Escolar Documentos

Profissional Documentos

Cultura Documentos

Risk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOM

Enviado por

nsadnanTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Risk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOM

Enviado por

nsadnanDireitos autorais:

Formatos disponíveis

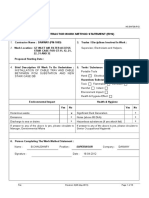

HS.SAF.09.

F12

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : DANWAY (4600003190) 3. Trades / Disciplines Involved In Work :

2. Work Location : POT LINE 1 A (ELECTRICAL Engineer, Supervisor, Electricians and Helpers.

ROOM - Bldg: 5115-01)

Proposed Starting Date :

4. Brief Description of Work to Be Undertaken: 5. Tools / Substance

INSTALLATION OF PLC CABINET IN SECTION Portable Tools

ELECTRICAL ROOM. Hand Electrical Pneumatic

Hazardous Substances

Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

Hazardous waste x Significant Dust Generation x

Emissions x Noise (above 85 DbA) x

Discharge to sea or drains x Hazardous substances (if yes attach list) x

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

6. Person Completing The Work Method Statement :

Name : Position : Company :

Signature : Date :

File: Revision: 0(26-May-2011) Page 1 of 8

HS.SAF.09.F12

7. Approvals

Contractors Site Rep. Name Signature : Date :

EMAL Representative Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

EMAL EHS Department

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

After the Area Owners approval the Work Method Statement shall be forwarded to EHS department for

approval

The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

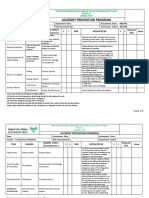

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low Severity LP x MS LP x HS

1x1=1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very minor).

File: Revision: 0(26-May-2011) Page 2 of 8

HS.SAF.09.F12

8. Safety Analysis

Severity x Probability =

Risk

Individual Activities To Identified Hazard(s) Persons Exposed To Precautions and Plan of actions To Be Taken To

Complete Work. List In Associated With Activity Hazard Remove / Control Hazards Residual Risk

Sequence of Activity (Use Risk Estimator

Chart)

PREPARATION. Slips, trips and fall at Emal rep., Engr., After getting valid permit from EMAL only

Supv. Elec, and 2x2=4

the same level. starts work.

Hot environment helpers Engineer / supervisor ensure that the work

Manual handling permit is valid for the date and time

hazards. Electrical room is under Electrical

maintenance team and they should be

informed while doing the installation job.

Electrical room having LV Live panels, care

should be taken not to touch or disturb the

live panel.

Ensure the operatives must be go through

EMAL POTLINE Electrical Hazard Training

and Big Five Training.

All personnel involve in the activities must

wear the required PPEs at all times(eg.hard

hat, appropriate safety glass, electrical

insulated safety shoe, hand gloves, dust

mask, fire retardant long sleeve shirt / pants)

All personnel involve in the activity must be

aware of heat stress, supervisor to ensure

cold drinking water and electrolyte are

available at site all time. Use heat

radiation shield.Ensure that Storage of

File: Revision: 0(26-May-2011) Page 3 of 8

HS.SAF.09.F12

drinking water while working in Live Potline

and basement must be well outside the

Potline battery limit. (After the Yellow

barricade).

Power cables are running below false floor

care should be taken to not to damage those

cable while fixing the panel, supervisor to

ensure.

Ensure that Material handling through ramp

shall be manual handling only and pick up

and any other vehicles are not allowed on

that area.

Ensure that access ladder will be use only for

access, donot as a working platform

Ensure that people working in duct side

should be rotated every 1 hour.

Advance planning by contractor considering

the time consumption to receive the permit

from EMAL

Emergency procedure must be displayed at

prominent location and cascade to

operatives on regular interval and recorded.

The operatives must be go through DANWAY

safety induction.

Extra care should be taken while working in

Live Potline and Basement.

Danway supervisor to ensure that danway

employees should not go near the live pot /

busbars and not touching the superstructure.

Use only specific Entry and exit route to

potline.Co-ordinate with shift supervisor for

File: Revision: 0(26-May-2011) Page 4 of 8

HS.SAF.09.F12

the specific Entry and exit route.

Only day shift are allowed to work in potline

and danway supervisor to ensure that yellow

lines should not crossed by the any danway

employees.

All hand tools to be used must be in good

condition, no handmade hand tools to be

used at site.

INSTALLATION OF PLC The area is highly magnetic and tool may

Hand tools Supv. Elec & helpers 2x1=2

CABINET move uncontrollably. Extra care should be

taken while handling and tools should not

reach to the near by busbars and it should

be non magnetic tools.

Supervisor to inspect the battery operated

Using damaged drill machine and make sure it is in good

battery operated tools. Elect & helpers condition with valid colour coding. 2x2=4

Minor Electrocution Dont use excessive force to drill machine

during drilling

Provide appropriate safety glass &respiratory

Emal, Engr., Supv.

Dust mask. 2 x 1 =2

Elec, and helpers

Cordon the work area to avoid unauthorized

entry.

Provide applicable safety warning

signboards

All workers near by Do not keep unwanted materials on 2x2=4

Fall of materials

top of the ladder/scaffold.

Materials to be removed should be in

safe manner one by one--, ensure no

materials to be dropped.

File: Revision: 0(26-May-2011) Page 5 of 8

HS.SAF.09.F12

Use only fiber or wooden ladder.

Ensure that ladder are using for

access purpose only.

Height of the wooden ladder should

not exceed 5 mtrs.

Dont stack unnecessary materials

Using damaged ladder. inside working area.

Dont leave cut cable inside the

Fall from height or Supv. Elect & helpers 3x1=3

building & top of panels.

from

Always climb up and down facing the

ladder/scaffold/raised

floor. Ladder/scaffold.

Working area inside elecrical room is raised

flooring and care should be taken for

different level, workers can fall in case of

dislocated tiles or open tiles.

Don't carry tools or materials in your hand

while climbing up and down scaffold.

Manual handling. Supervisor to give toolbox regarding proper

Supv. Elec, and manual handling.

Slip and fall of PLC helpers

3 x 1 =3

cabinet while fixing. Extra care while fixing PLC cabinet.

Workers may slip, trip & Maintain house keeping around the area

Supv. Elec, and

fall at same ground or helpers Walkway and gangway to be kept free of 3 x 1 =3

from height obstruction

Extra care while installing through PLC

Sharp edges from

Elec & helpers cabinet. 2 x 1 =2

cable PLC cabinet.

Use hand gloves while installing PLC cabinet

Incompetent workers Elect & helpers Competent workers to be deployed,

2x1=2

supervisor to ensure work safe system

File: Revision: 0(26-May-2011) Page 6 of 8

HS.SAF.09.F12

Other workers Only competent and authorized person to do

Unauthorized workers the inspection, ensure notified the DUBAL 3x1=3

INSPECTION nearby

with all necessary documents..

This sheet must be properly completed detailing all of the steps required to complete the job along with the sequence of events and each of the hazards

arising. Failure to properly complete the form will result in non-approval.

(Additional sheets to be used as required

9. Chemical Analysis (This form to be used as required)

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Number of People Exposed

Duration of Exposure

Frequency of Exposure

File: Revision: 0(26-May-2011) Page 7 of 8

HS.SAF.09.F12

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

This sheet must be properly completed detailing all the necessary information. Failure to properly complete the form will result in non-approval.

File: Revision: 0(26-May-2011) Page 8 of 8

Você também pode gostar

- Contractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingDocumento8 páginasContractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingnsadnanAinda não há avaliações

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDocumento16 páginasPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanAinda não há avaliações

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDocumento20 páginasRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanAinda não há avaliações

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDocumento13 páginasRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanAinda não há avaliações

- Risk Ass. - INSTALLATION OF 25 MM G.I. PIPE WITH EXISTING LINEDocumento12 páginasRisk Ass. - INSTALLATION OF 25 MM G.I. PIPE WITH EXISTING LINEnsadnanAinda não há avaliações

- Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatDocumento6 páginasRisk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatnsadnanAinda não há avaliações

- Risk Assessment For GIS Preparation For HV Cable TestDocumento11 páginasRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMDocumento16 páginasRisk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMnsadnanAinda não há avaliações

- 007 - Risk Ass. - CE-0994-MEP WorksDocumento9 páginas007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Documento3 páginasRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Documento4 páginasRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanAinda não há avaliações

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocumento9 páginasRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Documento3 páginasRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocumento3 páginasRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocumento6 páginasJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocumento6 páginasRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocumento10 páginasRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Documento11 páginas012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanAinda não há avaliações

- Risk Assessment Relocation Overhead LineDocumento5 páginasRisk Assessment Relocation Overhead Lineghada gattouchAinda não há avaliações

- 6.risk Assessment of Epoxy Coating System (Rev-2) NEW OKDocumento7 páginas6.risk Assessment of Epoxy Coating System (Rev-2) NEW OKRisal SinuAinda não há avaliações

- RA For HydrotestDocumento26 páginasRA For HydrotestSandeep kumarAinda não há avaliações

- Environmental, Health and Safety Risks AnalysisDocumento2 páginasEnvironmental, Health and Safety Risks AnalysisKrishna PatilAinda não há avaliações

- Risk Assessment Record Activity: Installation ofDocumento17 páginasRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- Replacement of Flowmeter - Risk AssessmentDocumento3 páginasReplacement of Flowmeter - Risk Assessmentanishdev660% (5)

- Risk Assessment For Installation of Drainage Pipes and FittingsDocumento8 páginasRisk Assessment For Installation of Drainage Pipes and Fittingsfaizan khan100% (1)

- Risk Assessment (Installation of Cables & Wires)Documento6 páginasRisk Assessment (Installation of Cables & Wires)michael acosta100% (3)

- 20-RAS-Transformer InstallationDocumento2 páginas20-RAS-Transformer InstallationWalid MarhabaAinda não há avaliações

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocumento6 páginasRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanAinda não há avaliações

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Documento3 páginas(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisAinda não há avaliações

- Job Risk Assessment Design and Installation of New Scada SystemDocumento17 páginasJob Risk Assessment Design and Installation of New Scada Systemzee khanAinda não há avaliações

- 2 - Pulling CablesDocumento5 páginas2 - Pulling CablesAhmed KhaledAinda não há avaliações

- Risk Assessment For Installation of Cable Tray & TrunkingDocumento7 páginasRisk Assessment For Installation of Cable Tray & Trunkingfaizan khanAinda não há avaliações

- SWMS - HVAC ShiftingDocumento6 páginasSWMS - HVAC ShiftingParas100% (1)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocumento6 páginasRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Cable Pulling / Laying, Glanding and Termination SopDocumento12 páginasCable Pulling / Laying, Glanding and Termination SopStansilous Tatenda Nyagomo0% (1)

- Changing Faulty Flood Light JSA (BoomLift)Documento2 páginasChanging Faulty Flood Light JSA (BoomLift)black_3289Ainda não há avaliações

- Risk Generator Risk AssessmentDocumento2 páginasRisk Generator Risk AssessmentBaher MohamedAinda não há avaliações

- Risk Assessment For Use of Power ToolsDocumento2 páginasRisk Assessment For Use of Power ToolsRicardo DalisayAinda não há avaliações

- Doku - Pub Risk-AssessmentDocumento10 páginasDoku - Pub Risk-AssessmentUlviyye ElesgerovaAinda não há avaliações

- Safety Data Sheet: ARDROX 907PB AerosolDocumento11 páginasSafety Data Sheet: ARDROX 907PB Aerosolabdulbaset alselwi100% (1)

- SOP SOP0022 Concrete Core DrillDocumento3 páginasSOP SOP0022 Concrete Core Drillkristian08Ainda não há avaliações

- 326-Project Training Plan Rev 000Documento1 página326-Project Training Plan Rev 000francisAinda não há avaliações

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDocumento3 páginasLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINAinda não há avaliações

- Mobilization and Installation of CHW PipesDocumento8 páginasMobilization and Installation of CHW PipesYounis KhanAinda não há avaliações

- Critical Steps Analysis - Risk Assessment: 28/06/2018 Welding OperationsDocumento2 páginasCritical Steps Analysis - Risk Assessment: 28/06/2018 Welding OperationsdnmuleAinda não há avaliações

- 19.17 (SWMS) All Work HvacDocumento17 páginas19.17 (SWMS) All Work Hvacsyed khaja misbhuddinAinda não há avaliações

- Sand FillingDocumento1 páginaSand FillingGyanendra Narayan NayakAinda não há avaliações

- Risk AssessmetDocumento9 páginasRisk AssessmetAshoka Indunil WickramapalaAinda não há avaliações

- Risk Assessment - Placing of Transformer - TTSDocumento6 páginasRisk Assessment - Placing of Transformer - TTSnsadnan100% (2)

- 011 Duct Lifter SWMSDocumento2 páginas011 Duct Lifter SWMSJ JohnsonAinda não há avaliações

- Ehs Risk AssessmentDocumento2 páginasEhs Risk AssessmentRohit Singh100% (1)

- 2 - REV. 2 Cable Pulling JHA Rev. 2Documento23 páginas2 - REV. 2 Cable Pulling JHA Rev. 2naiyarAinda não há avaliações

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocumento7 páginasProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohnAinda não há avaliações

- Risk Assessment For Installation of Air OutletsDocumento8 páginasRisk Assessment For Installation of Air Outletsfaizan khanAinda não há avaliações

- 18 - RA Roadworks Risk AssessmentDocumento1 página18 - RA Roadworks Risk AssessmentkumarAinda não há avaliações

- TTEC Fencing RADocumento7 páginasTTEC Fencing RAGeml TrinidadAinda não há avaliações

- Risk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTDocumento9 páginasRisk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTnsadnanAinda não há avaliações

- Contractor Work Method Statement (Ehs)Documento11 páginasContractor Work Method Statement (Ehs)nsadnanAinda não há avaliações

- Modification of Cable Ladder in Bath Processing PlantDocumento14 páginasModification of Cable Ladder in Bath Processing PlantnsadnanAinda não há avaliações

- Risk Ass. - Load Current Measurement and Cleaning of Oil CoolerDocumento7 páginasRisk Ass. - Load Current Measurement and Cleaning of Oil CoolernsadnanAinda não há avaliações

- ONVIF Profile T Specification v1-0Documento77 páginasONVIF Profile T Specification v1-0nsadnanAinda não há avaliações

- 1 45Documento3 páginas1 45nsadnan0% (1)

- ONVIF Profile - S Specification v1-2Documento42 páginasONVIF Profile - S Specification v1-2nsadnan0% (1)

- ONVIF Profile Feature Overview v2-2Documento6 páginasONVIF Profile Feature Overview v2-2nsadnanAinda não há avaliações

- DDC Systems2Documento28 páginasDDC Systems2nsadnan100% (1)

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocumento5 páginasPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanAinda não há avaliações

- BSIA Cyber Secure It January 2019Documento16 páginasBSIA Cyber Secure It January 2019nsadnanAinda não há avaliações

- HVAC ManualDocumento107 páginasHVAC ManualWissam JarmakAinda não há avaliações

- Exc Fibre Installation GuideDocumento38 páginasExc Fibre Installation GuidensadnanAinda não há avaliações

- Testing and Commissioning Pre-Check List (ID 1506)Documento1 páginaTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Excel Intelligent PduDocumento21 páginasExcel Intelligent PdunsadnanAinda não há avaliações

- Checklist For Access Control System InstallationDocumento6 páginasChecklist For Access Control System Installationnsadnan71% (7)

- Exc Fibre Installation GuideDocumento16 páginasExc Fibre Installation GuideMohamad FaifAinda não há avaliações

- Excel Intelligent Pdu User InstructionsDocumento2 páginasExcel Intelligent Pdu User InstructionsnsadnanAinda não há avaliações

- Checklist For Pre Commissioning of CCTV SystemDocumento1 páginaChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- ADDC Electricity Wiring Regulations - Mar.2014Documento276 páginasADDC Electricity Wiring Regulations - Mar.2014hajimak89% (18)

- Checklist For Commissioning of CCTV SystemDocumento2 páginasChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- Exc Installation GuideDocumento1 páginaExc Installation GuidensadnanAinda não há avaliações

- Sensor Line Cable InstallationDocumento6 páginasSensor Line Cable InstallationnsadnanAinda não há avaliações

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Documento1 páginaCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Documento4 páginasRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanAinda não há avaliações

- 109 Installation CCTV Systems PDFDocumento60 páginas109 Installation CCTV Systems PDFRodelDavidAinda não há avaliações

- Risk Assessment - Tk-4741-Removal Works For Site Office FacilitiesDocumento14 páginasRisk Assessment - Tk-4741-Removal Works For Site Office FacilitiesnsadnanAinda não há avaliações

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocumento3 páginasRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- RISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolerDocumento5 páginasRISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolernsadnanAinda não há avaliações

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocumento6 páginasRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanAinda não há avaliações

- Risk Assessment - Installation of Ventilation FanDocumento6 páginasRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Documento3 páginasRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocumento3 páginasRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocumento10 páginasRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Respiratory Protection - Harmonized - PolicyDocumento26 páginasRespiratory Protection - Harmonized - PolicyZubaidi OthmanAinda não há avaliações

- Safety Rules BrochureDocumento12 páginasSafety Rules BrochureSuraj DeodathAinda não há avaliações

- Mooring Deck Guidelines UpdateDocumento20 páginasMooring Deck Guidelines UpdateAlchemist_JVCAinda não há avaliações

- JKR20710 0001 11Documento13 páginasJKR20710 0001 11keesinvong100% (2)

- JSA - Drilling ActivitiesDocumento4 páginasJSA - Drilling ActivitiesAMIN100% (1)

- Ergonomics Manual ToolsDocumento4 páginasErgonomics Manual ToolsZeeshan Bajwa100% (1)

- MSDS Artistri P5910 White Pigment Ink 071808Documento10 páginasMSDS Artistri P5910 White Pigment Ink 071808Cisca BebetzAinda não há avaliações

- SulfolaneAppendices A EDocumento158 páginasSulfolaneAppendices A Erkhandelwal9604Ainda não há avaliações

- Safety and Health Committee Regulation 1996Documento11 páginasSafety and Health Committee Regulation 1996Reza100% (1)

- Msds Colamulse Emultron PMDocumento4 páginasMsds Colamulse Emultron PMmndmatt100% (2)

- Rozmus Snares LOPA PDFDocumento6 páginasRozmus Snares LOPA PDFVíctor LeónAinda não há avaliações

- Vamac G Ethylene Acrylic Elastomer: Material Safety Data SheetDocumento18 páginasVamac G Ethylene Acrylic Elastomer: Material Safety Data Sheetchethugowda7Ainda não há avaliações

- Excavations OSHA 2226Documento44 páginasExcavations OSHA 2226Al DubAinda não há avaliações

- Hazard. Norma Shell. Shell StandardDocumento86 páginasHazard. Norma Shell. Shell Standardgustavoemir100% (1)

- CH 3Documento54 páginasCH 3hagos dargoAinda não há avaliações

- 4wce 600700Documento53 páginas4wce 600700Ahmed Elhoseeny100% (1)

- LG-1102 SdsDocumento4 páginasLG-1102 SdsZarul ZafranuddinAinda não há avaliações

- Method Statement BlankDocumento5 páginasMethod Statement BlankBassam AbdulwahabAinda não há avaliações

- Electrical Installation Regulations 2009Documento25 páginasElectrical Installation Regulations 2009Tony van der MeschtAinda não há avaliações

- SAPI Working at Heights Training 2011Documento63 páginasSAPI Working at Heights Training 2011Suharto AriAinda não há avaliações

- Workplace Inspection Checklist V1 25 May 2017Documento83 páginasWorkplace Inspection Checklist V1 25 May 2017M Kashif JunaidAinda não há avaliações

- ChE4140 AccidentCaseStudy G8DraftDocumento8 páginasChE4140 AccidentCaseStudy G8DraftEthan MuddAinda não há avaliações

- SBS List of Training Courses020615Documento14 páginasSBS List of Training Courses020615badar13Ainda não há avaliações

- fm2798 818 819 820 PDFDocumento4 páginasfm2798 818 819 820 PDFOrellana Zeballos Luis CristianAinda não há avaliações

- Safe Isolation Booklet PDFDocumento0 páginaSafe Isolation Booklet PDFThe Lone GunmanAinda não há avaliações

- Resource For Development and Delivery of Training To WorkersDocumento52 páginasResource For Development and Delivery of Training To WorkersAsifAinda não há avaliações

- Nebosh Favourite Questions IGC1Documento4 páginasNebosh Favourite Questions IGC1AfzalAinda não há avaliações

- Eh40 (WEL)Documento80 páginasEh40 (WEL)Cip ZerkopAinda não há avaliações

- Poor Leadership: E. Kevin Kelloway Niro Sivanathan Lori Francis Julian BarlingDocumento24 páginasPoor Leadership: E. Kevin Kelloway Niro Sivanathan Lori Francis Julian Barlings0nakhanAinda não há avaliações

- PWS Fuel Meter Calibration 01 AUG 15Documento29 páginasPWS Fuel Meter Calibration 01 AUG 15Paul BarnardAinda não há avaliações