Escolar Documentos

Profissional Documentos

Cultura Documentos

Astm d1557

Enviado por

salpache0 notas0% acharam este documento útil (0 voto)

176 visualizações10 páginasnorma

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentonorma

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

176 visualizações10 páginasAstm d1557

Enviado por

salpachenorma

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF ou leia online no Scribd

Você está na página 1de 10

Designation: D 1557 - 02"

Standard Test Methods for

Laboratory Compaction Characteristics of Soil Using

Modified Effort (56,000 ft-Ibf/ft? (2,700 kN-m/m*))*

“Ts sad eel rh design D157 se mmr inset fon be enn inden he et of

‘gol pre i he ee often, yx la eon A sambur in pchne sore yao at eapeoal A

Sipe pion sos neal ngs sce hla evan aero

Nem Pargagh 10353 ws sed esl in November 2005

4, Scope*

LL These tes methods cover laboratory compaction meth-

ods used to determine the relationship between water content

and dry unit weight of sols (compaction eure) compacted in

4 of Gin. (101.6 oF 152-4 mm) diameter mold with 10-bf.

(44.5-N) rammer dropped from a height of 18 in. (457 mm)

producing a compactive elfert of $6,000 fibUM (2,700

Amin

Nore 1—Solls and sllagpreeso mints shoul, be regan as

nul occuring he or couse-prined soil or compos o tes

ff natural sol, intr of maul od processed sols oF aguezses

Such st, eve, rere ook

Nor 2—The euprzat and procedures are the suo as proposed by

the US. Cope of Enger in 1945. The odie elo tat (ce 322)

te rometnes selene to atthe Modited Proctor Compaton Tet.

1.2 These test methods apply only to sols (materials) that

have 30 % or less by mass of their particles retained on the

Yorn. (19.0-m) sieve.

[Nowe 3 For elaonsip between unit ejghs and water cosets of

soils wit 30% or as by weigh of muta retuned on the Yn.

((9.-am) see o unt weighs and wae comets of he fection pus

The Yen (19.0) sive, Soe PacceD 18

1.3 Thee alternative methods are provided. The method

used shall be as indicated in the specification for the material

being tested. If no method is specified, the choice should be

based on the material gradation,

13. Method A

13.11 Mold—4in, (101.6.mm) diametes

13.1.2 Materiai—Passing No. 4 (4.7S-mm) sieve.

13.13 Layers—Five.

13.14 Blows per layer—25.

13.1.5 Use—May be used if 20 % or less by mass of the

material i retained on the No. 4 (4.75-mm) sieve.

"Ts andar vse he Justo of ASTM Comes D186 Sl nd

oc nt es eon of abconnies DI ado Tmt Paty

i Dans Cort Sa

‘Crea an pees Now 10, 2002 Pb Seay 20. Oiny

poids D 15535 prea 1553-00.

1.3.1.6 Other Use his method isnot specified, materials.

that meet these gradation requirements may be tested using

Methods B oC.

132 Method Bt

132.1 Mold—4in, (101.6mm) diameter.

132.2 Marerlat—Passing Yin, (9.5mm) sieve.

1323 Layers—Five.

13.24 Blows per layer—25.

4.32.5. Use—Shall be used if more tn 20°% by mass of

‘he material is retained on the No. 4 (475-mm) sieve and 20 %

ir less by mass of the material is retsined on the ¥+in,

(@5.mm) sieve.

13.2.6 Other Use—If this method isnot specified, materials

that meet these gradation requirements may be tested using.

Method C.

133 Method C:

133.1 Mold—6-n, (1524-mum) diameter,

133.2 Material—Passing Yin, (19.0-mm) sieve,

1333 Layers—Five

1334 Blows per layer—S6.

1335 Use—Shall be used if more than 20% by mass of

the material retained on the Yin, (9.53-mam) sieve and less

than 30% by mass of the material is retained on the Yin.

(19.0-mxn) sieve

134 The 6-in.(1524-mm) diameter mold shall not be used

with Method A or B,

[ort 4—Results have been found to vary lightly when atrial it

tet the same compaative ello ia ein ie mols

1.4 IEthe test specimen contains more than 5 % by mass of

‘oversize fraction (coarse fraction) and the material will not be

included in the test, corrections must be mado 10 the unit

Weight and water content of the test specimen or (0 the

appropriate field in place density test specimen using Practice

Davis,

1.5 This test method will generally produce well defined

‘maximum dry unit weight for non-ftee draining soils. If this

test method is used for free draining soils the maximam unit

‘A Summary of Changs ection appears tthe en ofthis standad

‘te ©4504 a1 rn PO Bx, Wt abs PA HR Ua

nay sxe wall defined, ad canbe est han one

eis 23,

Tee Met Pepin ans ae obama te

ated in SI units are provided for

Jan The values

‘iaion oy.

£1 Ia de engi

‘interchange

neering profession its customary practice

iy, wits representing both mass anc for

se iaeer calclaions (F= Ma) are invelved, This

aeons two separate sytems of wits thats the

{eit Gem and the gravimetric sytem. tis sietifally

{ee oo combine te use of to separate systems within

Me eieed This test method has been writen using

mits (gravimetric system) where the pound (bf)

eee y anit of force. The use of mass (Ibm) is for

see cof units and isnot intended to convey the use is

‘mith correct Conversions are given in the SI system in

‘june with IEEEJASTM SI 10, The use of balances oF

gtterding pounds of mass (bm), oF the recording of

jy in boat? should not be regarded #s nonconformance

this standard

1 this sandard does not purport to address all of the

fy concerns, if any associated with its use, It is the

Unabilty of the user ofthis standard to establish appro

te sfery and health practices and determine the applica

of regulatory liitaions prior fo use.

teferenced Documents

ASTI Standards:

127 Test Method for Specific Gravity and Absorption of

Coase Agrezste®

136 Test Method for Sieve Analysis of Fine and Coarse

Agrees?

“22 Text Method for Panicle Size Analysis of Soils?

1653. Temsinology Relating to Soil, Rock, and Contuined

Fide

98 Tot Method for Labontory Compaction Chaser

Ines of Sil Using Standard lot (12,400 eb (600

Ned)?

884 Test Method fr Speci Gravity of Soils?

2168 Test Methods for Calibration of Laboratory

Meshanical-Rammer Soil Compactors

"2216 Test Method for Laboratary Determination of Water

(Moire) Coneat of Soi and Rock by Mass

"2487 Practice for Casifcaton of Soils for Eagineeing

Purposes (Unified Soil Classification System?

° 2488 Practice for Design and Tdenifaton of Seis

(Visust-Mansal Procedte?

"3140 Practice for Minimum Requirements for Ageaces

Engaged inthe Testing andor Inspection of Soil and Rock

26 Used in Engnenring Design and Consteveton®

"420 Practices for Preserving and. Tanspoting, Soil

Samples

"4253 Tet Methods for Maxima dex Density of Soils

Using» Vibatory Table

"18 Pace for Comeation of Unit Weight and Water

(oct ator Sey Yl ea

as

gy D 1880 — Uz

Content for Soils Containing Oversize Particles?

D753 Specification for Evaluating, Selecting and Speci-

fying Balances and Seales For Use in Soil, Rock, und

Construction Materials Testing?

14914 ‘Tse Methods for Density of Soil and Rock in Place

by the Sand Replacement Method in a Test Pi?

1D 5030 Test Method for Density of Soil and Rock in Place

by the Water Replacement Method in a Test Pit)

1 Specitiestion for ASTM Trermometers*

E'IL Specification for Wire-Cloth Sieves for Testing Pur-

310 Practice forthe Bvaluation of Single Pan Mechanical

‘Balances?

IEEE/ASTM SI 10 Standard for Use of the International

‘System of Unite (SI): The Modern Metric System

3. Terminology

{3.1 Definitions See Terminology D 653 for general defini-

sions.

32 Defniions of Terms Specific to This Standard

321 modified effort—the term for the 56000 flit?

(2700 kN-mim!) compactive effort applied by the equipment

and methods of this test,

3.22 modified maximum cry unit weight, Yanec DUN!

m'))—the maximum value defined by the compaction curve

for a compaction est using modified efor.

323 modifed optimum water content, w, (%)—the water

‘content at which the sol ean be compacted to the maximum

‘ry unit weight using modified compactive eff.

324 oversize fraction (coarse fraction), P_ (5)—the po

tiom of total sample not used in peeorming the compaction test,

it may be the portion of total sample retained on the No. 4

(4.75-mm), Yin, (95min), of Yin. (19.0-min) sieve.

5325 test fraction (ner fraction), Py (%)—the portion of

the toil sample used in performing the compaction test it may

‘oe fraction passing the No. 4 (4.7S-mm) sieve in Method A,

minus %-n. (@.5-mm) sieve in Method B, or minus 3%in,

(9.0m) sieve in Method €.

4, Summary of Test Method.

4.1 A oil ata solocted water content is placed in ive layers

into mald of given dimensions, with each layer compacted by

25 or 56 blows of a 10-If (44.5.N) rammer dropped from a

distance of 18-in, (457-mm), subjecting the soil to a total

teompactiveeffore of about 56 000 fT (2700 kN)

The resulting dy unit weight is determined. The procedue it

repeated for a suficient amber of water contents to establish

fa relationship between the dry unit weight and the water

content for the soil. This data, when ploted, sepresent 2

curvilinear relationship known as the compaction curve. The

values of optimum water content and modified maximum dry

‘nit weight ae determined from the compucion carve.

5, Significance and Use

51 Soil placed as enginering fill (embankments, founda-

tion pads, road bases) is compacted wo a dense state to obain

“tea Boo of AST Sd lO.

Anat of AST Saas 2

Gp 0108708"

satisfactory engineering properties such 2s, shear svength,

‘compress, or permeabliy. Also, foundation soils ae

‘often compacted to improve their engineeiog prope

‘Laboratory compaction tests provide the basi for determining

the percent compaction and Water content neeed to achieve

the fegurad engineering properties, and for conclling c00-

‘anetion fo aeure thatthe eqguved compaction and water

contents ae achieved

‘5.2 During desig of an engineered fil shear, consolidation,

pemesiiy or oer tats ruse prpartin of tet spec

Tent by compacing at some water costeat to some unit

‘weight It is common proctce to fist determine the

Sater content (7) and maximum dry unit Weigh (Youn) bY

toeans of couuction 1c. Test specimens ae compacted at

‘elected water content (eter wet ory of opsum (%)

‘rat opium (9), and aa selected dey unit weight elated (0

1 percentage of mahimum ey UNE WE}RAL (gy) ThE

seleton of water content (weiter wet or dry of opm

(or) at opm (i, and he dry Unit ELPA Can) DAY Bo

aged. on pait experience, or a range of values may” be

investigated n determine the necessary pecent of compaction,

'S3 Experience indiates thatthe methods outlived in 5.2 ot

‘the construction control aspects discussed in 5. are extemely

‘iia to implement or yield eronenus rel when dealing

with some sols. The folowing subsections deste typical

problem sol, the problems encountered wen desing with

{uch soll and possible solutions for these problems.

15.31 Oversize Fraction Soils containing more than 30 %

‘oversize fraction (material reisiad on the ein. (19mm)

sive) ae a probiem. For such soil, there is no ASTM test

‘method to contro her compaction and very Zow laboratories

sre equipped to determine she laboratory maximum unit weight

(Gensty) of sch ols (USDI Bureau of Reclanuion, Denve,

‘CO and US. Army Corps of Baginoes, Vicksburg, MS).

Although Test Methods 4914 and D S030 determine the

“eld” dey unt weight of soch soll, thay are dificult and

‘expensive to pefomn.

‘33.11 One mstiod to desig and cont! the compasion of

such ols ig toe a tet il fp determine the required degree

‘of compicton andthe method to ebain hat compaction. Then

‘be a method specification to contel the compaction. Compo.

‘eats ofa mst speciation typically conta the type and

‘ze of compaction equpment 10 uso, the Lit thickness, and

sumer of passes.

Now 5S in erating the compton contol of extvr

woke ies when + nnd pecitenton ted i MAY

pene pee be gully wd epics of the omer” a

“ape”

53.12 Anotir method is to apply the wie of deosiy

comction factors developed by the USDI Bureau of Reclama

‘on (12) and US. Corps of Engineers (3). These cozecton

factors may te applied for sil cotaniog up to sbout 80 2

‘70 & oversize rection. Both agencies use a dierent team for

here deoiy comection factors, The USDI Bureau of Recls-

eee nhen in pote eo ei thee

ston wes D rato (or D= VALUE, while he US. Caps of

gine ses Density ineterence Coen).

53.13 The we ofthe replacement tecniqu Tet Method

1387-18, Method D), in wich the ovesine fseton ix

"place witha ine faction, is inapropiat to determin ie

ssa dy ni WIRD Yay of Ss contining oversize

Fractions 6).

153.2 Degradoin Soil onsning parses that degrade

curing compacion are 2 poblemy especialy when mere

degrecaton occurs during laboratory compaction an Bed

compton, the pia! exe. Degradation Opiclly occu

shsng the compaction ofa grnularsesisal so o sprog,

‘When degradation occ, the mati ary-unie we se

Crests (4 spat the vesuling beater maxim ve fs

tocrepcsaative of fit conions Often, in ae case

tau ry Uni gh imposible to achive te el.

‘532.1 fai or sol subj dezadatin the uo est

ft and mated speceatons oy el, Use of pact

techies snot cone.

5.33 Gap GrodedGap-sraded soils (cil sonsning

sy lage pices ih ited sal pace) a probes

Seance Sie compacted sil wil hae lage voids tha weal,

“Torin tee Inge vos, standard est etd (aboreary

or ld) eprally Rave © Be moliad ung egies

Judgement

ow 6s galty of te set poited by ty Sande

dependent one speeace of the prone pening and he

‘tabi of he equpmant sed ier me. Agen that es he

‘Stare of racize D310 are gee ono ope of opt

‘St eject eng opingnspecontc, Uses of i sel

‘Stn hat omic win Price D340 donot ere

‘eli ress, Ree ress dpe on any fs Pre D380

poset of etoing Some ose ct

6. Apparatus

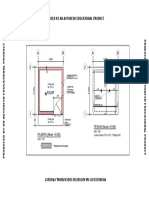

64 Mold Assendy—The molds shall be eyindicl in

‘made of rigid metal and be within te capacity and

imensons indicated in 11 or 61.2 and Fig, 1 and Fi. 2.

‘The walls of the mold may te slid, split, er tapered. The

“split” ype, may const of two haltzound sections, or a

seecon of pipe split alng one element, which ean be securely

locked tgetes to form a clinéer meeting the requirements of

this ection. The "tapered" type shall an internal diameter taper

{hat uniform and not more than 0-200 (16:7 ma) of

‘mold height. ach mold shal have a base plate and an

extension colar assembly, both made of right met and

fconsvcted so they can be securely atached and easly

‘ketchod fom the mod. The extension collar assembly salt

‘ve a height extenting above the top of the mold of atleast

20 in, (S038 mam) which may lace an upper section’ hat

‘ars ut to form 2 funnel provided there ie st least a O75:

(09.6-mm) straight elineal section teneath it. The. exten-

Sion collar shall liga wit the inside ofthe ao, The botam

‘ofthe baseplate and botom of he centrally recessed aea that

Aoceps th cynical mold shall be planar:

6.11 Mold, 4 in—A mold having a 4000 + 0.016.

(204.6 * 0mm) average inside diameter, abeight of 4.584 ©

‘0018 in. (1164 05 am) anda volume of 0833 = 0.0005

[Noms 1-8 Table 2 for metre.

pvt,

[Nora 1--See Tb 2 for mai suivants.

G2 Gynctoal Mol, 6m.

1948 = 14 6m), A mold assembly having the minimum

‘red feares is shown in Fig. 1.

6.1.2 Mold, 6 in—A mold having a 6000 + 0,026 in

1524 = 0.7 mm) average inside diameter, a height of 4.584 =

‘Of in (1164 2 0.5 mm), and a volume of 0.75: 0.0009,

12124 = 25 em, A mold aasemly having the minimum

sired fetues is shown in Fig. 2.

62 Rammer—A rammes, either ramally operstd as do

sited further in 6.2.1 or mechanically operated as deseribed

162.2, The ram shall fal fealy through a gstanee of 18.

$008 in, (457-2 + 1.3 mam) from the surface ofthe specizven.

“Ye mass ofthe rammoer shall be 10 * 0.02 Ibm (4.54 * 0.01

{except thatthe mass of the mechanical ramamers may be

Aisted as deseribed in Test Methods D 2168 (see Note 7).

7e siting face of the raamer shall be planar and eteuar,

‘sept 3 noted in 6.2.2.1, witha diameter when new of 2.000,

0005 in. (50.80 = 0.13 rum). "The rammer shal be replaced

[te striking fae becomcs wom or bellied to the extent thet

% diamecer exceeds 2.000 * 001 in, (50.80 = 0.25 mm).

NOTE 7Je x common and secetse peace i he ine-pond

Sone oe mer ew mt

ned sing ete logram of pun alan ond ise 10

"er or 04536 or UW ie 0.208 Ten or 0.1020,

ABE! Mant Rammer—the ramet shall be equipped

‘aude sleye that he eign clearance thatthe free

a

fall ofthe rammer shaft and hos is uot restricted. The guide

sleeve ahall have at lest four vent holes a each end (eight

holes ttl) located with centers 94 = Yin, (18.0 = 1.6 mn)

{rom each end and spaced 80° apart. The minions diameter of

the vent holes shall be in. (95 mm). Adetional holes or sles

‘may be incorporated in the guide sleeve.

62.2 Mechanical Rammer-Cireular Face—The ramme

shall operate mechanically in such & manner as to provide

‘uniform and complete coverage of th specimen surface. There

shal be 0.10 = 0.03-in. 25 + 0.8mm) clearance between the

fammer and tho inside surface of the mold at its smallest

diameter The mechanical rammer shall meet the calibration

requirements of Test Method D 2168, The mechanical ramimer

Stall be equipped with a positive mechanical means to support

the rammer whea notin operation.

62.21 Mechanical Ranmer Sector Face—When wsed with

the 60in. (152mm) mold, a sector face rammer may be

‘sed in place ofthe ciculr fac ramaer. The sposimen contact

face shall have the shape of a seta of a citle of radius equal

1290 = UG? in. (73.7 + U.S mm), he rammer stall operate

in Such a manne tat the venex ofthe sector is pestoned at

the center of the specimen.

63 Sample Exruder (optionalJA jack, frame o other

device adept forthe purpose of extuding compacted speci-

ne Lom the ms

Qy 01957-02"

6A Balance—A class GPS balance meeting the requre-

‘ments of Speifieation D 4753 fora balane of Ig readability.

165 Diying Oven-—Thermestatialy conuolle, preferably

of eforcod-draft type and capable of maintaining a uniform

temperate of 230 © 9°F (110 = 5°C) throughout the ying

chamber.

656 SralghaedgeA stiff meal straight of any conve=

isnt length ba notes than 10 ia. Q5é min). The tal length

ofthe strightedge shall bo machined seaght to tolerance of

£20005 in (£0.1 mm). The scraping edge shall be beveled if

is ticker dan 4 in. @ mm),

467 Sieves—M in. (19.0 mm), 34 jn. (85 mm), and No. 4

(4.75 mm), conforming to the equizements of Specification

Et

68 Mixing ools—Miscellancous ool such a mixing pan,

spoon, rowel, spats, spray bole, ete, oa suable mechanic

al device for thoroughly mixing the sample of sol with

Increments of wae

7. Calibration

71 efor calibrations befor iil we, aftr reps or

coer occurences that might alfet the test results, at imervals

‘not exceeding 1000 tet sposimens, or annually, whichever

‘secur st, fr the following apparatus:

“Td Balance—Evaate in accordance with Specification

Diss,

7.42. Molde—Deermine the volume as deserted in Anne

aL

73 Manual Ronmer-—Veily the free fll istace, ram

mer mass, and rammer face in accordance with 6.2. Verity the

‘uid slacve requirements in accordance with 62.1,

“714 Mechanical Rammer—Calbrate and adjust he me-

chanical rammer in sccordace with Tet Methods D 2168. ln

‘dition, the clearance between the rammer end the inside

‘Surface ofthe mold shall be vee in accordance with 622.

8, Test Sample

81 The required sample mass for Methods A and B is

proximately 38 Tbm (16 kg), and for Method C is approx-

satly 65 Ibm (29 kg) of dry Sil Therefore, the field simple

should ave a moist mass of at least 5D Tb (23 ks) and 100

bm (45 eg), respectively.

182 Deterain te of material by mass retained

‘on the No, 4 (475mm), 3-n. (9.5mm), of Mn. (19.0)

‘siove as appropriate for choosing Method A,B, or C. Make tis

svete Regt, in. am),

4 © average top dameie, in. am,

5 average boro diameter, i),

“Foe = constant to convert in 1, apd

‘hors = conta to convert ri 16 ce

‘ALS Comparison of Results

[AL5.1 The volume obiined by ether metho should be

within the volume tolerance roqiemens of 6.1.1 and 6.12.

[A152 The diflereac between the wo metus shold not

exoznd 0.5 of the nominal volume ofthe mol

‘A153 Repeat the deemination af volume if these ceria

‘AIS. Failure to obain satisfactory agreement between he

two methods, even after several til san indiation tat the

‘mold is Bey deformed an shouldbe replaced.

'ALSS Use the volume of the mold determined using the

wating mod st the asigad volume vale fr ese

Ting the moist and dry density see 114.

REFERENCES

(0) rt Mal, Ud Se Ben of Reclain, Pat I Ti

Efe, 1956p. 255260.

(2) bar Mano Vd Stes Boe of Resa: Pat 2, Tek

to, 990

(Tae, Vs Deng, RT, “Compe Col of Eh Rack

Motes: New Arpoch”Geseclnel Tein ural, HOD,

YW 17803, Sepa 1936 pp. TIS

(potato AW, nd Sabew. 1, Fass Ifurcing Compacon

‘Rea, gy Ren Bar Bue 316, Peon 987,

Nao Aca of Serco No Resnch Cos Wing

fen De. 509

(CRC Handost of Cnty on Py, Dai Lie, Eee

Ce, 1 on, 195-198

py 0 1887-02"

SUMMARY OF CHANGES

tn accordance with Committee DIB poie, this section identifies the locaton of changes to this standard since

the ist edition (2000) tat may impact the use ofthis standard,

) added Practice D740 to Referenced Documents, (G) Revised the numbering of existing notes.

3 Added anew pte onthe use of Practice D 3740 wo Section (4) In Section 6:2 changed the SI ierance for the Height of

op ofthe ramet

As marl ano nn eapecing ely of ary ptr rh ez in comet ayn ara

‘nha unl Lan esd a one de bat arco ety rym ata aoe ak

i rgaront of pe one Ba on eps

‘ni sls se int ay ity fe epee 2 te onde ay nd

somo stesoparredermintans, Yar canst Pita tcene tc saasor astra re

re tans opty AST maton 120 Hat Oe, PO Bat C7 es Contocan 88288

in Soe naka tre fang or mi) he stor my beta canary ASTM we are

uous ovat otoase 00m bony Stouse0806 fo)! covasaariman fala trugy he AST wee

‘mesur=

Você também pode gostar

- Concreto FrioDocumento7 páginasConcreto FrioJohann L ValerioAinda não há avaliações

- Produced by An Autodesk Educational ProductDocumento1 páginaProduced by An Autodesk Educational ProductsalpacheAinda não há avaliações

- Garzonpirewilliam 2013Documento137 páginasGarzonpirewilliam 2013jhonhmAinda não há avaliações

- Efectos de La Materia Organica Del Agua en La Resistencia Del ConcretoDocumento73 páginasEfectos de La Materia Organica Del Agua en La Resistencia Del ConcretosalpacheAinda não há avaliações

- HT Sika Plast 306Documento3 páginasHT Sika Plast 306Harol Will PAinda não há avaliações

- Ht-Plastiment TM 12 PDFDocumento3 páginasHt-Plastiment TM 12 PDFsalpacheAinda não há avaliações

- Pacco Mescco Juan FranciscoDocumento96 páginasPacco Mescco Juan FrancisconingergroverAinda não há avaliações

- Ley 1224 App Marco de Ocde MefDocumento72 páginasLey 1224 App Marco de Ocde MefsalpacheAinda não há avaliações

- Lista Alcantarilla y Badenes (Ultima)Documento10 páginasLista Alcantarilla y Badenes (Ultima)salpacheAinda não há avaliações

- 4515Documento5 páginas4515salpache100% (1)

- LISTA Tec - AsfaltoDocumento4 páginasLISTA Tec - AsfaltosalpacheAinda não há avaliações

- Micropavimento Tincoc Asf REPSOLDocumento5 páginasMicropavimento Tincoc Asf REPSOLGiorgio Paucar PaduaAinda não há avaliações

- Carta 023 Fuentes de AguaDocumento2 páginasCarta 023 Fuentes de AguasalpacheAinda não há avaliações

- LISTA Tec - AsfaltoDocumento4 páginasLISTA Tec - AsfaltosalpacheAinda não há avaliações

- Las EmulsionesDocumento16 páginasLas EmulsionessalpacheAinda não há avaliações

- Ley 1224 App Marco de Ocde MefDocumento16 páginasLey 1224 App Marco de Ocde MefgaarylarenasAinda não há avaliações

- Ligantes AsfalticosDocumento7 páginasLigantes AsfalticossalpacheAinda não há avaliações

- Rooster Cr2984Documento10 páginasRooster Cr2984salpacheAinda não há avaliações

- LISTA Tec - AsfaltoDocumento4 páginasLISTA Tec - AsfaltosalpacheAinda não há avaliações

- Manual Terratest 3000Documento59 páginasManual Terratest 3000salpacheAinda não há avaliações

- 1 Geotvial 161 GlazoDocumento22 páginas1 Geotvial 161 GlazosalpacheAinda não há avaliações

- Las EmulsionesDocumento16 páginasLas EmulsionessalpacheAinda não há avaliações

- Ligantes AsfalticosDocumento7 páginasLigantes AsfalticossalpacheAinda não há avaliações

- Cotizacion 0564-2017 - COSAPI SADocumento1 páginaCotizacion 0564-2017 - COSAPI SAsalpacheAinda não há avaliações

- PC-MVT-01-F1 Rev. 0 Autorización para Desmontaje, Demolición y ExcavaciónDocumento2 páginasPC-MVT-01-F1 Rev. 0 Autorización para Desmontaje, Demolición y ExcavaciónsalpacheAinda não há avaliações

- Encofrado de VigaDocumento1 páginaEncofrado de VigasalpacheAinda não há avaliações

- NTP 339.036-1999Documento10 páginasNTP 339.036-1999salpache100% (2)

- PPI-MVT-01 Rev. 0 Plan de Puntos de Inspección Trabajos de DomoliciónDocumento1 páginaPPI-MVT-01 Rev. 0 Plan de Puntos de Inspección Trabajos de DomoliciónsalpacheAinda não há avaliações

- Designación ASTM D 698-07Documento18 páginasDesignación ASTM D 698-07edununez21100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)