Escolar Documentos

Profissional Documentos

Cultura Documentos

CP-1000 - Chapter 06.2 - Repair - Tools and Aids 1.0

Enviado por

IMDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CP-1000 - Chapter 06.2 - Repair - Tools and Aids 1.0

Enviado por

IMDireitos autorais:

Formatos disponíveis

Repairs and maintenance

DD+DIS015.01E Tools and aids

Section 6.2

Contents

1 Recommended tools and testing equipment........................................................1

2 Test button and test program ................................................................................2

2.1 Using the test button (type 9462/106/206/846)......................................................2

2.2 Using the test button (type 9462/105/155/165/205/285/845) .................................3

2.3 Handling the test button.........................................................................................4

Edition 2, Revision 0 CURIX 60 / CP 1000 (type 9462) Section 6.2 / I

Repairs

DD+DIS015.01E Tools and aids

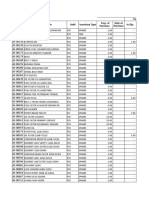

1 Recommended tools and testing equipment

In addition to the general tools which every service engineer has in his tool box, the following

additional aids are required to service the machine:

Aid Spare parts no. Use

Extractor for ICs in PLCC CM+9.9999.1005.0 Replacing EPROMs

housing

Earthing tape CM+9.9999.0830.0 Replacing EPROMs

Measuring beaker - Adjusting replenishment quantity

(measure), for developer / fixer

contents 500 ml

Service key CM+9.9999.0907.0 Bridging cover switch

Withdrawal tool CM+9.9999.0793.0 Removing AMP contacts

Test button CM+8.8966.0067.1 Test program

Edition 2, Revision 0 CURIX 60 / CP 1000 (type 9462) Section 6.2 / 1

Repairs

Tools and aids DD+DIS015.01E

2 Test button and test program

2.1 Using the test button (type 9462/106/206/846)

Disconnect the machine plug from the socket

Expose control board GS1. This is described in section 3. Then use the service key to bridge

interlock switch S1.

Put the jack of the test button on plug ST6 of control board.

ST6

946262am.cdr

Fig. 6.2 - 1

Put the mains plug into the socket and switch the machine on. All live

parts are now supplied with voltage again.

Section 6.2 / 2 CURIX 60 / CP 1000 (type 9462) Edition 2, Revision 0

Repairs

DD+DIS015.01E Tools and aids

2.2 Using the test button (type 9462/105/155/165/205/285/845)

Disconnect the machine plug from the socket

Expose control board GS1. This is described in section 3. Then use the service key to bridge

interlock switch S1.

Put the jack of the test button on plug ST22 of control board GS1.

946262bm.cdr

Fig. 6.2 - 2

Put the mains plug into the socket and switch the machine on. All live

parts are now supplied with voltage again.

Edition 2, Revision 0 CURIX 60 / CP 1000 (type 9462) Section 6.2 / 3

Repairs

Tools and aids DD+DIS015.01E

2.3 Handling the test button

When the machine is switched on, the switch-on cycle runs. Wait until the

machine finishes the switch-on cycle itself and changes into standby, before

activating the test button.

The test program consists of six stages.

Stage Outcome, triggered consumer Time limit

1. Press the test button once. Lower dryer fan starts (5M2) 25 s

2. Press the test button again IR heaters (5HZ1, 5HZ2) light up 5s

within the time limit of stage 1 and lower fan dryer (5M2) starts

(25 ).

3. Press the test button again Replenishment pump (M2) starts 30 s

within the time limit of stage 2 (5 ).

4. Wait until the time limit of stage Replenishment pump (M2) and 3s

3 (30 s) has expired, and turn the lower dryer fan (5M2) start

left-hand film feed detection roller

by hand

5. Wait until the time limit of stage Replenishment pump (M2) and 3s

4 (3 s) has expired and turn the lower dryer fan (5M2) start

right-hand film feed detection

roller by hand.

6. Wait until the time limit of stage Replenishment pump (M2) and 180 s

5 (3 s) has expired and press the lower dryer fan (5M2) start

replenishment button (S3)

After 180 s the test program is finished and the machine changes to standby mode. If the

button is not pressed for a longer period of time in between the individual stages, then the

machine also changes into the standby mode.

Section 6.2 / 4 CURIX 60 / CP 1000 (type 9462) Edition 2, Revision 0

Você também pode gostar

- Reference Manual DRYSTAR 2000 PDFDocumento146 páginasReference Manual DRYSTAR 2000 PDFIMAinda não há avaliações

- CP-1000 - Chapter 14 - Installation Planning, Internal Upda 1 PDFDocumento22 páginasCP-1000 - Chapter 14 - Installation Planning, Internal Upda 1 PDFIMAinda não há avaliações

- CP-1000 - Chapter 12 - Maintenance, Internal Update 1.0Documento34 páginasCP-1000 - Chapter 12 - Maintenance, Internal Update 1.0IM0% (1)

- CP-1000 - Chapter 07 - Codes and Circuit Diagrams 1.0Documento20 páginasCP-1000 - Chapter 07 - Codes and Circuit Diagrams 1.0IMAinda não há avaliações

- CP-1000 - Chapter 06.6 - Repair - Software and Hardware Adj 1 PDFDocumento16 páginasCP-1000 - Chapter 06.6 - Repair - Software and Hardware Adj 1 PDFIMAinda não há avaliações

- CP-1000 - Chapter 06.3 - Repair - Troubleshooting 1.0Documento19 páginasCP-1000 - Chapter 06.3 - Repair - Troubleshooting 1.0IMAinda não há avaliações

- CP-1000 - Chapter 09 - Accessories 1.0Documento14 páginasCP-1000 - Chapter 09 - Accessories 1.0IMAinda não há avaliações

- CP-1000 - Chapter 06.1 - Repair - Safety Regulations, Rapair 1 PDFDocumento3 páginasCP-1000 - Chapter 06.1 - Repair - Safety Regulations, Rapair 1 PDFIMAinda não há avaliações

- CP-1000 - Chapter 02 - Controls and Connections - Edition 1.0 PDFDocumento3 páginasCP-1000 - Chapter 02 - Controls and Connections - Edition 1.0 PDFIMAinda não há avaliações

- CP-1000 - Chapter 06.1 - Repair - Safety Regulations, Rapair 1 PDFDocumento3 páginasCP-1000 - Chapter 06.1 - Repair - Safety Regulations, Rapair 1 PDFIMAinda não há avaliações

- Villa Endos AC-ACP - Service ManualDocumento122 páginasVilla Endos AC-ACP - Service ManualIM67% (3)

- Cawomat 2000 IR - Reference ManualDocumento142 páginasCawomat 2000 IR - Reference ManualIM100% (1)

- Agfa Curix HT 330uDocumento459 páginasAgfa Curix HT 330uIMAinda não há avaliações

- M-sr-130 Rev 6 Ul - sn413 - XXXDocumento38 páginasM-sr-130 Rev 6 Ul - sn413 - XXXIM100% (1)

- EUB 5500 Instruction Q1E EA0612 14Documento559 páginasEUB 5500 Instruction Q1E EA0612 14IM50% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 15 IluminareDocumento13 páginas15 IluminareadyemptyAinda não há avaliações

- 4116RDocumento2 páginas4116Rkirten1Ainda não há avaliações

- 04 - Electromechanical Starters and EnclosuresDocumento26 páginas04 - Electromechanical Starters and EnclosuresPac CoolAinda não há avaliações

- MAS100 Auto Synch RelayDocumento18 páginasMAS100 Auto Synch RelayAdetunji Taiwo100% (1)

- Circuit-Breaker, 3 Pole, 2500A, 66 Ka, Selective Operation, IEC, Fixed Part No. IZMX40B3-V25F-1 Catalog No. 183707 EL-Nummer (Norway) 4398196Documento4 páginasCircuit-Breaker, 3 Pole, 2500A, 66 Ka, Selective Operation, IEC, Fixed Part No. IZMX40B3-V25F-1 Catalog No. 183707 EL-Nummer (Norway) 4398196Jose HernandezAinda não há avaliações

- Dual 5V Regulator With Reset: DescriptionDocumento10 páginasDual 5V Regulator With Reset: DescriptionSandroCezardeAraujoAinda não há avaliações

- Industrial Drives and ApplicDocumento2 páginasIndustrial Drives and ApplicChenilleAinda não há avaliações

- HP Service Note 412AR 2Documento1 páginaHP Service Note 412AR 2xibmAinda não há avaliações

- Cooper Power Systems - Recloser Guide PDFDocumento16 páginasCooper Power Systems - Recloser Guide PDFAerwin BautistaAinda não há avaliações

- Arc Flash Study-SpecsDocumento7 páginasArc Flash Study-SpecsSellappan MuthusamyAinda não há avaliações

- GIS Primary Components: Peter Glaubitz, Carolin Siebert, and Klaus ZuberDocumento21 páginasGIS Primary Components: Peter Glaubitz, Carolin Siebert, and Klaus ZuberCésar Díaz LiberonaAinda não há avaliações

- Sentron Harmonic Mitigating Transformers (HM1 & HM2)Documento2 páginasSentron Harmonic Mitigating Transformers (HM1 & HM2)Alfredorodriguez GutierrezAinda não há avaliações

- Tle Eim - Grade10 - QTR4 Week7 8Documento10 páginasTle Eim - Grade10 - QTR4 Week7 8SashaAinda não há avaliações

- EE540: Power System Transients and Insulation CoordinationDocumento9 páginasEE540: Power System Transients and Insulation CoordinationHania ZahraAinda não há avaliações

- Slip Speed Control 10.2Documento23 páginasSlip Speed Control 10.2Manimozhi RamasamyAinda não há avaliações

- GFDI - Ground Fault Detection Interruption: Technical Journal - July, 2015Documento2 páginasGFDI - Ground Fault Detection Interruption: Technical Journal - July, 2015Anil PooniaAinda não há avaliações

- 21-Ht Ele & Panel Boq With CostDocumento32 páginas21-Ht Ele & Panel Boq With CosttceterexAinda não há avaliações

- ROTEL RA-06 Service ManualDocumento11 páginasROTEL RA-06 Service ManualLincolnAinda não há avaliações

- Paper OTADocumento6 páginasPaper OTAFelipe MancillaAinda não há avaliações

- 3SK11111AB30 Datasheet enDocumento8 páginas3SK11111AB30 Datasheet enmtcsjogoAinda não há avaliações

- Lucy ManualDocumento49 páginasLucy Manualjunaid_libra0% (1)

- Bijur Delimon Cable Plug 66925P1 - GB PDFDocumento1 páginaBijur Delimon Cable Plug 66925P1 - GB PDFEwin ApriansyahAinda não há avaliações

- 7th Edition UL 1008 White PaperDocumento8 páginas7th Edition UL 1008 White PaperMarcelo CamachoAinda não há avaliações

- Cost Data 2019-20Documento9 páginasCost Data 2019-20Rashmit GohelAinda não há avaliações

- Site Test Report Date: Al-Osais Co. KHUDARIYAH S/S 115/13.8 KV S/S CT Supervision Relay - MVTPDocumento4 páginasSite Test Report Date: Al-Osais Co. KHUDARIYAH S/S 115/13.8 KV S/S CT Supervision Relay - MVTPsikander843562Ainda não há avaliações

- LM317 Regulator CircuitDocumento9 páginasLM317 Regulator Circuitapi-3775664100% (2)

- Auxiliary Circuit-ConventionalDocumento10 páginasAuxiliary Circuit-ConventionalriajulAinda não há avaliações

- Indent JSBayDocumento7 páginasIndent JSBayTallapureddy SarweswarareddyAinda não há avaliações

- Electric Water Heater: Brand Type RP (000) FeaturesDocumento2 páginasElectric Water Heater: Brand Type RP (000) Featureswahyudi septiadiAinda não há avaliações

- Ile All 2Documento429 páginasIle All 2Eyob HaylemariamAinda não há avaliações