Escolar Documentos

Profissional Documentos

Cultura Documentos

Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Omb

Enviado por

nsadnanDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Omb

Enviado por

nsadnanDireitos autorais:

Formatos disponíveis

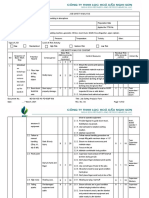

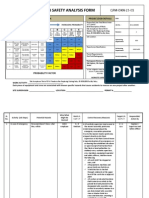

EHS RISK ASSESSMENT

ACTIVITY: INSTALLATION AND TESTING VAV BOXES & CONTROLS IN OMB

Current Risk Final Risk

Task (Steps) Potential Hazard Existing Control Additional Control Prob

Cons. Prob. Risk Cons. Risk

.

Supervisor to ensure all applicable

PTW to be available prior to

commencement of the task.

Obtain LOTOV as required.

Proper coordination with client.

Toolbox talks to be held at site, this

PREPARATION

shall cover the method statement

and risk assessment.

Obtain work

Only competent and authorized

permit Unauthorized

Arranging the personnel to be deployed,

workers supervisor to ensure all workers Ensure that all personals involved in the

tools and Slip, trips and fall 4 3 12 3 2 6

involve in the activity received EHS activity must undergo LOTOV (Lock

materials out Tag out).

induction from EMAL, AFC and

Conduct toolbox

DANWAY.

talk

Pre-work checklist has to be

Inform OMB in

completed.

charge before

Area to be cordon off and proper

starting the work.

sign boards to be placed.

In case of emergency, immediately

contact EMAL Emergency

Response Team without fail,

EMERGENCY NO:02-509 2111

All personnel involve in the activity

must be aware of heat stress,

supervisor to ensure cold drinking Follow the Ministerial Order Mid day

Heat stress. water/electrolyte are available all 4 3 12 break 3 2 6

the time. Conduct tool box talk about heat stress

Provide rest shed with air

conditions

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 1 of 9

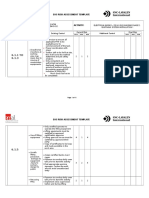

EHS RISK ASSESSMENT

ACTIVITY: INSTALLATION AND TESTING VAV BOXES & CONTROLS IN OMB

All personnel involve in the

activities must wear their P.P.E.'s at

site (hard hat, clear safety glass,

Working without safety shoes, safety harness, hand

gloves, coverall & reflective vest 3 3 9

P.P.E.s

etc.).

Note: This is applicable to all

activities.

INSTALLATION

OF VAV &

CONTROLS

Brin

g tools to

the site

Pro Cordon the work area to avoid

vide the Unwanted fall of unauthorized entry.

support for objects, tools, and Provide applicable safety warning

the VAV materials may signboards.

4 3 12

Inst cause injury to Use appropriate PPEs

all the VAV workers No materials or hand tools to be

Co underneath stocked on the top of

nnect it to scaffold/ladder.

the duct

Ins

ulate

Clo

se the

ceiling.

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 2 of 9

EHS RISK ASSESSMENT

ACTIVITY: INSTALLATION AND TESTING VAV BOXES & CONTROLS IN OMB

Examine the load to make sure it is

Manual handling not too heavy or awkward

hazards Always get close to the object to

(Back injury to

carry.

personnel. Hand 3 3 9

Ensure to see over the load when

and foot injury)

carrying it.

Use proper Hand gloves and foot

protection

All hand tools must be in good

condition, no homemade hand

tools to be used at site, supervisor

Damaged hand to check.

tools 3 2 6

Damage hand tools to be returned

to store.

Colour coding to be followed as

per EMAL procedure.

Close supervision will be

implemented

Competent operator for the use of Use proper PPEs.(face shield & ear

Damaged/unsafe power tool, inspect before use and plug etc)

drilling ensure valid colour coding.

Only 110V to be used at site.

machine/other Obtain a hot work permit before prior 5 4 20 3 2 6

power tools Cover flammable materials with fire

to start the work

Electrocution/fire Fire watchman equipped with blanket if not possible to relocate.

sufficient fire extinguisher to be

made available during the drilling

activities

Provide appropriate safety glass

Dust while drilling 3 2 6

&dust mask while drilling

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 3 of 9

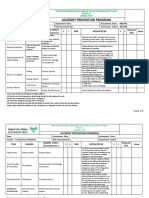

EHS RISK ASSESSMENT

ACTIVITY: INSTALLATION AND TESTING VAV BOXES & CONTROLS IN OMB

Use three point contacts while

climbing up and down ladder.

Damaged/unsafe Use only wooden/fibre ladder in

A type ladder EMAL projects and should be

colour coded.

Ladder to have valid inspection tag.

3 3 9

Always climb up and down facing

the ladder

Dont carry tools or materials in

your hand while climbing up and

down ladder

Bad

housekeeping, Maintain good housekeeping

around the working area.

Personnel may 3 2 6

Walkway and gangway to be

slip, trip and fall at kept free of obstruction

the same ground.

Installation of

Distribution All hand tools must be in good

Board condition, no homemade hand

tools to be used at site, supervisor

Bring the DB to Damaged hand to check.

the site. tools 3 2 6

Damage hand tools to be returned

Provide the to store.

support on the Colour coding to be followed as

wall per EMAL procedure.

Fix the DB

Inspect step ladder before use, one

man should hold the ladder on the

Damaged step ground while is in used.

ladder.

Use only wooden/fibre ladder and 4 3 12

should be colour coded

Ladder to have valid inspection tag.

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 4 of 9

EHS RISK ASSESSMENT

ACTIVITY: INSTALLATION AND TESTING VAV BOXES & CONTROLS IN OMB

Supervisor to inspect the drill

machine and make sure it is in

good condition.

Damaged hand Dont use excessive force to drill

power tools. 3 4 12

machine during drilling.

Electrocution/fire

Only competent and authorized

worker for the using if power tools

Only 110V to be used at site

Provide appropriate safety glass

Dust while drilling 3 2 6

&dust mask while drilling

Bad

housekeeping, Maintain good housekeeping

around the working area.

Personnel may 3 2 6

Walkway and gangway to be

slip, trip and fall at kept free of obstruction

the same ground.

MODIFICATION

OF EXISTING Isolation by EMAL Representative

DB

All hand tools must be in good

Damaged hand

condition with valid colour code, no

tools 3 2 6

homemade hand tools to be used

at site, supervisor to check.

Slip / Trip / Fall - Maintain good housekeeping

3 2 6

same level around the area.

Supervisor to conduct daily crew

meeting discuss about kinetic

handling methods prior to start

Injury to workers 3 3 9

work

(back,hands,foot) Use proper PPEs.

Ergonomics to be considered.

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 5 of 9

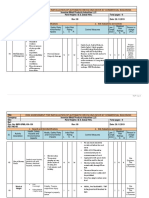

EHS RISK ASSESSMENT

ACTIVITY: INSTALLATION AND TESTING VAV BOXES & CONTROLS IN OMB

Obtain LOTOV permit.

Strictly follow EMAL LOTOV

procedure

Supervisor to ensure approved

PTW is available on site prior to

commencement the task.

Toolbox talks to be held at site

MARKING AND and documented.

DRILL THE Inspect hand tools before use.

Use of

Inspect drill machine before use

GLAND PLATE. damaged Hand

tools. and ensure dead man switch.

Using of drill Ensure proper grounding.

Remove the

machine. Ensure area to be drill is clear

gland plate from 4 3 12

Dust from drill from any services.

DB

machine. Only competent and authorized

Mark the glanding

worker for the using of power

location Electrocution.

tools.

Drill the marked Sprains & strains

Provide dust mask 3M 8210 or

area according to to hands and

arms 3M respiratory mask. .(where

the gland size. ever required)

Only 110 V to be used at site.

Use of cutting fluid when drilling

to avoid burns, damage to

equipments.

Close unused holes in gland

plate by grommets or PVC plug.

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 6 of 9

EHS RISK ASSESSMENT

ACTIVITY: INSTALLATION AND TESTING VAV BOXES & CONTROLS IN OMB

Obtain LOTOV permit.

Strictly follow EMAL LOTOV

procedure

When doing the termination in

GLANDING, existing system ensure that

JOINTING AND power is isolated and no current

TERMINATION: in the working place.

Opening of Use of sharp All hand tools must be in good

insulation hand tools. condition with valid colour code,

and cut the Competency of no homemade hand tools to be

cable for electrician/cabl used at site, supervisor to check.

jointing/ter e jointer. Torque wrench must be in good

mination. Using damaged condition with calibrated sticker

Crimp the hand tools/ on it. Supervisor to check.

lugs/ferrule Torque wrench Supervisor to ensure the

s to the 3 4 12

Use of Heat gun competency of electrician/cable

cable. (hot blower), jointer.

Remove electrocution/ Inspect heat gun before use;

the bolt burns. ensure that heat gun is in good

from the

Using damaged condition with valid colour coded.

breaker

hydraulic Only 110 V to be used at site

and tight

the cable

crimping tool Provide firewatcher and fire

lugs with extinguisher as required.

bolts to the Ensure that hydraulic crimping

breaker. tool to be used is calibrated and

functional

Ensure that crimping tool must

be compatible or same size with

the lugs or connectors.

Only competent and authorized

Unauthorized person to do the inspection, ensure

INSPECTION workers notified the client with all

3 3 9

necessary documents.

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 7 of 9

EHS RISK ASSESSMENT

ACTIVITY: INSTALLATION AND TESTING VAV BOXES & CONTROLS IN OMB

Maintain good housekeeping

around the working area.

Slip / Trip / Fall - Walkway and gangway to be kept

same level 3 2 6

free of obstruction.

All temporary cable should be

properly organized.

TESTING &

COMMISSIONI

NG OF HVAC

VAV & All hand tools must be in good

Using damaged

CONTROLS hand tools condition, no homemade hand 3 2 6

tools to be used at site, supervisor

Operate the VAV

to check.

from the

thermostat and

confirm that it is

operating.

Access towards to the testing area

to be barricaded and watchman to

be posted.

Testing area to be barricaded and

proper sign boards to be placed

which read "TESTING IN

Unauthorized PROGRESS KEEP AWAY".

person. Avoid cable joint.

Electrocution 3 3 9

Ensure that all power power sources

to be connected with ELCB.

All testing equipments must be in

good condition and with valid test

calibration.

Clear everybody from the area

where testing is in progress.

Using damaged All testing equipments must be in

testing equipment. good condition and with valid

3 2 6

calibration test certificates.

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 8 of 9

EHS RISK ASSESSMENT

ACTIVITY: INSTALLATION AND TESTING VAV BOXES & CONTROLS IN OMB

Bad

housekeeping, Maintain good housekeeping

around the working area.

Personnel may 3 2 6

Walkway and gangway to be

slip, trip and fall at kept free of obstruction

the same ground.

NOTE: All Current Risk ranked above C-15 must have additional control measures: Risk = Consequence x Probability (R = C x P)

Tolerable Risk (Low) = 1-6, Medium = 8 -12, (Methods statement), Intolerable Risks (High) = 15 25 (Method Statement plus additional Control Measures in place)

Consequence

Consequence ( Severity) Rating Factors (5) Probability Rating Factors (5) Frequency/Probability

(Severity)

No Safety Health Environ. Financial No Frequency A B C D E

1 First Aid Immediate Minor <AED 1k <1 hr A (1) Practically impossible or Once in 10 years 5 5 10 15 20 25

2 Medical Temporary Short term <AED50K 1-2 hrs B (2) Not likely or Once per year 4 4 8 12 16 20

3 Lost Time Short term Long term >AED300k 2-4 hrs C (3) Could happen or Monthly 3 3 6 9 12 15

4 Disability Long term Serious >AED500k 4-8 hrs D (4) Has happened or Weekly 2 2 4 6 8 10

5 Fatality Fatal Catastrophic >AED1m >1 shift E (5) Common or Daily 1 1 2 3 4 5

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 9 of 9

Você também pode gostar

- JSA For Cutting, Grinding and Welding in AtmosphereDocumento21 páginasJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- 2 - Pulling CablesDocumento5 páginas2 - Pulling CablesAhmed KhaledAinda não há avaliações

- SWMS2 Confined Space EntryDocumento9 páginasSWMS2 Confined Space EntryIslam Sarhan100% (1)

- Risk AssessmentDocumento4 páginasRisk AssessmentBishop Ojonuguwa AmehAinda não há avaliações

- Risk Assessment For Installation of SMDB DBDocumento12 páginasRisk Assessment For Installation of SMDB DBRAMA100% (1)

- Ehs Risk AssessmentDocumento2 páginasEhs Risk AssessmentRohit Singh100% (1)

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Documento11 páginas012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanAinda não há avaliações

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDocumento23 páginasCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- Risk Assessment Record Activity: Installation ofDocumento17 páginasRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- Cable Tray Fixing - HiraDocumento175 páginasCable Tray Fixing - HiraVENKATESAN MAinda não há avaliações

- Risk Assessment - Installation of Ventilation FanDocumento6 páginasRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment - Installation of Ventilation FanDocumento6 páginasRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- 20-RAS-Transformer InstallationDocumento2 páginas20-RAS-Transformer InstallationWalid MarhabaAinda não há avaliações

- Risk Assessment ForkliftDocumento2 páginasRisk Assessment Forkliftmohamed ghaly100% (2)

- 5.19 JSP Electrical Power InstallationDocumento4 páginas5.19 JSP Electrical Power InstallationDarius DsouzaAinda não há avaliações

- 63 Risk Assesments Testing and Pre-Commissioning WorksDocumento18 páginas63 Risk Assesments Testing and Pre-Commissioning WorksEngr.Syed Amjad100% (3)

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Documento3 páginasTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreAinda não há avaliações

- Risk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light FittingsDocumento6 páginasRisk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light Fittingsnsadnan86% (21)

- 007 - Risk Ass. - CE-0994-MEP WorksDocumento9 páginas007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Documento3 páginasRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Documento3 páginasRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Risk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Documento12 páginasRisk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Sachwin SachuAinda não há avaliações

- Risk Assessment - Placing of Transformer - TTSDocumento6 páginasRisk Assessment - Placing of Transformer - TTSnsadnan100% (2)

- Laying of Road Crossing Duct For Irrigation WorksDocumento9 páginasLaying of Road Crossing Duct For Irrigation Workssajin0% (2)

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDocumento3 páginasLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINAinda não há avaliações

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocumento8 páginasRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- RAPID-P0027-0005-CON-JHA-3215-0005 - Rev. A JHA of Blasting and PaintingDocumento4 páginasRAPID-P0027-0005-CON-JHA-3215-0005 - Rev. A JHA of Blasting and Paintingshaiful annuarAinda não há avaliações

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocumento10 páginasRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- DDC Systems2Documento28 páginasDDC Systems2nsadnan100% (1)

- RA Pump TemoraryDocumento12 páginasRA Pump TemoraryCarlos ImmanuelAinda não há avaliações

- Risk Assessment For .TESTING AND COMMISSIONING OF LV CABLEDocumento19 páginasRisk Assessment For .TESTING AND COMMISSIONING OF LV CABLEarun kurlan100% (3)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocumento3 páginasRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Cable Pulling / Laying, Glanding and Termination SopDocumento12 páginasCable Pulling / Laying, Glanding and Termination SopStansilous Tatenda Nyagomo0% (1)

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDocumento14 páginasRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- SWMS - HVAC ShiftingDocumento6 páginasSWMS - HVAC ShiftingParas100% (1)

- RA For Installation of Earthing & Bonding SystemDocumento10 páginasRA For Installation of Earthing & Bonding SystemProjects INTSAinda não há avaliações

- Checklist For Access Control System InstallationDocumento6 páginasChecklist For Access Control System Installationnsadnan71% (7)

- Abrasive Wheels Risk AssessmentDocumento4 páginasAbrasive Wheels Risk AssessmentAhmed El-sherpiniAinda não há avaliações

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Documento3 páginas(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisAinda não há avaliações

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Documento5 páginas012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocumento6 páginasRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocumento6 páginasRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Flushingchemical Cleaning of Chilled Water PipesDocumento9 páginasFlushingchemical Cleaning of Chilled Water PipesAnandu AshokanAinda não há avaliações

- Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)Documento6 páginasSafe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)tamoor sarwarAinda não há avaliações

- 10 - Updated - LV Cable Installation and TerminationDocumento22 páginas10 - Updated - LV Cable Installation and TerminationShah Muzzamil100% (1)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocumento12 páginasRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocumento6 páginasRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanAinda não há avaliações

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocumento6 páginasRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanAinda não há avaliações

- JSA For Service MaintenanceDocumento8 páginasJSA For Service Maintenancemohamed yasinAinda não há avaliações

- Microsoft PowerPoint - ASEP - NSCP 2015 Chapter6 - WOODDocumento75 páginasMicrosoft PowerPoint - ASEP - NSCP 2015 Chapter6 - WOODRay Ramilo67% (9)

- IM-08-B HSE Wall Grinding For Finishing WorkDocumento2 páginasIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisAinda não há avaliações

- RA Underground Fire Pipe Installation Work R02Documento15 páginasRA Underground Fire Pipe Installation Work R02vinayAinda não há avaliações

- JSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility RelayDocumento9 páginasJSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility Relayfrancis_e_tan100% (2)

- JSA-Scaffolding Erection & Dismantling Works RV-00Documento2 páginasJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarAinda não há avaliações

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDocumento13 páginasRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanAinda não há avaliações

- Risk Assessment For Pov TestingDocumento9 páginasRisk Assessment For Pov TestingvinodhyperAinda não há avaliações

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Documento4 páginasRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanAinda não há avaliações

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Documento4 páginasRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanAinda não há avaliações

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Documento4 páginasRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanAinda não há avaliações

- Job Hazard Analysis: Format For JHA WorksheetDocumento3 páginasJob Hazard Analysis: Format For JHA WorksheetWaseem AhmadAinda não há avaliações

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocumento6 páginasRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocumento6 páginasRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Risk Assessment - T&C For Medium Voltage SwitchgearDocumento8 páginasRisk Assessment - T&C For Medium Voltage SwitchgearMuhammad Irfan0% (1)

- Risk Assessment For GIS Preparation For HV Cable TestDocumento11 páginasRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- Risk Assessment For GIS Preparation For HV Cable TestDocumento11 páginasRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDocumento20 páginasRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanAinda não há avaliações

- Installation of Diesel GeneratorDocumento12 páginasInstallation of Diesel Generatoramal100% (1)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocumento6 páginasRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocumento6 páginasRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Documento3 páginasRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Documento3 páginasRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocumento2 páginasRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor50% (4)

- JSA For MEP Work FormatDocumento3 páginasJSA For MEP Work FormatmohdAinda não há avaliações

- Boiler Safety ProgramDocumento8 páginasBoiler Safety ProgramHussain KhanAinda não há avaliações

- Checklist For Commissioning of CCTV SystemDocumento2 páginasChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- Testing and Commissioning Pre-Check List (ID 1506)Documento1 páginaTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Checklist For Pre Commissioning of CCTV SystemDocumento1 páginaChecklist For Pre Commissioning of CCTV Systemnsadnan71% (7)

- Pipe Welding ProceduresDocumento257 páginasPipe Welding ProceduresKhaeril Anwar100% (1)

- Wärtsilä 20 Product GuideDocumento178 páginasWärtsilä 20 Product Guidedaniel adam0% (1)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Documento1 páginaCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- D85A-21 Parts PDFDocumento599 páginasD85A-21 Parts PDFBudi setyantoAinda não há avaliações

- Risk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMDocumento8 páginasRisk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMnsadnan100% (1)

- 011 Duct Lifter SWMSDocumento2 páginas011 Duct Lifter SWMSJ JohnsonAinda não há avaliações

- ONVIF Profile - S Specification v1-2Documento42 páginasONVIF Profile - S Specification v1-2nsadnan0% (1)

- BSIA Cyber Secure It January 2019Documento16 páginasBSIA Cyber Secure It January 2019nsadnanAinda não há avaliações

- 1 45Documento3 páginas1 45nsadnan0% (1)

- ONVIF Profile Feature Overview v2-2Documento6 páginasONVIF Profile Feature Overview v2-2nsadnanAinda não há avaliações

- ONVIF Profile T Specification v1-0Documento77 páginasONVIF Profile T Specification v1-0nsadnanAinda não há avaliações

- Excel Intelligent Pdu User InstructionsDocumento2 páginasExcel Intelligent Pdu User InstructionsnsadnanAinda não há avaliações

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocumento5 páginasPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanAinda não há avaliações

- Contractor Work Method Statement (Ehs)Documento11 páginasContractor Work Method Statement (Ehs)nsadnanAinda não há avaliações

- Digital Document Processing and ManagementDocumento312 páginasDigital Document Processing and ManagementJuanAinda não há avaliações

- Hercules Engines c2 90d Engine Service ManualDocumento7 páginasHercules Engines c2 90d Engine Service ManualRicardoAinda não há avaliações

- Jovan Marjanovic Theory of Gravity MachinesDocumento10 páginasJovan Marjanovic Theory of Gravity MachinesWilhelm HartmanAinda não há avaliações

- Lista Comandi Tk1m06Documento3 páginasLista Comandi Tk1m06Shahram SherkatAinda não há avaliações

- Datasheet PDFDocumento10 páginasDatasheet PDFRodrigo BarbosaAinda não há avaliações

- Carrier SelectionDocumento13 páginasCarrier SelectionRanesh SinglaAinda não há avaliações

- Datalogic Gryphon GM4100 User GuideDocumento52 páginasDatalogic Gryphon GM4100 User Guidebgrabbe92540% (1)

- AcetophenoneDocumento1 páginaAcetophenoneDinda Melissa ArdiAinda não há avaliações

- HSD Area Security GuardDocumento2 páginasHSD Area Security GuardSavita matAinda não há avaliações

- CS4411 Operating Systems Exam 2 Solutions Spring 2019Documento7 páginasCS4411 Operating Systems Exam 2 Solutions Spring 2019DoremonAinda não há avaliações

- SI Failure of Bremi Ignition Coils E36 - 7, E39, E46, E53Documento2 páginasSI Failure of Bremi Ignition Coils E36 - 7, E39, E46, E53strexxAinda não há avaliações

- Experiment 1Documento5 páginasExperiment 1Cheng BauzonAinda não há avaliações

- Quadrature Amplitude ModulationDocumento10 páginasQuadrature Amplitude ModulationSafirinaFebryantiAinda não há avaliações

- TIOut Brickwork 1Documento4 páginasTIOut Brickwork 1kevin smithAinda não há avaliações

- 02 February 1990Documento108 páginas02 February 1990Monitoring TimesAinda não há avaliações

- 2015 - Fatigue Behavior and Modeling of Short Fiber Reinforced Polymer Composites - A Literature ReviewDocumento25 páginas2015 - Fatigue Behavior and Modeling of Short Fiber Reinforced Polymer Composites - A Literature ReviewSubramani PichandiAinda não há avaliações

- Quectel MC60 at Commands Manual V1.2Documento262 páginasQuectel MC60 at Commands Manual V1.2Adimaro MontoyaAinda não há avaliações

- CFRD 05 - BayardoDocumento23 páginasCFRD 05 - BayardodiegofernandodiazsepAinda não há avaliações

- Transfer FunctionDocumento19 páginasTransfer FunctionVinay Kumar SmartyAinda não há avaliações

- QUEST M3s Coffee Roaster-110V (Semi-Direct Fire Semi-Hot Air)Documento7 páginasQUEST M3s Coffee Roaster-110V (Semi-Direct Fire Semi-Hot Air)portfoliographyAinda não há avaliações

- Numerical Modeling of MHD Convective Heat and Mass Transfer in Presence of First-Order Chemical Reaction and Thermal RadiationDocumento20 páginasNumerical Modeling of MHD Convective Heat and Mass Transfer in Presence of First-Order Chemical Reaction and Thermal Radiationmanasdutta3495Ainda não há avaliações

- CPP Schematic Diagram Duplex Complete 9 Jan 2019Documento1 páginaCPP Schematic Diagram Duplex Complete 9 Jan 2019BdSulianoAinda não há avaliações

- Print PDFDocumento11 páginasPrint PDFFe CasarolliAinda não há avaliações

- KinematicsDocumento33 páginasKinematicsErik MagnoAinda não há avaliações