Escolar Documentos

Profissional Documentos

Cultura Documentos

Material Handling PDF

Enviado por

Jessica SaballeroTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Material Handling PDF

Enviado por

Jessica SaballeroDireitos autorais:

Formatos disponíveis

MATERIAL HANDLING

MATERIALS HANDLING

I. INTRODUCTION

Material handling is a field involving the transport, storage, and control of goods and

products throughout the processes of manufacturing, distribution, consumption and disposal of

all related materials. The focus of the material handling industry is on the methods, mechanical

equipment, systems and related controls used to achieve necessary functions.

Factors to consider in Selecting the Material Handling Equipment:

Selection of material handling equipment is an important decision as it affects both the cost and

efficiency of handling system. The following factors are to be taken into account while selecting

the material handling equipment.

1. Properties of the Material

Whether the material is solid, liquid or gas, and in what size, shape and weight it is to be moved,

are important decisions and can be lead to a preliminary elimination from the range of available

equipment under review. Similarly, if the material is fragile, corrosive or toxic this will imply that

certain handling method and containers will be preferable to others.

2. Layout and Characteristic of the building

Another restricting factor is availability of space for handling. Low-level ceiling many preclude the

use of hoist or cranes, and the presence of supporting columns in awkward places can limit the

size of material handling equipment. If the building is multi-storeyed, chutes or ramp for industrial

trucks may be used. Layout itself will indicate the type of production operation (continuous,

intermittent, fixed position or group) and indicate some items of equipment that will be more

suitable than others. Floor capacity also helps in selecting the best material handling equipment.

3. Production Flow

If the flow is fairly constant between two fixed positions that are not likely to be changed, fixed

equipment such as conveyors or chutes can be successfully used. If, on the other hand, the flow

is not constant and the direction changes occasionally from one point to another because several

products are being produced simultaneously, moving equipment such as trucks would be

preferable.

4. Cost Considerations

This is the most important consideration. The above factors can help narrow the range of

suitable equipment, while costing can help in taking the final decision. Several cost elements

need to be taken into consideration when comparisons are made between various items of

equipment that are all capable of handling the same load. Initial investment and operating and

maintenance cost are the major costs to be considered. By calculating and comparing the total

cost of each items of equipment under consideration, a more rational decision can be reached

on the most appropriate choice.

5. Nature of Operations

Selection of equipment also depends on the nature of operations like whether handling is

temporary or permanent, whether the flow is continuous or intermittent and material, flow

pattern-horizontal or vertical.

6. Engineering Factors

Engineering factors such as door, ceiling dimensions, floor space, floor conditions and structural

strengths are also taken in consideration in the selection of equipment.

-ABANADOR ASA PATENIA NALUZ 1

MATERIAL HANDLING

7. Equipment reliability

Reliability of the equipment and supplier reputation and the after sale services plays an important

role in selecting the equipment.

Goals of Material Handling

1. Maintain product quality, reduce damage and provide protection of materials.

2. Promote safety and improve working conditions.

Improve productivity through:

Materials should move as short distance as possible

Increase the size of materials handled

Mechanize /Automate Material Handling

Maintain/Improve material handling ratios

Increase throughput by using automated material handling equipment

3. Promote increase use of facilities

Increase cubic utilization

Purchase versatile equipment

Standardize material handling equipment

Maintain, and replace as needed, all equipment and develop a preventive maintenance

program

4. Integrate all material handling equipment into a system

5. Reduce tare weight (describe the weight of packaging material).

6. Control inventory.

How Does Materials Handling Works

Material handling is a necessary and significant component of any warehousing and

logistics activity. Material handling means providing the right amount of the right material, in the

right condition, at the right place, at the right time, in the right position and for the right cost, by

using the right method. It applies to the movement of raw materials, work in process, finished

goods, packing materials, and disposal of scraps. In general, hundreds and thousands of tons of

materials are handled daily requiring the use of a large amount of manpower and equipment while

the movement of materials takes place from one processing area to another or from one

department to another department of the plant.

As a process, material handling incorporates a wide range of manual, semi-automated

and automated equipment and systems that support logistics and make the supply chain work.

Their application helps with:

Forecasting

Resource allocation

Production planning

Flow and process management

Inventory management and control

Customer delivery

After-sales support and service

-ABANADOR ASA PATENIA NALUZ 2

MATERIAL HANDLING

Principles of Material Handling

By analyzing the goals of the material handling process and aligning them to guidelines, such as

the 10 Principles of Material Handling, a properly designed system will improve customer service,

reduce inventory, shorten delivery time, and lower overall handling costs in manufacturing,

distribution and transportation (Mhi.org, 2017). These principles include:

1. Planning: Define the needs, strategic performance objectives and functional specification

of the proposed system and supporting technologies at the outset of the design. The plan

should be developed in a team approach, with input from consultants, suppliers and end

users, as well as from management, engineering, information systems, finance and

operations.

2. Standardization: All material handling methods, equipment, controls and software should

be standardized and able to perform a range of tasks in a variety of operating conditions.

3. Work: Material handling processes should be simplified by reducing, combining,

shortening or eliminating unnecessary movement that will impede productivity. Examples

include using gravity to assist in material movement, and employing straight-line

movement as much as possible.

4. Ergonomics: Work and working conditions should be adapted to support the abilities of

a worker, reduce repetitive and strenuous manual labor, and emphasize safety.

5. Unit load: Because less effort and work is required to move several individual items

together as a single load (as opposed to moving many items one at a time), unit loads

such as pallets, containers or totes of itemsshould be used.

6. Space utilization: To maximize efficient use of space within a facility, it is important to

keep work areas organized and free of clutter, to maximize density in storage areas

(without compromising accessibility and flexibility), and to utilize overhead space.

7. System: Material movement and storage should be coordinated throughout all processes,

from receiving, inspection, storage, production, assembly, packaging, unitizing and order

selection, to shipping, transportation and the handling of returns.

8. Environment: Energy use and potential environmental impact should be considered

when designing the system, with reusability and recycling processes implemented when

possible, as well as safe practices established for handling hazardous materials.

9. Automation: To improve operational efficiency, responsiveness, consistency and

predictability, automated material handling technologies should be deployed when

possible and where they make sense to do so.

10. Life cycle cost: For all equipment specified for the system, an analysis of life cycle costs

should be conducted. Areas of consideration should include capital investment,

installation, setup, programming, training, system testing, operation, maintenance and

repair, reuse value and ultimate disposal.

II. MATERIAL HANDLING SYSTEM EQUATION

Before planning, one should be very clear about perspective, material handling equation which

emphasizes the necessity of careful analyzing both the material to be handled and the move to

be made before selecting method. Such an equation is also helpful in the planning stage of

selection of materials handling equipment for the proposed project. (Comprehensive production

and operation management (1st ed., p. 304), Arora, K. (2004))

Why What Where + When How + Who

Unnecessary Material Move Method

Factors to be considered: Factors to be considered: Factors to be considered:

1. Type 1. Source 1. Unit handled

2. Characteristics destination 2. Equipment

3. Quantity 2. Logistics 3. Manpower

3. Characteristics 4. Physical restrictions

4. Type

-ABANADOR ASA PATENIA NALUZ 3

MATERIAL HANDLING

Viewing the complex nature of materials handling, one can conclude that it needs through

planning for smooth and economic running of any productive and distributive system. It further

needs a large amount of data necessary for planning, no matter one is using it within an industry

or on a national transportation basis.

III. MATERIAL HANDLING SYSTEMS CLASSIFICATION

Mechanized System

Most mechanized systems combine different handling devices

Moderate fixed and variable cost with good flexibility

Examples

o Forklift

o Rider pallet trucks

o Towlines

o Tractor trailers

o Conveyors

o Carousels

o Paperless picking

labor capability: machine

Control capability: human

Automated System

Automated materials handling (AMH) refers to any automation that reduces or eliminates

the need for humans to check-in, check-out, sort material, or to move totes and bins

containing library material.

Highest fixed cost, lowest variable and labor cost with low flexibility

Potential to automate is the elimination of direct labor by substituting capital equipment

Examples

o Order selection systems

o Automated storage and retrieval system (AS/RS)

The mechanical equipment used in AMH systems includes:

o check-in machines

o sorters

o conveyors

-ABANADOR ASA PATENIA NALUZ 4

MATERIAL HANDLING

o singulators

o stackers and unstackers

o totes

o bins

o trolleys

o tote carriers.

labor capability: machine

Control capability: machine

Semi-automated System

Most existing material handling equipment is only semi-automated because a human

operator is needed for tasks like loading/unloading and driving that are difficult and/or too

costly to fully automate, although ongoing advances in sensing, machine intelligence, and

robotics have made it possible to fully automate an increasing number of handling tasks.

High fixed cost, low variable cost with low flexibility

Examples:

o Automated guided vehicles (AGV)

o Sortation systems

o Robotics

Build and breakdown unit loads

o Live racks

-

Information-directed System

Moderate fixed and variable cost with high flexibility and utilization

Offers selected benefits of automation without substantial capital investment

Main drawback is accountability regarding work assignment

Examples

o RF wireless (Wi-Fi)

Use lift trucks, RFID scanners and data collection terminals

o Pick-to-light carousel system

Characteristics of Materials

size

weight

shape

other (slippery, fragile, sticky, explosive, frozen)

-ABANADOR ASA PATENIA NALUZ 5

MATERIAL HANDLING

IV. FOUR MAIN CATEGORIES MATERIAL HANDLING EQUIPMENT

1. Storage And Handling Equipment

Storage equipment is usually limited to non-automated examples, which are grouped in with

engineered systems. Storage equipment is used to hold or buffer materials during downtimes,

or times when they are not being transported. These periods could refer to temporary pauses

during long-term transportation or long-term storage designed to allow the buildup of stock. The

majority of storage equipment refers to pallets, shelves or racks onto which materials may be

stacked in an orderly manner to await transportation or consumption. Many companies have

investigated increased efficiency possibilities in storage equipment by designing proprietary

packaging that allows materials or products of a certain type to conserve space while in inventory.

Examples of storage and handling equipment include:

Racks, such as pallet racks, drive-through or

drive-in racks, push-back racks, and sliding

racks

Source: http://www.ontarioindustrial.com/

Stacking frames

Source: https://www.worksafe.qld.gov.au

Shelves, bins and drawers

Source: http://www.nationwideindustrialsupply.com

Mezzanines

Source: http://www.aw-systems.com

-ABANADOR ASA PATENIA NALUZ 6

MATERIAL HANDLING

2. Engineered Systems

An engineered system is one that is typically

automated. Such systems are also usually created from a variety of units. When combined, they

work to enable both storage and transportation.

AUTOMATED STORAGE AND RETRIEVAL SYSTEM

There are several types of automated storage and retrieval systems. Their common feature is

the ability to quickly and directly access each designated storage location. There are also

different levels of automation for these systems, depending on the type of equipment

used. Storage and retrieval systems primarily are used to:

Store raw materials or bulk containers of goods for later use in manufacturing or distribution

operations

Temporarily store or buffer items between various manufacturing processes

Store and stage items for picking and kitting in distribution or assembly operations

Store and sequence finished goods in manufacturing facilities prior to shipping

Some of the most common type of Automated Storage and Retrieval System are as follows:

Unit Load Automated Storage & Retrieval

Systems (AS/RS)

These systems are designed to handle

common size unit loads such as totes or

pallets of goods. The goods are usually stored

on static racking (or on pitched gravity

conveyors in flow through systems). The

items are stored and retrieved via automated

cranes that move through aisles between the

racks. Source: http://www.isddd.com

Vertical Lift Module (VLM) Storage &

Retrieval Systems

These systems are primarily intended to store

product for quick access in picking and kitting

operations. Goods are placed on trays that

are stored and retrieved by a shuttle

mechanism within the unit. Some advantages

of this unit are:

Fast, direct, random access to all

stored items

Secure storage of items within the

unit's enclosure

Dense storage of items in a small

footprint Source: http://www.isddd.com

Better utilization of vertical building

space

Automatic presentation of the next item

to pick

Reduction of worker travel distance to

retrieve or store items

Multiple access points on the same or

multiple building floors are possible

Available with refrigerated enclosures

-ABANADOR ASA PATENIA NALUZ 7

MATERIAL HANDLING

Carousel-type Storage & Retrieval

Systems

Carousels come in vertical and horizontal

models and have the same uses as Vertical

Lift Module-type storage and retrieval

units. Goods are stored on shelves in vertical

carousels and in bins or shelves on horizontal

carousels. The shelves or bins are linked to

each other by a chain. Like the name implies,

the units rotate in a carousel-like manner to

the appropriate item storage location. Vertical

carousels have the same advantages as VLM-

type storage systems except for the direct, Source: http://www.isddd.com

random access and multiple access points.

CONVEYORS

Flat belt conveyor - Flat belt conveyor is that

in which the belt runs flat on the carrying side

over straight roller type idler or a set of idlers.

Flat belt conveyors are suitable for lower

capacity, low speed requirement and for

handling unit goods or bulk material of small

lump size and higher angle of repose.

Declination is undesirable. Source: http://beltconveyorsystems.in/products/

Belt Conveyor is typically used in package

handling, raw material handling, and small part

handling. It is effectively used for elevation

change or incline/decline applications. A more

common application of belt conveyor you

might not notice is in the check-out line at your

local grocery store.

Source:

http://www.haroldsequipment.com/equipment/belt-

conveyors

Minimum Pressure Conveyor is used in

short sections of accumulation, general

transport of product, and is ideal for medium

to light loads such as package handling

applications.

Source: http://www.automatedconveyors.com/

Drag Chain is typically used for handling

extremely heavy loads, special pallet

configurations, and extremely low- to high-

temperature areas.

Source: http://sites.dksh.com/htm/620/en/Drag-Chain-

Interflex-SLE-Steel-line.htm

-ABANADOR ASA PATENIA NALUZ 8

MATERIAL HANDLING

Roller Roller pallet conveyor is typically

used for handling extremely heavy loads and

is ideal for accumulation zones in pack out

areas.

Source: http://www.arrcoolingtowers.com/roller-

conveyors.html

Live Roller Conveyor is typically used in

general transport when product accumulation

is not required. It is also used in package

handling applications and is ideal for light- to

medium-product loads.

http://www.lewcoinc.com/conveyors/conveyors

Diverter

Stationary or movable arms that

deflect, push, or pull a product to

desired destination

Since they do not come in contact with

the conveyor, they can be used with

almost any flat surface conveyor

Usually hydraulically or pneumatically

operated, but also can be motor driven Source: http://www4.ncsu.edu/

Simple and low cost

Pop-Up Device

One or more rows of powered rollers or

wheels or chains that pop up above

surface of conveyor to lift product and

guide it off conveyor at an angle;

wheels are lowered when products not

required to be diverted

Only capable of sorting flat-bottomed

Source: http://www4.ncsu.edu/

items

Pop-up rollers are generally faster than

pop-up wheels

Sliding Shoe Sorter

Sliding shoe sorter (a.k.a. moving slat

sorter) uses series of diverter slats that

slide across the horizontal surface to

engage product and guide it off

conveyor

Slats move from side to side as

product flows in order to divert the

product to either side Source: http://www4.ncsu.edu/

Gentle and gradual handling of products

AUTOMATED GUIDED VEHICLES

- AGVs do not require an operator

- Good for high labor cost, hazardous, or environmentally sensitive conditions (e.g., clean-

room)

- Also termed "automated" guided vehicle

-ABANADOR ASA PATENIA NALUZ 9

MATERIAL HANDLING

- AGVs good for low-to-medium volume medium-to-long distance random material flow

operations (e.g., transport between work cells in a flexible manufacturing system (FMS)

environment)

Two means of guidance can be used for AGV systems:

i. Fixed path: Physical guidepath (e.g., wire, tape, paint) on the floor used for guidance

ii. Free-ranging: No physical guidepath, thus easier to change vehicle path (in software), but

absolute position estimates (from, e.g., lasers) are needed to correct dead-reckoning error

a. Tow AGV

- Used to pull a train of trailers

- Automated version of a tractor trailer

Trailers usually loaded manually (early type of

AGV, not much used today)

Source: http://www4.ncsu.edu/

b. Unit Load AGV

- Have decks that can be loaded

manually or automatically

- Deck can include conveyor or lift/lower

mechanism for automatic loading

- Typically 4 by 4 feet and can carry 1

2,000 lb. loads

- Typically less than 10 vehicles in AGV Source: http://www4.ncsu.edu/

system

c. Assembly AGV

- Used as assembly platforms (e.g., car

chassis, engines, appliances)

- Greatest development activity during

the 1980s (alternative to AEMs)

- Typically 50100 vehicles in AGV

system

Source: http://www4.ncsu.edu/

3. Industrial Trucks

This term is another broad definition that can be applied to many different types of equipment.

Such pieces of equipment do have one thing in common, though they all provide transportation.

Trucks have the capability to lift via powered or manual means, and can be ridden upon in a

drivers cab, or simply power-assisted when pushed. Such tucks can also be steered by human

intervention, or can be completely automated, following a pre-defined track on the production

floor, sunken or raised tracks, or colored strips that are laid out and sensed by optical sensors.

Such automated industrial trucks also have anti-collision technology that senses when an

employee or other obstacle is near.

Characteristics of Industrial Trucks:

Pallet/Non-Pallet: Does the truck have forks for handling pallets, or does the truck have

a flat surface on which to place loads. Non-Pallet (usually) other means required to load

truck.

-ABANADOR ASA PATENIA NALUZ 10

MATERIAL HANDLING

Manual/Powered: Does the truck have manual or powered vertical (lifting) and/or

horizontal (travel) movement capabilities. Manual => walk => operator provides the force

needed for lifting loads and/or pushing the vehicle. Powered => on-board power source

(e.g., batteries) used for lifting and/or travel.

Walk/Ride: For non-automated trucks, can the operator ride on the truck (in either a

standing or sitting position) or is the operator required to walk with the truck during travel.

Walk => manual or powered travel possible => powered travel speed limited to a normal

walking pace. Ride => powered => travel speed can be faster than a walking pace.

Stack/No Stack: Can the truck be used to lift loads for stacking purposes. Stack => can

also be used as no stack => more expensive to add stacking capability. No Stack may lift

a load a few inches to clear the floor for subsequent travel (e.g., pallet jack), but the loads

cannot be stacked on top of each other or on shelves.

Narrow Aisle: Is the lift truck designed to have a small turning radius or does it not have

to turn at all in an aisle when loading/unloading. Narrow Aisle => greater cost and (usually)

standing operator => less aisle space required. Counterbalance and/or straddle used for

load support. Small turning radius => load support via straddle or reaching capabilities.

No turning required => even narrower aisle => only one-side loading (sideloaders) or the

capability to rotate the load (turret truck).

Automated: Is the truck automated so that it can transport loads without requiring an

operator. Non-Automated => direct labor cost of operator is by far the largest cost to

operate a non-automated truck. Semi-Automated => operator used to control

loading/unloading, but automated transport control (e.g., the S/R machine of a Man-on-

board AS/RS). Automated => Automated Guided Vehicle (AGV) => no direct labor cost,

but higher equipment costs.

Hand Truck

Two-Wheeled Hand Truck - Load tilted during

travel

Source: http://www4.ncsu.edu/

Dolly - Three or more wheeled hand truck with

a flat platform in which, since it has no handles,

the load is used for pushing

Source: http://www4.ncsu.edu/

Floor Hand Truck - Four or more wheeled

hand truck with handles for pushing or hitches

for pulling. Sometimes referred to as a "cart"

or "(manual) platform truck".

Source: http://www4.ncsu.edu/

Pallet Jack - Front wheels are mounted inside the end of the forks and extend to the floor as

the pallet is only lifted enough to clear the floor for subsequent travel

-ABANADOR ASA PATENIA NALUZ 11

MATERIAL HANDLING

Pallet restrictions: reversible pallets cannot be used, double-faced nonreversible pallets cannot

have deckboards where the front wheels extend to the floor, and enables only two-way entry into

a four-way notched-stringer pallet because the forks cannot be inserted into the notches.

Manual Pallet Jack - Manual lifting and/or

travel

Source: http://www4.ncsu.edu/

Powered Pallet Jack - Powered lifting and/or

travel

Source: http://www4.ncsu.edu/

Walkie Stacker

Manual Walkie Stacker - Manual lifting

and/or travel (and straddle load support)

Source: http://www4.ncsu.edu/

Powered Walkie Stacker - Powered lifting

and/or travel (and either counterbalance or

straddle load support)

Source: http://www4.ncsu.edu/

Pallet Truck - Same pallet restrictions as a pallet jack

- Control handle typically tilts to allow operator to walk during

loading/unloading

-ABANADOR ASA PATENIA NALUZ 12

MATERIAL HANDLING

- Powered pallet jack is sometimes referred to as a "(walkie) pallet truck"

Figure 31. Pallet Truck

Source: http://www4.ncsu.edu/

Platform Truck - used to provide support for nonpalletized loads

- Used for skid handling; platform can lift skid several inches to allow it to

clear the floor

- Greater lifting capacity compared to fork trucks because the platform

provides a greater lifting surface to support a load

Walkie Platform Truck -

Operator walks next to truck

Floor hand truck is sometimes

referred to as a "(manual) platform

truck"

Source: http://www4.ncsu.edu/

Rider Platform Truck - Operator

can ride on truck

Source: http://www4.ncsu.edu/

Counterbalanced (CB) Lift Truck

- Also referred to as fork truck.

- Weight of vehicle (and operator) behind the front wheels of truck counterbalances weight

of the load (and weight of vehicle beyond front wheels); front wheels act as fulcrum or

pivot point.

- Rated capacity reduced for load centers greater than 24 in. and lift heights greater than

13 ft.

Sit-Down Counterbalanced Lift Truck

- Operator sits down; 12-13 ft. minimum

aisle width requirement

Source: http://www4.ncsu.edu/

Stand-Up Counterbalanced Lift Truck

- Operator stands up, giving vehicle

narrow-aisle capability; 9-11 ft. minimum

aisle width requirement;

Source: http://www4.ncsu.edu/

-ABANADOR ASA PATENIA NALUZ 13

MATERIAL HANDLING

Narrow-Aisle (NA) Straddle Truck

- Similar to stand-up CB lift truck, except outrigger arms straddle a load and are used to

support the load instead of the counterbalance of the truck

- 7-8 ft. minimum aisle width requirement

- Less expensive than stand-up CB lift truck and NA reach truck

- Since the load is straddled during stacking, clearance between loads must be provided for

the outrigger arms

- Arm clearance typically provided through the use of load-on-beam rack storage or single-

wing pallets for load-on-floor storage

Figure 36. Narrow-Aisle (NA) Straddle Truck

Source: http://www4.ncsu.edu/

Narrow-Aisle (NA) Reach Truck

- Similar to both stand-up CB lift truck and NA straddle truck

- 8-10 ft. minimum aisle width requirement

- Load rests on the outrigger arms during transport, but a pantograph (scissors) mechanism

is used for reaching, thereby eliminating the need to straddle the load during stacking

- Reaching capability enables the use of shorter outrigger arms (arms > 1/2 load depth) as

compared to NA straddle truck (arms = load depth)

- Counterbalance of the truck used to support the load when it extends beyond the outrigger

arms

- Although the NA reach truck requires slightly wider aisles than a NA straddle truck since

its outrigger arms do not enter a rack during storage, it does not require arm clearance

between loads (arm clearance is still required when the truck must enter a storage lane

when block stacking or drive-in or -through racks are used)

- Extended reaching mechanisms are available to enable double-deep storage

Figure 37. Narrow-Aisle (NA) Reach Truck

Source: http://www4.ncsu.edu/

Turret Truck

- Greater stacking height compared to other narrow-aisle trucks (40 ft. vs. 25 ft.), but greater

investment cost

- Forks rotate to allow for side loading and, since truck itself does not rotate during stacking,

the body of the truck can be longer to increase its counterbalance capability and to allow

the operator to sit

- Can function like a sideloader for transporting greater-than-pallet-size load

-ABANADOR ASA PATENIA NALUZ 14

MATERIAL HANDLING

Operator-Down Turret Truck - Operator not

lifted with the load; 5-6 ft. minimum aisle width

requirement

Source: http://www4.ncsu.edu/

Operator-Up Turret Truck - Operator lifted

with the load to allow precise stacking and

picking; 5-7 ft. minimum aisle width

Source: http://www4.ncsu.edu/

requirement

Order Picker

- Similar to NA straddle truck, except operator lifted with the load to allow for less-than-unit-

load picking

- Typically has forks to allow the truck to be used for pallet stacking and to support a pallet

during less-than-pallet-load picking

- "Belly switch" used for operator safety during picking

Figure 40. Order Picker

Source: http://www4.ncsu.edu/

Sideloader

- Forks mounted perpendicular to direction of travel to allow for side loading and straddle

load support

- 5-6 ft. minimum aisle width requirement

- Can be used to handle greater-than-pallet-size loads (e.g., bar stock)

Figure 41. Sideloader

Source: http://www4.ncsu.edu/

Tractor-Trailer

- Non-load-carrying tractor used to pull a train of trailers (i.e., dollies or floor hand trucks)

- Extends the transporting capacity of floor hand trucks

- Typically used at airports for baggage handling

Figure 42. Tractor-Trailer

Source: http://www4.ncsu.edu/

Personnel and Burden Carrier

- Non-load-carrying vehicle used to transport personnel within a facility (e.g., golf cart,

bicycle, etc.)

-ABANADOR ASA PATENIA NALUZ 15

MATERIAL HANDLING

Figure 43. Personnel and Burden Carrier

Source: http://www4.ncsu.edu/

Automatic Guided Vehicle (AGV)

Bulk Handling Material Equipment

Materials Handling Equipment that falls into the bulk material handling category is used to control

loose materials in bulk form such as food or liquid. Equipment such as conveyor belts or

elevators are designed to move large quantities of material in loose form, or in packaged form,

through the use of drums and hoppers.

Some equipment used in Bulk Handling

Stackers - Stackers are bulk stockpiling

machines that are used to stack material in

stockyards in different shapes according to

specific requirements.

Source: http://www.ameco.eu.com/our-

products/stackers/

Reclaimers - These devices work closely with

stackers. Reclaimers are also large pieces of

machinery. They are used to recover bulk

material that has been placed in a stockpile.

Reclaimers often use bucket wheels to

recover the material from stockpiles and, like

stackers, are capable of moving horizontally,

vertically, and rotationally. The majority of

reclaimers used today are computer

automated.

Source: http://www.zyfzg.com/82.html

Bucket elevators - Elevating products to

processing or storage is easy with our

industrial duty bucket elevators

Source:http://www.ashoka.cc/material-handling-

equipment.html

Hoppers - Hoppers are wide, bin-like entries :

that help feed bulk materials into other https://www.rouramh.com/

machines. Generally, a hopper is open at the

top and it tapers at the bottom to assist with

feeding the machine.

-ABANADOR ASA PATENIA NALUZ 16

MATERIAL HANDLING

REFERENCES

Anon, (2017). Material Handling Systems. [online] Available at:

http://www2.isye.gatech.edu/~mgoetsch/cali/logistics_systems_design/material_handling_systems/materi

al_handling_systems.pdf [Accessed 12 Feb. 2017].

Bayt.com. (2017). What is the Types of Material Handling Equipment?. [online] Available at:

https://www.bayt.com/en/specialties/q/184810/what-is-the-types-of-material-handling-equipment/

[Accessed 12 Feb. 2017].

Galecia.com. (2017). Automated Materials Handling: More Information | The Galecia Group. [online]

Available at: http://galecia.com/content/automated-materials-handling-more-information [Accessed 12 Feb.

2017].

Isddd.com. (2017). Automated Storage and Retrieval Systems | Integrated Systems Design. [online]

Available at: http://www.isddd.com/storage-retrieval-systems [Accessed 12 Feb. 2017].

Kaseconveyors.com. (2017). Belt Conveyors | Screw Conveyors | Bucket Elevators | Bulk Material Handling

Equipment Manufacturer. [online] Available at: http://www.kaseconveyors.com/ [Accessed 12 Feb. 2017].

Lom200704.blogspot.com. (2017). Material Handling Equipment: Goals of Material Handling. [online]

Available at: http://lom200704.blogspot.com/2007/01/goals-of-material-handling.html [Accessed 12 Feb.

2017].

Materials Handling. (2017). 1st ed. [ebook] Available at: http://discovery.bits-

pilani.ac.in/dlpd/courses/coursecontent/courseMaterial/mmzg511/MOML12.pdf [Accessed 12 Feb. 2017].

S.p.A., T. (2017). Bulk material handling - TENOVA. [online] Tenova.com. Available at:

http://www.tenova.com/products-technologies/mining/bulk-material-handling/ [Accessed 12 Feb. 2017].

San Jose, D., Thang, S. and Muhammad, I. (2017). Selection of Material Handling Equipment. [online]

Asilogi.blogspot.com. Available at: http://asilogi.blogspot.com/2008/01/selection-of-material-handling.html

[Accessed 12 Feb. 2017].

Team, (2017). Information-directed Systems | BMS.co.in. [online] BMS.co.in : Bachelor of Management

Studies. Available at: http://www.bms.co.in/information-directed-systems/ [Accessed 12 Feb. 2017].

Thomasnet.com. (2017). About Material Handling Equipment. [online] Available at:

http://www.thomasnet.com/about/material-handling-equipment-50140409.html [Accessed 12 Feb. 2017].

Www4.ncsu.edu. (2017). Industrial Trucks. [online] Available at:

http://www4.ncsu.edu/~kay/mhetax/TransEq/IndusTr/index.htm#Hand truck [Accessed 12 Feb. 2017].

www.alllifting.com.au. (2017). MATERIALS HANDLING EQUIPMENT WHAT ARE THE DIFFERENT

TYPES?. [online] Available at: https://www.alllifting.com.au/materials-handling-equipment [Accessed 12

Feb. 2017].

-ABANADOR ASA PATENIA NALUZ 17

Você também pode gostar

- Material Handling NewDocumento70 páginasMaterial Handling Newphilo minaAinda não há avaliações

- Chapter 3 - MATERIAL HANDLING PDFDocumento10 páginasChapter 3 - MATERIAL HANDLING PDFShiverrania 29080% (1)

- Material HandlingDocumento26 páginasMaterial HandlingRohit AroraAinda não há avaliações

- Material Handling & Storage SystemsDocumento22 páginasMaterial Handling & Storage SystemsShikha KathuriaAinda não há avaliações

- Stores Management and Materials HandlingDocumento21 páginasStores Management and Materials HandlingMr. Umang PanchalAinda não há avaliações

- Organization For Materials ManagementDocumento60 páginasOrganization For Materials ManagementNaushad PulikkandyAinda não há avaliações

- Principles of Material Handling AssignmentDocumento27 páginasPrinciples of Material Handling AssignmentMuriithi MichaelsAinda não há avaliações

- Material HandlingDocumento55 páginasMaterial HandlingNishaThakuri100% (2)

- Material Handling SystemsDocumento30 páginasMaterial Handling SystemsSaadShees100% (1)

- Material Handling Notes 2013Documento198 páginasMaterial Handling Notes 2013taridan100% (1)

- PGDM OM 3.3 Material ManagementDocumento1 páginaPGDM OM 3.3 Material ManagementAlok SinghAinda não há avaliações

- Material HandlingDocumento4 páginasMaterial HandlingVaidehiranaAinda não há avaliações

- Production ManagementDocumento25 páginasProduction ManagementAurelio Espinoza AbalosAinda não há avaliações

- Just in TimeDocumento4 páginasJust in TimeMariano RodriguezAinda não há avaliações

- International Business: WTO Functions and Objectives Aoa, Gats, Trips, Trims by - Shraddha VichareDocumento12 páginasInternational Business: WTO Functions and Objectives Aoa, Gats, Trips, Trims by - Shraddha VichareSHRADDHAAinda não há avaliações

- Inventory ManagementDocumento38 páginasInventory ManagementMckarey RobinsonAinda não há avaliações

- Value Analysis and Material ManagementDocumento9 páginasValue Analysis and Material Managementsimply_cooolAinda não há avaliações

- Types of Production SystemDocumento6 páginasTypes of Production SystemJyoti NawlaniAinda não há avaliações

- Chapter - 1: A Study On Inventory Management at Precot Meridian LTD HindupurDocumento76 páginasChapter - 1: A Study On Inventory Management at Precot Meridian LTD HindupurSudeep SAinda não há avaliações

- Material Handling EquipmentDocumento7 páginasMaterial Handling EquipmentT ShanmugavelAinda não há avaliações

- Factors Influencing Indian Supply ChainsDocumento11 páginasFactors Influencing Indian Supply ChainsGourav SihariyaAinda não há avaliações

- Types of Economic Analysis: Presented By: DR M Rashid Malik Assistant Professor Institute of Business ManagementDocumento10 páginasTypes of Economic Analysis: Presented By: DR M Rashid Malik Assistant Professor Institute of Business ManagementChakresh Pathak100% (1)

- Material HandlingDocumento43 páginasMaterial HandlingAtulMauryaAinda não há avaliações

- CH01 - Introduction To Operations Management Rev.01Documento44 páginasCH01 - Introduction To Operations Management Rev.01Izzaty Riang RiaAinda não há avaliações

- NITIE Future MastersDocumento8 páginasNITIE Future MastersVarun MitraAinda não há avaliações

- Types of Material Handling EquipmentDocumento7 páginasTypes of Material Handling EquipmentWilly K. Ng'etichAinda não há avaliações

- Material HandlingDocumento99 páginasMaterial HandlingsalunkensAinda não há avaliações

- BVC 1-3 ChapterDocumento62 páginasBVC 1-3 ChapterJyothi RameshAinda não há avaliações

- Operations Management BabDocumento109 páginasOperations Management BabBenjamin Adelwini BugriAinda não há avaliações

- Material HandlingDocumento13 páginasMaterial HandlingSigei LeonardAinda não há avaliações

- Layout TypesDocumento6 páginasLayout TypeswearematalabiAinda não há avaliações

- 20 Principles of Material HandlingDocumento3 páginas20 Principles of Material HandlingNerz CionAinda não há avaliações

- Plant Layout Operation ManagementDocumento7 páginasPlant Layout Operation ManagementKAPIL VARSHNEYAinda não há avaliações

- Explaining The Role of Information Technology in Human Resource Development (Case Study: Staff and Faculty Members of Islamic Azad University, Darab)Documento8 páginasExplaining The Role of Information Technology in Human Resource Development (Case Study: Staff and Faculty Members of Islamic Azad University, Darab)TI Journals PublishingAinda não há avaliações

- Chapter 3 Process Design Layout and Capacity ManagementDocumento20 páginasChapter 3 Process Design Layout and Capacity ManagementJimmy Ong Ah HuatAinda não há avaliações

- Thesis of Inventory Control With InflationDocumento20 páginasThesis of Inventory Control With Inflationgarvitasingh100% (1)

- Men - Machines - Methods - Money - MaterialsDocumento42 páginasMen - Machines - Methods - Money - MaterialsAbhirup MukherjeeAinda não há avaliações

- ME Module 1Documento104 páginasME Module 1vinod kumarAinda não há avaliações

- Raymond ProjectDocumento5 páginasRaymond Projectpratibha bawankuleAinda não há avaliações

- Aqm Assignment 2Documento7 páginasAqm Assignment 2Jyoti RawalAinda não há avaliações

- Inventory ManagementDocumento41 páginasInventory ManagementK. ShruthiAinda não há avaliações

- Material ManagementDocumento17 páginasMaterial ManagementSunil Krishnappa0% (1)

- Material Handling Unit 1Documento42 páginasMaterial Handling Unit 1Shyamasis GhoshAinda não há avaliações

- Production SystemDocumento5 páginasProduction SystemPratiksinh VaghelaAinda não há avaliações

- 7-Principles of Material Handling-170811Documento5 páginas7-Principles of Material Handling-170811pammy313Ainda não há avaliações

- Warehousing AssignmentDocumento10 páginasWarehousing AssignmentERICK MLINGWA0% (1)

- E-Enabled Selling and DistributionDocumento24 páginasE-Enabled Selling and DistributionNikhil Kothari0% (3)

- Plant Layout To Start A New Bank BranchDocumento15 páginasPlant Layout To Start A New Bank Branchshraddha mehtaAinda não há avaliações

- What Is A ProductDocumento2 páginasWhat Is A ProductAli Md. Hasan 2025144660Ainda não há avaliações

- A Study On VED Analysis Done at SRI IYYAN TEXTILE MILL PVT LTD, CoimbatoreDocumento25 páginasA Study On VED Analysis Done at SRI IYYAN TEXTILE MILL PVT LTD, CoimbatoreKrishna Murthy AAinda não há avaliações

- Economic Order QuantityDocumento9 páginasEconomic Order Quantitybanhi.guhaAinda não há avaliações

- Facilities Layout and Materials HandlingDocumento22 páginasFacilities Layout and Materials HandlingHarish PadmanabanAinda não há avaliações

- Trade Project OrientationDocumento12 páginasTrade Project OrientationIts John50% (2)

- Spork Product Design, Analysis & It's Mould Design Using Cad-Cae TechnologyDocumento8 páginasSpork Product Design, Analysis & It's Mould Design Using Cad-Cae TechnologyAMIT SOMWANSHIAinda não há avaliações

- Production & Operations ManagementDocumento6 páginasProduction & Operations ManagementAjay LalwaniAinda não há avaliações

- Work StudyDocumento21 páginasWork StudysivainamduguAinda não há avaliações

- Materials HandlingDocumento18 páginasMaterials HandlingJessica SaballeroAinda não há avaliações

- MM ch6Documento7 páginasMM ch6thebestofworld2014Ainda não há avaliações

- MM CH 6Documento7 páginasMM CH 6dawitsam7Ainda não há avaliações

- UNIT 1 - Introduction To Material Handling EquipmentsDocumento20 páginasUNIT 1 - Introduction To Material Handling EquipmentsAdugna GosaAinda não há avaliações

- Approval Sheet: Melongena (Eggplant) Peel and Synthesized TioDocumento1 páginaApproval Sheet: Melongena (Eggplant) Peel and Synthesized TioJessica SaballeroAinda não há avaliações

- Title PageDocumento1 páginaTitle PageJessica SaballeroAinda não há avaliações

- DataDocumento1 páginaDataJessica SaballeroAinda não há avaliações

- Materials HandlingDocumento18 páginasMaterials HandlingJessica SaballeroAinda não há avaliações

- Material HandlingDocumento17 páginasMaterial HandlingJessica SaballeroAinda não há avaliações

- Instruction For Obe Requirement For Computer ApplicationsDocumento1 páginaInstruction For Obe Requirement For Computer ApplicationsJessica SaballeroAinda não há avaliações

- The Problem and Its BackgroundDocumento10 páginasThe Problem and Its BackgroundJessica SaballeroAinda não há avaliações

- Concept PaperDocumento3 páginasConcept PaperJessica SaballeroAinda não há avaliações

- PrintDocumento2 páginasPrintJessica SaballeroAinda não há avaliações

- Modine PDP ManualDocumento64 páginasModine PDP Manualbuisson-21Ainda não há avaliações

- Bombay wp-1537-2023Documento22 páginasBombay wp-1537-2023surajsharma199705Ainda não há avaliações

- 025.0593 0 SRP 3015 3020 3030 3050 Anal. Ingl. SOA 02 07Documento48 páginas025.0593 0 SRP 3015 3020 3030 3050 Anal. Ingl. SOA 02 07Douglas SchusterAinda não há avaliações

- Aircraft Engine: Manufacturing Industry Development History Shaft EnginesDocumento12 páginasAircraft Engine: Manufacturing Industry Development History Shaft EnginesMARCELA LA QUE SE MEAAinda não há avaliações

- Natural Frequency, Ride Frequency and Their InfluenceDocumento5 páginasNatural Frequency, Ride Frequency and Their InfluenceMielito CalparsoroAinda não há avaliações

- Cylinder Installation PDFDocumento45 páginasCylinder Installation PDFMahdi Khanfir HachenniAinda não há avaliações

- Manual GTR57JYF-specDocumento6 páginasManual GTR57JYF-specAmanda ViverosAinda não há avaliações

- D9A260Documento2 páginasD9A260AnbarasanAinda não há avaliações

- Fire Prevention and Response ManualDocumento2 páginasFire Prevention and Response ManualGodfrey Jr Jr.Ainda não há avaliações

- New Trends in Cold-Chamber Die Casting Machine DesDocumento6 páginasNew Trends in Cold-Chamber Die Casting Machine DesDinh Thi TruongAinda não há avaliações

- AR-2 Antilock Relay Valve (SD-13-4796)Documento12 páginasAR-2 Antilock Relay Valve (SD-13-4796)emmanuelAinda não há avaliações

- Patrol Light RH-LDocumento1 páginaPatrol Light RH-Ldrawing yamahaAinda não há avaliações

- National Number Knockout: X X X X X X X XDocumento2 páginasNational Number Knockout: X X X X X X X XDaniela Cordovez HidalgoAinda não há avaliações

- Reuse EV BatteriesDocumento130 páginasReuse EV Batteriesdavidvandaalen100% (1)

- Volvo Wheel Loader Parts Catalog L220HDocumento1.348 páginasVolvo Wheel Loader Parts Catalog L220HUsman gani100% (2)

- A400 Parts Manual BizerbaDocumento242 páginasA400 Parts Manual Bizerbaivan boras50% (2)

- Kubota D722-E3b - SpecificationsDocumento2 páginasKubota D722-E3b - SpecificationsGeorge100% (2)

- Brought To You by Pro Gear & Transmission. For Parts or Service CallDocumento3 páginasBrought To You by Pro Gear & Transmission. For Parts or Service CallOscar GonzálezAinda não há avaliações

- Catalogue PDR Zl60gDocumento156 páginasCatalogue PDR Zl60ggoxmad50% (2)

- Project On Harley DavidsonDocumento37 páginasProject On Harley DavidsonViPul86% (7)

- 11.1 Forklifts and Power Tools PDFDocumento86 páginas11.1 Forklifts and Power Tools PDFzeidan111Ainda não há avaliações

- Cyclo 6000Documento168 páginasCyclo 6000Abdul100% (1)

- Race Harness Install Guide v1.5Documento3 páginasRace Harness Install Guide v1.5Hybrid Racing0% (1)

- Car Wars - Errata (Jan 2013)Documento12 páginasCar Wars - Errata (Jan 2013)Nothing GoodAinda não há avaliações

- NCERT Solutions Class 5 English Chapter 9Documento7 páginasNCERT Solutions Class 5 English Chapter 9PRIYANKA SEHGALAinda não há avaliações

- Specialized ManualDocumento8 páginasSpecialized ManualAndreaAlberoAinda não há avaliações

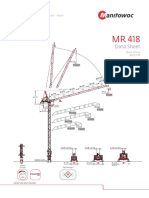

- MR418-FEM-Top Slewing Tower Cranes Imperial PDFDocumento8 páginasMR418-FEM-Top Slewing Tower Cranes Imperial PDFCompass equipmentAinda não há avaliações

- Soal Casr Untuk PPCDocumento10 páginasSoal Casr Untuk PPCIqbal MasyhuriAinda não há avaliações

- 015 - Legend For 3748761 - #170112 - 08 - 03-3746450enDocumento15 páginas015 - Legend For 3748761 - #170112 - 08 - 03-3746450enhectorAinda não há avaliações

- Air Compressor Script AUX MACHDocumento5 páginasAir Compressor Script AUX MACHRalph Jay M. TaladroAinda não há avaliações

- Elevate and Dominate: 21 Ways to Win On and Off the FieldNo EverandElevate and Dominate: 21 Ways to Win On and Off the FieldNota: 5 de 5 estrelas5/5 (7)

- Becky Lynch: The Man: Not Your Average Average GirlNo EverandBecky Lynch: The Man: Not Your Average Average GirlNota: 4.5 de 5 estrelas4.5/5 (15)

- Crazy for the Storm: A Memoir of SurvivalNo EverandCrazy for the Storm: A Memoir of SurvivalNota: 3.5 de 5 estrelas3.5/5 (217)

- The Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsNo EverandThe Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsNota: 4 de 5 estrelas4/5 (49)

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthNo EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthNota: 4 de 5 estrelas4/5 (59)

- Eat & Run: My Unlikely Journey to Ultramarathon GreatnessNo EverandEat & Run: My Unlikely Journey to Ultramarathon GreatnessAinda não há avaliações

- Peak: The New Science of Athletic Performance That is Revolutionizing SportsNo EverandPeak: The New Science of Athletic Performance That is Revolutionizing SportsNota: 5 de 5 estrelas5/5 (97)

- Life Is Not an Accident: A Memoir of ReinventionNo EverandLife Is Not an Accident: A Memoir of ReinventionNota: 3.5 de 5 estrelas3.5/5 (7)

- Strong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerNo EverandStrong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerNota: 4 de 5 estrelas4/5 (5)

- Badasses: The Legend of Snake, Foo, Dr. Death, and John Madden's Oakland RaidersNo EverandBadasses: The Legend of Snake, Foo, Dr. Death, and John Madden's Oakland RaidersNota: 4 de 5 estrelas4/5 (15)

- What Winners Won't Tell You: Lessons from a Legendary DefenderNo EverandWhat Winners Won't Tell You: Lessons from a Legendary DefenderNota: 4.5 de 5 estrelas4.5/5 (7)

- Bloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyNo EverandBloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyNota: 4 de 5 estrelas4/5 (8)

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveNo EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveAinda não há avaliações

- The Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItNo EverandThe Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItAinda não há avaliações

- Can't Nothing Bring Me Down: Chasing Myself in the Race Against TimeNo EverandCan't Nothing Bring Me Down: Chasing Myself in the Race Against TimeNota: 4 de 5 estrelas4/5 (1)

- Patriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionNo EverandPatriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionNota: 3.5 de 5 estrelas3.5/5 (30)

- The Rise of Superman: Decoding the Science of Ultimate Human PerformanceNo EverandThe Rise of Superman: Decoding the Science of Ultimate Human PerformanceNota: 4.5 de 5 estrelas4.5/5 (194)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNo EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsAinda não há avaliações

- Earnhardt Nation: The Full-Throttle Saga of NASCAR's First FamilyNo EverandEarnhardt Nation: The Full-Throttle Saga of NASCAR's First FamilyNota: 3.5 de 5 estrelas3.5/5 (7)

- Body Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialNo EverandBody Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialNota: 4 de 5 estrelas4/5 (2)