Escolar Documentos

Profissional Documentos

Cultura Documentos

BSC6900 GSM Installation Guide (V900R012C01 - 05)

Enviado por

Deepak KaushalTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

BSC6900 GSM Installation Guide (V900R012C01 - 05)

Enviado por

Deepak KaushalDireitos autorais:

Formatos disponíveis

BSC6900 GSM

V900R012C01

Installation Guide

Issue 05

Date 2011-05-19

HUAWEI TECHNOLOGIES CO., LTD.

Copyright Huawei Technologies Co., Ltd. 2011. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior written

consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and the

customer. All or part of the products, services and features described in this document may not be within the

purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information,

and recommendations in this document are provided "AS IS" without warranties, guarantees or representations

of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute the warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://www.huawei.com

Email: support@huawei.com

Issue 05 (2011-05-19) Huawei Proprietary and Confidential i

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide About This Document

About This Document

Overview

This document describes how to install the BSC6900 UMTS devices, including the external

power cables, PGND cables, boards, signal cables, cabinet accessories, Local Maintenance

Terminal (LMT) PC, and alarm box. It also describes how to check the hardware installation.

In addition, the document provides the method of making connectors for the power cables and

signal cables, the method of making and attaching engineering labels, and the requirements for

the operational environment of the equipment.

Product Version

The following table lists the product version related to this document.

Product Name Product Version

BSC6900 V900R012C01

Intended Audience

This document is intended for installation personnel.

Organization

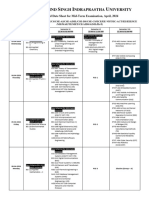

1 Changes in the BSC6900 GSM Installation Guide

This chapter describes the changes in the BSC6900 GSM Installation Guide.

2 Preparations for Installation

Before the BSC6900 installation, you need to arrange the installation tools, unpack the packing

cases, and check the items.

3 Procedures for Installation

Issue 05 (2011-05-19) Huawei Proprietary and Confidential iii

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

About This Document Installation Guide

This chapter describes how to install the BSC6900 and its accessories, power cables and PGND

cables, OMUa boards, signal cables, Local Maintenance Terminal (LMT) PC, and alarm box.

4 Installing the Power Cables and PGND Cables

This chapter describes how to install the power cables and PGND cables between the

BSC6900 and the power distribution frame (PDF) and also how to install the PGND cables

between the cabinets of the BSC6900.

5 Checking and Setting the Subrack DIP Switch

This chapter describes how to check and set the DIP switch of a subrack. In general, the subrack

is installed in the cabinet before delivery.

6 Installing Boards and Setting Board DIP Switches

The boards except the OMUa board are installed in the subrack before delivery. If the EIUa/

PEUa board is installed in the cabinet, you need to check and set the DIP switches of the EIUa/

PEUa board. The OMUa should be installed on site.

7 Installing the Signal Cables

This chapter describes how to install the signal cables according to the layout requirements. The

signal cables to be installed include clock signal cables, Ethernet cables, E1/T1 cables and optical

cables.

8 Installing the Local Maintenance Terminal (LMT) PC and the Alarm Box

This chapter describes how to install the LMT PC and the alarm box. If the LMT PC and the

alarm box are installed in the maintenance room, install them together with the BSC6900

equipment.

9 Attaching the Engineering Labels to the Cables

This chapter describes how to attach engineering labels to the power, PGND, and signal cables

after the cables are installed

10 Checking the Hardware Installation

This chapter describes how to check the hardware installation. The hardware consists of the

cabinet, cables, Local Maintenance Terminal (LMT) PC, and alarm box. In addition, you should

check the installation environment.

11 Installation Illustrations

This chapter describes the exploded views of cabinet, cabinet assembly diagrams, and cable

connections of cabinets.

12 Hardware Installation Records

The hardware installation records provide templates for recording the information about the

BSC6900 hardware installation.

Conventions

Symbol Conventions

The symbols that may be found in this document are defined as follows.

iv Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide About This Document

Symbol Description

Indicates a hazard with a high level of risk, which if not

avoided, will result in death or serious injury.

Indicates a hazard with a medium or low level of risk, which

if not avoided, could result in minor or moderate injury.

Indicates a potentially hazardous situation, which if not

avoided, could result in equipment damage, data loss,

performance degradation, or unexpected results.

Indicates a tip that may help you solve a problem or save

time.

Provides additional information to emphasize or supplement

important points of the main text.

General Conventions

The general conventions that may be found in this document are defined as follows.

Convention Description

Times New Roman Normal paragraphs are in Times New Roman.

Boldface Names of files, directories, folders, and users are in

boldface. For example, log in as user root.

Italic Book titles are in italics.

Courier New Examples of information displayed on the screen are in

Courier New.

Command Conventions

The command conventions that may be found in this document are defined as follows.

Convention Description

Boldface The keywords of a command line are in boldface.

Italic Command arguments are in italics.

[] Items (keywords or arguments) in brackets [ ] are optional.

{ x | y | ... } Optional items are grouped in braces and separated by

vertical bars. One item is selected.

[ x | y | ... ] Optional items are grouped in brackets and separated by

vertical bars. One item is selected or no item is selected.

Issue 05 (2011-05-19) Huawei Proprietary and Confidential v

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

About This Document Installation Guide

Convention Description

{ x | y | ... }* Optional items are grouped in braces and separated by

vertical bars. A minimum of one item or a maximum of all

items can be selected.

[ x | y | ... ]* Optional items are grouped in brackets and separated by

vertical bars. Several items or no item can be selected.

GUI Conventions

The GUI conventions that may be found in this document are defined as follows.

Convention Description

Boldface Buttons, menus, parameters, tabs, window, and dialog titles

are in boldface. For example, click OK.

> Multi-level menus are in boldface and separated by the ">"

signs. For example, choose File > Create > Folder.

Keyboard Operations

The keyboard operations that may be found in this document are defined as follows.

Format Description

Key Press the key. For example, press Enter and press Tab.

Key 1+Key 2 Press the keys concurrently. For example, pressing Ctrl+Alt

+A means the three keys should be pressed concurrently.

Key 1, Key 2 Press the keys in turn. For example, pressing Alt, A means

the two keys should be pressed in turn.

Mouse Operations

The mouse operations that may be found in this document are defined as follows.

Action Description

Click Select and release the primary mouse button without moving

the pointer.

Double-click Press the primary mouse button twice continuously and

quickly without moving the pointer.

Drag Press and hold the primary mouse button and move the

pointer to a certain position.

vi Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide Contents

Contents

About This Document...................................................................................................................iii

1 Changes in the BSC6900 GSM Installation Guide..............................................................1-1

2 Preparations for Installation....................................................................................................2-1

2.1 Installation Tools.............................................................................................................................................2-2

2.2 Unpacking the Cases and Checking the Items................................................................................................2-2

3 Procedures for Installation.......................................................................................................3-1

4 Installing the Power Cables and PGND Cables..................................................................4-1

4.1 Power Cables and PGND Cables to Be Installed............................................................................................4-2

4.2 Connections of the Power Cables and PGND Cables.....................................................................................4-2

4.3 Principles of Installing the Power Cables and PGND Cables.........................................................................4-3

4.4 Installing the Power Cables and PGND Cable Between the BSC6900 and the PDF.....................................4-4

4.4.1 Installing the Power Cables and PGND Cables Between the BSC6900 and the PDF (Overhead Cabling)

.........................................................................................................................................................................4-4

4.4.2 Installing the Power Cables and PGND Cables Between the BSC6900 and the PDF (Underfloor Cabling)

.........................................................................................................................................................................4-7

4.5 Installing the PGND Cables Between Adjacent Cabinets.............................................................................4-10

4.6 Checking the Power-On Performance...........................................................................................................4-11

5 Checking and Setting the Subrack DIP Switch...................................................................5-1

6 Installing Boards and Setting Board DIP Switches.............................................................6-1

6.1 Safety Precautions for Board Installation........................................................................................................6-2

6.2 Installing the OMUa Boards...........................................................................................................................6-2

6.3 Checking and Setting the DIP Switch on the Board.......................................................................................6-4

6.4 DIP Switches on the BSC6900 Boards...........................................................................................................6-5

6.4.1 DIP Switches on the EIUa Board...........................................................................................................6-5

6.4.2 DIP Switch on the PAMU Board...........................................................................................................6-8

6.4.3 DIP Switches on the PEUa Board..........................................................................................................6-8

6.4.4 DIP Switch on the PFCU Board...........................................................................................................6-11

6.4.5 Pins on the PFCB Board.......................................................................................................................6-13

7 Installing the Signal Cables.....................................................................................................7-1

7.1 Signal Cables to Be Installed..........................................................................................................................7-3

7.2 Principles of Installing the Signal Cables.......................................................................................................7-5

Issue 05 (2011-05-19) Huawei Proprietary and Confidential vii

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Contents Installation Guide

7.3 Installing the Inter-TNUa Cables....................................................................................................................7-8

7.4 Installing the Clock Signal Cables................................................................................................................7-12

7.4.1 Installing the Y-Shaped Clock Cables.................................................................................................7-13

7.4.2 Installing the BITS Clock Signal Cables..............................................................................................7-15

7.5 Installing the Ethernet Cables.......................................................................................................................7-18

7.5.1 Arranging the Ethernet Cables.............................................................................................................7-18

7.5.2 Installing the Inter-SCUa Cables Between Different Subracks...........................................................7-19

7.5.3 Installing the Ethernet Cables Between the OMUa Board and the LAN.............................................7-26

7.5.4 Installing the Ethernet Cables Between the XPUa/XPUb Board and the CBC...................................7-29

7.5.5 Installing the Ethernet Cables Between the FG2a/FG2c Board and the Other Equipment..................7-31

7.6 Installing the E1/T1 Cables...........................................................................................................................7-33

7.6.1 Arranging the E1/T1 Cables Between the EIUa/PEUa Board and the DDF........................................7-34

7.6.2 Installing the E1/T1 Cables Between the EIUa/PEUa Board and the DDF in Overhead Cabling Mode

.......................................................................................................................................................................7-35

7.6.3 Installing the E1/T1 Cables Between the EIUa/PEUa Board and the DDF in Underfloor Cabling Mode

.......................................................................................................................................................................7-42

7.7 Installing the Optical Cables.........................................................................................................................7-49

7.7.1 Using the Accessories of the Optical Cable.........................................................................................7-49

7.7.2 Arranging the Optical Cables...............................................................................................................7-52

7.7.3 Installing the Optical Splitter/Combiner..............................................................................................7-53

7.7.4 Installing the Optical Cables Between the OIUa/GOUa/GOUc/POUc Boards and the Other Equipment

.......................................................................................................................................................................7-56

7.8 Installing the EMU RS485 Communication Cables.....................................................................................7-58

7.9 Connecting the GPS Surge Protector to the GCGa Board............................................................................7-60

8 Installing the Local Maintenance Terminal (LMT) PC and the Alarm Box....................8-1

8.1 Installing the Local Maintenance Terminal (LMT) PC...................................................................................8-2

8.2 Installing the Alarm Box.................................................................................................................................8-2

9 Attaching the Engineering Labels to the Cables..................................................................9-1

9.1 Attaching the Engineering Labels to the Power Cables and PGND Cables...................................................9-2

9.2 Attaching the Engineering Labels to the Signal Cables..................................................................................9-2

10 Checking the Hardware Installation..................................................................................10-1

10.1 Checklist for BSC6900 Cabinet Installation...............................................................................................10-2

10.2 Checklist for BSC6900 Cable Installation..................................................................................................10-2

10.3 Checklist for the Installation of the BSC6900 GPS Antenna System.........................................................10-2

10.4 Checklist for the Installation of the LMT Computer and Alarm Box.........................................................10-2

10.5 Checklist for Field Cleanliness of BSC6900 Installation............................................................................10-2

11 Installation Illustrations.......................................................................................................11-1

11.1 Exploded View of the N68E-22 Cabinet.....................................................................................................11-2

11.2 Components of the Cabinet.........................................................................................................................11-4

11.3 Cable Connections of the Cabinet...............................................................................................................11-8

11.3.1 Connections of Power Cables and PGND Cables in the Cabinet......................................................11-9

11.3.2 Connections of Signal Cables for the MPR.....................................................................................11-15

viii Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide Contents

11.3.3 Connections of Signal Cables for the EPR.......................................................................................11-26

11.3.4 Connections of Signal Cables for the TCR .....................................................................................11-29

12 Hardware Installation Records............................................................................................12-1

Index.................................................................................................................................................i-1

Issue 05 (2011-05-19) Huawei Proprietary and Confidential ix

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide Figures

Figures

Figure 2-1 Shockwatch label................................................................................................................................2-4

Figure 2-2 Straightening the tongue.....................................................................................................................2-6

Figure 2-3 Removing the cover............................................................................................................................2-6

Figure 2-4 Removing side boards........................................................................................................................ 2-7

Figure 2-5 Unpacking a carton.............................................................................................................................2-7

Figure 4-1 Connections of the power cables and PGND cables.......................................................................... 4-3

Figure 4-2 Installing the power cables and PGND cables in overhead cabling mode.........................................4-5

Figure 4-3 Installing the OT terminal...................................................................................................................4-7

Figure 4-4 Installing power cables and PGND cables in underfloor cabling mode.............................................4-8

Figure 4-5 Installing the OT terminal.................................................................................................................4-10

Figure 4-6 Installing the PGND cables of the adjacent cabinets........................................................................4-11

Figure 5-1 Cover for the DIP switch of the subrack............................................................................................ 5-1

Figure 6-1 Installing the board.............................................................................................................................6-3

Figure 6-2 Layout of the DIP switches on the EIUa board..................................................................................6-6

Figure 6-3 Layout of the DIP switch on the PAMU board..................................................................................6-8

Figure 6-4 Layout of the DIP switches on the PEUa board.................................................................................6-9

Figure 6-5 DIP switch on the PFCU board........................................................................................................6-12

Figure 6-6 DIP switch on the PFCU board........................................................................................................6-12

Figure 6-7 Pins on the PFCB board....................................................................................................................6-13

Figure 6-8 Pins on the PFCB board....................................................................................................................6-14

Figure 7-1 Bending and binding signal cables.....................................................................................................7-7

Figure 7-2 Connection of the inter-TNUa cables between two subracks...........................................................7-10

Figure 7-3 Connection of the inter-TNUa cables between three subracks.........................................................7-11

Figure 7-4 Connection of the inter-TNUa cables between four subracks..........................................................7-12

Figure 7-5 Connecting the Y-shaped clock cables.............................................................................................7-15

Figure 7-6 Connecting the cables between the GCUa and the BITS clock........................................................7-17

Figure 7-7 Connection of the inter-SCUa cables between two subracks...........................................................7-22

Figure 7-8 Connection of the inter-SCUa cables between three subracks.........................................................7-23

Figure 7-9 Connection of the inter-SCUa cables between four subracks..........................................................7-24

Figure 7-10 Connection of the inter-SCUa cables in full configuration of two cabinets...................................7-26

Figure 7-11 Connections of Ethernet cables between the OMUa board and the LAN......................................7-28

Figure 7-12 Connection between the XPUa/XPUb board and the CBC (taking the XPUa board as an example)

.............................................................................................................................................................................7-30

Issue 05 (2011-05-19) Huawei Proprietary and Confidential xi

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Figures Installation Guide

Figure 7-13 Connection between the FG2a/FG2c board and the other equipment (taking the FG2a board as an

example)..............................................................................................................................................................7-32

Figure 7-14 Installing non-active/standby E1/T1 cables between the EIUa/PEUa board and the DDF in overhead

cabling mode ......................................................................................................................................................7-36

Figure 7-15 Installing active/standby E1/T1 cables between the EIUa/PEUa board and the DDF in overhead cabling

mode....................................................................................................................................................................7-37

Figure 7-16 Opening the cover plate of the back cable trough..........................................................................7-38

Figure 7-17 Bundling E1/T1 cables led from the boards (non-active/standby E1/T1 cable as example)..........7-39

Figure 7-18 Routing the E1/T1 cables through the back cable trough...............................................................7-40

Figure 7-19 E1/T1 cables bundled on the side of the cabinet............................................................................7-40

Figure 7-20 E1/T1 cables bundled on the cable tray I........................................................................................7-41

Figure 7-21 E1/T1 cables bundled on the cable tray II......................................................................................7-41

Figure 7-22 Installing non-active/standby E1/T1 cables between the EIUa/PEUa board and the DDF in underfloor

cabling mode ......................................................................................................................................................7-44

Figure 7-23 Installing active/standby E1/T1 cables between the EIUa/PEUa board and the DDF in underfloor

cabling mode ......................................................................................................................................................7-45

Figure 7-24 Opening the cover plate of the back cable trough..........................................................................7-46

Figure 7-25 Bundling E1/T1 cables from the boards (non-active/standby E1/T1 cables as an example).........7-47

Figure 7-26 Routing the E1/T1 cables through the back cable trough...............................................................7-48

Figure 7-27 Appearance of an SC/PC adapter...................................................................................................7-50

Figure 7-28 Appearance of an FC/PC adapter...................................................................................................7-50

Figure 7-29 Appearance of an LC/PC adapter...................................................................................................7-51

Figure 7-30 Installation position of the fiber management tray.........................................................................7-52

Figure 7-31 Connections of optical splitters/combiners.....................................................................................7-54

Figure 7-32 Routing of the optical splitters/combiners......................................................................................7-55

Figure 7-33 Connection of the optical cables between the OIUa/GOUa/GOUc/POUc and the other equipment

(taking the OIUa and GOUa as an example).......................................................................................................7-57

Figure 7-34 Connections of cables between the EMU and the power distribution box.....................................7-60

Figure 7-35 Connecting the GPS surge protector to the GCGa board...............................................................7-62

Figure 7-36 Installing the surge protector to its fastener....................................................................................7-63

Figure 7-37 Installing the fastener of the surge protector..................................................................................7-64

Figure 11-1 Structure of the N68E-22 cabinet...................................................................................................11-2

Figure 11-2 Components of the MPR (configured with the OMU board)/EPR/TCR........................................11-5

Figure 11-3 Components of the MPR (configured with the GBAM)................................................................11-7

Figure 11-4 Connections of power cables and PGND cables in the cabinet (configured with the high-power power

distribution box) ...............................................................................................................................................11-10

Figure 11-5 Connections of power cables and PGND cables in the MPR (configured with IBM X3650T)...11-12

Figure 11-6 Connections of power cables and PGND cables in the MPR (configured with HUAWEI C5210 or HP

CC3310)............................................................................................................................................................11-14

Figure 11-7 Connections of signal cables for an MPR that is configured with one MPS and two EPSs .......11-16

Figure 11-8 Connections of signal cables for the MPR (configured with IBM X3650T)...............................11-20

Figure 11-9 Connections of signal cables for the MPR (Configured with C5210 or HP CC3310).................11-21

Figure 11-10 Connections of signal cables for an EPR that is configured with three EPSs............................11-27

Figure 11-11 Connections of signal cables for the TCR..................................................................................11-30

xii Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide Tables

Tables

Table 2-1 Tools required for installation..............................................................................................................2-2

Table 4-1 Power cables and PGND cables to be installed for each cabinet.........................................................4-2

Table 5-1 Meaning of the DIP Bits......................................................................................................................5-2

Table 5-2 Setting of the DIP switch.....................................................................................................................5-2

Table 6-1 Description of the DIP switches on the EIUa board............................................................................6-6

Table 6-2 Description of the different DIP switches............................................................................................6-7

Table 6-3 DIP switch on the PAMU board..........................................................................................................6-8

Table 6-4 Description about DIP switches on the PEUa board..........................................................................6-10

Table 6-5 DIP switch on the PFCU board (in a fan box of the service subrack)...............................................6-12

Table 6-6 DIP switch on the PFCU board (in the independent fan subrack).....................................................6-13

Table 6-7 Pins on the PFCB board (in a fan box of the service subrack)..........................................................6-13

Table 6-8 Pins on the PFCB board (in the independent fan subrack)................................................................6-14

Table 7-1 Signal cable..........................................................................................................................................7-3

Table 7-2 Bending radius of the signal cables......................................................................................................7-6

Table 7-3 Cabling of the inter-TNUa cables........................................................................................................7-9

Table 7-4 Cabling of the Y-shaped clock cables................................................................................................7-14

Table 7-5 Cabling of the inter-SCUa cables when the TCS is configured remotely..........................................7-20

Table 7-6 Cabling of the inter-SCUa cables when the TCS is configured locally.............................................7-24

Table 7-7 Connecting different types of connectors to peer equipment.............................................................7-58

Table 11-1 Details of the installation of a cabinet..............................................................................................11-3

Table 11-2 Components of the cabinet and their configurations........................................................................11-5

Table 11-3 Components of the MPR and their configurations...........................................................................11-7

Table 11-4 Connections of power cables and PGND cables in the BSC6900 cabinet.....................................11-11

Table 11-5 Connections of power cables and PGND cables in the MPR (configured with IBM X3650T)....11-13

Table 11-6 Connections of power cables and PGND cables in the MPR (configured with HUAWEI C5210 or HP

CC3310)............................................................................................................................................................11-15

Table 11-7 Connections of signal cables for the MPR.....................................................................................11-17

Table 11-8 Connections of signal cables for the MPR.....................................................................................11-22

Table 11-9 Connections of signal cables for the EPR......................................................................................11-28

Table 11-10 Connections of signal cables for the TCR....................................................................................11-31

Issue 05 (2011-05-19) Huawei Proprietary and Confidential xiii

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 1 Changes in the BSC6900 GSM Installation Guide

1 Changes in the BSC6900 GSM Installation

Guide

This chapter describes the changes in the BSC6900 GSM Installation Guide.

05 (2011-05-19)

This is the fifth commercial release of V900R012C01.

Compared with issue 04 (2011-03-07), this issue includes the following new topics:

l 7.7.3 Installing the Optical Splitter/Combiner

Compared with issue 04 (2011-03-07), this issue incorporates the following changes:

Content Description

2.2 Unpacking the Cases and Checking the The procedures of unpacking the cases and

Items checking the items are modified.

7.3 Installing the Inter-TNUa Cables The procedures of installing the Inter-TNUa

cables are modified.

7.6.2 Installing the E1/T1 Cables Between The procedures of installing the E1/T1 cables

the EIUa/PEUa Board and the DDF in are modified.

Overhead Cabling Mode

7.6.3 Installing the E1/T1 Cables Between The procedures of installing the E1/T1 cables

the EIUa/PEUa Board and the DDF in are modified.

Underfloor Cabling Mode

Compared with issue 04 (2011-03-07), this issue does not exclude any topics.

04 (2011-03-07)

This is the fourth commercial release of V900R012C01.

Compared with issue 03 (2010-09-20), this issue does not include any new topics.

Compared with issue 03 (2010-09-20), this issue incorporates the following changes:

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 1-1

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

1 Changes in the BSC6900 GSM Installation Guide Installation Guide

Content Description

6.2 Installing the OMUa Boards The procedure and the figure of the installing

the board are modified.

Compared with issue 03 (2010-09-20), this issue does not exclude any topics.

03 (2010-09-20)

This is the third commercial release of V900R012C01.

Compared with issue 02 (2010-06-21), this issue does not include any new topics.

Compared with issue 02 (2010-06-21), this issue incorporates the following changes:

Content Description

7.4.1 Installing the Y-Shaped Clock Cables The length of Y-Shaped Clock Cable is

modified.

7.5.2 Installing the Inter-SCUa Cables The figures of the connection of inter-SCUa

Between Different Subracks cables between different subracks when the

TCS is in remote configuration mode are

modified.

Compared with issue 02 (2010-06-21), this issue does not exclude any topics.

02 (2010-06-21)

This is the second commercial release of V900R012C01.

Compared with issue 01 (2010-04-10), this issue does not include any new topics.

Compared with issue 01 (2010-04-10), this issue incorporates the following changes:

Content Description

5 Checking and Setting the Subrack DIP The description about the caution is

Switch optimized.

Compared with issue 01 (2010-04-10), this issue does not exclude any topics.

01 (2010-04-10)

This is the first commercial release of V900R012C01.

Compared with issue 04 (2010-01-30) of V900R011C00, this issue does not include any new

topics.

Compared with issue 04 (2010-01-30) of V900R011C00, this issue does not incorporate any

changes.

1-2 Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 1 Changes in the BSC6900 GSM Installation Guide

Compared with issue 04 (2010-01-30) of V900R011C00, this issue does not exclude any topics.

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 1-3

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 2 Preparations for Installation

2 Preparations for Installation

About This Chapter

Before the BSC6900 installation, you need to arrange the installation tools, unpack the packing

cases, and check the items.

2.1 Installation Tools

The tools required for installing the BSC6900 are tools for measuring, marking, drilling, and

fastening, small tools, auxiliary tools, instruments, and special tools.

2.2 Unpacking the Cases and Checking the Items

This section describes how to unpack the cases containing the BSC6900 at the installation site

and check the items in the cases to facilitate installation.

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 2-1

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

2 Preparations for Installation Installation Guide

2.1 Installation Tools

The tools required for installing the BSC6900 are tools for measuring, marking, drilling, and

fastening, small tools, auxiliary tools, instruments, and special tools.

Table 2-1 lists the tools required for installation.

Table 2-1 Tools required for installation

Common Tools Measuring tools Long measuring tape, ruler (1 m), angle square,

industrial horizontal ruler, and plumb

Marking tools Marking pen or ink fountain

Drilling tools Percussion drill (16 drill bit) and vacuum cleaner

Fastening tools M3-M6 straight screwdrivers

M3-M6 Phillips screwdrivers

Adjustable wrench

Socket wrenches M6, M8, M12, M14, M17, and M19

Double offset ring wrenches M6, M8, M12, M14,

M17, and M19

Long-arm wrench

Small tools Sharp-nose pliers, diagonal pliers, pliers, hand-held

electric drill, file, handsaw, crowbar, rubber hammer,

and claw hammer

Auxiliary tools Tweezers, brush, bellows, paper knife, bellows,

electric iron, solder wires, ladder, pallet truck, panel

lifter, heat gun, and electric outlet (with three 2-phase

sockets and three 3-phase sockets, rated current higher

than 15 A)

Special tools ESD wrist strap, glove, cable peeler, clamp pincer, feeder cutter, SMB

crimping pliers, RJ-45 crimping pliers, and wire cutter

Meters Earth resistance tester, Ethernet cable tester, multimeter, 500 V

megohmmeter, optical multimeter, and optical power meter

2.2 Unpacking the Cases and Checking the Items

This section describes how to unpack the cases containing the BSC6900 at the installation site

and check the items in the cases to facilitate installation.

Prerequisite

l Site preparation for the installation is complete.

l The cases that contain the cabinets and components are delivered to the site.

2-2 Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 2 Preparations for Installation

l The required tools are available. The tools are wrench, flat-head screwdriver, claw hammer,

and paper knife.

Context

CAUTION

Electronic devices are prone to electrostatic discharge (ESD). Wear an ESD wrist strap correctly

and touch only the edges of the boards, especially when dealing with components such as boards.

l When carrying or placing the equipment, you should ensure that it does not collide with

doors, walls, shelves, or other objects.

l When transporting or installing the equipment, components, or parts, you should avoid

touching their uncoated metal surfaces with sweaty or dirty gloves.

Procedure

Step 1 Unload the cases.

CAUTION

When unloading the cases, you should place the cases in sequence. Ensure that the labels on the

cases face the same direction for the ease of inspection.

Step 2 After unloading the cases, check whether the number of cases on site matches the Packing List

and whether the place of delivery is the same as the actual installation place.

If... Then...

The number of cases on site is the same as that mentioned in the Packing Go to Step 3.

List

The number of cases on site does not match that in the Packing List Go to Step 4.

Step 3 Check the shockwatch labels on both sides of each case to determine whether each case has been

hit.

If... Then...

Both labels on a case are transparent, as The case has not been hit. Go to Step 5.

shown by part 1 in Figure 2-1

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 2-3

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

2 Preparations for Installation Installation Guide

If... Then...

Any label on a case becomes red, as shown The case has been hit by a force greater than

by part 2 in Figure 2-1 50g (g is the standard gravity) during

transportation. Such hit may damage the

cabinet or boards in the case. To handle this

problem, go to Step 4.

Figure 2-1 Shockwatch label

Step 4 In case of any disagreement, the installation supervisor must stop the unpacking immediately

and send the Cargo Problems Report to the order management engineer in the local Huawei

office within three days. Note that this report must be signed by the customer.

Step 5 Check whether the packing cases are intact and the equipment is placed upright during the

transportation.

If... Then...

Any case is severely damaged or soaked, Go to Step 6.

The cases are intact, Go to Step 7.

Step 6 Stop the unpacking immediately, find the causes, and contact the order management engineer

in the local Huawei office to further handle the problem.

2-4 Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 2 Preparations for Installation

CAUTION

To protect the equipment and find out the causes, perform the following actions: Move the

unpacked equipment indoors for proper storage, take photos of the storage environment, the

rusted or corroded equipment, packing cases, and packing materials. Keep these photos for future

verification. Store the packing cases and materials properly.

Step 7 Unpack the wooden cases.

CAUTION

l Before the unpacking, move the wooden cases into or close to the equipment room if

sufficient space is available. This prevents damage to the cabinets during the transportation.

l When you unpack the wooden cases, find the one labeled Packing List. Then, you can find

articles rapidly according to the names, codes, positions, and quantities described in the

Packing List.

l The following description takes the wooden case that contains the cabinet as an example.

The methods for unpacking other types of wooden cases are similar.

1. Place the wooden case on the ground. Ensure that the side with the wooden frame faces the

bottom.

2. Use a wrench, flat-head screwdriver, or a claw hammer to straighten the tongues on the

four sides of the cover.

See Figure 2-2.

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 2-5

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

2 Preparations for Installation Installation Guide

Figure 2-2 Straightening the tongue

3. Remove the cover. If the wooden case contains a carton, take out the carton, and then open

it according to Step 8. If the wooden case contains a cabinet, go to the next step. See Figure

2-3.

Figure 2-3 Removing the cover

2-6 Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 2 Preparations for Installation

4. Remove the side boards from the wooden case by using the same method. See Figure

2-4.

Figure 2-4 Removing side boards

5. Erect the cabinet with the BOTTOM side down.

CAUTION

This operation needs three to five installers. Prevent the cabinet from falling during the

erection to avoid injury to the personnel.

6. Remove the bottom of the case, that is, the side with the wooden frame.

7. Remove the foamed wrap angles.

8. Remove the vacuum plastic bag.

Step 8 Unpack the carton. See Figure 2-5.

Figure 2-5 Unpacking a carton

1 Carton label 2 Strap 3 Pressure-sensitive tape

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 2-7

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

2 Preparations for Installation Installation Guide

4 Foam plate 5 Board label 6 Board

1. Check the types and quantities of the items in the carton according to the carton label.

2. Cut the straps by using diagonal pliers.

3. Rip the tape along the joint seams by using the paper knife. Do not insert the knife too deep,

or else the items may be damaged.

4. Unpack the carton and take out the items.

Step 9 Unpack boards.

CAUTION

l When unpacking the boards, take proper ESD prevention measures, for example, wear the

ESD wrist strap to prevent electrical damage to the boards.

l The ESD bag contains the desiccant to keep the bag dry. When taking the board from a cold

dry place to a hot damp place, wait at least 30 minutes before unpacking. Otherwise, moisture

condensed on the board surface may damage the board.

1. Check for the evident damage on the board packages.

2. Open the packages and ensure that the boards are in good condition. For any board problem,

contact the order management engineer at the local Huawei office.

Step 10 Check whether the unpacked boards need to be installed immediately, and then proceed with

the installation accordingly.

If... Then...

The unpacked boards need to be installed Place the boards on an ESD surface and let the

immediately, static electricity to discharge to facilitate the

installation.

The unpacked boards need not be installed Pack the boards with the original materials and

immediately, place them in a cool dry place away from direct

sunlight or strong electromagnetic radiation.

Step 11 Take out the Packing List from the carton labeled Packing List. Then, check the articles one by

one according to the name, type, and quantity of each article described in the Packing List.

The checking of item covers the following aspects:

l Appearance: Check whether there are defects in the appearance of the cabinet, whether the

cabinet is loose, distorted, or damaged, whether the identification is legible, and whether all

nameplates and decorating plates are available and meet the requirements.

l Integrity: Check whether all the parts and accessories required for the installation of cabinets

are available.

l Computer terminal: Check whether the monitor, keyboard, and mouse are all available and

in good condition.

2-8 Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 2 Preparations for Installation

l Boards: Check whether the type and quantity of the boards are consistent with that described

in the Packing List, and whether the printed circuit board is broken or components are

detached from the board.

NOTE

The project supervisor should take the major role in checking the equipment and components whose electric

characteristics are likely to be affected.

If... Then...

The Packing List indicates "shortage of The installation supervisor must inform the order

articles", management engineer at the local Huawei office.

Then, sign the Packing List along with the

customer.

There are any short, wrong, or extra Representatives of Huawei and the customer

shipment, or any damaged items, must sign the Unpacking Inspection Memo and

Packing List. The installation supervisor must fill

in the Cargo Problems Report and inform the

order management engineer at the local office in

three days. The installation supervisor must keep

the problematic items (including the inner and

outer packing) intact for future investigation and

verification.

The shipment is intact, Place the checked articles by type. Do not discard

the packing cases of the equipment until the

Packing List is signed.

----End

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 2-9

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 3 Procedures for Installation

3 Procedures for Installation

This chapter describes how to install the BSC6900 and its accessories, power cables and PGND

cables, OMUa boards, signal cables, Local Maintenance Terminal (LMT) PC, and alarm box.

Prerequisite

l The equipment is unpacked and checked.

l The tools required for the installation are available.

Procedure

Step 1 Install the cabinet and its accessories. See the N68E-22 Cabinet Installation Guide.

Step 2 Install the power cables and PGND cables. See 4 Installing the Power Cables and PGND

Cables.

Step 3 Install the OMUa boards. See 6.2 Installing the OMUa Boards.

Step 4 Install the signal cables. See 7 Installing the Signal Cables.

Step 5 Install the Local Maintenance Terminal (LMT) PC and the alarm box. See 8 Installing the Local

Maintenance Terminal (LMT) PC and the Alarm Box.

Step 6 Attach the engineering labels to the cables. See 9 Attaching the Engineering Labels to the

Cables.

Step 7 Check the installation. See 10 Checking the Hardware Installation.

----End

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 3-1

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 4 Installing the Power Cables and PGND Cables

4 Installing the Power Cables and PGND

Cables

About This Chapter

This chapter describes how to install the power cables and PGND cables between the

BSC6900 and the power distribution frame (PDF) and also how to install the PGND cables

between the cabinets of the BSC6900.

4.1 Power Cables and PGND Cables to Be Installed

The power cables and PGND cables to be installed are the external -48 V power cables, external

RTN cables, external PGND cable, and inter-cabinet PGND cables.

4.2 Connections of the Power Cables and PGND Cables

This section describes the connections of the power cables and PGND cables between the

BSC6900 and the PDF. It also describes the connections of the PGND cables between the

adjacent cabinets.

4.3 Principles of Installing the Power Cables and PGND Cables

This section describes the principles of installing the power cables and PGND cables. When

installing the power cables and PGND cables, you should follow the routing and binding

principles.

4.4 Installing the Power Cables and PGND Cable Between the BSC6900 and the PDF

This section describes how to install the power cables and PGND cables between the

BSC6900 cabinet and the PDF in overhead and underfloor cabling modes.

4.5 Installing the PGND Cables Between Adjacent Cabinets

This section describes how to connect the upper, middle and lower parts of the PGND busbar

of one cabinet to those of its adjacent cabinet(s) through the PGND cables.

4.6 Checking the Power-On Performance

This section describes how to check the power supply to the cabinet. In addition, this describes

how to check that the power supply to the subrack, the fan box and boards in the subrack are

normal.

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 4-1

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

4 Installing the Power Cables and PGND Cables Installation Guide

4.1 Power Cables and PGND Cables to Be Installed

The power cables and PGND cables to be installed are the external -48 V power cables, external

RTN cables, external PGND cable, and inter-cabinet PGND cables.

Table 4-1 lists the external power cables and PGND cables that must be installed for each

cabinet.

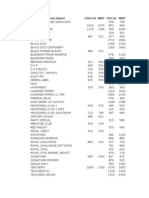

Table 4-1 Power cables and PGND cables to be installed for each cabinet

Name Color Cross- Bending Connector Connector Quantity

Section Radius Type/ Type/

al Area (mm) Installatio Installatio

(mm2) n Position n Position

External Blue 25/35 30 OT OT 4

-48 V terminal/-48 terminal/48

power V input of V output of

cable the cabinet the PDF

External Black 25/35 30 OT terminal/ OT terminal/ 4

RTN RTN input RTN output

power of the of the PDF

cable cabinet

External Green 25/35 30 OT terminal/ OT terminal/ 1

PGND and PGND input PGND

cable yellow of the output of the

cabinet PDF

Inter- Green 6 15 OT terminal/ OT terminal/ 3

cabinet and PGND PGND

PGND yellow busbar of the busbar of the

cable cabinet cabinet

NOTE

The required length of power cables and of PGND cables is specified in the site survey report. Appropriate

length of power cables and of PGND cables must be obtained and cable terminals must be crimped on site.

l By default, the colors of the power cables and PGND cables are those specified in Table 4-1. These

colors must be in accordance with the customer requirements.

l For details about the description of the power cables, see Power Cables. For details about the

description of the PGND cables, see PGND Cables.

4.2 Connections of the Power Cables and PGND Cables

This section describes the connections of the power cables and PGND cables between the

BSC6900 and the PDF. It also describes the connections of the PGND cables between the

adjacent cabinets.

Figure 4-1 shows the connections of the power cables and PGND cables.

4-2 Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 4 Installing the Power Cables and PGND Cables

Figure 4-1 Connections of the power cables and PGND cables

NOTE

The PGND cables of the cabinet should be connected to the nearest ground bar. When the PDF is far away

from the cabinet, for example, the PDF is not in the same equipment room as the cabinet, you should

connect the PGND cable for the cabinet to the nearest ground bar co-grounded with the PDF rather than

connect the PGND cable directly to the PDF. In this case, the methods of installing and routing the PGND

cables are the same as those of connecting the PGND cables directly to the PDF. In practice, the PGND

cables of the cabinet must be connected on the basis of the requirements of the customer.

4.3 Principles of Installing the Power Cables and PGND

Cables

This section describes the principles of installing the power cables and PGND cables. When

installing the power cables and PGND cables, you should follow the routing and binding

principles.

Cable Routing Requirements

l The layout of power cables and PGND cables should facilitate future capacity expansion.

l The power cables and PGND cables must be separated from the other cables. When the

power cables and the PGND cables are laid parallel to signal cables, the spacing between

them must be at least 30 mm.

l Ensure that the bending radius is five times longer than the diameter of the cable.

l In underfloor cabling mode, a surplus length of power cable must be reserved outside the

cable inlet of the power distribution box on the top of the cabinet. This facilitates the

installation of the terminal. In addition, the cables must be laid flat on the top of the cabinet.

l When connecting power cables to the terminals of the power distribution box, lay the cables

straight and smoothly.

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 4-3

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

4 Installing the Power Cables and PGND Cables Installation Guide

Cable Binding Requirements

l The power cables and PGND cables must be separated from the signal cables.

l The spacing between the cable ties should be 200 mm.

l If the underfloor cabling mode is used, the power cables and PGND cables should be routed

along the middle column on the right of the cabinet front.

l The selection of cable ties (150 mm/300 mm) depends on the diameter and quantity of

cables.

l The cable ties are bound in the same direction. The extra length of the cable ties are cut

and the cut surfaces are smooth without sharp edges.

4.4 Installing the Power Cables and PGND Cable Between

the BSC6900 and the PDF

This section describes how to install the power cables and PGND cables between the

BSC6900 cabinet and the PDF in overhead and underfloor cabling modes.

4.4.1 Installing the Power Cables and PGND Cables Between the BSC6900 and the PDF

(Overhead Cabling)

This section describes how to lay and install the power cables and PGND cables between the

BSC6900 cabinet and the PDF in overhead cabling mode.

4.4.2 Installing the Power Cables and PGND Cables Between the BSC6900 and the PDF

(Underfloor Cabling)

This section describes how to lay and install the power cables and PGND cables between the

BSC6900 cabinet and the PDF in underfloor cabling mode.

4.4.1 Installing the Power Cables and PGND Cables Between the

BSC6900 and the PDF (Overhead Cabling)

This section describes how to lay and install the power cables and PGND cables between the

BSC6900 cabinet and the PDF in overhead cabling mode.

Prerequisite

l The cabinet to be connected with power cables and PGND cables is installed.

l The power distribution switches of the relevant PDF output terminals are set to OFF.

l All the switches on the power distribution box of the cabinets are set to OFF.

l The components required for the installation are available. The components are the power

cables and PGND cables.

l The materials required for the installation are available. The materials are cable ties, wax

strings, and PVC insulation tape.

l The tools required for the installation are available. The tools are diagonal pliers, handsaw,

wire cutter, wrench, Phillips screwdriver, and flat-head screwdriver.

Context

When the overhead cabling mode is used, the power cables are led out of the PDF through the

upper cable hole, and then onto the cable tray, and finally routed to the top of each cabinet.

4-4 Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 4 Installing the Power Cables and PGND Cables

Figure 4-2 shows how to install the power cables and PGND cables between the cabinet and

the PDF in overhead cabling mode.

Figure 4-2 Installing the power cables and PGND cables in overhead cabling mode

Procedure

Step 1 Determine the length of the required power cables and PGND cables by referring to the related

engineering design or by measuring the actual cabling route.

Step 2 Uncoil the power cable roll and the PGND cable roll on site. Obtain appropriate length of cables

by using the tape measure or other measuring tools. Then, cut the cables by using the handsaw

(teeth space: 0.8 mm) or the wire cutter (KT35). When cutting the cables, you should leave a

little slack.

CAUTION

When laying out the cable, you should replace it with a new one if the reserved length is

insufficient. Do not make connectors or solder joints.

Step 3 Attach temporary labels to both ends of the cables. The contents on the temporary labels are not

restricted because they are only for distinguishing the cables after the layout.

Step 4 Route the power cables and the PGND cables between the cabinet and the PDF. The cables are

routed in such a way that the power cables are led out of the PDF through the upper cable hole,

and then onto the cable tray, and finally routed to the top of each cabinet.

NOTE

l If the height difference between the cable tray and the top of the cabinet exceeds 800 mm, a downward

cable ladder must be used.

l Ensure that the bending radius is five times longer than the diameter of the cable.

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 4-5

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

4 Installing the Power Cables and PGND Cables Installation Guide

Step 5 Connect the power cables and the PGND cables to the cabinet.

1. Determine the actual length of the cables that you need according to the installation position

of each cable. Then, cut the cable with extra length for some slack..

2. Obtain the cable terminals delivered with the equipment. Then, crimp the OT terminal of

the power cable and the OT terminal of the PGND cable on one side of the cabinet by

referring to Assembling the OT Terminal and the Power Cable.

3. Remove the left and right plastic cover plates at the rear of the cabinet top. Cut each cover

plate appropriately so that the hole on the cover plate matches the power cable inlet of the

power distribution box.

4. Place the two cover plates in their original positions.

5. Through the hole on the cover plate on top of the cabinet, connect the OT terminals of the

-48 V power cable to the wiring terminals labeled "3(-)" and "1(-)" in both part A and part

B of the power distribution box, and connect the OT terminals of the RTN power cable to

the wiring terminals labeled "3(+)" and "1(+)" in both part A and part B of the power

distribution box.

6. Connect the OT terminals of the -48 V power cable and of the RTN power cable to the

wiring post in the power distribution box.

7. Fix the OT terminal of the PGND cable to the ground bolt at the rear of the cabinet top.

Step 6 Lead the power cables and the PGND cables to the output terminals of the PDF.

1. Determine the actual length of the cables that you need according to the installation position

of each cable. Then, cut the cable with extra length for some slack.

2. Obtain the OT terminals of the cables delivered with the equipment. Then, crimp the OT

terminals of the power cable and of the PGND cable by referring to Assembling the OT

Terminal and the Power Cable.

3. Connect the -48 V power cables, the RTN power cables, and the PGND cables to the

matching wiring posts inside the PDF.

NOTE

When connecting the OT terminals to the RTN, PGND copper bars, and 48 V wiring posts, you

should add the flat washers and spring washers and arrange the cables neatly.

Figure 4-3 shows how to install the OT terminal.

4-6 Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 4 Installing the Power Cables and PGND Cables

Figure 4-3 Installing the OT terminal

1 Power cable 2 Heat-shrinkable tube 3 Nut

4 Spring washer 5 Flat washer 6 Terminal bolt

4. Record the installation results in the templates provided in 12 Hardware Installation

Records.

----End

4.4.2 Installing the Power Cables and PGND Cables Between the

BSC6900 and the PDF (Underfloor Cabling)

This section describes how to lay and install the power cables and PGND cables between the

BSC6900 cabinet and the PDF in underfloor cabling mode.

Prerequisite

l The cabinet to be connected with power cables and PGND cables is installed.

l The power distribution switches of the relevant PDF output terminals are set to OFF.

l All the switches on the power distribution box of the cabinets are set to OFF.

l The components required for the installation are available. The components are the power

cables and PGND cables.

l The materials required for the installation are available. The required materials are the cable

ties, wax strings, PVC insulation tape, and lifting rope.

l The tools required for the installation are available. The tools are diagonal pliers, handsaw,

wire cutter, wrench, Phillips screwdriver, and flat-head screwdriver.

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 4-7

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

4 Installing the Power Cables and PGND Cables Installation Guide

Context

When the underfloor cabling mode is used, the power cables are led out of the PDF through the

lower cable hole, and then to the bottom of the cabinet beneath the ESD floor, and finally routed

to the top of the cabinet along the middle column in the cabinet. Figure 4-4 shows how to install

the power cables and PGND cables between the cabinet and the PDF in underfloor cabling mode.

Figure 4-4 Installing power cables and PGND cables in underfloor cabling mode

Procedure

Step 1 Determine the length of the required power cables and PGND cables by referring to the related

engineering design or by measuring the actual cabling route.

Step 2 Uncoil the power cable roll and the PGND cable roll on site. Obtain appropriate length of cables

by using the tape measure or other measuring instrument. Then, cut the cables by using the

handsaw (teeth space: 0.8 mm) or the wire cutter (KT35). When cutting the cables, you should

leave a little slack.

4-8 Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 4 Installing the Power Cables and PGND Cables

CAUTION

When laying out the cable, you should replace it with a new one if the reserved length is

insufficient. Do not make connectors or solder joints.

Step 3 Attach temporary labels to both ends of the cables. The contents on the temporary labels are not

restricted because they are only for distinguishing the cables after the layout.

Step 4 Lay the power cables and PGND cable according to the requirements for routing cables and

engineering requirements.

1. Lead one PGND cable and four pairs of power cables out of the PDF through the cable

outlet at the bottom of the PDF. Then, route the cables under the ESD floor to the N68E-22

cabinet.

2. Divide the four pairs of power cables into two groups, with two pairs in each group. Use

the cables ties to bind one group and the PGND cable, and then use the cable ties to bind

the other group separately. Route the two bundles of cables to the middle columns on the

left and right sides of the cabinet respectively.

3. Route one end of the lifting rope to the top of the middle column. Route the other end of

the lifting rope to the bottom of the cabinet through the middle column and bind the rope

to the power cables and PGND cable in the lower part of the middle column.

4. Pull the upper end of the lifting rope appropriately so that the power cables and PGND

cable are routed to the top of the cabinet through the middle column.

5. Remove the lifting rope and remove the cable ties from the power cables and PGND cable.

Step 5 Connect the power cables and the PGND cables to the cabinet.

1. Determine the actual length of the cables that you need according to the installation position

of each cable. Then, cut the cable with extra length for some slack.

2. Obtain the cable terminals delivered with the equipment. Then, crimp the OT terminal of

the power cable and the OT terminal of the PGND cable on one side of the cabinet by

referring to Assembling the OT Terminal and the Power Cable.

3. Remove the left and right plastic cover plates at the rear of the cabinet top. Cut each cover

plate appropriately so that the hole on the cover plate matches the power cable inlet of the

power distribution box.

4. Place the two cover plates in their original positions.

5. Through the hole on the cover plate on top of the N68E-22 cabinet, connect the OT terminals

of the -48 V power cable to the wiring terminals labeled "3(-)" and "1(-)" in both part A

and part B of the power distribution box, and connect the OT terminals of the RTN power

cable to the wiring terminals labeled "3(+)" and "1(+)" in both part A and part B of the

power distribution box.

6. Connect the OT terminals of the -48 V power cable and of the RTN power cable to the

wiring post in the power distribution box.

7. Fix the OT terminal of the PGND cable to the ground bolt at the rear of the cabinet top.

Step 6 Lead the power cables and the PGND cables to the output terminals of the PDF.

1. Determine the actual length of the cables that you need according to the installation position

of each cable. Then, cut the cable with extra length for some slack.

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 4-9

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

4 Installing the Power Cables and PGND Cables Installation Guide

2. Obtain the OT terminals of the cables delivered with the equipment. Then, crimp the OT

terminals of the power cable and of the PGND cable by referring to Assembling the OT

Terminal and the Power Cable.

3. Connect the -48 V power cables, the RTN power cables, and the PGND cables to the

matching wiring posts inside the PDF.

NOTE

When connecting the OT terminals to the RTN, PGND copper bars, and 48 V wiring posts, you

should add the flat washers and spring washers and should arrange the cables neatly.

Figure 4-5 shows how to install the OT terminal.

Figure 4-5 Installing the OT terminal

1 Power cable 2 Heat-shrinkable tube 3 Nut

4 Spring washer 5 Flat washer 6 Terminal bolt

4. Record the installation results in the templates provided in 12 Hardware Installation

Records.

----End

4.5 Installing the PGND Cables Between Adjacent Cabinets

This section describes how to connect the upper, middle and lower parts of the PGND busbar

of one cabinet to those of its adjacent cabinet(s) through the PGND cables.

Prerequisite

All the power distribution switches of the relevant PDF output terminals are set to OFF.

4-10 Huawei Proprietary and Confidential Issue 05 (2011-05-19)

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

Installation Guide 4 Installing the Power Cables and PGND Cables

Procedure

Step 1 As shown in Figure 4-6, use inter-cabinet PGND cables to connect the upper, middle, and lower

PGND busbars on the mounting bar of the adjacent cabinets by referring to 4.2 Connections of

the Power Cables and PGND Cables.

Figure 4-6 Installing the PGND cables of the adjacent cabinets

----End

Follow-up Procedure

Record the installation result in the templates provided in 12 Hardware Installation

Records.

4.6 Checking the Power-On Performance

This section describes how to check the power supply to the cabinet. In addition, this describes

how to check that the power supply to the subrack, the fan box and boards in the subrack are

normal.

Prerequisite

l The power cables and PGND cables are installed between the cabinet and the PDF.

Issue 05 (2011-05-19) Huawei Proprietary and Confidential 4-11

Copyright Huawei Technologies Co., Ltd.

BSC6900 GSM

4 Installing the Power Cables and PGND Cables Installation Guide

l The subracks, fan boxes, and boards are installed in the cabinet.

l The required tool (multimeter) is available.

Context

The cabinet uses the DC power supply. Technical Specifications of the Power Distribution Box

lists the specifications for the input power of the cabinet.

CAUTION

Wear the ESD wrist strap correctly. Ensure that the ESD wrist strap is properly connected to the

ESD connector on the cabinet.

Before powering on a subrack, do not insert a board into or remove a board from the subrack to

avoid static damage to boards.

Procedure

Step 1 Set the corresponding output switches on the PDF to OFF and set all the output switches on the

power distribution box of the cabinet to OFF.

Step 2 Set the multimeter to the resistance scale, and then measure the resistance at the power output

terminal for the PDF and at the input and output terminals for the power distribution box of the

cabinet. Ensure that there is no short-circuit either between the -48 V working power and the

RTN working ground or between the -48 V working power and the PGND protection ground.

Step 3 Set the corresponding output switches on the PDF to ON and all the output switches on the power

distribution box of the cabinet to OFF.

Then, the power distribution box enters the self-check state. (The RUN and ALM LEDs on the

power distribution box are ON at the same time and the buzzer sounds.) When the self-check is

complete, the power distribution box requests for registration at the SCUa board (the RUN LED

on the power distribution box blinks at 2 Hz) until the registration is successful (the RUN LED

blinks at 0.5 Hz). For the description about the status of LEDs on the power distribution box,

see LEDs on the PAMU Board.

Step 4 Set the multimeter to the voltage scale. Ensure that the PDF output voltage and input voltage of