Escolar Documentos

Profissional Documentos

Cultura Documentos

Project Specification: Saudi Arabian Oil Company

Enviado por

zhangTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Project Specification: Saudi Arabian Oil Company

Enviado por

zhangDireitos autorais:

Formatos disponíveis

SAUDI ARABIAN OIL COMPANY

OPRNS

THIS DOCUMENT AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN WHOLE OR PART SHALL BE MADE WITHOUT THE PRIOR WRITTEN CONSENT OF THE OWNER.

PMT

CERT

ENGG

PROJECT SPECIFICATION

DESCRIPTION

JO/EWO

CATALYST AND CHEMICAL SUMMARY

DATE

POWER GENERATION BLOCK

REV NO.

DISCIPLINE

ENGINEER

_______________

DATE _________

PROJECT

ENGINEER

_______________

DATE _________

JIGCC PROJECT

_______________

CERTIFIED

JAZAN

DATE _________ SAUDI ARABIA

CONSTRUCTION

AGENCY

_______________

DATE _________

OPERATIONS

_______________

DATE _________

C3 25/2/2013 Issue for Client Approval GR RS RS

EDSD VERIFICATION

------------------------------

CONTROL NUMBER

DATE: __________

BY: ____________

C2 30/1/2013 Issue for Client Approval GR RS RS

C1 19/12/212 Issue for Client Review GR RS RS

B1 3/12/2012 Issue for EDC GR RS RS

Rev Date Description Prep Chk App Proj SAPMT

THIS INDICATES THAT REV. NO. ______

KBR Revision History (to be removed at IFP issue)

FOR ALL APPROVAL / CERTIFICATION

OF THIS DOCUMENT IS COVERED,

REVISION CERTIFICATION

REQUIREMENTS, BY DOCUMENT

COMPLETION CERTIFICATE

(DCC) NO. ___________

PROJECT DESIGN BASIS DWG. TYPE PLANT INDEX DOC. SHT. REV.

Catalyst and Chemical Summary DOC

A10 A VE-726242 1

IGCC of C3

5

JAZAN SAUDI ARABIA

SAUDI ARABIAN OIL COMPANY

OPRNS

THIS DOCUMENT AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN WHOLE OR PART SHALL BE MADE WITHOUT THE PRIOR WRITTEN CONSENT OF THE OWNER.

Table of Contents

PMT

1 INTRODUCTION............................................................................... 4

CERT

2 CATALYST AND CHEMICAL REQUIREMENTS ............................. 4

2.1 Catalyst ...................................................................................... 4

ENGG

2.2 Chemicals .................................................................................. 4

Oxygen Scavenger:.................................................................... 4

Neutralizing Amine (pH Control): ............................................... 4

DESCRIPTION

Corrosion/Scale Inhibitor (Phosphate): ...................................... 5

TABLE 1 Catalyst Requirements ...................................................... 4

TABLE 2 Chemical Storage Requirements ....................................... 5

JO/EWO

DATE

REV NO.

DISCIPLINE

ENGINEER

_______________

DATE _________

PROJECT

ENGINEER

_______________

DATE _________

CERTIFIED

_______________

DATE _________

CONSTRUCTION

AGENCY

_______________

DATE _________

OPERATIONS

_______________

DATE _________

EDSD VERIFICATION

------------------------------

CONTROL NUMBER

DATE: __________

BY: ____________

THIS INDICATES THAT REV. NO. ______

FOR ALL APPROVAL / CERTIFICATION

OF THIS DOCUMENT IS COVERED,

REVISION CERTIFICATION

REQUIREMENTS, BY DOCUMENT

COMPLETION CERTIFICATE

(DCC) NO. ___________

PROJECT DESIGN BASIS DWG. TYPE PLANT INDEX DOC. SHT. REV.

Catalyst and Chemical Summary DOC

A10 A VE-726242 2

IGCC of C3

5

JAZAN SAUDI ARABIA

SAUDI ARABIAN OIL COMPANY

OPRNS

THIS DOCUMENT AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN WHOLE OR PART SHALL BE MADE WITHOUT THE PRIOR WRITTEN CONSENT OF THE OWNER.

List of Acronyms & Abbreviations

PMT

Use of acronyms and abbreviations shall be in accordance with Jazan

CERT

Integrated Gasification Combined Cycle Acronyms and Abbreviations.

The following acronyms and abbreviations are used in this document:

ENGG

BFW Boiler Feed Water

DESCRIPTION

CCB Combined Cycle Block

FEED Front End Engineering and Design

HRSG Heat Recovery Steam Generator

JO/EWO

JIGCC Jazan Integrated Gasification Combined Cycle

DATE

IP Intermediate Pressure

REV NO.

PGB Power Generation Block

DISCIPLINE

ENGINEER

_______________

PPM Parts per Million

DATE _________

PROJECT

ENGINEER

WBS Work Breakdown Structure

_______________

DATE _________

VHP Very High Pressure

CERTIFIED

_______________

DATE _________

CONSTRUCTION

AGENCY

_______________

DATE _________

OPERATIONS

_______________

DATE _________

EDSD VERIFICATION

------------------------------

CONTROL NUMBER

DATE: __________

BY: ____________

THIS INDICATES THAT REV. NO. ______

FOR ALL APPROVAL / CERTIFICATION

OF THIS DOCUMENT IS COVERED,

REVISION CERTIFICATION

REQUIREMENTS, BY DOCUMENT

COMPLETION CERTIFICATE

(DCC) NO. ___________

PROJECT DESIGN BASIS DWG. TYPE PLANT INDEX DOC. SHT. REV.

Catalyst and Chemical Summary DOC

A10 A VE-726242 3

IGCC of C3

5

JAZAN SAUDI ARABIA

SAUDI ARABIAN OIL COMPANY

OPRNS

THIS DOCUMENT AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN WHOLE OR PART SHALL BE MADE WITHOUT THE PRIOR WRITTEN CONSENT OF THE OWNER.

1 INTRODUCTION

PMT

Aramco Services Company, ASC, have employed the services of KBR to

CERT provide Front End Engineering and Design (FEED) for the Jazan Integrated

Gasification Combined Cycle project, from here on referred to as JIGCC.

This document summarizes the catalyst and chemical requirements

ENGG

necessary for the Power Generation Block (PGB).

2 CATALYST AND CHEMICAL REQUIREMENTS

DESCRIPTION

2.1 Catalyst

Not Applicable This work breakdown structure (WBS) has no catalyst

requirements.

JO/EWO

Catalyst Loading Catalyst Volume

Type Method (m3)

DATE

REV NO.

TABLE 1 Catalyst Requirements

DISCIPLINE

ENGINEER Supplier (Mandatory): Not Applicable This WBS has no catalyst

_______________

requirements

DATE _________

2.2 Chemicals

PROJECT

ENGINEER

_______________ Oxygen Scavenger:

DATE _________ The oxygen scavenger specified in Table 2 is required to minimize corrosion in

CERTIFIED the condensate and Boiler Feedwater (BFW) system as well as the Heat

_______________

Recovery Steam Generator (HRSG). Typical chemicals used include

DATE _________

Hydroquinone or Erythorbic Acid. The solution injection location will be located

either downstream of the deaerator feedwater and condensate mixing, near

CONSTRUCTION

AGENCY

the HRSG area, in one (1) common header or directly into the deaerator.

_______________ Injection location and any alternative locations shall be confirmed during

DATE _________ detailed engineering. There will be one (1) oxygen scavenger skid per

OPERATIONS

combined cycle block (CCB). The chemical volume specified in Table 2 is

estimated for 60 days of normal operation based on a ratio of 120 parts per

_______________

million (ppm) chemical feed solution (diluted to 10% active Hydroquinone) to

DATE _________

feedwater resulting in a dosing rate of 0.22 m3/day and is for one (1) CCB

only. This will be confirmed by the detailed engineering contractor.

EDSD VERIFICATION

------------------------------

CONTROL NUMBER

DATE: __________

BY: ____________

Neutralizing Amine (pH Control):

The neutralizing amine for pH control, specified in Table 2, is required to

manage the acidity of the BFW and condensate. Typical chemicals used

THIS INDICATES THAT REV. NO. ______

include Morpholine and Cyclo-hexylamine. The solution injection location will

FOR ALL APPROVAL / CERTIFICATION

be located either downstream of the deaerator feedwater and condensate

OF THIS DOCUMENT IS COVERED,

REVISION CERTIFICATION

REQUIREMENTS, BY DOCUMENT

mixing, near the HRSG area, in one (1) common header or directly into the

COMPLETION CERTIFICATE

(DCC) NO. ___________

PROJECT DESIGN BASIS DWG. TYPE PLANT INDEX DOC. SHT. REV.

Catalyst and Chemical Summary DOC

A10 A VE-726242 4

IGCC of C3

5

JAZAN SAUDI ARABIA

SAUDI ARABIAN OIL COMPANY

OPRNS

THIS DOCUMENT AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN WHOLE OR PART SHALL BE MADE WITHOUT THE PRIOR WRITTEN CONSENT OF THE OWNER.

deaerator. Injection location and any alternative locations shall be confirmed

during detailed engineering. There will be one (1) amine skid per CCB. The

PMT

chemical volume specified in Table 2 is estimated for 60 days of normal

CERT operation based on a dosing rate of 0.28 m3/day and is for one (1) CCB only.

This is based on the estimate of a concentration of 1 ppm amine to

condensate flow. This will be confirmed by the detailed engineering

ENGG

contractor.

DESCRIPTION

Corrosion/Scale Inhibitor (Phosphate):

The corrosion/scale inhibitor specified in Table 2 is required to minimize the

formation of corrosion and scale (dissolved solids, i.e. hardness) on the heat

transfer surfaces of the HRSG. Typical chemicals used include blends of Di &

Tri -sodium Phosphates. The solution shall be injected into the Very High

JO/EWO

Pressure (VHP) and Intermediate Pressure (IP) steam drums of each HRSG.

Injection location and any alternative locations shall be confirmed during

detailed engineering. The chemical volume specified in Table 2 is estimated

DATE

for 60 days based on a maximum continuous blowdown rate of 5% and a

concentration of 5 ppm Phosphate to feedwater water. The resultant dosing

REV NO.

rate is 0.08 m3/day and is for one (1) CCB only. This will be confirmed by the

detailed engineering contractor.

DISCIPLINE

ENGINEER

_______________

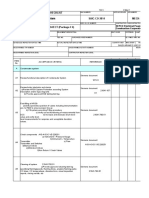

60-Day Storage Volume, m3

DATE _________ Chemicals

(Notes 1 & 2)

PROJECT

ENGINEER Oxygen Scavenger -

_______________ 13.5 m3

Hydroquinone or Erythorbic Acid

DATE _________

Neutralizing Amine (pH Control) -

CERTIFIED

Morpholine and Cyclo- 17.5 m3

_______________

hexylamine

DATE _________

Scale Inhibitor (Phosphate) -

CONSTRUCTION

AGENCY blend of di & tri -sodium 5.0 m3

_______________

Phosphates

DATE _________

OPERATIONS

_______________

TABLE 2 Chemical Storage Requirements One Combined

DATE _________

Cycle Block

Notes:

EDSD VERIFICATION

------------------------------

CONTROL NUMBER

DATE: __________

BY: ____________

1. Detailed engineering contractor to finalize chemical selection and

determine all chemicals requirements.

2. The volumes in Table 2 are for bulk chemical storage and are based on a

100% chemical concentration. Additional dilution tanks may be required

for mixing purposes.

THIS INDICATES THAT REV. NO. ______

FOR ALL APPROVAL / CERTIFICATION

OF THIS DOCUMENT IS COVERED,

REVISION CERTIFICATION

REQUIREMENTS, BY DOCUMENT

COMPLETION CERTIFICATE

(DCC) NO. ___________

PROJECT DESIGN BASIS DWG. TYPE PLANT INDEX DOC. SHT. REV.

Catalyst and Chemical Summary DOC

A10 A VE-726242 5

IGCC of C3

5

JAZAN SAUDI ARABIA

Você também pode gostar

- A10 A Pid Va 718768 206Documento1 páginaA10 A Pid Va 718768 206zhangAinda não há avaliações

- PB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyDocumento1 páginaPB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyzhangAinda não há avaliações

- PB02-STG-001 Steam Turbine System (A10-P-2001)Documento1 páginaPB02-STG-001 Steam Turbine System (A10-P-2001)zhangAinda não há avaliações

- PB02-STG-001 Steam Turbine System (A10-P-2001)Documento1 páginaPB02-STG-001 Steam Turbine System (A10-P-2001)zhangAinda não há avaliações

- Method Statement For ACC BHELDocumento7 páginasMethod Statement For ACC BHELHsebepl NkAinda não há avaliações

- RE-286330 - MS Installation & Commissioning Rev ADocumento12 páginasRE-286330 - MS Installation & Commissioning Rev AJohn Philip Buntales100% (1)

- 000-Performance Test Procedure (General)Documento10 páginas000-Performance Test Procedure (General)K R Kumar RanjanAinda não há avaliações

- Class 1: Pttep International Limited (Myanmar) Zawtika Development ProjectDocumento10 páginasClass 1: Pttep International Limited (Myanmar) Zawtika Development ProjectfajarAinda não há avaliações

- Air Cooled Condenser Specification for 300MW Coal Power PlantDocumento182 páginasAir Cooled Condenser Specification for 300MW Coal Power Plantsuparnabhose100% (1)

- R1234yf 2018Documento22 páginasR1234yf 2018bogdan100% (1)

- 20TPH Dump Condenser Datasheet 12-1-2022Documento4 páginas20TPH Dump Condenser Datasheet 12-1-2022Manoj BAinda não há avaliações

- A4-P 1.0 enDocumento21 páginasA4-P 1.0 enmkpqAinda não há avaliações

- RE-286329 - ITP Rev ADocumento3 páginasRE-286329 - ITP Rev AJohn Philip Buntales100% (1)

- Air Cooled COndenser PDFDocumento7 páginasAir Cooled COndenser PDFRajAnandAinda não há avaliações

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDocumento12 páginasSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoAinda não há avaliações

- Pts 0800 - A (Process Description)Documento6 páginasPts 0800 - A (Process Description)ingegnere1234Ainda não há avaliações

- JO003-10-MA - MDD-DSP-001 P&ID Steam WaterDocumento1 páginaJO003-10-MA - MDD-DSP-001 P&ID Steam WaterHasan MustafaAinda não há avaliações

- National Oil Corporation: Rev Date Description Checked ApprovedDocumento13 páginasNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliAinda não há avaliações

- Boiler ProblemsDocumento59 páginasBoiler ProblemsDharmendra BurraAinda não há avaliações

- P&ID Process Gas System PDFDocumento2 páginasP&ID Process Gas System PDFmuieed siddiquiAinda não há avaliações

- A43 A Doc Ve 728823 - 0001Documento14 páginasA43 A Doc Ve 728823 - 0001SIVA100% (1)

- DS For Chlorine Analyzer-Rev-0Documento26 páginasDS For Chlorine Analyzer-Rev-0anbesivam87_49857255Ainda não há avaliações

- CB2-M-ZEN-21-20003-P&ID - Symbol & Legend (3of3) - Rev.DDocumento1 páginaCB2-M-ZEN-21-20003-P&ID - Symbol & Legend (3of3) - Rev.Dari wibowoAinda não há avaliações

- RE-285103 - Materials Data Sheets Rev ADocumento9 páginasRE-285103 - Materials Data Sheets Rev AJohn Philip BuntalesAinda não há avaliações

- 2 X 660MW NCC POWER PROJECT VALVE SCHEDULEDocumento53 páginas2 X 660MW NCC POWER PROJECT VALVE SCHEDULEkkumar_717405Ainda não há avaliações

- HAazopDocumento35 páginasHAazopSaravanan ElangovanAinda não há avaliações

- 1aha054179 ADocumento56 páginas1aha054179 Adebu1985Ainda não há avaliações

- Saudi Aramco CEMS Analyzer DrawingsDocumento22 páginasSaudi Aramco CEMS Analyzer Drawingszizu1234Ainda não há avaliações

- A-K Document OverviewDocumento3 páginasA-K Document OverviewHasan MustafaAinda não há avaliações

- J20 e Dat VD 525651 PDFDocumento4 páginasJ20 e Dat VD 525651 PDFAariz Khan100% (1)

- JO003-10-MAV-MDD-DSP-001 P&ID Lubrication OilDocumento1 páginaJO003-10-MAV-MDD-DSP-001 P&ID Lubrication OilHasan Mustafa0% (1)

- QIPP MPN018 J00 2304 (1) Instr ListDocumento9 páginasQIPP MPN018 J00 2304 (1) Instr Listsivasri999Ainda não há avaliações

- JO003-10-LC - MDD-IDM-001-3 Condensate SystemDocumento2 páginasJO003-10-LC - MDD-IDM-001-3 Condensate SystemHasan Mustafa0% (1)

- NOC Pressure Instrument SpecificationDocumento26 páginasNOC Pressure Instrument SpecificationRochdi SahliAinda não há avaliações

- Tunnel Operations, Maintenance, Inspection and Evaluation (Tomie) ManualDocumento398 páginasTunnel Operations, Maintenance, Inspection and Evaluation (Tomie) ManualGiuseppe Gentile100% (1)

- Specification For Air Compressors and Air Dryer PackagesDocumento21 páginasSpecification For Air Compressors and Air Dryer PackagesSudjono BroAinda não há avaliações

- Gresik Gas Cogeneration Plant PT Pembangunan Perumahan Gresik Gas Cogeneration Plant ProjectDocumento56 páginasGresik Gas Cogeneration Plant PT Pembangunan Perumahan Gresik Gas Cogeneration Plant ProjectwahyuAinda não há avaliações

- N2 Purging Demand Calculation Shutdown - Flare SystemDocumento54 páginasN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridAinda não há avaliações

- R2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDocumento6 páginasR2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDiana Paula Echartea Molina0% (1)

- Aux Steam Ee 00100 Axs 002Documento15 páginasAux Steam Ee 00100 Axs 002anbarasusivaprakasam100% (1)

- Orifice Cal. Rev.2Documento75 páginasOrifice Cal. Rev.2waheed2286Ainda não há avaliações

- Part eDocumento81 páginasPart egovindharajaluAinda não há avaliações

- Qurayyah CCPP Block Load Control DocDocumento20 páginasQurayyah CCPP Block Load Control Docanbesivam87Ainda não há avaliações

- r2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Documento377 páginasr2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Diana Paula Echartea MolinaAinda não há avaliações

- PP10CC 0009 6mal Yr Abc 001Documento30 páginasPP10CC 0009 6mal Yr Abc 001anbesivam87Ainda não há avaliações

- Attachment#6 Burner SystemDocumento3 páginasAttachment#6 Burner SystemzhangAinda não há avaliações

- Attachmnet#8 Rotor Air SystemDocumento3 páginasAttachmnet#8 Rotor Air SystemzhangAinda não há avaliações

- Commissioning Completion Certificate: Attachment#4Documento3 páginasCommissioning Completion Certificate: Attachment#4zhangAinda não há avaliações

- Manual Valve (NT2-L1-M-HAL.56-209130 - Rev - 00) PDFDocumento81 páginasManual Valve (NT2-L1-M-HAL.56-209130 - Rev - 00) PDFlele862014Ainda não há avaliações

- Va1 Dec 00100 I M1D Pid 8301 PDFDocumento1 páginaVa1 Dec 00100 I M1D Pid 8301 PDFAnonymous JtYvKt5XEAinda não há avaliações

- N2 Gas Bottle Outline DrawingDocumento2 páginasN2 Gas Bottle Outline DrawingMathivanan AnbazhaganAinda não há avaliações

- HRSG Equipment ListDocumento20 páginasHRSG Equipment ListManuel Jesus Perez MelgarAinda não há avaliações

- Saudi Aramco Oil Analyzer Specification SheetsDocumento10 páginasSaudi Aramco Oil Analyzer Specification Sheetszizu1234Ainda não há avaliações

- Va1 Dec 00100 I M1D Pid 8204 PDFDocumento1 páginaVa1 Dec 00100 I M1D Pid 8204 PDFAnonymous JtYvKt5XEAinda não há avaliações

- SGGP Reference No: P0116-TAK-P01-0023-02Documento16 páginasSGGP Reference No: P0116-TAK-P01-0023-02Jabel Oil Services Technical DPTAinda não há avaliações

- Mucog 1910502 Mec DS 055Documento12 páginasMucog 1910502 Mec DS 055vinodAinda não há avaliações

- MD1-0-T-030-05-00397-A - ITP For STGDocumento25 páginasMD1-0-T-030-05-00397-A - ITP For STGTran KhuynhAinda não há avaliações

- Temporary Control Valve For Steam Blowing Temporary Valve: #1 VHP Drum SH SH HP #2 VHP Drum SH SHDocumento1 páginaTemporary Control Valve For Steam Blowing Temporary Valve: #1 VHP Drum SH SH HP #2 VHP Drum SH SHzhangAinda não há avaliações

- A10 A Pid Va 718589 203Documento1 páginaA10 A Pid Va 718589 203zhangAinda não há avaliações

- insulation cal (绝热厚度计算)Documento4 páginasinsulation cal (绝热厚度计算)huangjlAinda não há avaliações

- Floor Plan Legend General Notes Abbreviations List Standard Mounting HeightsDocumento1 páginaFloor Plan Legend General Notes Abbreviations List Standard Mounting HeightsBu B OiAinda não há avaliações

- TA-Luft:: Cummins Engine Company, Inc FR-10302 QSX15-G8Documento1 páginaTA-Luft:: Cummins Engine Company, Inc FR-10302 QSX15-G8mohsen_cumminsAinda não há avaliações

- Gas and Liquid Dehydration Systems for IndustriesDocumento29 páginasGas and Liquid Dehydration Systems for IndustriesRomi MailandiAinda não há avaliações

- Project approval status and commentsDocumento2 páginasProject approval status and commentstvpham123Ainda não há avaliações

- Attachment - #5 Valve Inspection ListDocumento4 páginasAttachment - #5 Valve Inspection ListzhangAinda não há avaliações

- Satip Co 3001Documento3 páginasSatip Co 3001zhangAinda não há avaliações

- Saic Co 3014Documento8 páginasSaic Co 3014zhangAinda não há avaliações

- Installation of Main Steel Structure/ Platform & Steam SilencerDocumento4 páginasInstallation of Main Steel Structure/ Platform & Steam SilencerzhangAinda não há avaliações

- Attachment#5 Blowdown SystemDocumento3 páginasAttachment#5 Blowdown SystemzhangAinda não há avaliações

- Ses-Pgb-Co-Itp-0058 Itp For HRSG SystemDocumento4 páginasSes-Pgb-Co-Itp-0058 Itp For HRSG SystemzhangAinda não há avaliações

- Saudi Aramco Test Report: Commissioning of HRSG System MechDocumento2 páginasSaudi Aramco Test Report: Commissioning of HRSG System MechzhangAinda não há avaliações

- Attachment#9 Auxiliary SystemDocumento3 páginasAttachment#9 Auxiliary SystemzhangAinda não há avaliações

- Saudi Aramco Typical Commissioning Inspection Plan: Ot Procedure Name Ses-Pgb-Co-Otp-0003Documento2 páginasSaudi Aramco Typical Commissioning Inspection Plan: Ot Procedure Name Ses-Pgb-Co-Otp-0003zhangAinda não há avaliações

- Review of Pressure Testing ProceduresDocumento24 páginasReview of Pressure Testing ProcedureszhangAinda não há avaliações

- Saic Co 3014Documento18 páginasSaic Co 3014zhangAinda não há avaliações

- Satip Co 3014Documento3 páginasSatip Co 3014zhangAinda não há avaliações

- Satip Co 3014Documento3 páginasSatip Co 3014zhangAinda não há avaliações

- Satr Co 3008Documento1 páginaSatr Co 3008zhangAinda não há avaliações

- Saudi Aramco Hot Reheat Steam ChecklistDocumento12 páginasSaudi Aramco Hot Reheat Steam ChecklistzhangAinda não há avaliações

- Steam Line SummaryDocumento9 páginasSteam Line SummaryzhangAinda não há avaliações

- Satr Co 3008Documento1 páginaSatr Co 3008zhangAinda não há avaliações

- VHP Steam LineDocumento9 páginasVHP Steam LinezhangAinda não há avaliações

- Saudi Aramco Hot Reheat Steam ChecklistDocumento12 páginasSaudi Aramco Hot Reheat Steam ChecklistzhangAinda não há avaliações

- A10 L Iso VB 433961 105 - 01BDocumento1 páginaA10 L Iso VB 433961 105 - 01BzhangAinda não há avaliações

- Satr-P-3219 Rev 7 FinalDocumento7 páginasSatr-P-3219 Rev 7 FinalzhangAinda não há avaliações

- Installation of Main Steel Structure/ Platform & Steam SilencerDocumento4 páginasInstallation of Main Steel Structure/ Platform & Steam SilencerzhangAinda não há avaliações

- Saudi Arabian Oil Company: A10-24"-HRH-11001-9CM1P Hot Reheat SteamDocumento1 páginaSaudi Arabian Oil Company: A10-24"-HRH-11001-9CM1P Hot Reheat SteamzhangAinda não há avaliações

- A10 A Pid Va 449162 001 - 01aDocumento1 páginaA10 A Pid Va 449162 001 - 01azhangAinda não há avaliações

- SATR-P-3413 Rev 7 FinalDocumento4 páginasSATR-P-3413 Rev 7 FinalzhangAinda não há avaliações

- eCOMPRESSOR OIL PDFDocumento1 páginaeCOMPRESSOR OIL PDFKeshav Shrivastava KSAinda não há avaliações

- RDSO Test Procedures of SoilDocumento20 páginasRDSO Test Procedures of SoilAshok ChaudharyAinda não há avaliações

- Byk Bykjet 9170Documento2 páginasByk Bykjet 9170ankitleedsAinda não há avaliações

- Checklist of Material Submission (Concrete)Documento10 páginasChecklist of Material Submission (Concrete)Yau Ka Ki Jacky0% (1)

- FTIR Spectrometer AnalysisDocumento16 páginasFTIR Spectrometer AnalysisßraiñlĕsšȜĭnšteĭñAinda não há avaliações

- Plastic Mixed Reinforced Concrete - BehaviourDocumento4 páginasPlastic Mixed Reinforced Concrete - BehaviourThiaga RajanAinda não há avaliações

- Underground Storage in Rock Caverns: Rajan K PillaiDocumento37 páginasUnderground Storage in Rock Caverns: Rajan K PillaiBhaskar ReddyAinda não há avaliações

- Defogging rear window with thin heating elementDocumento3 páginasDefogging rear window with thin heating elementMuhammad MoollaAinda não há avaliações

- Washing MCDocumento8 páginasWashing MCHatsune MikuAinda não há avaliações

- Description Assembly Order No.: Static DataDocumento30 páginasDescription Assembly Order No.: Static DataMROstop.comAinda não há avaliações

- Danby Premiere Dehumidifier User's ManualDocumento39 páginasDanby Premiere Dehumidifier User's ManualRick AndersonAinda não há avaliações

- Lean Manufacturing A1Documento14 páginasLean Manufacturing A1Ankita SinhaAinda não há avaliações

- Tcsi Quality Plan: One Ayala Avenue Project Makati City, Metro ManilaDocumento20 páginasTcsi Quality Plan: One Ayala Avenue Project Makati City, Metro ManilaEugene Santiago PadillaAinda não há avaliações

- 108-1 SL ManualDocumento19 páginas108-1 SL ManualphongredAinda não há avaliações

- Valvula Check 717 VictaulicDocumento6 páginasValvula Check 717 Victaulicrvalentino2012Ainda não há avaliações

- 2710 100 Series - Screw Side-Action GripsDocumento4 páginas2710 100 Series - Screw Side-Action GripsLitarmjAinda não há avaliações

- DiffusionDocumento15 páginasDiffusionBryan Jesher Dela CruzAinda não há avaliações

- V Series Catalog Vb015e 05Documento64 páginasV Series Catalog Vb015e 05jotalopecincoAinda não há avaliações

- What is a Composite MaterialDocumento42 páginasWhat is a Composite MaterialabhiAinda não há avaliações

- Metal Spinning Machines Technical Data 2007Documento2 páginasMetal Spinning Machines Technical Data 2007Andres Lp100% (1)

- Food Process EngineeringDocumento9 páginasFood Process Engineeringvineeth vipparthiAinda não há avaliações

- Finite Element Analysis of The Stability of Tunnel Surrounding Rock With Weak Rock LayerDocumento6 páginasFinite Element Analysis of The Stability of Tunnel Surrounding Rock With Weak Rock LayerVahid ShariatyAinda não há avaliações

- Insulflex SizeDocumento1 páginaInsulflex SizeAnonymous ItzBhUGoiAinda não há avaliações

- As71164a CHECK LISTDocumento9 páginasAs71164a CHECK LISTJulio HernandezAinda não há avaliações

- Dye Bath LubricantsDocumento6 páginasDye Bath Lubricantsthedevil666100% (1)

- Dwnload Full Operations Management Sustainability and Supply Chain Management 12th Edition Heizer Test Bank PDFDocumento36 páginasDwnload Full Operations Management Sustainability and Supply Chain Management 12th Edition Heizer Test Bank PDFardellazusman100% (13)