAinda não há avaliações

- S. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentDocumento5 páginasS. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentashoknrAinda não há avaliações

- Certificate 1 Biomedical Waste Management PVDDocumento3 páginasCertificate 1 Biomedical Waste Management PVDashoknrAinda não há avaliações

- NHAI LetterDocumento1 páginaNHAI LetterashoknrAinda não há avaliações

- Road Note No. 4 Method/DOE MethodDocumento11 páginasRoad Note No. 4 Method/DOE MethodashoknrAinda não há avaliações

- Po 1Documento1 páginaPo 1ashoknrAinda não há avaliações

- Justifications 17.9.18Documento23 páginasJustifications 17.9.18ashoknrAinda não há avaliações

- NHAI LetterDocumento1 páginaNHAI LetterashoknrAinda não há avaliações

- ACI MethodDocumento57 páginasACI MethodashoknrAinda não há avaliações

- S. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentDocumento5 páginasS. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentashoknrAinda não há avaliações

- Po 1Documento1 páginaPo 1ashoknrAinda não há avaliações

- Presented BY: Ashok KumarDocumento50 páginasPresented BY: Ashok KumarashoknrAinda não há avaliações

- Raw Materials of Portland: - Lime - Silica - Alumina - Iron OxideDocumento10 páginasRaw Materials of Portland: - Lime - Silica - Alumina - Iron OxideashoknrAinda não há avaliações

- Unit-I-Aggregate GradingDocumento22 páginasUnit-I-Aggregate GradingashoknrAinda não há avaliações

- External Audit Format - 25022021Documento17 páginasExternal Audit Format - 25022021ashoknrAinda não há avaliações

- Chapter Name-Airport Obstructions Add Sections: 1) Imaginary Surfaces: A) Add Video B) Quiz C) Lecture Notes In-Video QuizDocumento1 páginaChapter Name-Airport Obstructions Add Sections: 1) Imaginary Surfaces: A) Add Video B) Quiz C) Lecture Notes In-Video QuizashoknrAinda não há avaliações

- Lab Manual of Concrete Technology: Chetan S. PatilDocumento76 páginasLab Manual of Concrete Technology: Chetan S. PatilashoknrAinda não há avaliações

- Proposals For IIC in WIT SolapurDocumento1 páginaProposals For IIC in WIT SolapurashoknrAinda não há avaliações

- Walchand Institute of Technology, Solapur B.E. Part-II 2018-19 (CBCS Pattern) In-Sem. Examination - IIIDocumento2 páginasWalchand Institute of Technology, Solapur B.E. Part-II 2018-19 (CBCS Pattern) In-Sem. Examination - IIIashoknrAinda não há avaliações

- Live Interactions Via Google Meet: Kameswari Chebrolu Department of CSE, IIT BombayDocumento5 páginasLive Interactions Via Google Meet: Kameswari Chebrolu Department of CSE, IIT BombayAshok Kumar RajanavarAinda não há avaliações

- Integrating Images and External MaterialsDocumento2 páginasIntegrating Images and External Materialskuirt miguelAinda não há avaliações

- CV NguyenLamTruong EngNew PDFDocumento1 páginaCV NguyenLamTruong EngNew PDFhoa leAinda não há avaliações

- Guidance On Complying With Section IX, QG-106: Updated To Address Revisions in The 2021 EditionDocumento5 páginasGuidance On Complying With Section IX, QG-106: Updated To Address Revisions in The 2021 EditionSurat ButtarasriAinda não há avaliações

- Hype Cycle For The Telecommu 260996Documento102 páginasHype Cycle For The Telecommu 260996Enrique de la RosaAinda não há avaliações

- Iphone 4s Case Design GuidelinesDocumento16 páginasIphone 4s Case Design GuidelinesJayoshomeAinda não há avaliações

- Asce 8-02Documento22 páginasAsce 8-023132197270Ainda não há avaliações

- Amperis Manual XDP IIDocumento28 páginasAmperis Manual XDP IIme_vahabi100% (1)

- FoxitDocumento13 páginasFoxitFariz DaffaAinda não há avaliações

- Visvesvaraya Technological University Belagavi - 590018: Developments in Solar Dryers, Collectors and Absorber MaterialsDocumento1 páginaVisvesvaraya Technological University Belagavi - 590018: Developments in Solar Dryers, Collectors and Absorber MaterialsM.A rajaAinda não há avaliações

- Spare Parts Catalogue: Bajaj Auto LimitedDocumento44 páginasSpare Parts Catalogue: Bajaj Auto LimitedRahul KhadeAinda não há avaliações

- LNG Man Es Methane Slip Technical PaperDocumento20 páginasLNG Man Es Methane Slip Technical PaperLeo TvrdeAinda não há avaliações

- StdlinearcrossDocumento50 páginasStdlinearcrossKostas KitharidisAinda não há avaliações

- Sap CommandsDocumento2 páginasSap CommandsAmbrish NigamAinda não há avaliações

- NXC100 ControllerDocumento2 páginasNXC100 ControllermartinimartiiniAinda não há avaliações

- Presented By:: Kemal Muhammet Akkaya Sr. Instrument Engineer Humod M. Al-Shammari Maintenance SuperintendentDocumento54 páginasPresented By:: Kemal Muhammet Akkaya Sr. Instrument Engineer Humod M. Al-Shammari Maintenance Superintendentmaria neneng bulakAinda não há avaliações

- 16oct Csit 315Documento21 páginas16oct Csit 315Majety S LskshmiAinda não há avaliações

- 8065 Kt21e2002Documento92 páginas8065 Kt21e2002bajricaAinda não há avaliações

- Agung Laksamana - PERHUMASDocumento46 páginasAgung Laksamana - PERHUMASDaeng Mudrikan NacongAinda não há avaliações

- Er Shutdown For 15.12.21 Rev1Documento8 páginasEr Shutdown For 15.12.21 Rev1Gitesh PatelAinda não há avaliações

- Electrical Findings 6Documento13 páginasElectrical Findings 6Lester Musca100% (1)

- Pro 5632Documento9 páginasPro 5632Phat HoangAinda não há avaliações

- Markdown PDFDocumento11 páginasMarkdown PDFaweber_252469038Ainda não há avaliações

- 2nd Group Makalah of Letter of EnquiryDocumento12 páginas2nd Group Makalah of Letter of EnquiryInas Afifah ZahraAinda não há avaliações

- 19xr Spare Part List Frame 2 Pic 6 ControlDocumento42 páginas19xr Spare Part List Frame 2 Pic 6 ControlJuha VainioAinda não há avaliações

- 2464 Manual v1 07eDocumento0 página2464 Manual v1 07eDota NgAinda não há avaliações

- Key Factors For The Pwa Solution: Agam SetiawanDocumento18 páginasKey Factors For The Pwa Solution: Agam SetiawanYsn ArrfAinda não há avaliações