Escolar Documentos

Profissional Documentos

Cultura Documentos

M & E QC Plan - 02 REV. 0

Enviado por

Anonymous 3eHGEDbxTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

M & E QC Plan - 02 REV. 0

Enviado por

Anonymous 3eHGEDbxDireitos autorais:

Formatos disponíveis

XYZ Page 1 of 8

QC~PLAN.

Project No. & Name:

Name of Client/ Consultant:

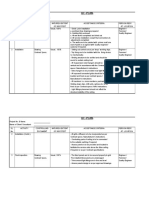

Sl. ACTIVITY CONTROLLING NATURE & EXTENT ACCEPTANCE PERSON RESP.

No. DOCUMENT OF INSP. / TEST CRITERIA AT LOCATION

1 Check cable entries & Contract Specs. Visual 100% Covers removed shall be Engineer/

covers. reassembled after completion Foremen/

of work. Quality Engineer

All entries shall be sealed against

ingress of water, dust.

2 Check handling Contract Specs. Visual 100% Stored at cable yard. Engineer/

Compliance to Vendor Foremen/

instructions. Quality Engineer

3 Check other service Contract Specs. Visual where applicable, Cables shall be identified and Engineer/

cable. by test pits separated from HV, LV, Foremen/

telecoms instrument, cable. Quality Engineer

4 Check pipe crossings Contract Specs. Visual where applicable Pipe Crossings shall be avoided. Engineer/

and parallel run pipe. Physical separation between cable Foremen/

and pipe shall be 300 mm. Quality Engineer

Crossing shall be underneath pipes

5 Check cable route close to pipe Contract Specs. Visual where applicable Cables shall be insulated to Engineer/

carrying Hot gases, maintain ext. temp. 60C. Foremen/

liquid. Cables shall be laid above pipes Quality Engineer

6 Check laying pattern Contract Specs. Visual Cables shall be laid according to Engineer/

cable route drawings & schedules. Foremen/

Trefoil for single core cable. Quality Engineer

7 Check rotation of drum. Directions on drum Visual where applicable Shall be rotated according to Engineer/

marking on drum. Foremen/

Quality Engineer

8 Check type of cable. Cable schedule Visual 100% Cable schedule Engineer/

Verification of records Foremen/

Quality Engineer

349618313.xls Date: January 26, 2001

XYZ Page 2 of 8

QC~PLAN.

Project No. & Name:

Name of Client/ Consultant:

Sl. ACTIVITY CONTROLLING NATURE & EXTENT ACCEPTANCE PERSON RESP.

No. DOCUMENT OF INSP. / TEST CRITERIA AT LOCATION

9 Check cable pulling Installation Visual where applicable Cables shall be laid by using Engineer/

drawings rollers kept at intervals. Foremen/

Quality Engineer

10 Check approval of Drawings Verification of records Any change in cable route due to site Engineer/

Route Cable condition shall be done after approval Foremen/

from Client Representative/consultant. Quality Engineer

11 Check spacing for Manufacturer's Visual throughout route Minimum spacing gap of 50 mm. Engineer/

cable racks, trays. recommendations shall be maintained between Foremen/

and rating factors rack, trays, columns. Quality Engineer

12 Check cables in racks Contract Specs. Visual 100% Damages to cable are avoided by Engineer/

and trays. using adequate number of cable Foremen/

spacers. Quality Engineer

13 Check cable route in fire Contract Specs. Visual where applicable Cables shall be protected from Engineer/

resistant area where fire by fire resistant barriers after Foremen/

applicable approval from Company. Quality Engineer

14 Check fixing of cables Contract Specs. Visual random Cables shall be tied with ties, Engineer/

in tray and racks straps, suitable cable glands. Foremen/

Quality Engineer

15 Check cable supports Contract Specs. Visual 100% Non magnetic type for single core Engineer/

cable. No mechanical strain for Foremen/

terminations, cable glands. Saddle Quality Engineer

Cleats used wherever required.

349618313.xls Date: January 26, 2001

XYZ Page 3 of 8

QC~PLAN.

Project No. & Name:

Name of Client/ Consultant:

Sl. ACTIVITY CONTROLLING NATURE & EXTENT ACCEPTANCE PERSON RESP.

No. DOCUMENT OF INSP. / TEST CRITERIA AT LOCATION

16 Check bonding of cable Contract Specs. Continuity test All metal parts and trays shall be Engineer/

trays. bonded and connected to earth grid. Foremen/

Quality Engineer

17 Check cable identifier Contract Specs. Visual random Shall be numbered at ends and Engineer/

at every intervals of every 5 mts. Foremen/

It shall be of lead embossed plain Quality Engineer

strips for UG cable length.

18 Check cable before Contract Specs. Testing of cable 100% Continuity OK Engineer/

termination Insulation resistance shall be Foremen/

very high in (Mega OHMS). Quality Engineer

Less Leakage current during

pressure test for HV cables.

19 Check Technician. Contract Specs. Verification of documents Fully trained to carry out job. Engineer/

for H. T. Cables Foremen/

Quality Engineer

20 Check glands. Gland selection Visual dimensional check Shall be of correct size. Engineer/

chart random Hexagon type Foremen/

Retain cable without damage. Quality Engineer

Explosion proof.

With close fitting shroud.

21 Check connections. Contract Specs. Visual random Electrically sound. Engineer/

Mechanical protection for damages, Foremen/

vibration. Quality Engineer

Terminated with less strain.

349618313.xls Date: January 26, 2001

XYZ Page 4 of 8

QC~PLAN.

Project No. & Name:

Name of Client/ Consultant:

Sl. ACTIVITY CONTROLLING NATURE & EXTENT ACCEPTANCE PERSON RESP.

No. DOCUMENT OF INSP. / TEST CRITERIA AT LOCATION

22 Check length of cable Contract Specs. Visual Shall be adequate length to reach Engineer/

tail. any terminal. Foremen/

Quality Engineer

23 Check cable bending. Manufacturer's Visual Bending radius shall be 8 times Engineer/

recommendations the overall cable dia. Foremen/

Quality Engineer

24 Check terminal Contract Specs. Visual random Compressed type lugs used for Engineer/

connections conductors above 10 cum. Foremen/

If soldering type, melting point of Quality Engineer

solder to be greater than 185C.

25 Check final connections. Drawings Visual 100% Shall be tight. Engineer/

Continuity test results OK Foremen/

Insulation test results OK Quality Engineer

Pressure test results OK

(HV Cables only)

26 Check earth continuity. Contract Specs. Testing of cable 100% Rigid clamping of armour with Engineer/

gland. Foremen/

Metal parts bonded and connected Quality Engineer

to earth grid.

27 Check for plan Contract Specs. Visual 100% Ensure the activities in accordance Engineer/

completion with acceptance criteria. Foremen/

Quality Engineer

Work Location: Quality Engineer: Engineer / Foremen:

Remarks: Date: Date:

349618313.xls Date: January 26, 2001

XYZ Page 5 of 8

QC~PLAN.

Cables

Doc. No. M & E QC~Plan- 002/ REV. 0

RECORD

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

As-Built drawing

--

Inspection report

M & E QC~Form- 002-01/ REV. 0

349618313.xls Date: January 26, 2001

XYZ Page 6 of 8

QC~PLAN.

Cables

Doc. No. M & E QC~Plan- 002/ REV. 0

RECORD

Inspection report

M & E QC~Form- 002-01/ REV. 0

As-Built Drawings

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

349618313.xls Date: January 26, 2001

XYZ Page 7 of 8

QC~PLAN.

Cables

Doc. No. M & E QC~Plan- 002/ REV. 0

RECORD

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

M & E QC~Form- 002-02/ REV. 0

M & E QC~Form- 002-03/ REV. 0

Cable Jointer certificate

by Manufacturer.

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

349618313.xls Date: January 26, 2001

XYZ Page 8 of 8

QC~PLAN.

Cables

Doc. No. M & E QC~Plan- 002/ REV. 0

RECORD

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

Inspection report

M & E QC~Form- 002-01/ REV. 0

M & E QC~Form- 002-03/ REV. 0

M & E QC~Form- 002-01/ REV. 0

Certificate of Conformity

349618313.xls Date: January 26, 2001

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- LFZP11x R5911DDocumento714 páginasLFZP11x R5911Drian020180% (5)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- NQA ISO 45001 Implementation GuideDocumento36 páginasNQA ISO 45001 Implementation GuideAnonymous 3eHGEDbx100% (11)

- Elec Wiring Regs 2007 Rev 01Documento240 páginasElec Wiring Regs 2007 Rev 01Anonymous 3eHGEDbxAinda não há avaliações

- Historical Record Dimensions and PropertiesDocumento145 páginasHistorical Record Dimensions and PropertiesAnonymous 3eHGEDbxAinda não há avaliações

- MR-96A Service Manual V3.0 enDocumento57 páginasMR-96A Service Manual V3.0 enHussain Amir Ali0% (1)

- Holley Carb Manual PDFDocumento2 páginasHolley Carb Manual PDFPaul PerezAinda não há avaliações

- B, RB EngineDocumento25 páginasB, RB Enginemoparman175% (4)

- The ArmatronDocumento20 páginasThe ArmatronCar Jav EspAinda não há avaliações

- National Gypsum Steel StudPartitionsDocumento9 páginasNational Gypsum Steel StudPartitionsAnonymous 3eHGEDbxAinda não há avaliações

- Acoustic Brochure PDFDocumento6 páginasAcoustic Brochure PDFAnonymous 3eHGEDbxAinda não há avaliações

- Steel Window Service: Scale Drawn CheckedDocumento1 páginaSteel Window Service: Scale Drawn CheckedAnonymous 3eHGEDbxAinda não há avaliações

- MOUNT - Fixing PlatesDocumento8 páginasMOUNT - Fixing PlatesAnonymous 3eHGEDbxAinda não há avaliações

- Pub 100427Documento5 páginasPub 100427Engr Nabeel AhmadAinda não há avaliações

- Xyz Company: PurposeDocumento3 páginasXyz Company: PurposeAnonymous 3eHGEDbxAinda não há avaliações

- Purpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingDocumento4 páginasPurpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingAnonymous 3eHGEDbxAinda não há avaliações

- M & e MST - 038 Rev. 0Documento3 páginasM & e MST - 038 Rev. 0Anonymous 3eHGEDbxAinda não há avaliações

- M & e MST - 036 Rev. 0Documento3 páginasM & e MST - 036 Rev. 0Anonymous 3eHGEDbxAinda não há avaliações

- Xyz Company: PurposeDocumento3 páginasXyz Company: PurposeAnonymous 3eHGEDbxAinda não há avaliações

- Xyz Company: PurposeDocumento5 páginasXyz Company: PurposeAnonymous 3eHGEDbxAinda não há avaliações

- 018 Insitu FlooringDocumento4 páginas018 Insitu FlooringAnonymous 3eHGEDbxAinda não há avaliações

- 021-Suspended CeilingDocumento4 páginas021-Suspended CeilingAnonymous 3eHGEDbxAinda não há avaliações

- M & E QC Plan - 0063b REV. 0Documento4 páginasM & E QC Plan - 0063b REV. 0Anonymous 3eHGEDbxAinda não há avaliações

- 051 GlazingDocumento2 páginas051 GlazingAnonymous 3eHGEDbxAinda não há avaliações

- 015-Roofing, Insulation &water ProofingDocumento4 páginas015-Roofing, Insulation &water ProofingAnonymous 3eHGEDbxAinda não há avaliações

- 019-Carpentary, Joinery & General FixingDocumento2 páginas019-Carpentary, Joinery & General FixingAnonymous 3eHGEDbxAinda não há avaliações

- 315 D CaterpillarDocumento4 páginas315 D CaterpillarJose nildo lobato Mendes Mendes100% (1)

- Catalogo Comercial Troidon 44 (Ing)Documento3 páginasCatalogo Comercial Troidon 44 (Ing)EDWIN ESPEJOAinda não há avaliações

- Entech ControlsDocumento12 páginasEntech Controlsmanmohansingh1999Ainda não há avaliações

- cMT-G03 Datasheet ENG PDFDocumento2 páginascMT-G03 Datasheet ENG PDFAshutosh Vivek ParabAinda não há avaliações

- 12352201-107 en Es FRDocumento121 páginas12352201-107 en Es FRAnibal Jose Cruz LarezAinda não há avaliações

- DMW 3305 30116 1 3305 602 - Is00Documento1 páginaDMW 3305 30116 1 3305 602 - Is00nuramirah2023Ainda não há avaliações

- LED VideowallDocumento11 páginasLED VideowallIvan AphoninAinda não há avaliações

- M101Documento1 páginaM101Eong Huat Corporation Sdn BhdAinda não há avaliações

- FL-2100B AMP Operators ManualDocumento7 páginasFL-2100B AMP Operators Manualoctavian barbuAinda não há avaliações

- Rhino EngDocumento2 páginasRhino EngDiego BernalAinda não há avaliações

- ltc1760 Dual Smart Battery System ManagerDocumento48 páginasltc1760 Dual Smart Battery System ManagerBig BoyAinda não há avaliações

- Gbd-Plus: Compact Glass Break DetectorDocumento2 páginasGbd-Plus: Compact Glass Break DetectorDidier Samir GuillenAinda não há avaliações

- 051790c0.sch-1 - Tue May 21 09:07:19 2002Documento19 páginas051790c0.sch-1 - Tue May 21 09:07:19 2002Italo BocattuAinda não há avaliações

- Boss 332 545 551 Use - Maintenance ManualDocumento140 páginasBoss 332 545 551 Use - Maintenance ManualbadrezzineAinda não há avaliações

- Fanuc PMS IO MapDocumento12 páginasFanuc PMS IO Mapjitap52882Ainda não há avaliações

- InteliCharger 120 12 24 DatasheetDocumento2 páginasInteliCharger 120 12 24 Datasheetjean sanchezAinda não há avaliações

- 17 MiscellaneousDocumento42 páginas17 MiscellaneousNicolae SanduAinda não há avaliações

- XRXS 566 CD XRVS 606 CD: Parts List For Portable CompressorsDocumento162 páginasXRXS 566 CD XRVS 606 CD: Parts List For Portable CompressorsSales AydinkayaAinda não há avaliações

- Smart Anchor PricelistDocumento25 páginasSmart Anchor PricelistAjay MedikondaAinda não há avaliações

- Ovivo Eimix Brochure 0915 WebDocumento4 páginasOvivo Eimix Brochure 0915 WebAdrian BorsosAinda não há avaliações

- 17HX Stepper Hybrid 198-200 v6.09Documento5 páginas17HX Stepper Hybrid 198-200 v6.09dharmil.gopaniAinda não há avaliações

- Atmega AVR Microcontroller 1500 Projects List - EbookDocumento96 páginasAtmega AVR Microcontroller 1500 Projects List - EbookWise Tech100% (1)

- MB W210 AC Diagnostics and Flap TestDocumento4 páginasMB W210 AC Diagnostics and Flap TestStoica Daniel0% (1)

- Low Voltage Products: Fusegear Switch Fuses OSDocumento80 páginasLow Voltage Products: Fusegear Switch Fuses OSSalehAinda não há avaliações

- Using Voltage Supervisors With Picmicro Microcontroller Systems Which Implement In-Circuit Serial Programming™Documento8 páginasUsing Voltage Supervisors With Picmicro Microcontroller Systems Which Implement In-Circuit Serial Programming™opamp2000Ainda não há avaliações