Escolar Documentos

Profissional Documentos

Cultura Documentos

Report - Broken Pile (26!04!12)

Enviado por

jurieskTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Report - Broken Pile (26!04!12)

Enviado por

jurieskDireitos autorais:

Formatos disponíveis

PILE CRACK ANALYSIS REPORT

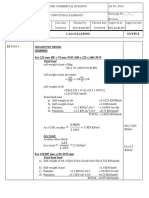

A. PILE STRESSES DUE TO AXIAL LOAD F

L= 1,200 cm, pile length F F

k= 2.0000 , extreme scenario

Ix = 522,509 cm4

Wx = 17,417 cm3

L

A= 1,571 cm2

ix = 18.24 cm

l = k.L/ix = 131.59 d d

fc' = 60 MPa = 600 kg/cm2 k=2 k = 0.707

E= 36,406 MPa = 364,060 kg/cm2 Model #1 Model #2

lg = p.(E/0.7fc') = 92.49366

2

lc = l / lg = 1.422697 > 1, hence w=2.381lc

w = 4.819301 , slenderness amplification factor

m

E M1 = EM2 1

E P1 + EK1 = EP2 + E K2 m

h

Since V1 = 0 & h2 = 0 then EP1 = EK2 therefore

2

m.g.h1 = 1/2m.V22, hence

2

with g = 10 m/s & h = 1.1 m, then L

V2 = (2g.h1) = 4.6904 m/s

E M2 = W = F.h, therefore

2

F = 1/2m.V2 /h, with m = 7000 kg

2

= 70,000 kg.m/s = 70 kN = 7 ton.f

s= w.F/A = 36.90 kg/cm2 < 600 kg/cm2 ... OK

(pile compression stress during driving)

B. PILE STRESSES DUE TO BENDING EFFECT OF INCLINED PILE

Mmax = 19.3 ton.m

s = Mmax/Wx = 110.81 kg/cm2, allowable pile stress due to bending

d = Mmax/F = 2.76 m

Hence pile crack caused by inclined pile can be happen when pile deviate 2.76m from one end to another.

C. PILE STRESSES DUE TO REBOUND

A rebar = 797.71 mm2, 12 nos diameter 9.2mm pc bar with fy = 1400 MPa

P= 33.50 ton, allowable pile tension (30% of pc bar only due to prestressing)

s= 21.33 kg/cm2, allowable pile stress due to tension

Since 1/2m.V22 = P.h, therefore m = 2P.h/V22 hence

m= 3.35 ton, load that can cause pc bar to yield ,

with pile weight of 409 kg/m1 this load can be generated from pile with the length of

= 8.19 m1 caused by rebound force.

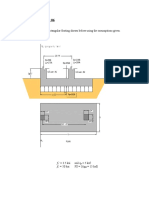

CONCLUSION

1. Base on above ilustration, can be seen that stress generated from the heaviest hammer

on site is much lesser than the pile stress capacity itself, therefore crack caused by tension is more

dominant especially due to rebound rather than compression , and circular crack is

the sign of this failure which can be seen from most of the crack pile on site.

2. From the soil profile we can see that residual soil can be reached by the second pile onwards.

This type of soil generate rebound to the pile, then the biggest pulling impact will be born

by pile above ground. This force will cause circular crack if the rebar stress is exceeded.

SOLUTION / PROPOSAL

1. To keep the drop height low during driving of second pile onwards to reduce pile rebound effect.

Extra care need to be taken during driving when the pile is still 8 m high above ground.

2. The use of higher grade pile (with more tension bar) is advisable especially start from second pile

onwards. In this case class B spun pile is applicable.

3. To replace driven pile with bored pile when above solutions are failed.

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Beam Formulas With Shear and Mom PDFDocumento16 páginasBeam Formulas With Shear and Mom PDFPanagiotis StamatisAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Periodic Structural Inspection of Existing BuildingDocumento14 páginasPeriodic Structural Inspection of Existing BuildingSarah SullivanAinda não há avaliações

- Force Method 2Documento46 páginasForce Method 2shawn100% (1)

- RC Pile Cap Design (ACI318)Documento4 páginasRC Pile Cap Design (ACI318)topukuet75% (4)

- S PMT Best Practice GuideDocumento29 páginasS PMT Best Practice Guidejuriesk100% (1)

- Bending of Plates and ShellsDocumento22 páginasBending of Plates and ShellsHarish Kuppusamy100% (1)

- Pressure Vessel Design (Basic)Documento10 páginasPressure Vessel Design (Basic)Jason Gibbs100% (1)

- Design of Welded Steel StructuresDocumento198 páginasDesign of Welded Steel StructuresyogeshAinda não há avaliações

- Stab CalcDocumento4 páginasStab CalcjurieskAinda não há avaliações

- Maximum Spacing of PilesDocumento10 páginasMaximum Spacing of PilesAtul ShrivastavaAinda não há avaliações

- Embankment Dam PDFDocumento106 páginasEmbankment Dam PDFAubel50% (2)

- Hollow Pot Design WorksheetDocumento7 páginasHollow Pot Design Worksheetpatrick chegeAinda não há avaliações

- Conventional Slab On GradeDocumento14 páginasConventional Slab On Gradejklo12Ainda não há avaliações

- Large Open Pit Slope StabilityDocumento53 páginasLarge Open Pit Slope Stabilitysaifuddin_ariefAinda não há avaliações

- Pile Driving Record (Blow Count Record)Documento3 páginasPile Driving Record (Blow Count Record)jurieskAinda não há avaliações

- 1.5 Practice Questions & Answers - 1 PDFDocumento5 páginas1.5 Practice Questions & Answers - 1 PDFMega GamesAinda não há avaliações

- Const Manual Bar JoistsDocumento5 páginasConst Manual Bar JoistsjurieskAinda não há avaliações

- Const Manual Doors Window Install DetailsDocumento12 páginasConst Manual Doors Window Install DetailsjurieskAinda não há avaliações

- Const Manual Crane DetailsDocumento4 páginasConst Manual Crane DetailsjurieskAinda não há avaliações

- Welding Issues For Seismic Design Requirements - MBMA 2008 PDFDocumento4 páginasWelding Issues For Seismic Design Requirements - MBMA 2008 PDFcaioAinda não há avaliações

- EngpilcpDocumento5 páginasEngpilcpjurieskAinda não há avaliações

- Combined Footing 08Documento7 páginasCombined Footing 08jurieskAinda não há avaliações

- Combined Footing 02Documento5 páginasCombined Footing 02jurieskAinda não há avaliações

- Single Beam EDocumento3 páginasSingle Beam EjurieskAinda não há avaliações

- 01 PDFDocumento15 páginas01 PDFjurieskAinda não há avaliações

- FM PDFDocumento3 páginasFM PDFjurieskAinda não há avaliações

- H-L Series Crane Dimensional Data Sheet: ContactDocumento3 páginasH-L Series Crane Dimensional Data Sheet: ContactjurieskAinda não há avaliações

- F Ksi F Ksi Q KSF: Combined Footing - 01Documento7 páginasF Ksi F Ksi Q KSF: Combined Footing - 01jurieskAinda não há avaliações

- Combined Footings 06: Design The Combined Rectangular Footing Shown Below Using The Assumptions GivenDocumento6 páginasCombined Footings 06: Design The Combined Rectangular Footing Shown Below Using The Assumptions GivenjurieskAinda não há avaliações

- Eotc 1Documento3 páginasEotc 1jurieskAinda não há avaliações

- Eotc 5Documento4 páginasEotc 5jurieskAinda não há avaliações

- Prefabricated Column PDFDocumento2 páginasPrefabricated Column PDFjurieskAinda não há avaliações

- Eotc 2Documento3 páginasEotc 2jurieskAinda não há avaliações

- Eotc 1Documento3 páginasEotc 1jurieskAinda não há avaliações

- Fencing Spec...Documento3 páginasFencing Spec...jurieskAinda não há avaliações

- Pilecap Mesh Specifications - : BRC Asia Limited. All Rights ReservedDocumento2 páginasPilecap Mesh Specifications - : BRC Asia Limited. All Rights ReservedjurieskAinda não há avaliações

- Exercise V SRD Ivana B 3 VSRD StevensDocumento14 páginasExercise V SRD Ivana B 3 VSRD StevensjurieskAinda não há avaliações

- Prefabricated Column Reinforcement SpecificationsDocumento2 páginasPrefabricated Column Reinforcement SpecificationsjurieskAinda não há avaliações

- Wave Equation TheoryDocumento13 páginasWave Equation TheoryjurieskAinda não há avaliações

- Exercise VI Follower Modelling 2Documento3 páginasExercise VI Follower Modelling 2jurieskAinda não há avaliações

- Exercise VI Follower Modelling 1Documento1 páginaExercise VI Follower Modelling 1jurieskAinda não há avaliações

- Etabs Modelling 6Documento3 páginasEtabs Modelling 6ashraf04_ceAinda não há avaliações

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum Course Title: Strength of Material (Code: 3331904)Documento6 páginasGujarat Technological University, Ahmedabad, Gujarat Course Curriculum Course Title: Strength of Material (Code: 3331904)Harshad JoshiAinda não há avaliações

- Yield States and Stress-Strain Relationships in A Natural Plastic Clay. Graham, Noonan, and Lew (1983)Documento15 páginasYield States and Stress-Strain Relationships in A Natural Plastic Clay. Graham, Noonan, and Lew (1983)Jesus GonzalezAinda não há avaliações

- Tutorial 2Documento2 páginasTutorial 2nprashantshekharAinda não há avaliações

- Me2303 - Design of Machine ElementsDocumento14 páginasMe2303 - Design of Machine Elementsdsathiya0% (1)

- Engineering Structures: Qiang Han, Yulong Zhou, Yuchen Ou, Xiuli DuDocumento12 páginasEngineering Structures: Qiang Han, Yulong Zhou, Yuchen Ou, Xiuli Duserkanozen80Ainda não há avaliações

- Chapter D Design of Members For Tension:, Is The Total Cross-Sectional Area of The MemberDocumento18 páginasChapter D Design of Members For Tension:, Is The Total Cross-Sectional Area of The MemberEusebio Tocas MenaAinda não há avaliações

- Cold Formed Steel DesignDocumento2 páginasCold Formed Steel DesignkiplingkipAinda não há avaliações

- Ijert Ijert: Design and Development of Material Handling CraneDocumento8 páginasIjert Ijert: Design and Development of Material Handling CraneAnonymous PufNjgAinda não há avaliações

- 2016 CodeUGM Usingn Code Design Life For Fatigue of WeldsDocumento32 páginas2016 CodeUGM Usingn Code Design Life For Fatigue of WeldsdddAinda não há avaliações

- Strength of Materials-I Chapter - 1 And: Stress StrainDocumento42 páginasStrength of Materials-I Chapter - 1 And: Stress StrainColorgold BirlieAinda não há avaliações

- Geotechnical Measurements DataDocumento11 páginasGeotechnical Measurements Datamahi5061Ainda não há avaliações

- Bumper PDFDocumento7 páginasBumper PDFTj BalaAinda não há avaliações

- Loma Prieta Quake 89Documento9 páginasLoma Prieta Quake 893alliumcourtAinda não há avaliações

- Basic Concept Method:: Flexural Stresses: Second Moment of Inertia, IDocumento6 páginasBasic Concept Method:: Flexural Stresses: Second Moment of Inertia, IJeremiah VillanuevaAinda não há avaliações

- Design of Concrete Structures 15th Edition Darwin Solutions Manual 1Documento36 páginasDesign of Concrete Structures 15th Edition Darwin Solutions Manual 1gracegreenegrsqdixozy100% (24)

- Additive Manufacturing: Tait D. Mclouth, Joseph V. Severino, Paul M. Adams, Dhruv N. Patel, Rafael J. ZaldivarDocumento7 páginasAdditive Manufacturing: Tait D. Mclouth, Joseph V. Severino, Paul M. Adams, Dhruv N. Patel, Rafael J. ZaldivarRui MatiasAinda não há avaliações

- Web TVGT 5064 PDFDocumento101 páginasWeb TVGT 5064 PDFDannyChaconAinda não há avaliações

- An Analytical and Experimental Study of Stretch Flanging N.-M. W O and M. L. WennerDocumento13 páginasAn Analytical and Experimental Study of Stretch Flanging N.-M. W O and M. L. Wenner0511018Ainda não há avaliações