Escolar Documentos

Profissional Documentos

Cultura Documentos

PSV Data Sheet Wetted

Enviado por

Ioana PopescuDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PSV Data Sheet Wetted

Enviado por

Ioana PopescuDireitos autorais:

Formatos disponíveis

Page: 1 of 7

Date: 2017-02-25 14:11:22

Project: New project

Tag No:

LESER Job

Sizing - Medium

1000 Designation Ethyl tertbutyl

1004 Formula C6H14O

1001 Molar mass M 102 kg/kmol

1002 Ratio of specific heats k 1.067

1003 Compressibility factor Z 0.934

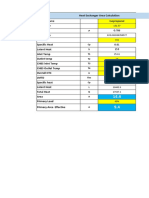

Sizing - Firecase

1050 Calculation type Wetted

1051 Type of vessel Horizontal

Ellipsoidal

1052 Vessel head design

head

1053 Vessel elevation H 1m

1054 Vessel diameter D 4m

1055 Vessel length L 16 m

1056 Liquid depth Y 3.5 m

1066 Effective liquid level Yeff 3.5 m

1061 Wetted surface, calculated Awet 175.15 m

1062 Wetted surface, manual Awet

1057 Drainage presence No

Bare

1058 Type of isolation

vessel

1059 Environment factor F 1.000

1060 Heat of evaporation Hvap

1072 Minimum required mass flow W

Name API 520

Date 2017-02-25 14:11:22

Rev.No 1

Page: 2 of 7

Date: 2017-02-25 14:11:22

Project: New project

Tag No:

LESER Job

Sizing - Service condition

1009 Case for blow off Firecase

1100 Maximum allowable working pressure

1101 Set pressure p 0.49 bar-g

1102 Constant superimposed back pressure paf 0.013 bar-g

2102 Variable superimposed back pressure 0.25 bar-g

1103 Built up back pressure pae 0.06 bar

1104 Backpressure 0.323 bar-g

1105 Overpressure dp 70.00 psi

1106 Environmental pressure pu 1.013 bar

1107 Relieving Temperature T 100 C

1111 Operating Temperature 40 C

1108 Required massflow qm,ab 15,160 kg/h

1109 Volume flow to be discharged (working condition) qvb,ab 680.571 m/h

Volume flow to be discharged (std condition) [T=60 F

1110 qvn,ab 1,935.218 SCFM

P=14.7 psi]

1120 Rupture disc correction factor Kc 1.000

Initial Sizing according to API 520 for conventional safety valve

1150 NPS inlet Orifice NPS outlet 4M6

1151 PR inlet x PR oultet #300 x #150

1152 Material WCB

1153 Required orifice M

1154 Selected orifice M

Sizing - Calculation

1200 Certified massflow qm,zu 26,072.704 kg/h

1201 Certified volumeflow (operating condition) qvb,zu 1,170.469 m/h

1203 Certified volumeflow (standard condition) qvn,zu 5,655.491 m/h

1204 Maximum mass flow qm,max 28,969.671 kg/h

1205 Maximum volume flow (working condition) qvb,max 1,300.521 m/h

1206 Maximum volume flow (standard condition) qvn,max 6,283.879 m/h

1207 Capacity exceed 71.98 %

Name API 520

Date 2017-02-25 14:11:22

Rev.No 1

Page: 3 of 7

Date: 2017-02-25 14:11:22

Project: New project

Tag No:

LESER Job

Valve - General

1500 Article number 4884.8882

1512 Reseller article number

1513 Quantity of safety valve 1

1501 Certified coefficient of discharge for steam and gases K,DG 0.721

1502 Certified coefficient of discharge for liquid K,F 0.472

1453 Orifice N

1505 Bonnet / Lifting device Cap H2

1506 Body-/ Inlet base material 1.4404 / 316L

1511 Bonnet Closed Bonnet

1514 Order code 4884.8882-0.49 bar_g-L79L86-3.1

Inlet connection

1300 Pipe standard DIN 11850

1303 Connection standard DIN 32676

1304 DN / NPS 80

1360 Code SO

1305 PN / PR 10

1302 Information Clamp acc. to DIN 32676 (pipe

standard acc. to DIN 11850)

Outlet connection

1350 Pipe standard DIN 11850

1353 Connection standard DIN 32676

1354 DN / NPS 125

1361 Code SO

1355 PN / PR

1352 Information Clamp acc. to DIN 32676 (pipe

standard acc. to DIN 11850)

Valve - Dimensions

1400 Discharge area Ao 4,300.84 mm

1401 Discharge diameter do 74 mm

1402 Centre to Face dimensions a 124 mm

1403 Centre to Face dimensions b 178 mm

1405 Height H 637.2 mm

1406 Weight M 39 kg

Name API 520

Date 2017-02-25 14:11:22

Rev.No 1

Page: 4 of 7

Date: 2017-02-25 14:11:22

Project: New project

Tag No:

LESER Job

Lift

1507 Standard 18 mm

Valve - Calculation

1200 Certified massflow qm,zu 26,072.704 kg/h

1201 Certified volumeflow (operating condition) qvb,zu 1,170.469 m/h

1203 Certified volumeflow (standard condition) qvn,zu 5,655.491 m/h

1204 Maximum mass flow qm,max 28,969.671 kg/h

1205 Maximum volume flow (working condition) qvb,max 1,300.521 m/h

1206 Maximum volume flow (standard condition) qvn,max 6,283.879 m/h

1207 Capacity exceed 71.98 %

1600 Required actual discharge area Ao, req 2,500.728 mm

1601 Required discharge diameter do,req 56.427 mm

1603 Noise level in 1m distance from the valve (acc. to API 520) L 136.369 dB

1611 Reaction force (acc. to API 520) Fr 1,822.922 N

1617 Back pressure correction factor Kb 1.000

1618 Cold differential test pressure CDTP

1620 Cold differential test pressure, manually CDTP

Name API 520

Date 2017-02-25 14:11:22

Rev.No 1

Page: 5 of 7

Date: 2017-02-25 14:11:22

Project: New project

Tag No:

LESER Job

Valve - Part list

PosNo Denomination Q Material ASME Material DIN

12010 1 Body 1 316L 1.4404

12050 5 Seat 1 316L 1.4404

12070 7 O-ring-disc 1 316L/EPDM [D] 1.4404/EPDM [D]

12080 8 Guide 1 316L 1.4404

12090 9 Bonnet 1 316L 1.4404

12120 12 Spindle 1 316L 1.4404

12140 14 Split ring 2 316L 1.4404

12160 16 Spring plate 1 316L 1.4404

12170 17 Spring plate 1 316L 1.4404

12180 18 Adjusting screw 1 430/PTFE 1.4104/PTFE

12190 19 Lock nut 1 316L 1.4404

12400 40 Cap H2 1 316L 1.4404

12540 54 Spring 1 Stainless steel 1.4310

12570 57 Pin 1 Stainless steel 1.4310

12600 60 O-ring 1 EPDM [D] EPDM [D]

12610 61 Ball washer 1 316 1.4401

12680 68 Ring 2 B8M 1.4401

12700 70 Elastomer bellows 1 EPDM EPDM

LESER is free to upgrade materials without further notice.

Name API 520

Date 2017-02-25 14:11:22

Rev.No 1

Page: 6 of 7

Date: 2017-02-25 14:11:22

Project: New project

Tag No:

LESER Job

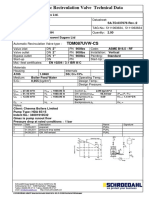

Drawing

Drawing is a view; the effective geometry could deviate from this view.

Name API 520

Date 2017-02-25 14:11:22

Rev.No 1

Page: 7 of 7

Date: 2017-02-25 14:11:22

Project: New project

Tag No:

LESER Job

Drawing

Drawing is a view; the effective geometry could deviate from this view.

Name API 520

Date 2017-02-25 14:11:22

Rev.No 1

Você também pode gostar

- Leser API 520 LiquidDocumento6 páginasLeser API 520 LiquidWidyaAinda não há avaliações

- 107D Iv Feg 05a 00012Documento68 páginas107D Iv Feg 05a 00012vinayak jadhavAinda não há avaliações

- Art Movements From 1870 To PresentDocumento150 páginasArt Movements From 1870 To PresentOliver GemmaAinda não há avaliações

- Moparm Action - December 2014 USADocumento100 páginasMoparm Action - December 2014 USAenricoioAinda não há avaliações

- Chiller Product Report Design Conditions PDFDocumento2 páginasChiller Product Report Design Conditions PDFSiddharth JainAinda não há avaliações

- TK1510 Desgin Calculations For V3501 RevA PDFDocumento11 páginasTK1510 Desgin Calculations For V3501 RevA PDFHoLinhAinda não há avaliações

- Flare Calc Sheet API - RP 521Documento13 páginasFlare Calc Sheet API - RP 521ionutlaur86100% (1)

- Handbook of Heating, Ventilating and Air ConditioningNo EverandHandbook of Heating, Ventilating and Air ConditioningNota: 4 de 5 estrelas4/5 (6)

- Max Piping Oper PressDocumento8 páginasMax Piping Oper PressSandi ApriandiAinda não há avaliações

- Line Size 2010 VerBBDocumento12 páginasLine Size 2010 VerBBchemkumar16Ainda não há avaliações

- Well Stimulation TechniquesDocumento165 páginasWell Stimulation TechniquesRafael MorenoAinda não há avaliações

- Single Col - Tank-2013Documento35 páginasSingle Col - Tank-2013Hgagselim SelimAinda não há avaliações

- Pump NPSH CalculationDocumento18 páginasPump NPSH CalculationDarwinAinda não há avaliações

- EN 14015 ExampleDocumento85 páginasEN 14015 ExampleMIKE MALAinda não há avaliações

- Common OPCRF Contents For 2021 2022 FINALE 2Documento21 páginasCommon OPCRF Contents For 2021 2022 FINALE 2JENNIFER FONTANILLA100% (30)

- Ammonia TankDocumento17 páginasAmmonia TankIoana PopescuAinda não há avaliações

- 1000TR Entravac Centrifugal Chiller Product ReportDocumento2 páginas1000TR Entravac Centrifugal Chiller Product ReportEdwin CalpitoAinda não há avaliações

- LR Format 1.2Documento1 páginaLR Format 1.2Ch.Suresh SuryaAinda não há avaliações

- Heat Exchanger Area & Boilup Rate CalculationDocumento19 páginasHeat Exchanger Area & Boilup Rate CalculationNitin KurupAinda não há avaliações

- Stress Analysis of Piping SystemsDocumento108 páginasStress Analysis of Piping SystemsShijumon KpAinda não há avaliações

- 114-F - OASE Solution Storage Tank - R0 PDFDocumento33 páginas114-F - OASE Solution Storage Tank - R0 PDFManish542Ainda não há avaliações

- Vessel Volume Calculation: Tag No. V-101 Chemical Engineering Calculations Description Receiver Date 20/09/14 by ChecalcDocumento17 páginasVessel Volume Calculation: Tag No. V-101 Chemical Engineering Calculations Description Receiver Date 20/09/14 by ChecalcDHAVALESH AM100% (1)

- PT Pim: Vent Steam Silencer Data SheetDocumento3 páginasPT Pim: Vent Steam Silencer Data SheetIrwansyah MuchtarAinda não há avaliações

- Pump Sizing Calculation SpreadsheetDocumento26 páginasPump Sizing Calculation Spreadsheetsterling100% (1)

- PDM-P-CS-002 - HP Prod SeparatorDocumento6 páginasPDM-P-CS-002 - HP Prod Separatorfirman adiyantoAinda não há avaliações

- PHE SelectionsDocumento67 páginasPHE SelectionsSelva Kumar Selva KumarAinda não há avaliações

- Business Plan GROUP 10Documento35 páginasBusiness Plan GROUP 10Sofia GarciaAinda não há avaliações

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDocumento17 páginas181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542Ainda não há avaliações

- Design Calculation-Oil Cooler MaK-2011Documento8 páginasDesign Calculation-Oil Cooler MaK-2011Fauzan Rusmayadi ReharderAinda não há avaliações

- Module 5 - Multimedia Storage DevicesDocumento10 páginasModule 5 - Multimedia Storage Devicesjussan roaringAinda não há avaliações

- Calculation Sheet: Calc No Project Title Proj No Client Phase/CTR Calculation Title of Activity FileDocumento12 páginasCalculation Sheet: Calc No Project Title Proj No Client Phase/CTR Calculation Title of Activity FileTifano KhristiyantoAinda não há avaliações

- Ejercicio 246 PSV438 RESUELTODocumento2 páginasEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaAinda não há avaliações

- 37R 06Documento8 páginas37R 06mirakul100% (2)

- TNCT Q2 Module3cDocumento15 páginasTNCT Q2 Module3cashurishuri411100% (1)

- Check Test SeparatorDocumento76 páginasCheck Test SeparatorAnonymous cwDU3hAinda não há avaliações

- PSV No. Cause Calculation:: ReferenceDocumento3 páginasPSV No. Cause Calculation:: ReferencerevinAinda não há avaliações

- PSV Data Sheet UnwettedDocumento7 páginasPSV Data Sheet UnwettedIoana PopescuAinda não há avaliações

- 030-PSV-1801,1901 CASE-2 (API 520 Gas)Documento2 páginas030-PSV-1801,1901 CASE-2 (API 520 Gas)khushbu sharmaAinda não há avaliações

- Ing Xanab 201 Pa 1200 026 - CDocumento26 páginasIng Xanab 201 Pa 1200 026 - Celimon1102Ainda não há avaliações

- Laser PSV Data SheetDocumento6 páginasLaser PSV Data SheetZaw Htet WinAinda não há avaliações

- UntitledDocumento4 páginasUntitledAshish DhokAinda não há avaliações

- Sizing Sheet PSV Air 175PSIG - CommentsDocumento6 páginasSizing Sheet PSV Air 175PSIG - CommentshaseebAinda não há avaliações

- PSV-1100B Rev 3Documento6 páginasPSV-1100B Rev 3einhaw1985Ainda não há avaliações

- Safety Valve Technical DetailsDocumento5 páginasSafety Valve Technical DetailsvineethvskkdAinda não há avaliações

- Sizing PSV-100 R0Documento5 páginasSizing PSV-100 R0XxavierAinda não há avaliações

- Nmr-601 Rev 03 PZV Po 1345 Binzagr Mrp-061 - Copy 22Documento1 páginaNmr-601 Rev 03 PZV Po 1345 Binzagr Mrp-061 - Copy 22Hajarath AliAinda não há avaliações

- Sizing Acc. To ASME VIII For Liquid VALVESTAR® - v.7.3.1.60920 Sizing - MediumDocumento6 páginasSizing Acc. To ASME VIII For Liquid VALVESTAR® - v.7.3.1.60920 Sizing - Mediummurthy challapalliAinda não há avaliações

- 40qea01bb101 (Asme Viii Gas)Documento6 páginas40qea01bb101 (Asme Viii Gas)Asep DarojatAinda não há avaliações

- Sizing PSV-201 301 401 501 601 701 Glycol CASE R0Documento5 páginasSizing PSV-201 301 401 501 601 701 Glycol CASE R0XxavierAinda não há avaliações

- 1100tr-Design - Water Cooled ChillerDocumento2 páginas1100tr-Design - Water Cooled ChillerRamAinda não há avaliações

- Plate Heat Exchanger Customer Data Sheet: Duty 1 Process Data Hot ColdDocumento1 páginaPlate Heat Exchanger Customer Data Sheet: Duty 1 Process Data Hot ColdzhyhhAinda não há avaliações

- Plate Heat Exchanger Customer Data Sheet: Duty 1 Process Data Hot ColdDocumento1 páginaPlate Heat Exchanger Customer Data Sheet: Duty 1 Process Data Hot ColdzhyhhAinda não há avaliações

- Hoja de Datos PSVDocumento6 páginasHoja de Datos PSVMarc MarAinda não há avaliações

- P294-94-Cal-013 Svd-Prm-Pip-Cal-4037-0006 05-1fso-Ge-Prm-L-Ca-0004Documento6 páginasP294-94-Cal-013 Svd-Prm-Pip-Cal-4037-0006 05-1fso-Ge-Prm-L-Ca-0004aryoAinda não há avaliações

- ARC Datasheet DB-K11-0789-1Documento1 páginaARC Datasheet DB-K11-0789-1Sudip KhalipeAinda não há avaliações

- Flow Capacity - Sizing Thermal Relief Valve OC 1Documento3 páginasFlow Capacity - Sizing Thermal Relief Valve OC 1docente.mauricioAinda não há avaliações

- Flare Calc Sheet API RP 521Documento11 páginasFlare Calc Sheet API RP 521PIDAinda não há avaliações

- PSVDocumento8 páginasPSVtetiospamAinda não há avaliações

- Ps Pipeline SDN BHD: Detail Engineering Design For KVDT T-501 Diesel Tank Conversion To Ulg95 T-501 Tank DatasheetDocumento3 páginasPs Pipeline SDN BHD: Detail Engineering Design For KVDT T-501 Diesel Tank Conversion To Ulg95 T-501 Tank DatasheetBukhory Ahmad TajudinAinda não há avaliações

- New Microsoft Office Excel WorksheetDocumento2 páginasNew Microsoft Office Excel WorksheetDarshit GolwalaAinda não há avaliações

- 5500 I.D. 1400 I.D. 1000: Vessel SpecificationDocumento2 páginas5500 I.D. 1400 I.D. 1000: Vessel SpecificationMustafa AhsanAinda não há avaliações

- Development of AerofoilDocumento6 páginasDevelopment of Aerofoilvaisakp777Ainda não há avaliações

- API 620 Tank CalculationsDocumento11 páginasAPI 620 Tank CalculationsSatoru GojoAinda não há avaliações

- Dual Fuel Genset - Heat Recovery-1-2Documento2 páginasDual Fuel Genset - Heat Recovery-1-2Ab Sami100% (1)

- Spray Water - Rev 00Documento2 páginasSpray Water - Rev 00Jacky KaruppaiahAinda não há avaliações

- Pump NPSH CalculationDocumento3 páginasPump NPSH CalculationDarwinAinda não há avaliações

- Heat Exchanger Specification Sheet Us Units: C:/Htri/Xchangersuite5/Samples/Xist - Shellsinseries - HtriDocumento1 páginaHeat Exchanger Specification Sheet Us Units: C:/Htri/Xchangersuite5/Samples/Xist - Shellsinseries - HtriNatarajan RavisankarAinda não há avaliações

- Flare Calc Sheet API RP 521Documento9 páginasFlare Calc Sheet API RP 521Miftahul HudaAinda não há avaliações

- Master Flo Choke Control Valve Sizing - Version 7.1.0.0046I CV Sizing Calculation - Surface ValvesDocumento2 páginasMaster Flo Choke Control Valve Sizing - Version 7.1.0.0046I CV Sizing Calculation - Surface ValvesFabian Solano100% (1)

- s5113 Mm41 Plate CoolerDocumento79 páginass5113 Mm41 Plate CoolerJorge AguilarAinda não há avaliações

- ANEXO II - de NadaDocumento2 páginasANEXO II - de NadaRafael BarretoAinda não há avaliações

- 8.data Sheet 150 DL 57.5Documento4 páginas8.data Sheet 150 DL 57.5Gokula Krishnan CAinda não há avaliações

- c3 To FCCDocumento1 páginac3 To FCCIoana PopescuAinda não há avaliações

- Air Cooled Heat ExchangersDocumento6 páginasAir Cooled Heat ExchangersIoana PopescuAinda não há avaliações

- CerceiDocumento1 páginaCerceiIoana PopescuAinda não há avaliações

- Pierderi Caldura Caz 5B1Documento3 páginasPierderi Caldura Caz 5B1Ioana PopescuAinda não há avaliações

- 42 - Pe-P-Roa07114227006-Me-Dwg-003-01-E - Plan LegaturiDocumento1 página42 - Pe-P-Roa07114227006-Me-Dwg-003-01-E - Plan LegaturiIoana PopescuAinda não há avaliações

- Ems EdDocumento1 páginaEms EdIoana PopescuAinda não há avaliações

- DS VFD PDFDocumento2 páginasDS VFD PDFIoana PopescuAinda não há avaliações

- Ariadna Data Sheet RezervorDocumento2 páginasAriadna Data Sheet RezervorIoana PopescuAinda não há avaliações

- DE ProektDocumento3 páginasDE ProektIoana PopescuAinda não há avaliações

- Air EmissionDocumento727 páginasAir EmissionIoana PopescuAinda não há avaliações

- Stripping Column PDFDocumento3 páginasStripping Column PDFIoana PopescuAinda não há avaliações

- PSV 6r8 Api - 526lDocumento1 páginaPSV 6r8 Api - 526lIoana PopescuAinda não há avaliações

- PSV Calculation Report - Liquid Relief Sizing Case: Const. VarDocumento1 páginaPSV Calculation Report - Liquid Relief Sizing Case: Const. VarIoana PopescuAinda não há avaliações

- TM 5 3895 358 14 and PDocumento1 páginaTM 5 3895 358 14 and PIoana PopescuAinda não há avaliações

- Cars Air France: Line 2: Etoile - Porte Maillot / Aéroport Paris-Charles de GaulleDocumento5 páginasCars Air France: Line 2: Etoile - Porte Maillot / Aéroport Paris-Charles de GaulleIoana PopescuAinda não há avaliações

- AMS SpecDocumento1 páginaAMS SpecIoana PopescuAinda não há avaliações

- Pump Sizing Calculation: Data FlowrateDocumento4 páginasPump Sizing Calculation: Data FlowrateIoana PopescuAinda não há avaliações

- Battery TM PDFDocumento28 páginasBattery TM PDFIoana PopescuAinda não há avaliações

- Amsterdam and Region Day Card Map 2015Documento2 páginasAmsterdam and Region Day Card Map 2015Ioana PopescuAinda não há avaliações

- Sala Unirii PDFDocumento1 páginaSala Unirii PDFIoana PopescuAinda não há avaliações

- Site Condition PDFDocumento4 páginasSite Condition PDFIoana PopescuAinda não há avaliações

- Cars Air France: Line 2: Etoile - Porte Maillot / Aéroport Paris-Charles de GaulleDocumento5 páginasCars Air France: Line 2: Etoile - Porte Maillot / Aéroport Paris-Charles de GaulleIoana PopescuAinda não há avaliações

- Site Condition PDFDocumento4 páginasSite Condition PDFIoana PopescuAinda não há avaliações

- Statable 1Documento350 páginasStatable 1Shelly SantiagoAinda não há avaliações

- QuestionDocumento7 páginasQuestionNgọc LuânAinda não há avaliações

- ProAim InstructionsDocumento1 páginaProAim Instructionsfeli24arias06Ainda não há avaliações

- Types of Electrical Protection Relays or Protective RelaysDocumento7 páginasTypes of Electrical Protection Relays or Protective RelaysTushar SinghAinda não há avaliações

- Mix Cases UploadDocumento4 páginasMix Cases UploadLu CasAinda não há avaliações

- Journalism Cover Letter TemplateDocumento6 páginasJournalism Cover Letter Templateafaydebwo100% (2)

- ARISE 2023: Bharati Vidyapeeth College of Engineering, Navi MumbaiDocumento5 páginasARISE 2023: Bharati Vidyapeeth College of Engineering, Navi MumbaiGAURAV DANGARAinda não há avaliações

- How Can You Achieve Safety and Profitability ?Documento32 páginasHow Can You Achieve Safety and Profitability ?Mohamed OmarAinda não há avaliações

- TATA Power - DDL:ConfidentialDocumento15 páginasTATA Power - DDL:ConfidentialkarunakaranAinda não há avaliações

- S200 For Sumber RezekiDocumento2 páginasS200 For Sumber RezekiIfan JayusdianAinda não há avaliações

- Annisha Jain (Reporting Manager - Rudrakshi Kumar)Documento1 páginaAnnisha Jain (Reporting Manager - Rudrakshi Kumar)Ruchi AgarwallAinda não há avaliações

- Tech Mahindra Sample Verbal Ability Placement Paper Level1Documento11 páginasTech Mahindra Sample Verbal Ability Placement Paper Level1Madhav MaddyAinda não há avaliações

- NCR Minimum WageDocumento2 páginasNCR Minimum WageJohnBataraAinda não há avaliações

- Seminar Report of Automatic Street Light: Presented byDocumento14 páginasSeminar Report of Automatic Street Light: Presented byTeri Maa Ki100% (2)

- INTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Documento7 páginasINTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Shashank DurgeAinda não há avaliações

- TokyoDocumento6 páginasTokyoMarcio BonziniAinda não há avaliações

- Common Base AmplifierDocumento6 páginasCommon Base AmplifierMuhammad SohailAinda não há avaliações

- Solved - in Capital Budgeting, Should The Following Be Ignored, ...Documento3 páginasSolved - in Capital Budgeting, Should The Following Be Ignored, ...rifa hanaAinda não há avaliações

- Alphacenter Utilities: Installation GuideDocumento24 páginasAlphacenter Utilities: Installation GuideJeffersoOnn JulcamanyanAinda não há avaliações

- Rhino HammerDocumento4 páginasRhino HammerMichael BAinda não há avaliações

- AN610 - Using 24lc21Documento9 páginasAN610 - Using 24lc21aurelioewane2022Ainda não há avaliações

- Rundown Rakernas & Seminar PABMI - Final-1Documento6 páginasRundown Rakernas & Seminar PABMI - Final-1MarthinAinda não há avaliações

- MPPWD 2014 SOR CH 1 To 5 in ExcelDocumento66 páginasMPPWD 2014 SOR CH 1 To 5 in ExcelElvis GrayAinda não há avaliações