Escolar Documentos

Profissional Documentos

Cultura Documentos

Heap and Dump Leach Process at The Buchi PDF

Enviado por

GanangPramudyaAhmadRifaiTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Heap and Dump Leach Process at The Buchi PDF

Enviado por

GanangPramudyaAhmadRifaiDireitos autorais:

Formatos disponíveis

HEAP AND DUMP LEACH PROCESS AT THE BUCHIM COPPER PROJECT-

METALLURGICAL TESTWORK

G. Savov, T. Angelov, V. Tsekov, I. Grigorova, I. Nishkov

Directior Recearch and Development, Iontech Engineering Ltd., 1113 Sofia, Bulgaria, phone: +359 2 8164431, fax:

+359 2 8164461, e-mail: savov@ionteching.com

Senior Technologist, Iontech Engineering Ltd., 1113 Sofia, Bulgaria, phone: +359 2 8164431, fax: +359 2 8164461, e-

mail: savov@ionteching.com

Chief Executive Officer, Iontech Engineering Ltd., 1113 Sofia, Bulgaria, phone: +359 2 8164431, fax: +359 2 8164461,

e-mail: savov@ionteching.com

Asst. Prof. Dr., University of Mining and Geology St.Ivan Rilski, Department of Mineral Processing and Recycling,

1700 Sofia, Bulgaria, phone: +359 02 8060253, e-mail: irena_mt@abv.bg

Vice Dean of Faculty of Mines, Professor, University of Mining and Geology St.Ivan Rilski, Department of Mineral

Processing and Recycling, 1700 Sofia, Bulgaria, phone: +359 02 8060253, e-mail: inishkov@gmail.com

ABSTRACT The Buchim Copper Project, now under construction, is located in eastern Macedonia, 95 km

from the Skopje capital and 170 kilometers from the nearest port Thessaloniki (Republic of Greece) at an

altitude of 620 m above sea level. The mineralization of Buchim ore deposit is porphyry.

Extensive metallurgical testwork was carried out to determine the effect on the projects feasibility and to

provide information needed for the plant design.

Ore body/reserve data, basic mineralogy and lithology are defined from representative sample for each

ore category prior to planning the metallurgical test program.

The metallurgical test program including detailed determination of physical and mechanical properties,

mineralogy, size distribution, total and acid soluble copper and conducting of elemental analysis (standard

ICP scan), acid consumption and acid cure tests as well as bottle-roll tests was performed.

A series of column leach tests represent the most important part of the testing program. Operating

parameters such as particle size, leach time, flow rate, heap height and acid addition are evaluated. Physical

tests and water tests are also was conducted to provide additional design information.

A dump leach-ion exchange-solvent extraction-electrowinning process was selected to treat the Buchim

ore to produce 2500 tpy of cathode copper.

The results obtained as well as the design criteria selected for the process are discussed in this paper.

Keywords: hydrometallurgy, copper ore, metallurgical test program, leaching, column tests.

1. INTRODUCTION test program, which involves a sequence of bottle

roll tests and column tests, was carried out in the

The Buchim Copper Project, scheduled for early stages of development in order to determine

construction and operation in 2011 is a leaching and the effect on the projects feasibility, and to provide

treatment facility at the Buchim mine site in information needed for the basic and detailed

Macedonia. The facility is envisaged to organize design.

leaching of low grade ore from Bucim dump and Subject of this paper is testwork on a

oxide heap of Vrsnik orebody and treat the pregnant representative sample of ore from old dump.

leach solutions via combination of Ion Exchange, The testwork is aimed at determining the

Solvent Extraction and Electrowinning to recover amenability of this ore to leaching, which depends

copper into high grade copper cathodes (Jergensen, on the characteristic of the ore with respect to

1999). porosity and permeability to leach liquor,

To ensure the success of copper leaching percolation, acid consumption, and metal recovery.

project, the metallurgical characteristics of the

subjected ores must be well defined. An extensive

2. BUCHIM COPPER DEPOSIT The kaolinization and the chloritization are

connected with the hydrothermal activity in the ore

2.1. General deposit. Main mining phenomena occur in the

Buchim copper mine is situated near the village of primary zones, where the chalcopyrite occurs as

Buchim and in the south borders of Plachkovitsa basic copper mineral. Other minerals present are:

Mountain, in Republic of Macedonia. Dominating top pyrite, hematite, magnetite, and seldom

in the immediate surrounding is Versnik, on 720 molybdenite. The precious metals, gold and silver,

occur in smaller concentrations, but though enough

meters above the sea level, while 620 meters is the

for their valorization. The zone of secondary

average above the sea altitude of the ore deposit.

sulphide enrichment is insignificantly developed.

Buchim mine territorially and administratively

Besides the minerals from the primary zone,

belongs to the municipality of Radovis. It is 14

chalcosine and small quantity of copper carbonates

kilometers away from the city of Radovis, and 30

occur.

kilometers from Stip. The mine has good Low grade ore stored on old dump is from mining

communication lines. Asphalt road, about 3.5 activities on the Central ore body of Bucim mine.

kilometers long, is connecting the mine with Veles - This orebody is characterized of primary copper

Stip - Radovis regional road. mineralization and it is created around the latitic

The climate in the region is Mediterranean- dike. The ore mineralization mainly occurs in the

continental. gneisses, but as a ring around the latitic burst. The

The specific geographical and topographical ore body is in The Central ore body is a typical

situation of the region provides for its specific representative of the primary copper mineralization

landmark: long and warm summers with high and it is created around the latitic dike. The ore

average daily temperatures and reduced mineralization mainly occurs in the gneisses, but as

precipitation, low winter temperatures and a ring around the latitic burst. The ore body is in

occurrence of winds from all directions. shape of upturned, cut cone and morphologically it

2.2. Geology is following the shape of the volcanic body. Its mine

mineral is the chalcopyrite, accompanied by pyrite,

Buchim mining field is occupying the northern parts magnetite, hematite, cubanite, valerite, natural gold,

of Buchim-Damjan-Borov Dol mining region, created borite, etc. Bucim mine consist also of Bunardzik,

between two major geotectonic units: the Serbian- Vrsnik and Cukar ore bodies which are well

Macedonian massif and the Vardar zone. According investigated and are of subject for further

the positioning of the tectonic plate this is a place of exploration.

depositing i.e. place of contact of the two

geotectonic units, at which point the Vardar zone is

sinking under the Serbian-Macedonian massif. This

mining field is defined with lower rank fault planes,

alkaline fractions of the tertiary intermediary

magmatic and copper porphyry mineralization. The

geologic structure of this region is quite complex

with explicit tectonics. Buchim ore deposit occupies

the southern parts of Buchim mining field. The

geologic structure of Buchim ore deposit features

mainly Precambrian metamorphic rocks (gneisses,

micashists and amphibolites) and tertiary volcanic

rocks. The gneisses are the most frequent lithologic

members in the ore deposit, and they are at the

same time the most favorable lithologic environment

for disposal of ore mineralization. The mineralization

of Buchim ore deposit is porphyric. The copper

Figure 1. Bucim dump

mineralization is connected with the process of

silification, and it occurs in the gneisses and the

amphibolites and biotitic schist, as well as at the 3. EXPERIMENTAL

point of their contact with the andesites. In the rifts

of these rocks there are mineralized quartz ledges 3.1. Sampling

with presence of fine impregnation at the same time. For the metallurgical testwork, approximately 2 tons

The copper minerals are also present in the of samples were taken from Bucim dump Figure 1,

andesites, but their content is considerably according the following procedure: (1) determination

decreasing proportionally with the increase of the of ten pre-selected places spread across a large

andesite distance from the contact with gneisses. areal extent of the mine area; (2) excavation of ten

different pits (5 meters deep) at each of the pre- The total quantity of ore is dumped carefully on a

selected places; (3) collection of 200 kg sample of clean, concrete surface so as not to break the larger

each pit, simply excavating a full sample at once. particles. A 200 kg representative sample is

Each pit sample is collected into separate steel prepared and then crushed to -20 mm. The

drum with the sample locations clearly identified on representative sample are coned and quartered in

the drums with sample identification numbers; (4) the classic fashion to produce a 15 kg head sample.

shipment of the 10 pit samples, to the laboratory for Part of it is further crushed to -2 mm, and another

further preparation, assay and characterization. part is ground to -150 (-0.15 mm). These

samples are designed to determine the physical and

3.2. Metallurgical Testwork Program mechanical properties and chemical composition of

The metallurgical testwork program typically the ore, as well as for conducting of phase and

involves a sequence of the following stages, namely mineralogical analysis, acid consumption and bottle-

mineralogical examinations, bottle roll tests and roll tests. From the remaining crushed ore, 60 kg

column tests, optionally followed by piloting on test are taken for the column leach tests.

heaps. Mineralogical examinations are fundamental

4.2. Sample Characterization

to the metallurgical behavior, and therefore to the

technical and economic amenability of an ore to In Tables 1, 2 and 3 are shown physical

exploitation. They are normally performed first, to and mechanical properties, analysis of ore sample

obtain information about mineralized zones within by elements and phase analysis.

the ore body and the potential recovery. By

additional examination of the ore samples, the type Table 1. Physical and mechanical tests results.

and location of valuable minerals in the ore can be

determined and the gangue minerals can be No Parameter Unit Value

characterized. Bottle roll tests are the second stage 1 Volume density, g/cm3 2.57

of the metallurgical program. In these tests on a 2 Specific density,s g/cm3 2.67

bottle roll apparatus all the material remains in 3 Water absorption, W % 1.21

continuous motion and a pulp air interface is created

for aeration of the pulp. The main variables to be

considered are pulp density, acid concentration, Table 2. AES-ICP results.

ferric concentration, retention time and temperature.

No Parameter Unit Value

Generally bottle roll tests give an indication of metal

1 Cr % 0.006

recovery and acid consumption.

2 Fe % 3.7

On the other hand the column leach tests

give much more accurate information about metal 3 Co % 0.0023

recovery and acid consumption in the trickle 4 Ni % 0.0026

bed conditions as well as an initial indication of the 5 Cu % 0.4

possible percolation problems (Miller and Newton, 6 Zn % 0.49

1999). 7 Ga % 0.0009

Metallurgical test work with the Buchim ore was 8 As % 0.0074

carried out at the Iontech laboratory, based in the 9 Mo % 0.0017

University of Mining and Geology "St. Ivan Rilski", 10 Cd % 0.0007

Sofia. Tests were done using bottle-rolling and 11 Sn % 0.0064

column leaching techniques. 12 Sb % 0.0006

13 Te % 0.0002

3.3. Laboratory Facility Description 14 Pb % 0.007

The laboratory facility consists of a leaching, ion 15 Bi % 0.0007

exchange, solvent extraction and electrowining

section. It also has a sample preparation and Table 3. Phase analysis results.

analytical laboratory. The leaching sections include

standard bottle roll apparatus and 4 leach columns, Fraction Cu %

each 10 diameter and 1m high. The laboratory Fraction I (Cu in oxidized minerals) 0.204

facility is closed with a ion exchange, solvent Fraction II (Cu in secondary sulphides) 0.069

extraction and electrowining sections. Fraction III (Cu in primary sulphides -

chalcopyrite) 0.124

TOTAL for ore sample 0.397

4. RESULTS AND DISCUSION

4.1. Sample Preparation As can be seen from the table above most of the

copper presented is in oxide form (0.204%), the

content of primary sulphides-chalcopyrite is also

relatively high (0.124%), while the content of Column leach tests are the most important

secondary sulphides is only 0.069%. part of the metallurgical testwork program. The two

key results which can be determinate from the

column tests are the maximum copper extraction

4.2.1. Mineralogy and acid consumption under percolation-contact

Main minerals are limonite, cuprite, mode. Leach tests are carried out using four 1 m

tenorite, native copper, goethite, malachite, columns (2 sets x 2 columns) in closed-cycle. Leach

azurite, but relicts from pyrite, chalcopyrite, cycle in the first columns set (columns 1-1 and 1-2)

chalcocite, specularite, rutile, magnetite, etc also is 103 days, and the leach cycle in second columns

occurs set (columns 2-1 and 2-2) is 73 days.

According the complex X-ray thermal analysis the The main conditions of the column tests are

sample is represented by Quartz-25%; Labradorit given in the table below:

25%; Mikrocline 22%; Ortho-chamosite 12%,

Muscovite 9%; Pyrite 3% and Calcite 2%. Table 4. Column tests conditions.

From this analysis can be concluded the

following:

Acid concentration

Acid concentration

Application rate

(1) The main gangue minerals are silicates,

after14th day

solutions(g/l)

solutions(g/l)

Ore quantity

first 14 days

in the leach

in the leach

Column No

inorganic compounds with high chemical and

(l/h.m2)

structural complexity, which are the most significant

(kg)

acid consuming component. However, they react

incompletely with sulfuric acid and with most of

them the rate of chemical reaction acid-gangue is a

function of the acid strength in the leach solution.

The moderate reactivity to acid of these minerals 1-1 13 6-8 6-8 6

limits the acid consumption; 1-2 13 12-14 6-8 6

(2) The content of calcite, mineral which reacts 2-1 13 6-8 6-8 12

violently even with very dilute sulfuric acid solutions 2-2 13 12-14 6-8 12

is only 2%, that suggesting moderate levels of acid

consumption during leaching process;

The results after 103 days and 73 days of

(3) The content of the main acid generating mineral

leaching are summarized in Table 5.

pyrite is 3%,which means that effective leaching cou

ld be achieved only by adding of a sufficient amount

of sulfuric acid from the outside. Table 5. Column leach tests results.

4.3 Acid Consumption

consumption

Acid/Copper

recovery,%

Column No

Net acid

Copper

In general, acid consumption depends mainly on the

kg/kg

kg/t

occurrence of acid-consuming minerals and crush

size of the ore, but also from the increased

contact time lixiviant - ore and the acid strength of

the leach solution. Determined by The Acid

1-1 53.66 34.45 8.68

Consumption Procedure-Short method, the gross

acid consumption is 22.3 kg / ton ore, while the 1-2 44.29 32.34 8.15

2-1 49.65 35.93 9.05

net acid consumption is 21.7 kg / ton ore. In the

same time according to the standard methodology - 2-2 66.10 52.08 13.12

Typical Acid Consumption Procedure-the gross acid

consumption is 28.6 kg / ton ore, while the net Copper recovery and net acid consumption for both

acid consumption is 27.1 kg / ton ore. sets are presented in Figures 2 and 3.

Copper tenor in Pregnant Leach Solutions (PLS) of

4.4. Bottle Roll Tests the four columns is presented in Table 6.

Bottle roll tests are conducted on a bottle roll

apparatus under standard procedure and provide Table 6. PLS Copper tenor.

initial information for copper extraction and

acid consumption. The obtained copper recovery is Column No PLS Copper tenor g/l

low -31, 9%, while the acid consumption of 29.3 1-1 0.453

kg / ton (gross) and 27.4 kg / ton (net) is relatively 1-2 0.513

high, so these results should rather be treated as 2-1 0.398

semi-quantitative. 2-2 0.512

4.5. Column Leach Tests

5. PROJECT DESIGN CRITERIA

The project designs criteria are selected based on

the metallurgical testwork carried out at the lab

facility, and are summarized in Table 7.

Table 7. Project design criteria.

Process Parameter,unit Value

LEACHI Design ore grade, 0.25

NG Application rate,l/h.m2 12

(L) Acid concentration in the 15

leach solution(first 2

weeks),g/l

Acid concentration in the 6-8

leach solution,g/l

PLS copper tenor,g/l 0.5

PLS pH 1.8-2.2

Process Parameter,unit Value

ION IX feed copper tenor,g/l 0.5

EXCHAN IX feed pH 1.8-2.2

GE Filtrate copper tenor,g/l 0.02

(IX) Filtrate acid concentration, 3

g/l

Regenerate copper 15.6

Figure 2. Copper recovery and net acid tenor,g/l

consumption for columns 1-1 (blue line) and 1-2 Regenerate acid 20

(red line) concentration,g/l

Process Parameter,unit Value

SOLVEN Configuration (Extr. x 3Ex2S

T Strip.)

EXTRAC SX feed copper tenor,g/l 10.4

-TION SX feed acid 14

(SX) concentraion,g/l

Raffinate copper tenor,g/l 1.04

Rafinate acid 29

concentration, g/l

Process Parameter,unit Value

ELECTR Strong electrolyte copper 44

O- tenor,g/l

WINNIN Strong electrolyte acid 160

G concentraion,g/l

(EW) Spent electrolyte copper 32

tenor,g/l

Spent electrolyte acid 180

concentraion,g/l

Current density,A/m2 280-300

Cathode quality LME

Grade A

Cathode production,t/y 2400

The block flow diagram for the Buchim Copper

project is given in Figure 4.

Figure 3. Copper recovery and net acid

consumption for columns 2-1 (green line) and 2-

2 (black line)

REERENCES

Radovish municipality, FYR Macedonia, RfP

21/2008, Feasibility assessment and

Development of a main technical design for

water protection measure Buchim mine.

Bartlett, R. (1992). Solution Mining: Leaching and

Fluid Recovery of Materials, Second Edition,

Gordon and Breach Science Publishers, p. 443.

Jergensen, V. G. (1999). Copper Leaching, Solvent

Extraction and Electrowinning Technology, SME,

p. 296.

Tsekov, V., Savov, G., Kanev, V., Garvanov, T.,

Angelov, T., & Kovacheva, V. (2003). Production

of copper cathode by leaching-SX/EW method in

Tzar Asen, Proceeding of the X Balkan Mineral

Processing Congress, p. 4.

Figure 4. Process flowsheet Tsekov, V., Savov, G., Angelov, T., Kovacheva, V.

Figure 4 depicts the overall process whereas L- (2005). Practical Aspects of Economically Proven

leaching, IX-ionexchange, SX-solvent extraction, Copper Cathode Production by Ion Exchange

EW electrowinning, O-ore, W-spent ore, PLS- Technologies. Proceeding of the XI Balkan

pregnant leach solution, F-filtrate, LR-loaded resin, Congress of Mineral Processing, Albania, p. 7.

SR-regenerated resin, RF-raffinate, RS-regenerate, Bayer, A. G., (1997). Instructions for laboratory trials

LO-loaded organic, SO-stripped organic, PE- with selective resin. Technical Information,

pregnant electrolyte, SE-spent electrolyte, C- Edition, p. 8.

charging, R-regeneration, E-extraction, S-stripping. Miller, G., Newton, T. (1999). Copper heap leach

testing, interpretation and scale-up. ALTA

Copper Hydrometallurgy Forum, QLD, p. 27.

6. CONCLUSIONS Kordosky, G., Virnig, M., Mackenzie, M., (2006),

Solvent extraction reagents and selectivity

Extensive metallurgical testwork has been control, Cognis Corporation, p. 20.

conducted to define the process for the Buchim Kordosky, G, (2000), Copper Solvent Extraction

Copper Project. Bottle roll tests and column tests Reagents, Past, Present and Future, Cognis

were carried out at laboratory scale during the Corporation, p. 13.

conceptual study and ion exchange, solvent Spence J. R., Soderstrom M.D., (1999), Practical

extraction and electrowinning tests were run at lab Aspects of Copper Solvent Extraction from Acidic

facility. Effects of particle size, application rate and Leach Liquors, p.17.

acid strength of the leach solutions were evaluated

and basic parameters like application rate, acid

consumption and copper recovery were selected.

A new combined Leach-Ion Exchange-Solvent

Extraction-Electrowinnig (L-IX-SX-EW) process

(Tsekov et al., 2005) has been selected to treat the

Buchim ore and to produce 2400 tpy of copper

cathodes.

The Buchim Copper project is now under

construction and is scheduled to come on stream in

late 2011.

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Interpretation Leached Outcrops BlanchardDocumento215 páginasInterpretation Leached Outcrops BlanchardRussell Hartill100% (7)

- Angostura Gold-Silver Underground ProjectDocumento294 páginasAngostura Gold-Silver Underground ProjectAnita Villablanca100% (1)

- Blasting Principles For Open Pit Mining Vol 1 William HustrulidDocumento412 páginasBlasting Principles For Open Pit Mining Vol 1 William HustrulidAditya Indra Chayadi100% (6)

- COAL MINING TECHNOLOGY. A Presentation by MANOJ KUMAR SINGH Manager (IE), NCL-HQ, Singrauli (MP) - 486 889 E-Mail - Mks - Ie@nclhq - Nic.Documento56 páginasCOAL MINING TECHNOLOGY. A Presentation by MANOJ KUMAR SINGH Manager (IE), NCL-HQ, Singrauli (MP) - 486 889 E-Mail - Mks - Ie@nclhq - Nic.Sidhartha sahu100% (1)

- Mineral Resource and Ore Reserve Estimation PDFDocumento902 páginasMineral Resource and Ore Reserve Estimation PDFivansssss100% (27)

- Type of DepositDocumento4 páginasType of DepositGuinevere RaymundoAinda não há avaliações

- 14underground Mining MethodsDocumento73 páginas14underground Mining MethodsJyoti Ranjan Maharana100% (1)

- Bond Work Index Formula-Equation - Mineral Processing & Extractive MetallurgyDocumento6 páginasBond Work Index Formula-Equation - Mineral Processing & Extractive MetallurgyJohn Calero Ortega100% (1)

- Guia1 Min540Documento2 páginasGuia1 Min540Luis Flores Sabando100% (1)

- Longwall MiningDocumento2 páginasLongwall MiningRiswan RiswanAinda não há avaliações

- Bolani Ores Mines at A GlanceDocumento1 páginaBolani Ores Mines at A GlanceRamesh Madhabattula100% (2)

- Sgs Port Klang Ann Joo Integrated Steel 03653-03731 (79samples)Documento8 páginasSgs Port Klang Ann Joo Integrated Steel 03653-03731 (79samples)Jasni JalaludinAinda não há avaliações

- Kci Kendilo ProfileDocumento1 páginaKci Kendilo Profileapi-167631790Ainda não há avaliações

- List of Ec Violation Cases in Telangana State Referred To The State Government For Taking Credible Action On Violation. As Per The Moe&F, Goi'S Om DTDocumento18 páginasList of Ec Violation Cases in Telangana State Referred To The State Government For Taking Credible Action On Violation. As Per The Moe&F, Goi'S Om DTProjectinsightAinda não há avaliações

- N 218 HistoryDocumento4 páginasN 218 HistoryDrako 2001Ainda não há avaliações

- Bid SheetDocumento10 páginasBid SheetVi KraAinda não há avaliações

- Volume-I - (Coal) 2014636129985100886136 PDFDocumento153 páginasVolume-I - (Coal) 2014636129985100886136 PDFAzhar KhanAinda não há avaliações

- AMPLA Twilight Seminar JORC PresentationDocumento65 páginasAMPLA Twilight Seminar JORC Presentationarief_7Ainda não há avaliações

- Legis Cir 03 2018Documento2 páginasLegis Cir 03 2018Deepak KumarAinda não há avaliações

- Bid Sheet: Mstc/Blr/Monitoring Committee /68/bangalore /19-20/15661 (222519)Documento3 páginasBid Sheet: Mstc/Blr/Monitoring Committee /68/bangalore /19-20/15661 (222519)Vi KraAinda não há avaliações

- LKAB Announcement 100402Documento2 páginasLKAB Announcement 100402api-3700704Ainda não há avaliações

- S4 John PeaceyDocumento16 páginasS4 John PeaceyAnonymous T02GVGzBAinda não há avaliações

- 煤矿专业常用英语词汇Documento33 páginas煤矿专业常用英语词汇葛云博Ainda não há avaliações

- Pemodelan Sistem Panas Bumi - Ailimaxpem AkamigasDocumento9 páginasPemodelan Sistem Panas Bumi - Ailimaxpem AkamigascitraAinda não há avaliações

- Piramide de KelsenDocumento3 páginasPiramide de Kelsensilvio huañahui huamaniAinda não há avaliações

- Company Profile NorasDocumento8 páginasCompany Profile NorasIvan MiharviAinda não há avaliações

- Varlam Off 1972Documento15 páginasVarlam Off 1972Cristian UbedaAinda não há avaliações

- Letter For Brgy. BasakDocumento4 páginasLetter For Brgy. BasakDennis DagoocAinda não há avaliações

- Mine Closure 2014 List of Approved AbstractsDocumento7 páginasMine Closure 2014 List of Approved AbstractsArthur FonteneleAinda não há avaliações

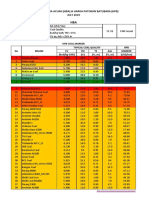

- Harga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) JULY 2019Documento8 páginasHarga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) JULY 2019Adnan NstAinda não há avaliações