Escolar Documentos

Profissional Documentos

Cultura Documentos

Contractor Work Method Statement-GIS Parts, Equipmentand Tools

Enviado por

nsadnanTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Contractor Work Method Statement-GIS Parts, Equipmentand Tools

Enviado por

nsadnanDireitos autorais:

Formatos disponíveis

HS.SAF.09.

F12

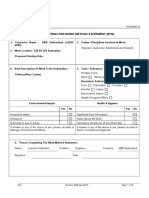

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : ABB Switzerland(TK-4842) 3. Trades / Disciplines Involved In Work :

Engineer, Supervisor, Electricians and Helpers.

2. Work Location : GIS building, Room 1&2

Proposed Starting Date :

4. Brief Description Of Work To Be Undertaken : 5. Tools / Substance

Shifting of GIS part, equipments and tools from ABB

Portable Tools

lay down to GIS building.

Hand Electrical Pneumatic

Hazardous Substances

Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

Hazardous waste Significant Dust Generation

Emissions Noise (above 85 DbA)

Discharge to sea or drains Hazardous substances (if yes attach list)

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

6. Person Completing The Work Method Statement :

Name : Joachim Kuhlmann Position : Engineer Company : ABB Switzerland

Signature : Date :

Revision: 0(26-May-2011) Page 1 of 10

HS.SAF.09.F12

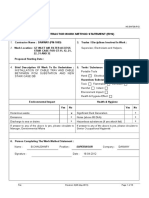

7. Approvals

Contractor Site Rep. Name Signature : Date :

SLII Representative Name Signature : Date :

EMAL Contract Admin. Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

EMAL EHS Department

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

After the Area Owners approval the Work Method Statement shall be forwarded to EHS department for

approval

The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low LP x MS LP x HS

Severity 1 x 1 = 1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very minor).

Revision: 0(26-May-2011) Page 2 of 10

HS.SAF.09.F12

Revision: 0(26-May-2011) Page 3 of 10

HS.SAF.09.F12

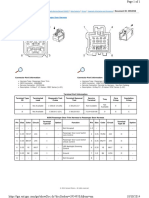

8. Safety Analysis

Identified Hazard(s) Persons Precautions and Plan of actions To Be Taken To Severity x Probability =

Individual Activities To Associated With Activity Exposed To Remove / Control Hazards Risk

Complete Work. List In Hazard

Sequence of Activity Residual Risk

(Use Risk Estimator Chart)

1.PREPARATION. Slips, trips and fall at the Maintain housekeeping around in the working area.

Emal / SNC rep.,

same level. 1x2=2

Engr., Supv. Elec.

All workers involve in the activity must be aware of

Emal / SNC rep.,

Hot weather. heat stress, supervisor to ensure drinking cold water 2x2=4

Engr., Supv. Elec. is available.

Supervisor to give tool box talk regarding proper

Manual handling hazards Supv. & Elec. manual handling. 1x1=2

Emal / SNC rep., Wear P.P.E.'s at all times (hard hat,

appropriate safety glass, safety shoes, hand gloves, 2x2=4

Not using P.P.E.'s Engr., Supv. Elec.

dust mask, coverall).

2. UNLOADING OF GIS

No specific available

PARTS,EQUIPMENTS & Supv.Elec., & Supervisor to ensure approved PTW is available

permit. 1x3=3

TOOLS BY USING help. on site.

BOOM TRUCK OR

MOBILE CRANE.

Revision: 0(26-May-2011) Page 4 of 10

HS.SAF.09.F12

Slips, trips and fall at the Maintain housekeeping around in the working area.

same level. Emal / SNC rep.,

1x2=2

Engr., Supv. Elec.

All workers involve in the activity must be aware of

Emal / SNC rep., heat stress, supervisor to ensure drinking cold water

Hot weather. is available. 2x2=4

Engr., Supv. Elec.

Supervisor to give tool box talk regarding proper

Manual handling hazards Elec. & help. manual handling. 1x1=2

Use of mobile equipments Supervisor to all mobile equipments are duly

Engr., Supv., inspected by EMAL / SLII with valid load test

e.g. boom truck/mobile 1x3=3

Elec., & helpers certificates.

crane

Provide appropriate dust mask or respiratory

Engr., Supv. mask.

2 x2=4

Dust Elec. & help.

Revision: 0(26-May-2011) Page 5 of 10

HS.SAF.09.F12

Use 3-point contact while climbing up and down

ladder.

Always climb up and down facing the ladder.

Use of ladder Elec. & help. Don't carry tools or materials in your hand while 1x3=3

climbing up and down ladder.

WARNING: When climbing down the ladder, BE

AWARE YOU ARE STILL ON THE BOOM

TRUCK / MOBILE CRANE

Attached tag line to load to guide and control.

Supv. Elec. &

Movement of suspended load 1x3=3

help.

All lifting gears must be in good condition with

Supv. Elec. & valid load test certificate.

1x3=3

Lifting gears help.

Ensure good condition of equipments with valid

Engr., Supv., load test certificate.

Poor condition of 1x2=2

crane or boom truck

Elec., & helpers Supervisor to ensure the equipment is duly

inspected by SLII with inspection sticker on it.

Correct position of crane on even and solid

Loose Surface, Engr., Supv., surface with wooden out rigger pad.

1x1=1

unstable of out riggers of Elec., & helpers

the equipment Secure the load on the boom truck during

transportation

Revision: 0(26-May-2011) Page 6 of 10

HS.SAF.09.F12

No or incompetent Competent & certified operator, rigger &

rigger or banksman, no Supv., Elec., & banksman to be deployed, barricade the working

1x2=2

signages and barricade helpers radius of the lifting equipment, post the warning

sign board which read KEEP AWAY LIFTING

WORKS IN PROGRESS.

All workers must receive the Emal Big 5 training,

Moving of mobile Engr., Supv. be aware of operation moving equipments and the

2x3=6

equipments of Emal scaffolders designated path walk.

operation.

Wear P.P.E.'s at all times (hard hat,

Engr., Supv. & appropriate safety glass, safety shoes, hand 2x2=4

Not using P.P.E.'s helper gloves, dust mask, coverall).

3. SHIFTING THE GIS

PARTS, EQUIPMENTS &

Proximity of energized Engr., Supv. &

TOOLS BY USING GIS equipments is in service DO NOT TOUCH or 1x2=2

equipments helper

PALLET TROLLEY. encroach in to the equipment area

Manual handling Elec. & help. Supervisor to give toolbox talk regarding proper 1x2=2

manual handling.

Revision: 0(26-May-2011) Page 7 of 10

HS.SAF.09.F12

Maintain good housekeeping around the

Supv., Elec. & area.

Slip / Trip & Fall same 1x2=2

Helpers

level

Supervisor to ensure that the pallet trolley is in

Supv., Elec. & good conditioned and check the safe working load

Pallet trolley. 1x3=3

Helpers against the weight of GIS parts, equipments and

tools.

Supervisor to ensure that the GIS parts,

equipments and tools are in stable position prior

to move the pallet trolley.

Supv., Elec. &

Unstable load 1x3=3

Helpers During movement of the trolley ensure GIS

parts, equipments and tools are well supported.

Keep good clearance walls and other fixtures

while moving.

Other workers Only competent and authorized person to do the

Unauthorized workers inspection, ensure notified the client with all 1x3=3

nearby

necessary documents.

Engr., Supv. & Wear P.P.E.'s at all times (hard hat, 2x2=4

Not using P.P.E.'s helper appropriate safety glass, safety shoes, hand

gloves, dust mask,coverall).

This sheet must be properly completed detailing all of the steps required to complete the job along with the sequence of events and each of the hazards

arising. Failure to properly complete the form will result in non-approval.

(Additional sheets to be used as required)

Revision: 0(26-May-2011) Page 8 of 10

HS.SAF.09.F12

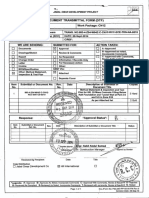

9. Chemical Analysis (This form to be used as required)

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Number of People Exposed

Duration of Exposure

Frequency of Exposure

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

This sheet must be properly completed detailing all the necessary information. Failure to properly complete the form will result in non-approval.

Revision: 0(26-May-2011) Page 9 of 10

HS.SAF.09.F12

Revision: 0(26-May-2011) Page 10 of

10

Você também pode gostar

- Contractor Work Method Statement (Ehs)Documento11 páginasContractor Work Method Statement (Ehs)nsadnanAinda não há avaliações

- Risk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001Documento12 páginasRisk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001nsadnanAinda não há avaliações

- Modification of Cable Ladder in Bath Processing PlantDocumento14 páginasModification of Cable Ladder in Bath Processing PlantnsadnanAinda não há avaliações

- Risk Ass. - Load Current Measurement and Cleaning of Oil CoolerDocumento7 páginasRisk Ass. - Load Current Measurement and Cleaning of Oil CoolernsadnanAinda não há avaliações

- RA For Fixing Warning LabelsDocumento5 páginasRA For Fixing Warning LabelsnsadnanAinda não há avaliações

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDocumento20 páginasRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanAinda não há avaliações

- Cable PullingDocumento10 páginasCable PullingnsadnanAinda não há avaliações

- Risk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTDocumento9 páginasRisk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTnsadnanAinda não há avaliações

- D02 MS Ra Pov PDFDocumento35 páginasD02 MS Ra Pov PDFnsadnanAinda não há avaliações

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDocumento16 páginasPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanAinda não há avaliações

- Risk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-003ADocumento6 páginasRisk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-003AnsadnanAinda não há avaliações

- Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMDocumento16 páginasRisk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMnsadnanAinda não há avaliações

- Risk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONDocumento6 páginasRisk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONnsadnan100% (1)

- Contractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingDocumento8 páginasContractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingnsadnanAinda não há avaliações

- Fuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)Documento8 páginasFuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)nsadnanAinda não há avaliações

- 4.5.3!01!06 First Aid Property Environmental ReportDocumento4 páginas4.5.3!01!06 First Aid Property Environmental Reportloveson709Ainda não há avaliações

- Warehouse Risk Assessment Aldir II IWPPDocumento25 páginasWarehouse Risk Assessment Aldir II IWPPMadhu MohanAinda não há avaliações

- Focus Audit Temp WorksDocumento2 páginasFocus Audit Temp WorksArunKumar GanesanAinda não há avaliações

- Method Statement of ExcavationDocumento19 páginasMethod Statement of ExcavationIrfan AliAinda não há avaliações

- HSE Documents-Fit-Out Work-Ris AssessmentDocumento3 páginasHSE Documents-Fit-Out Work-Ris AssessmentTom BobanAinda não há avaliações

- 8) SWP-08 Working at HeightsDocumento3 páginas8) SWP-08 Working at HeightsRachel NoraAinda não há avaliações

- Itp-Inspection & Test Plan: Title / Name:Installation of Distribution Boards & Accessories (For Al Riffastations)Documento2 páginasItp-Inspection & Test Plan: Title / Name:Installation of Distribution Boards & Accessories (For Al Riffastations)wagwahkiabatheAinda não há avaliações

- Method Statement For Cable Terminaton (CP3)Documento20 páginasMethod Statement For Cable Terminaton (CP3)Jacky TamAinda não há avaliações

- Job Safety Analysis: Client: ContractorDocumento7 páginasJob Safety Analysis: Client: Contractorloveson709Ainda não há avaliações

- Excavation and LiftingDocumento4 páginasExcavation and LiftingRapha RachoAinda não há avaliações

- Procurement Requisition: Form No. Version No. 5.1Documento1 páginaProcurement Requisition: Form No. Version No. 5.1loveson glariyansAinda não há avaliações

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Documento3 páginasRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- MDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - UptdDocumento21 páginasMDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - Uptdshamshad ahamedAinda não há avaliações

- FlowchartDocumento9 páginasFlowchartCatur PrihatmonoAinda não há avaliações

- JSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)Documento1 páginaJSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)abdulthahseen007Ainda não há avaliações

- Method Statement & Risk Assessment Hydrostatic Leak TestDocumento7 páginasMethod Statement & Risk Assessment Hydrostatic Leak TestWalid AmdouniAinda não há avaliações

- RA - 18 - For Concrete Topping On Hollow Core SlabDocumento14 páginasRA - 18 - For Concrete Topping On Hollow Core SlabIbrahim EsmatAinda não há avaliações

- 18 - RA Roadworks Risk AssessmentDocumento1 página18 - RA Roadworks Risk AssessmentkumarAinda não há avaliações

- A3E4U9 - Appendix A - A3 Surerus Hydrostatic Test PlanDocumento49 páginasA3E4U9 - Appendix A - A3 Surerus Hydrostatic Test PlanGilberto Yoshida100% (1)

- 4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1Documento4 páginas4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1loveson709Ainda não há avaliações

- Method Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFDocumento8 páginasMethod Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFFredie UnabiaAinda não há avaliações

- 08 Hirarc Form (r02)Documento2 páginas08 Hirarc Form (r02)Aizat Sera SuwandiAinda não há avaliações

- Minutes of MeetingDocumento3 páginasMinutes of MeetingNoriel BueranoAinda não há avaliações

- Pipeline HydrotestDocumento1 páginaPipeline HydrotestNsidibe EssienAinda não há avaliações

- Monthly Quality Report: Akt Oil ServicesDocumento4 páginasMonthly Quality Report: Akt Oil ServicesLaith SalmanAinda não há avaliações

- Light Assessment Readings GMPDocumento2 páginasLight Assessment Readings GMPloveson glariyansAinda não há avaliações

- SWMS 1 Loading, Unloading & ShiftingDocumento8 páginasSWMS 1 Loading, Unloading & ShiftingJ.j.JijoAinda não há avaliações

- JSA Pile Concrete Works OkDocumento9 páginasJSA Pile Concrete Works OkMon Trang NguyễnAinda não há avaliações

- Risk Assessment Removal of Walers & StrutsDocumento6 páginasRisk Assessment Removal of Walers & StrutsBhargav BbvsAinda não há avaliações

- Excel Construction Limited: Daily Works ReportDocumento4 páginasExcel Construction Limited: Daily Works ReportMunabaAinda não há avaliações

- SWP-12 Pressure TestDocumento3 páginasSWP-12 Pressure TestLumin HanAinda não há avaliações

- TRN 0515 B PDFDocumento15 páginasTRN 0515 B PDFrayAinda não há avaliações

- Method Statement For Ug Piping 6423dp420 00 00200 00 Rev03 PDFDocumento20 páginasMethod Statement For Ug Piping 6423dp420 00 00200 00 Rev03 PDFadventmanurungAinda não há avaliações

- C T 7 0901a RACI Chart WHS Plan AppendixDocumento14 páginasC T 7 0901a RACI Chart WHS Plan AppendixKathleen S. OrtizAinda não há avaliações

- Form Mobilization PlanDocumento2 páginasForm Mobilization PlanTaufik HidayatAinda não há avaliações

- Design Submission Programme - RevisedDocumento8 páginasDesign Submission Programme - RevisedUmesgAinda não há avaliações

- Groundwater Management Sub PlanDocumento16 páginasGroundwater Management Sub PlanibrahimAinda não há avaliações

- JN1350 - Fab Progress S Curve Structures 200217Documento12 páginasJN1350 - Fab Progress S Curve Structures 200217Rendra Maha Putra JfAinda não há avaliações

- Philip Bates: Piling Method Statement For Willmott Dixon Riverside Court, Birstall, Leicestershire LE4 4EHDocumento11 páginasPhilip Bates: Piling Method Statement For Willmott Dixon Riverside Court, Birstall, Leicestershire LE4 4EHYap Yee FooAinda não há avaliações

- QMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Documento10 páginasQMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Vasilica BarbarasaAinda não há avaliações

- Power and Control Cable Laying, Glading and TerminationDocumento9 páginasPower and Control Cable Laying, Glading and Terminationsalman100% (1)

- MRL-HRM-IMSF-03.01C (01) Training Seminar Conference RequestDocumento1 páginaMRL-HRM-IMSF-03.01C (01) Training Seminar Conference RequestFateh AliyaAinda não há avaliações

- Risk Assessment For GIS Preparation For HV Cable TestDocumento11 páginasRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatDocumento6 páginasRisk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatnsadnanAinda não há avaliações

- Cable Pulling, Glanding and TerminationsDocumento6 páginasCable Pulling, Glanding and TerminationsnsadnanAinda não há avaliações

- DDC Systems2Documento28 páginasDDC Systems2nsadnan100% (1)

- ONVIF Profile T Specification v1-0Documento77 páginasONVIF Profile T Specification v1-0nsadnanAinda não há avaliações

- BSIA Cyber Secure It January 2019Documento16 páginasBSIA Cyber Secure It January 2019nsadnanAinda não há avaliações

- ONVIF Profile Feature Overview v2-2Documento6 páginasONVIF Profile Feature Overview v2-2nsadnanAinda não há avaliações

- HVAC ManualDocumento107 páginasHVAC ManualWissam JarmakAinda não há avaliações

- ONVIF Profile - S Specification v1-2Documento42 páginasONVIF Profile - S Specification v1-2nsadnan0% (1)

- Excel Intelligent Pdu User InstructionsDocumento2 páginasExcel Intelligent Pdu User InstructionsnsadnanAinda não há avaliações

- Excel Intelligent PduDocumento21 páginasExcel Intelligent PdunsadnanAinda não há avaliações

- 1 45Documento3 páginas1 45nsadnan0% (1)

- Testing and Commissioning Pre-Check List (ID 1506)Documento1 páginaTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Checklist For Access Control System InstallationDocumento6 páginasChecklist For Access Control System Installationnsadnan71% (7)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Documento3 páginasRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocumento5 páginasPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanAinda não há avaliações

- Exc Fibre Installation GuideDocumento38 páginasExc Fibre Installation GuidensadnanAinda não há avaliações

- 109 Installation CCTV Systems PDFDocumento60 páginas109 Installation CCTV Systems PDFRodelDavidAinda não há avaliações

- Exc Installation GuideDocumento1 páginaExc Installation GuidensadnanAinda não há avaliações

- Exc Fibre Installation GuideDocumento16 páginasExc Fibre Installation GuideMohamad FaifAinda não há avaliações

- Checklist For Pre Commissioning of CCTV SystemDocumento1 páginaChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- Checklist For Commissioning of CCTV SystemDocumento2 páginasChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Documento1 páginaCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- Risk Assessment - Tk-4741-Removal Works For Site Office FacilitiesDocumento14 páginasRisk Assessment - Tk-4741-Removal Works For Site Office FacilitiesnsadnanAinda não há avaliações

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocumento6 páginasRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanAinda não há avaliações

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Documento4 páginasRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanAinda não há avaliações

- Sensor Line Cable InstallationDocumento6 páginasSensor Line Cable InstallationnsadnanAinda não há avaliações

- ADDC Electricity Wiring Regulations - Mar.2014Documento276 páginasADDC Electricity Wiring Regulations - Mar.2014hajimak89% (18)

- Risk Assessment - Installation of Ventilation FanDocumento6 páginasRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocumento3 páginasRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocumento10 páginasRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- RISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolerDocumento5 páginasRISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolernsadnanAinda não há avaliações

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocumento3 páginasRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Sage 200 Evolution Training JourneyDocumento5 páginasSage 200 Evolution Training JourneysibaAinda não há avaliações

- General Description Product Summery: Bvdss Rdson IDDocumento4 páginasGeneral Description Product Summery: Bvdss Rdson IDJose Angel TorrealbaAinda não há avaliações

- Pfmar SampleDocumento15 páginasPfmar SampleJustin Briggs86% (7)

- 4 FAR EAST BANK & TRUST COMPANY V DIAZ REALTY INCDocumento3 páginas4 FAR EAST BANK & TRUST COMPANY V DIAZ REALTY INCDanielleAinda não há avaliações

- BP Azspu Driver Fatigue & Tiredness Management ProcedureDocumento11 páginasBP Azspu Driver Fatigue & Tiredness Management ProcedureEl Khan100% (1)

- Assignment Business EnvironmentDocumento9 páginasAssignment Business EnvironmentVikram MayuriAinda não há avaliações

- X606 PDFDocumento1 páginaX606 PDFDany OrioliAinda não há avaliações

- User Manual OptiPoint 500 For HiPath 1220Documento104 páginasUser Manual OptiPoint 500 For HiPath 1220Luis LongoAinda não há avaliações

- Techgig Open Round CompetitionDocumento6 páginasTechgig Open Round CompetitionAnil Kumar GodishalaAinda não há avaliações

- Huzaima ResultDocumento2 páginasHuzaima ResultSaif Ali KhanAinda não há avaliações

- Reading Task CardsDocumento2 páginasReading Task CardscatnappleAinda não há avaliações

- Keywords: Communication, Technology, Collaborative, Evaluative Learning, InnovativeDocumento11 páginasKeywords: Communication, Technology, Collaborative, Evaluative Learning, InnovativeNnamani EmmanuelAinda não há avaliações

- CS506 Mid SubjectiveDocumento2 páginasCS506 Mid SubjectiveElma AlamAinda não há avaliações

- Scheduled Events in MySQL Load CSV Fileto MysqltabDocumento11 páginasScheduled Events in MySQL Load CSV Fileto Mysqltabboil35Ainda não há avaliações

- Vivado Power Analysis OptimizationDocumento120 páginasVivado Power Analysis OptimizationBad BoyAinda não há avaliações

- Tavera Vs Valdez 1 Phil 468Documento2 páginasTavera Vs Valdez 1 Phil 468John AmbasAinda não há avaliações

- Assignment 03 Investments in Debt SecuritiesDocumento4 páginasAssignment 03 Investments in Debt SecuritiesJella Mae YcalinaAinda não há avaliações

- Claim Age Pension FormDocumento25 páginasClaim Age Pension FormMark LordAinda não há avaliações

- CPI As A KPIDocumento13 páginasCPI As A KPIKS LimAinda não há avaliações

- MGT 201 Midterm Exam, Version BDocumento8 páginasMGT 201 Midterm Exam, Version BCybelle TradAinda não há avaliações

- CRM Module 1Documento58 páginasCRM Module 1Dhrupal TripathiAinda não há avaliações

- Final Answers Chap 002Documento174 páginasFinal Answers Chap 002valderramadavid67% (6)

- French Revolution EssayDocumento2 páginasFrench Revolution Essayapi-346293409Ainda não há avaliações

- Br2e Int Readingfile10 PDFDocumento2 páginasBr2e Int Readingfile10 PDFSanti RodriguezAinda não há avaliações

- CERES News Digest - Week 11, Vol.4, March 31-April 4Documento6 páginasCERES News Digest - Week 11, Vol.4, March 31-April 4Center for Eurasian, Russian and East European StudiesAinda não há avaliações

- Burberry Annual Report 2019-20 PDFDocumento277 páginasBurberry Annual Report 2019-20 PDFSatya PhaneendraAinda não há avaliações

- History of Phosphoric Acid Technology (Evolution and Future Perspectives)Documento7 páginasHistory of Phosphoric Acid Technology (Evolution and Future Perspectives)Fajar Zona67% (3)

- Data MiningDocumento721 páginasData MiningAuly Natijatul AinAinda não há avaliações

- Cyclical Iterative Design Process, Learning From ExperienceDocumento7 páginasCyclical Iterative Design Process, Learning From ExperiencemartinsmitAinda não há avaliações

- 15.910 Draft SyllabusDocumento10 páginas15.910 Draft SyllabusSaharAinda não há avaliações