Escolar Documentos

Profissional Documentos

Cultura Documentos

Amx3 Service Manual PDF

Enviado por

juan manuel0 notas0% acharam este documento útil (0 voto)

26 visualizações264 páginasTítulo original

amx3_service_manual.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

26 visualizações264 páginasAmx3 Service Manual PDF

Enviado por

juan manuelDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 264

GE Medical Systems

Technical

Publications

Direction 46-001118 (SM A0654F)

Revision 13

AMX-3

X-Ray Unit

Copyright® 1985, 1986, 1987, 1993, 1999 By General Electric Co.

Operating Documentation

DAMAGE IN TRANSPORTATION

Allpackages should be closely examined at time of delivery. damage is apparent,

have notation “damage in shipment” written on all copies ofthe freight or express

bill before delivery is accepted or “signed for” by a General Electric representative

or a hospital receiving agent. Whether noted or concealed, damage MUST be

reported to the carrier immediately upon discovery, or in any event, within 14 days

atter receipt, and the contents and containers held for inspection by the carrier. A

transportation company will not pay a claim for damage if an inspection is not

requested within this 14 day period

Call Traffic and Transportation, Milwaukee, Wi (414) 785—5052/8*323-5052 im-

mediately after damage is found. At this time be ready to supply name of carrier,

delivery date, consignee name, freight or express bill number, item damaged and

‘extent of damage.

‘Complete instructions regarding claim procedure are found in Section “S" of the

Policy & Procedure Bulletins.

sate

GE Medical Systems

GE Mocical Systems: Telex 3797971

PO. Bax 414, Mivaudoo, Wisconsin 52201 USA.

(Asia, Pact, Latn America, North Amerie)

GE Maccal ystems — Europe: Telex 261704

‘Shortands, Hammersmith, London Wé BEX UK.

GE MEDICAL SYSTEMS AMX~3 X-RAY UNIT

REV 13

CHAPTER

10

DIRECTION 46-001118 (SM AO6S4F)

TABLE OF CONTENTS

TITLE

REVISION HISTORY

REFER TO SEPARATE OPERATION MANUAL,

DIRECTION 46-001117 (OM A06S4F)

INSTALLATION AND CALIBRATION

FUNCTIONAL CHECKS

‘THEORY

SERVICE ADJUSTMENTS

‘SCHEMATICS

DIAGNOSTICS AND TROUBLESHOOTING (Not Available at this Time)

REFER TO SEPARATE RENEWAL PARTS DIRECTION 46-014661

PERIODIC MAINTENANCE,

NOTE: THE AMX-3 UTILIZES

A FACTORY HIGH LEVEL

OF ASSEMBLY

‘Tum to page iii for details on use

and structure of this manual.

act

ifi (Blank)

GENERAL ELECTRIC MEDICAL SYSTEMS

REVS.

AMX-3 X-RAY UNIT

‘SM A06S4F

INTRODUCTION

Because of the use of factory high level assembly,

this service manual has been written to provide the

following features.

High Level of Assembly

Because of factory performed tests, most of the

calibration procedures consist of first a check, and

then an adjustment to be performed only if the

expected check results are not obtained.

Functional Checks

Designed to provide a quick checklist of all major

functions of the unit. References are provided to

steer service personnel to correct adjustment

procedures when needed.

‘Two Level Theory .

Chapter 5 theory is designed to provide service

personnel with a basic understanding of the

operation of the AMX. The first level of theory is a

general description of the unit in large functional

blocks. The second level provides a more detailed

description of how individual circuits and

‘components operate.

Service Adjustments

In addition to service adjustments, Chapter 6 for

‘the AMX.3 also includes some procedures required

for installation, particularly for export units.

Facing Page Schematics and Field Adjustments

Facing page service adjustments are provided for

‘quick reference and readability. in addition, a three

Page overall schematic is provided at the beginning

of Chapter 7

Diagnostics and Troubleshooting

Input from any interested person is greatly

‘appreciated to be able to provide an adequate,

‘easy-to-use diagnostics and troubleshooting guide.

Please feel free to provide any suggestions you

might have using the OER form provided with this

manual.

Separate Renewal Parts

Renewal parts for this product are provided in a

separate direction (Direction 14661). This direction,

should be received with the unit.

Maintenance Checklist

Provides a simplified checklist for proper mainte-

nance of the AMX-3 X-ray Unit.

‘Any suggestions as to how to make this manual

more useful and/or straightforward are greatly

appreciated and should be submitted using OER

Direction 13861.

Copyright® 1985, 1986 by General electric Co

GE MEDICAL SYSTEMS AMX-—3 X-RAY UNIT

REV 13 DIRECTION 46-0011 18 (SM AO654F)

REVISION HISTORY

REV DATE REASON FOR CHANGE

- Dee. 30, 1983 ‘The predecessor to this manual, SM AO6S4F, used a different revision control

7 Apr. 42, 1985

8 July 14, 1986

9 Dec. 31, 1986

10 May 8, 1987

11 Aug. 13, 1993

12 Jan. 15, 1999

18 May 14, 1999,

method. The 12-3083 date code is the last of several date codes for that

manual

General updating.

Removed Chapter 1, OM AO654F, as a separate manual; moved some

procedures from Chapter 3 to Chapter 6 to reduce installation time; general

revisions.

Updated battery terminal torque specification, battery safety precautions, and

schematics.

Update HHS field tests in Chapter 4.

Made corrections to kVp selection tables in Chapter 6, Part 1, Section 1.

Updated 342 Filament Regulator Board Schematics (46—205872S) on pages

7=11Aand 7-116.

Updated 3A2 Filament Regulator Board Schematics (46—-205872S) on pages

7~11Aand 7-11C.

LIST OF EFFECTIVE PAGES

PAGE REVISION PAGE REVISION PAGE REVISION

NUMBER NUMBER NUMBER NUMBER NUMBER NUMBER

Title Page 13 3-26 and 3-27 7 4-7 11-681

3-28 8 4-8 52083

Damage in 3-29 9 a9 71081

‘Transportation - 3-30 8 4-10 7

a 3-308 i 4-11 thru 4-18, 8

i ae 3-308 8 4-19 thru 4—21 7

u 8 3-31 8 TAB ~ CH.5 -

= Blank 3-32 5-2083 5-i 8

vand vi 13 3-33 thru 3-35 8 5-il Blank

eo _ 3-36 S20 5-H 7

ea e TAB - CH. 4 = 5-2 Blank

oa! a ot 10 5-3 11-681

eee e at 8 5-4 Blank

3-3 thru 3-5 8 4-2 40

3-6 11-681 4-3 7 5-5 41-681

4-4 11-681 5-6 Blank

ee aeeae e 4-8 and 4-6 71081 5-7 11-681

3-9 7 Blank

ba, 5 5-8 lan

aay é 5-8 11-681

3-12 thru 3-25 8 a boats

GE MEDICAL SYSTEMS AMX—3 X-RAY UNIT

REV 13 DIRECTION 46-001118 (SM AO654F)

LIST OF EFFECTIVE PAGES (Cont.)

PAGE REVISION PAGE REVISION PAGE REVISION

NUMBER NUMBER NUMBER NUMBER NUMBER NUMBER

5-11 11-681 11-681 7-6 Blank

5-12 Blank 71081 7—7thu7-10 8

5-13 41-681 41-681 7-118 13

5-14 Blank 7-181 7-11B Blank

5-15 8~198 7 7-116 13

5-16 Blank 7-12 thu 7-14 7

5-17 thru 5-19 11-681 11-681 7-45, 9

7=1081

TAB - CH.6 = 41-681 7-16 12-3088

e-i " Blank 7-17 3

6-1-1 5~2069 9 7-18 11-681

6-1-1 thu 6-1-2614 7-19 7

6~1-27 and 6~1-28 12-3083 12-3083 7-29 8

aaeoe 3 11-681

9 7-21 12-3088

30 and 61-31 7 7-22 Blank

=32 Blank 11-681 735 a

=33 7 7 7-24and7-25 8

-34 thru 6—1-37 8 Blank 7-26 11-681

6-3-3and6-3-4 7

11-681 G-3-Sand6-3-6 71081 7-27 12-9089

8 7-28 and7-29 7

Blank 11-681 7-39 Blank

2A and 6-2-28 8 5-208 7-31 7=1081

—3 8 7 7-32 Blank

6-2-4 71081 8

7-38 71081

6-2-Sand6-2-6 52083 5 7-3hand7-95 7

-7 7

—Bthu6-2-19 71081 Blank TAB CH. 10 -

20 Blank 7 10-1 8

ee heen Blank 10-2 Blank

7 10-Sthu10-5 8

6-2-22 71081 Blank 10-6. Blank

6-2-2 thru 6-2-25 11-681 7 10-7 9

6-2-26 Blank 10-8 8

6-2-27 5-208 11-681

6-2-28 7-1081 Blank

11-681

GENERAL ELECTRIC MEDICAL SYSTEMS AMX-3 X-RAY UNIT

REVO ‘SM AO6S4F

CHAPTER 3.

INSTALLATION AND ADJUSTMENTS

TABLE OF CONTENTS

‘SECTION TITLE PAGE

1 PRE-INSTALLATION 5 ot

2 INSPECTION AND UNPACKING : coca 36

3 CASSETTE DRAWER REMOVAL .. 5 38

4 BATTERY INSTALLATION .... 310

5 PRELIMINARY GENERATOR CHECK a2

6 BATTERY CHARGER 3413

7 HV TRANSFORMER AND FILAMENT CHECK ..... cece I

8 FILAMENT AND ROTOR INTERLOCKS FUNCTIONAL CHECK .... 315

9 CONNECT HV DIVIDER 316

10 MA STABILIZER AND kVp ADJUSTMENT 317

" BACK-UP TIMER CHECK .. 321

12 mAs AND LOAD CHECKS .... : : : 3-22

18 MODIFICATIONS, 3-25

4 COLLIMATOR CHECKS . 3-26

15 COLLIMATOR BEAM ALIGNMENT CHECKS 3-29

16 DIAGNOSTIC SOURCE ASSEMBLY: INHERENT FILTRATION .... 3-31

7 MOTOR DRIVE SYSTEM .. 3-82

18 REPRODUCIBILITY OF EXPOSURE ....... 3-83

19 RECHARGE BATTERY . goncoc 3-83

20 COMPLETING THE INSTALLATION ........ 334

GENERAL ELECTRIC MEDICAL SYSTEMS

REV7

AMX-3 X-RAY UNIT

‘SM A0654F-O

CHAPTER 3 — INSTALLATION AND ADJUSTMENTS

‘SECTION 1 — PREINSTALLATION

1-1 Introduction

This AMX-3 installation procedure takes advantage of

the assembly and tests performed in the factory. Also,

‘System Functional Checks and Field Tests for HHS

‘Compliance are included in the installation procedure to

eliminate duplication.

Users of this publication are encouraged to report

errors, omissions, and their recommendations for im-

proving the publication (use Direction Form 13861).

1-2. Product Identification and Compatibility Re-

quirements for HHS Certification

‘The AMX-3 is identified by the following component

‘model numbers. To meet HHS requirements regarding

beam quality, exposure mAs, minimum fitration, beam

‘collimation, and source-to-skin distance, the sensitive

‘components making up the AMX are identified with the

nameplate statement, “this product conforms to all ap-

plicable standards under 21 CFR part 1020”, or, “com-

plies with radiation performance standards, 21 CFR

subchapter J”.

TABLE

Nameplate

Component Model No. Nameplate Location HHS Statement

Basic AMX-3 unit includes control, mobile | 46-217900G2 | On front of unit, beneath handswitch Yes

base, vertical column, and horizontal 46-217900G3 | bracket

telescoping arm (GE Export)

HV Transformer 46-184857G1 | Beneath terminal stip Yes

X-ray Tube Housing 46-155750G8 | On back trim cover of tube housing Yes

Xray Tube Insert 4612568668

Sentry Colimator 46-194759G2 | On rear trim cover Yes

Extension Cylinder (optional item) 46-138573G1 | On support plate Yes

Battery Cell Group (3 used per unit) 46-194409P1 | End of cell group case No

(Marathon)

46-194409P3

(Ge)

at Copyright © 1985 by Genera! Electric Co,

GENERAL ELECTRIC MEDICAL SYSTEMS

AMX-3 X-RAY UNIT

REV9 > Indicates Change

1-3 Safety Preca

‘Any person providing installation, maintenance, or ser-

Vice on this unit must foliow safe procedures to avoid

accidental injury.

Work on any electrical apparatus involves the risk of

electric shook. On a battery-operated unit such as this,

additional precautions are required because of the fol

lowing conditions:

1. This X-ray unit contains a 120V rechargeable battery

inside the cabinet. The battery is a source of power

when contacted directly even with all the switches

off,

._ fa conductive metallic object comes in contact with

the battery terminals, high currents may cause dam-

‘age to the object, to the battery, and severe burns to

the service representative.

WARNING: THE ELECTROLYTE USED IN

NICKEL-CADMIUM BATTERIES IS A CAUSTIC

SOLUTION OF POTASSIUM HYDROXIDE

‘SERIOUS BURNS WILL RESULT IF IT COMES IN

CONTACT WITH ANY PART OF THE BODY. IF

ELECTROLYTE GETS ON THE SKIN, WASH THE

AFFECTED AREAS WITH LARGE QUANTITIES

OF WATER, NEUTRALIZE WITH VINEGAR,

LEMON JUICE, OR 3 PERCENT ACETIC ACID. IF

ELECTROLYTE GETS INTO THE EYES, FLUSH

WITH WATER AND GET IMMEDIATE MEDICAL

ATTENTION.

. Because of the potential hazards mentioned above,

the service representative must remove rings, wrist

watch, etc., and WEAR SAFETY GOGGLES when

‘working on or near the battery, and must follow bat-

tery installation procedures, given in Chapter 3, and

maintenance procedure given in Chapter 6. The ser-

lew

32

‘SM. "AO6S4F

vice representative should not leave the X-ray unit

unattended with the battery compartment cover

and the cassette tray removed, unless adequate

warning signs and safety measures to limit access to

the area are made.

. The X-ray control access door can be opened only

by frst removing the X-ray control cover. Because of

the possible electrical shock and other hazards

Present when this door is opened, the service repre-

sentative should not leave this unit unattended with

the cover removed and the door open unless ade-

quate waming signs and safety measures to limit

access to the area are made.

. When recharging the battery, the X-ray unit must be

located in a large, ventilated room. During normal

charging conditions and when all batteries are func-

tioning property, there is litle or no gas emitted.

‘Should abnormal conditions develop, there could be

an accumulation of hydrogen gas which, if confined

in a.small space, would be explosive in the presence

of flame or electrical spark. Whenever the extension

cord plug is inserted in a wall outlet, a fan ventilates

the battery compartment. A hazardous situation will

not develop where the outflow from this compart-

ment is into a large well-ventilated room.

‘An audible tone and/or red “X-ray” light indicates

presence of radiation. If either indicator is on at any

time other than the expected X-ray exposure inter-

val, immediately release the handswitch X-RAY and

ROTOR buttons and move the main power circuit

breaker to OFF. Perform the procedure for discon-

necting the HV transformer before attempting to

determine the malfunction.

Battery Transportation Safety Precauti

Refer to Ni-Cd Battery Service Manual,

Direction 14066 (Rev 4 or later), Section 2-6,

“Transportation.”

Battery Disposal Safety Precaution: Refer to Ni-

Cd Battery Service Manual, Direction 14066

(Rev 4 or later), Section 2-7, “Disposal.”

WARNING: THIS UNIT IS NOT DESIGNED FOR

USE IN HAZARDOUS AREAS.

GENERAL ELECTRIC MEDICAL SYSTEMS

AMX.3 X-RAY UNIT

REV 8

1-4 Delivery Data

For domestic units, the unit is shipped fully assembled

as shown in Figure 3-1. Copies of the product delivery

instructions are included with the basic unit. These

should be used to inventory furnished parts on receipt of

shipment. For export units, refer to the product delivery

instruction to inventory furnished parts and equipment.

‘SM AO6S4F

15. Battery

The installation procedure is written on the basis thatthe

battery pack for this AMX-3 has been previously

charged and electrolyte level adjusted at a GE District

Office or other suitable facility. The charged battery is

then to be transported to the installation site of the

‘AMX-3 in the recommended shipping container.

item or Box

Marked...

Description

‘AOG54 Item A

Bag No. 1

Bag No. 5

Taped

Envelope for HV Cables, containing:

ABI048 Battery Pack for AMX-3 consisting of:

(8) 46-194409P1 or 46-194409P3

531286

(1) Adhesive backed plastic envelope

‘AMX-3 with vertical column, horizontal telescoping arm, tube yoke, HV transformer, HV cables, tube stator

and collimator cables, tube unit, and collimator assembled to the basic unit.

Furnished Parts (packed in the cassette drawer):

(6) 780148 Operator Keys

(1) 91645 Waymat Oil, 1 02. (28.4 g)

(2) No. 6 AWG x 6" (152.4 mm) black leads for battery interconnection

(4) 46-154021P1 Battery Insulator Boards

(1) GE Silicone Dielectric Compound G-635, 2 02. (56.7 9)

(1) Direction 13871, Application of Compound

Extension Cylinder (optional accessory to AMX-3)

Product locator fle packages. One each for AMX-3 unit, Transformer and Coli mator, each containing:

(1) Salmon colored envelope attached to mobile unit

Copyright © 1986 by Genera Electic Co.

GENERAL ELECTRIC MEDICAL SYSTEMS.

AMX-3 X-RAY UNIT

REVS

1-6 Tools and Test Equipment

‘The following will be required for installation in addition

to the standard service representative's tool kit. The

following list does not include additional tools or test

equipment required if difficuty is encountered during

the installation which requires troubleshooting or repair

10 the equipment.

‘© Standard wrench (507A935G1) for GE Type Il cable

terminals.

‘© Oscilloscope, Tektronix 564 or equivalent, dual trace,

memory type with algebraic addition feature and X10

Probes.

© 1 gallon (3.8 liters) Diala AX transformer oil for HV

transformer or HV divider.

‘© Can of 75-25 cleaning solvent and rags for cleaning

(do not use for cleaning covers).

© Socket or open end wrench, 1-1/16" hex for counter-

balance adjustment.

© Calibrated HV divider (C1515A) with two 5 ft. (1.5 m)

HV cables.

Copyright® 1965, 1986 by General Eletic Co.

‘SM A0654F

© Torpedo level.

‘© HHS Field Test Kit, 46-177372G1, including Recep-

tor Alignment Patterns and Standard Test Absorber,

46-173632G1.

‘© Digital multimeter, Beckman 3030 RMS or Fluke

‘Model 80304.

14x 17 (85.5 0mx 43.2 cm) cassette and X-ray film.

© Torque wrench, 0-4 ft-lb. oF 0-50in.-Ib. wth 9/64” hex

rive. Snap-on Tools Mode! TSQ-4 torque wrench

with TMA-4-1/29/64” hex drive or equivalent.

‘« Radiation meter (integrating dose type), Capintec

Model 192 or equivalent.

‘* Fiuoricon test pattem for demonstration radiographs.

‘¢ 17.5 tt. Belden Type 8422 coax cable (supplied with

‘mAS integrator board).

‘© mAs integrator kit, 46-216490G1, with new mAs

integrator board 46-226598G1

© 9/64 hex T-handle allen wrench 46-165137P1.

GENERAL ELECTRIC MEDICAL SYSTEMS

REV8

1-7 Documents and Forms

‘The following manuals, documents, and forms are re-

{quired or referred to during the installation of the AMX-3.

Product Delivery Instructions

Product Locator Cards

Set of 2 cards

Rd Stripe in

‘Salmon Envelope

(OM 0531388

‘SM D5313AB

Direction 14975

Direction 14700

Pages 10-7 and 10-8 of,

‘SM ADGS4F. (Formerly

called F3560.)

Pages 10-3 through 10-5 of

SM ADS4F, or last three

pages of OM AO6S4F.

(Formerty called F4250.)

Direction 13898

Form F3382

Direction 13861

Federal Form FO 2579

Direction 13288

‘SM D1154A (Microfiche Card

BL9+1 Ct and C2)

Direction 14066

Reference No. Description

SM ADSSAF Service Manual AMK-3

OM A064 Operating Manual AMS

Direction 14461 AMX -9 Renewal Parts

Direction 13871 Aeplicaton of G635 slicone grease

46-21790062, Basic AMX-3

46-185750G5, Tube Unit

46-194759G2 Coliimator

‘Set of cards for each of the following components:

46-217900G2 AMX-3 Basic

4§-155750G6 Tube Housing

46-125686G8 Tube Insert

46-184857G1 HV Transformer

46-194759G2 Sentry Colimator

45-138573G1 Extension Cylinder (optional)

Sentry Manual Collimator

Sentry Manual Colimator

‘Sentry Manual Coliimator Renewal Parts

AMX-3 Exposure Guide

(@) Battery Service Log Form

PMS Data Record, AMX-3 Mobile Unit

‘System Tests for HHS Compliance

Field Tests for HHS Compliance (Available from

Stationery Stock)

‘Technical Publications Error Report

Installers Report, “Report of Assembly of a Diagnostic

Xray Syste

“High-Voltage Bleeder”

Maxiray 75, HRT, ORN-18 Tube Units

NiCd Battery Service Manual

AMX-3 X-RAY UNIT

‘SM AD654F

35 Copyright) 1985, 1986 by General Electic Co.

GENERAL ELECTRIC MEDICAL SYSTEMS

11-681

‘SECTION 2 — INSPECTION AND UNPACKING

‘All packages should be closely examined at time of

delivery. If damage is apparent, have notation of “bad

order” placed by the delivering driver on all copies of the

freight or express bill. f damage is of a concealed na-

ture, notify transportation agent as soon as possible to

make an “inspection report of damage” but, in any

event, not later than 15 days after delivery. A transporta-

tion company usually will not pay a claim for concealed

damage it an inspection is not requested within this

15 day period. Complete instructions regarding claim

AMX-3 X-RAY UNIT

‘SM A0654F

procedure are found in Section “S" of the Policy and

Procedure Bulletins.

If shipment was handled by moving van service —

uncrated — call Traffic-Miwaukee immediately when

any damage is found. Do not attempt to call any local

agent. Atthis time, be ready to describe type of damage,

type of equipment, serial numbers, and, if possible, the

order number.

NOTE: Ifthe AMX-3 unitis an international delivery unit,

refer to Chapter 3, Section 2-2 at this time.

suesoPr0

FIGURE 9-1

36

GENERAL ELECTRIC MEDICAL SYSTEMS

REVS

2-1 Unpacking the Unit

‘The AMX-8 unit is shipped as shown in Figure 3-1. The

tube unit and collimator have been installed in the tac-

tory and the counterpoise spring in the vertical column

has been adjusted with the unit fully assembled. The.

telescoping arm is locked in place with the vertical arm

lock and the latch and latch bar. See Figure 3-2.

FIGURE 92

1. Remove the plastic cover from the AMX unit, Un-

‘wrap the cables tied to the horizontal telescoping

arm, but do not release or unstrap the telescoping

arm. Open the cassette drawer and inventory the

furnished parts, referring to Section 1-4 and copies

of the Product Delivery Instructions.

2. Before releasing the telescoping arm, four shims

located inside the column must be removed. To

remove shims, proceed as follows.

Unlatch telescoping arm latch and loosen arm lock.

(The arm has already been counterbalanced in the

factory.)

37

10.

1"

AMX-3 X-RAY UNIT

‘SM ADBS4F

Slowly raise arm 3-4 inches. The front shims will fall

loose. Raise arm further to remove foam pad.

Remove (2) front shims from inside column using

attached wire tied to arm lock knob.

To remove (2) rear shims, rotate column 180°,

lower arm so that carriage bearings clear shim

stock (8-4 inches below latch point). Unwind at-

tached wires from unit and remove (2) rear shims

from top of column,

. Do not unpack the battery cell groups at tis time.

From a safety standpoint, they should be unpacked

only when ready for installation in the unit.

1. Save all packing materials until the installation is

completed and all parts accounted for.

. Remove packing around tube unit and collimator.

. Remove packing from on top of operator panel.

”. Lower the arm until itis approximately 3 ft. (.9 m)

from the floor and lock the arm lock.

. Release the telescoping arm lock and press the

arm interlock button to extend the telescoping arm.

Pullout and discard the (4) rubber wedges between

the inner two sections of the telescoping arm.

Check smooth functioning of the telescoping arm

and then lock it extended a few inches.

. Release the yoke rotation lock and rotate the yoke

‘about the telescoping arm. Check for functioning

and detents every 90° of rotation.

Record functional check on PMS Data Record —

AMX-3 Mobile Unit.

Check for olleaks around end caps andat interface

between tube unit and collimator. If leaks exist,

tighten joints if possible. Ifleakis between tube unit

and collimator, remove collimator per Section 22 in

Chapter 6 and check tightness of “0” ring seals.

If problems persist in the tube unit, refer to

SM D1 154A fortube unit maintenance procedures.

‘Skip to Section 3 at this time.

Copyright © 1986 by Genera! Eectc Co,

GENERAL ELECTRIC MEDICAL SYSTEMS

REVS

2-2 International and Export Models

Units shipped intemationally have been disassembled

to facilitate shipping. Although high level assembly has

been performed at the factory where the unit has, been

completely assembled and calibrated, because of the

disassembly and transport for export models, some

calibration and assembly procedures will have to be

repeated at the installation site. Please pay close atten-

tion to any notes andlor references made inthis chapter

to procedures which apply to export units only

2-2-1 Unpacking and Inspection

1. Unpack all crates and inventory fumished parts,

referring to Section 1-4 and copies of the Product

Delivery Instructions. Note that the column, hori-

zontal telescoping arm, tube unit, colimator, HV

transformer, and HV cables have all been disas-

‘sembled for shipping.

Do not remove the two wooden shipping braces

fastened to the ends of the tube unit. They will be

removed ater the tube unit is mounted to the trun-

rion fork,

Check the tube unit for an oil leak or a broken insert.

Look for cil slick on the housing indicating an oil leak.

In the event an oil slicks found at any of the “O” ring

seals, tighten the seal. Make sure the leakage is

stopped.

Rotate and angulate the tube unit and listen for any

Noise which would indicate a broken insert. Using a

fiashlight, examine the insert through the Lexan

window.

NOTE: The tube unit is shipped with the collimator

interface plate prealigned and secured to the tube

unit face plate. Do not loosen any of the (4) 10-32

UNF hex head screws or move any of the eccentrics

which secure the intertace plate.

Do not unpack the battery cell groups at this time.

From a safety standpoint, they should be unpacked

‘only when ready for installation in the unit.

Save all packing materials until the installation is

completed and all parts accounted for.

‘Copyright © 1986 by General Electic Co.

AMX-3 X-RAY UNIT

‘SM A0654F

2-2-2 Mechanical Assembly

1. Install column by performing Steps 1-9 in Sec-

tion 13-2 of Chapter 6 in reverse order.

. Install horizontal telescoping arm per procedure

given in Section 16 of Chapter 6.

NOTE: In order to counterbalance the weight of the

tube unit and collimator, the horizontal arm is under a

high tension counterbalance cable system as de-

scribed in Section 13 of Chapter 6. When installing

the tube unit and collimator, extreme caution should

be taken.

Install the HV transformer per procedure given in

Section 18 of Chapter 6.

NOTE: Locate cables at this time and be preparedto

connect necessary cables when specified by text.

Refer to Sections 18 and 19 of Chapter 6 for com-

plete cable connection procedure.

. Install tube unit per instructions given in Section 15 of

Chapter 6.

5. While holding the telescoping arm against rising

carefully release the vertical arm lock and lower the

telescoping arm so that itis approximately 3

(0.9 m) off the floor. Relock the arm tightly

NOTE: It is advised fo use the latch and latch bar

also to hold the arm at this time.

Release the telescoping arm lock and press the arm

interlock button to extend the telescoping arm. Pull

out and discard the (4) rubber wedges between the

inner two sections of the telescoping arm. Check

‘smooth functioning of the telescoping arm and then

lock it extended a few inches.

Release the yoke rotation lock and rotate the yoke

about the telescoping arm. Check for functioning and

detents every 90° of rotation.

Record functional check on PMS Data Record —

‘AMX-3 Mobile Unit.

Carefully examine tube unitfor air bubbles. With port

up, look through X-ray window with the aid of a

flashlight, and gently rock tube unit either side of

horizontal. if an air bubble is observed, tube unit

must be removed and deaired following procedure

given in SM D1154A (Maxiray 75, HRT, ORN and

MMX Tube Units) before proceeding,

GENERAL ELECTRIC MEDICAL SYSTEMS

REV7 4 Indicates Change

ASECTION 3 — CASSETTE DRAWER REMOVAL

1. Lift out rubber bottom liner of cassette drawer.

2. Remove drawer as follows:

a. For drawer mounting with hinges (new method):

Loosen (2) siotted head screws, one in each front

‘comer of drawer (do not remove screws com-

pletely, loosen just enough to clear the pivot

pins). See Figure 3-34.

Lut drawer and pull it out from bottom to dis-

engage fom pivot shafts. Set aside drawer for

later reinstallation. (Do not remove carriage

bots.)

b. For drawer mounting with pivot blocks (old

method):

Loosen (4) screws, two in each front bottom

‘comer of drawer. Lift hinge retainers and slide

AMX.3 X-RAY UNIT

‘SM A0654F-O

each pivot block toward center of drawer to

disengage the pivot. See Figure 3-3B.

Remove drawer and set aside for later reinstal-

lation.

NOTE: Do not lose the spacers for each pivot

shaft.

3, Remove (3) 10-32 UNF BHMS on top skirt of kick

panel and (2) 10-32 UNF BHMS, one at each support

for the rear casters. Remove the kick panel.

4. Remove the battery retainer plate. Itis secured by (4)

10-32 UNF BHMS to the two side frame members.

Set aside with its hardware for later reinstallation.

5. Pry off the cover over the 8 panel. The cover is held

with (4) friction fasteners. Use a padded screwdriver

‘80 as not to mar the finish

HOLES FOR

(CARRIAGE BOLTS:

‘THREADED HOLE FOR

‘SLOTTED HEAD SCREW

p.

| NN Mince

PIVOT PIN 9067-021

DRAWER MOUNTING WITH HINGES (NEW METHOD)

FIGURE $-3A,

HINGE RETAINER —_NYLOK SCREWS CASSETTE DRAWER

46-104851P1 (46-208560P88)

FITS DOWN IN

‘SLOT WHEN

INSTALLED

‘SPACER

46-173511P1

(TYPICAL 2 PLACES)

PIVOT BLOCK 4618567701 |

(TYPICAL 2 PLACES)

NYLOK INSERT pwvor

21586-012

SHAFT

DRAWER MOUNTING WITH PIVOT BLOCKS (OLD METHOD)

FIGURE 3-38

39 Copyright © 1988 by General Electric Co.

GENERAL ELECTRIC MEDICAL SYSTEMS

REV8

SECTION 4— BATTERY INSTALLATION

WARNING: CHARGED BATTERIES: REVIEW THE

‘SAFETY PRECAUTIONS OF SECTION 1-3. REMOVE

RINGS, WATCHES, AND METALLIC OBJECTS

FROM POCKETS. WEAR SAFETY GOGGLES.

NOTE: This procedure assumes that the battery has

been precharged at the district office and electrolyte

level adjusted prior to the AMX installation. Ifthe battery

equires charging, it should be done using the proce-

dure in Chapter 3, Section 6, “Battery Charger.”

1. Unpack the battery cell groups from their transport

containers and set in front of the AMX unit. If vent

‘cap wrench is furnished with each cell group, save

the wrenches as they will be required for servicing

the battery.

2. Check that the main power circuit breaker on the

‘AMX (6CB1) is OFF. Locate the two No. 6 AWG x6”

(152.4 mm) black leads and the four 46-154021P1

7-3/4" x 16-3/4" (220 mm x 413 mm) red insulator

boards fumished with the AMX.

3. Fold back the mylar cover over the battery compart-

ment. Check that the loose insulating boards are

correctly positioned in the battery compartment and

that the primary leads are clear of the compartment.

. Cut six 1-1/2" x 3" (38.1 mm x 76.2 mm) strips of

insulation paper. Bend in hatf and wedge between

the first and second as well as last and second last

call in each group as shown in Figure 3-4. This will

Prevent damage to battery if a washer or screw

slips on connection of battery leads.

T 2ree010

FIGURE 3-4

Copyright® 1985, 1986 by General Elestie Co. 3-10

AMX-3 X-RAY UNIT

‘SM A0654F

5. Slide one 30-cell group in the right side of the bat-

tery compartment. Slide it tight against the right-

hand wall of the compartment to hold the insulator

board in place. Do not push it all the way in. Con-

rect the lead out of the top main circuit breaker that

islabeled (+) to the right front comer terminal of the

ccell group.

6. Siide another 30-cell group into the left side of the

battery compartment. Do not push it all the way in.

Connect the lead on the side of the main power

Circuit breaker that is labeled () to the front left

‘comer terminal of the cell group.

Side the remaining 30-cell group into the center of

the battery compartment. nserttwo 7-3/4" x 16-1/4"

(220 mm x 413 mm) red insulator boards (fur-

niished) between the right and center and two

others between the left and center cell groups.

‘These are to prevent the battery from sliding

around. See Figure 3-5.

(7-6 x 16-118

(220MM x 413 MM)

ED INSULATOR BOARDS

zie P10

FIGURE 35

8. Two No. 6 AWG leads 6” (152.4 mm) long are

furnished. Use them to interconnect the left, right,

and center battery packs. See Figure 3-5.

9. The battery terminals have flat sided washers as

part of the terminal hardware. Refer to Figure 3-4.

‘The flat side serves as a visual indicator during

torqueing. During initial screw engagement the

washerrotates and, upon tightening, rotation stops.

This indicates that the screw is tightened in the

GENERAL ELECTRIC MEDICAL SYSTEMS. AMX-3 X-RAY UNIT

REV9 >» Indicates Change SM AQ6S4F

terminal and not binding or bottoming when

proper torque is reached. Tighten all six ter-

minals to 30 to 35 in.-Ibs, (3.39 to 3.95 Nm)

torque for Marathon, or 44 in.-lbs. (4.97 Nm)

torque for GE. Push Temflex sleeving over

solderless terminal lug.

10. Place the mylar cover over the battery compart-

ment and reinstall the battery retainer plate.

GENERAL ELECTRIC MEDICAL SYSTEMS

REV.

‘SECTION 5— PRELIMINARY GENERATOR CHECK

WARNING: ON AMX-3 UNITS, ITIS NECESSARY TO

REMOVE THE X-RAY CONTROL COVER FOR X-

RAY UNIT INSTALLATION AND ADJUSTMENT.

WITH X-RAY CONTROL COVER REMOVED, EX-

TREME CAUTION SHOULD BE EXERCISED TO

PREVENT THE POSSIBILITY OF ELECTRICAL

‘SHOCK.

1. Tum main circuit breaker and keyswitch OFF.

2. Remove x-ray control cover. To gain access to the

six screws retaining the cover, the front and rear

covers must be removed first. Leave cover off for the

remainder off the electrical tests.

3. With main circuit breaker and keyswitch still off,

check to see that all circuit cards are firmly in place.

Check that all edge and pin connectors are tight.

‘Check connectors on SA1 board and check thatallIC

chips are plugged in firmly,

Copyright® 1985, 1985 by General Bectie Co,

312

AMX-3 X-RAY UNIT

‘SM A0654F

GENERAL ELECTRIC MEDICAL SYSTEMS

REVS.

SECTION 6 - BATTERY CHARGER

Charge battery and check cutoff setting as follows:

1. Plug charger cord into convenience outlet.

2. Turn circuit breaker to ON and keyswitch to

CHARGE. Charge light should come ON and

blower should run.

3. Check that motor drive system is disabled and

that x-ray control will not go into READY

condition when Rotor button is pressed.

4, Monitor battery voltage by connecting a DVM

(200VDC scale) to 3781-27 (+) and 3TB1-5{ -).

NOTE: This procedure may involve a long wait

between steps 4 and 5. Since the step 5 procedure

can be performed at any point in the installation,

save step 5 until just before lunch, or while filling in

forms for HHS reporting. However, you must

observe step 6 before continuing x-ray unit installa-

tion and adjustment

3.13,

AMX-3 X-RAY UNIT

‘SM AO6S4F

5. After charge complete indicator lights, check

4A1R30 setting as follows:

a. Turn keyswitch OFF and wait for battery

voltage to drop below 130 volts.

b. Turn keyswitch to CHARGE and note

voltage when Charge Complete indicator

lights.

«. Charge Complete indicator should light

between 131 and 132 volts. If not, re-adjust

4A1R30 per Chapter 6, Section 2, and

recheck.

d. Observe step 6 before continuing x-ray unit

installation and adjustment

For generator check-out and calibration, the

battery should have a terminal voltage of at

least 112 volts, and no more than 1 20 volts. If

the status panel indicates Recharge Im-

mediately during the installation procedure,

charge the battery for approximately one hour

before continuing.

Copyright © 1985, 1986 by General Electric Co

GENERAL ELECTRIC MEDICAL SYSTEMS

AMX-3 X-RAY UNIT

REV8

4 indicates Change

‘SECTION 7 — HV TRANSFORMER AND FILAMENT

CHECK

‘The HV transformer has been shipped installed. The oil

level has been checked and a cork gasket used to seal

the unit for shipment.

1. If there is evidence that the transformer has leaked

ol, it wll have to be removed from the unit in order to

locate and repair the leak and to reset the oil level.

Refer to Section 18, Chapter 6 for removal proce-

dure.

2. Remove the terminal cover over the HV transformer

primary leads. tis mounted with (4) No. 10-32 UNC x

1/2" BHMS. Set the cover and hardware aside for

later installation

3. Remove the threaded cover cap from the oil filler

hole. Do not attempt to remove the inner cover.

Discard the cork gasket located inside the cover cap

and reinstall the cover cap. Tighten the cover cap

ntl itis finger tight and then back off 1/4 tum, This

will allow the transformer to breathe as the oil

expands and contracts. See Figure 3-6.

COVER CAP

‘CORK GASKET

(DISCARD)

INNER PLUG

(00 NOT REMOVE)

2eeD10

FIGURE 3-6

4. If oil seepage around the cover becomes evident

during use, refer to Section 18 of Chapter 6 to check

the oil level

5-1 X-ray Tube Filament and Stator Check for

Intemational Units Only

44. Disconnect the leads to 7P1 and 7P2 and tape.

2. Tum main circuit breaker and keyswitch ON.

Copyright® 1985, 1986 by General Electic Co,

‘SM A0654F

3. Depress the handswitch Rotor button while looking

into the X-ray tube window. Only the small lament is,

connected. The large filament is not used in this unit.

If the filament does not glow, check for improper

filament circuit or HV cable connection. The small

filament is the one to the left when viewed from the

anode end through the X-ray window (see Fig-

ure 3-7).

2199410

FIGURE $7

4. Again depress the handswitch Rotor button while

looking into the X-ray tube window. The X-ray tube

anode should accelerate to a stable speed within the

2-1/2 second interval before the READY light glows.

If rotation does not occur, check for improper con-

nection of the stator cable.

5. Release the Rotor button. The anode should coast

for at least 10 seconds before stopping. If not, the

bearings in the X-ray tube are likely to seize and the

tube should be replaced.

6. With the operator's panel open, again depress the

Rotor button. Note that, after 2-1/2 seconds, the

READY indicator lights and that the neon bulb on the

3A1 board (81DS34) lights during the 2-1/2 second

interval. This indicates that the shutoff capacitor for

the 800 Hz inverter switch is charged.

7. Tum main circuit breaker and keyswitch OFF. Install

collimtor per instructions given in Section 22 of

Chapter 6.

Reconnect transformer primary leads at 7P1 and

7P2. Install cover over primary leads on transformer.

a8.

344

GENERAL ELECTRIC MEDICAL SYSTEMS

REV 8

A Indicates Change

4 SECTION 8—FILAMENT AND ROTOR INTERLOCKS

(FUNCTIONAL CHECK)

4. Tum main circuit breaker and keyswitch on.

2, Press Rotor button and verify:

© Ready lamp is it.

* Rotor is accelerating (listen for characteristic

sound).

3. Record on PMS Data Record — AMX-3 Mobile Unit.

a5

AMX-3 X-RAY UNIT

‘SM A0854F

Copyright © 1986 by General Electric Co.

GENERAL ELECTRIC MEDICAL SYSTEMS

REV 8

‘SECTION 9 — CONNECT HV DIVIDER

1. Check that the main circuit breaker and keyswitch

are OFF.

2. Position the tube unit, port up, with the horizontal

column about 2 feet (.6 m) off the floor.

3. Remove the cathode HV cable from the tube unit. If

Necessary, remove the last cable tie around the

cathode HV cable, stator cable, and collimator cable.

4, Connect the unit HV cables to the HV divider and

tube unit. Use transformer oil in the cable recep-

tacles of the HV divider and silicone insulating com-

pound, G635, at the tube unit. Apply silicone com-

pound per Direction 13877. Install rubber gasket at

each HV cable connection

AMX-3 X-RAY UNIT

‘SM A0654F

IMPORTANT!

HV cables from the AMX-3 unit to the HV divider

must be 10 feetiong. The cables from the divider to.

the tube unit must be 5 feet ong. The cable used to

Connect the scope tothe divider must be a 17.5 foot

Belden Type 8422 shielded coax cable. Calibra-

tion cannot be done without these cables. See Fig-

ure 3-11.

Close collimator blades and tape a sheet of 1/8

(8.175 mm) iead over collimator window. Cover tube

unit (primarily cathode end) with a lead apron or

place lead screens for additional radiation protec-

tion.

cover wir

118" (3.175 MM)

LEAD & CLOSE

COLLIMATOR

BLADED ~~

30 FT. (9M)

HV CABLE,

HV TRANSFORMER,

MODEL 46-10485761

X10 PROBES WITH. 175 FT. BELDEN 18738012

GROUNDED SHIELDS. ‘TYPE 8422 CABLE

cay

cH2

(GROUND AMX AND

‘SCOPE THROUGH

POWER CORD

‘TEKTRONIX 422 OR

‘564 OSCILLOSCOPE

(QUAL TRACE WITH

ALGEBRAIC ADDITION)

(OBSERVE SCOPE FROM

LEAD SHIELDED AREA

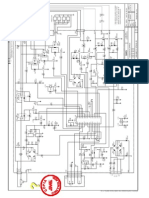

FIGURE 3-11

Copyright® 1985, 1986 by General Etoctic Co, 316

GENERAL ELECTRIC MEDICAL SYSTEMS.

REVS

4 Indicates Change

SECTION 10 — mA STABILIZER AND kV ADJUST-

MENT

‘410-1 mA Stabilizer Adjustment

The filament and mA regulator circuits were initially

adjusted during factory test. Readjustment at installa-

tion may be required because of tolerance variations

between batteries.

‘¢ Turn keyswitch and circuit breaker OFF.

© Shield tube unit and block X-ray port.

© Connect HV divider per Section 9.

‘© Open X-ray control panel

(See Figure 3-12A for pot and test point locations.)

NOTE: Battery indicator lights must be operating prop-

ery.

1. Tum circuit breaker and keyswitch to ON.

2. Check that Recharge Immediately ight is not on.

3. Select 50 kVp and 10 mAs. Take an exposure and

observe that sonalert tone and “X-ray ON" indi-

cator on status panel are on during exposure.

4. Select 80 kVp, 200 mAs.

8, Remove jumper from 3TB1-mA+ and mA—. Con-

ect DC-mA meter (0-150 mA, 1/2% accuracy)

between mA+ and mA~ to measure tube current.

46. Take an exposure and read the mA meter. If mA is

not 100 +42.0 mA, adjust 3A2R112 to obtain this

value.

NOTE: Do not take more than one exposure per

minute to stay within tube ratings.

317

AMX-3 X-RAY UNIT

‘SM A0654F

‘410-2 Battery Load Voltage Check

1. Tum circuit breaker and keyswitch ON.

2. Make an exposure at 80 kVp, 200 mAs, and note

battery voltage drop between standby, stator load,

and X-ray load.

3. Voltage drop from standby to stator load should be

typically 3V and from standby to X-ray load up to

24 volts. I'voltage dropis in excess of 24 volts, heck

tightness of primary terminal and connections to bat-

tery. I necessary, check each cell group voltage

under X-ray load to locate and correct cause of

excessive voltage drop.

4. Make a series of exposures at 10 mAs from 80 to

125 kVp. Observe scope waveform for signs of

arcing or transients.

5. Tum keyswitch and circuit breaker OFF. Do not dis

connect any test equipment.

Copyright) 1985, 1986 by General Electic Co.

AMX-3 X-RAY UNIT

GENERAL ELECTRIC MEDICAL SYSTEMS

‘SM A0654F

REVS.

H) | FRebes ee? we

DOO :

OOO"

Y lees ee ae

Be ae

i Pagers eee

yr af ats

-f

yp a} Lrlowamas?F0

T -F—<] 8 P2anacog

HO nnoe teu ome™ 3 7 seczosere 0}

snasonmmuaout

FIGURE 3-128

(OVERSHOOT (INCREASE FL. ORSP.CHG.)

“a a TURN-OFF SPIKE (MAY BE PRESENT)

}ERSHOOT (DECREASE FLOR SP.CHG)

lL 30Ms A 20ms a

FILAMENT AND SPACE CHARGE ADJUSTMENT

FIGURE 3-128

Copyright® 1986 by General Electric Co

GENERAL ELECTRIC MEDICAL SYSTEMS

REV8. ‘SM A06S4F

4A Indicates Change

AMX-3 X-RAY UNIT

‘410-3 kV Adjustment 4, a. Final kVp. Take exposures at .64, 10 and 100

mAs at 50, 80 and 125 kVp each. Record kVp

1. Using 80 kVp and 10 mAs adjust 3A2R114, if neces- values on Form F3382. Measured kVp values

sary, for lat waveform during first 30 ms of exposure.

Rotate 3A2R114 clockwise to reduce overshoot.

‘See Figure 3-12B. Define “flat” as follows: The kVp

during the first 30 miliseconds of the exposure shall

be within +42 kVp of the value during the second 30

miliseconds of the exposure. ignore the first three

Pulses.

2. Select 80 kVp, 10 mAs. Take an exposure and ob-

serve kVp waveform on scope. Measure kVp be-

tween 30 and 60 ms after exposure start. Select

‘switch positions on 5A1SW147 for 80 kVp per chart

below, if necessary. (Adjust switch positions if not

within +42 kVp of 80 kVp.)

cnn STA SUB

AB

0 cenad Ces

+2kVp Open ‘Closed eS

oer Se. Se | + OO00

ee ee! Sn

‘swia7

8. Select 50 kVp, 10 mAs. Take exposure and observe

waveform. (See Fig. 3-13.) Select 120 kVp, 10 mAs.

‘Take exposure and compare waveform to previous

exposure. it necessary, adjust 3A2R1 13 for the best

waveform for both 50 kVp and 120 kVp. Both wave~

forms should be flat during the first 30 ms of expo-

sure. Rotate SA2R113 counterclockwise to reduce

over-shoot.

319

should be 47 to 53 kVp for 50 kVp selection, 74 to

186 kVp for 80 kVp selection and 116 to 134 kVp

for 125 kVp selection.

9. f these values cannot be met, try changing the

kVp slope. Refer to schematic page 7-5, locations

E7 and H7. Taps 7B and 9B were factory con-

nected. To lower slope, reconnect to 7A and 9A.

To increase slope, reconnect to 7C and 9C.

‘These are the only allowable combinations. (Do

ot use 7A with 9B or 9C, or 7B with 9A or SC, or

7C with 9A or 9B.)

. If these values stil cannot be met. postpone in-

stallation until adjustments andlor repairs have

been made to satisfy these limits.

Copyright © 1985, 1986 by General Electnc Co

GENERAL ELECTRIC_MEDICAL SYSTEMS AMX-3 X-RAY UNIT

REV 8 ‘SM AOSS4F

10 mAs 125 kVp

10mAS 80 KVp

1OmAs 50KVp

| 64 mAs 125 kVp

E ‘SA mAs. 80 KV

164 mAs 50 kV

ee

134257710

KVP WAVEFORMS

FIGURE 3:13,

Copyright © 1986 by General Electic Co 3-20

GENERAL ELECTRIC MEDICAL SYSTEMS.

AMX-3 X-RAY UNIT

REV8

‘SECTION 11 — BACKUP TIMER CHECK

1. Temporarily disconnect the mAs selector lead at

‘STB1-21 and tape the lead.

2. Tum circuit breaker and keyswitch ON.

8. Select 50 kVp, 50 mAs, and take an exposure.

Measure exposure duration on scope kVp wave-

form.

get

‘SM AD654F

1. Exposure should be terminated within 3,2-3.9 sec-

‘onds by backup time delay relay 3K3.

5. Tum keyswitch and circuit breaker OFF. Reconnect

mAs switch lead to 3TB1-21.

. Record data.

a. F3982 HHS Test No. 3-2.

b. PMS Data Record — AMX-3 Mobile Unit

Copyright © 1986 by General Electric Co.

GENERAL ELECTRIC MEDICAL SYSTEMS

AMX-3 X-RAY UNIT

REVS

‘4 Indicates Change

‘SECTION 12 — mAs AND LOAD CHECKS

Remove HV divider and reinstall 10° cables.

12:1 mAs Integrator Calibration and Operation

Instructions

NOTE: The new mAs integrator board 46-226598G1 is

required for this procedure. (Do NOT use the old mAs

integrator board 46-214344G1.)

1. Remove 342 (Filament and mA regulator board) and

replace with mAs Integrator Board (on extender

card),

NOTE: Do not install 3A2 board at this time.

‘A. Connect scope probes to TP18 (+) and TP8

(GND).

. Select 1.0 msecidiv time base.

CC. Press rotor and verify that a 300 Hz square wave

(time between 3.328 msec and 3.334 msec) is

present at TP18.

‘¢ Wavelorm should “stand still” on scope dis-

play if on a 60 Hz line.

‘« Three cycles of the waveform should fil 10

divisions exactly.

D. Adjust R105 as required.

E, Remove scope probes.

F. Attach Fluke meterbetween TP12(+) andTP11.

G. Press rotor switch and adjust R106 to obtain 6.04

= .01 VOC.

H, Release rotor.

Copyright 1985, 1986 by General Elect Co.

3-22

‘SM A0654F

. Set switch positions as follows:

‘SWITCH SwiTcH

$90-64- 6.4 $104 ~ Off

$91-Clear $110 ~ On

‘$92~Integrate S111 -On

DS 109-On

‘A. Short TP7 to TPS.

B. Connect DVM to TP4 (+) and TPS (GND).

C. Press and hold rotor switch, adjust R75 (Null

offset) to 0.000 VDC + .5 mV DC.

D. Connect DVM to TP9 (+) and TPS (GND).

NOTE: TP7 and TP6 must remain shorted.

E. Press and hold rotor switch.

F. Verify that when $108 (reset) is pressed, a

reading of 0.000 VDC = .5 mV DCis obtained.

G. Release $108 and rotor switch.

H. Verify that a reading of 0.000 VOC + 5 MDVCis

obtained. Adjust RSS if necessary.

|, Remove jumper from TP7 and TP6.

. Set switch positions as follows:

‘SWITCH SWITCH

$90-64-6.4 8104 ~ Off

$91--See below $110 ~ On

$92--CAL S111 ~On

Ds 109-Off $108 ~- See below

Attach DVM from TP9 (+) to TP8 (GND).

NOTE: The following steps must occur in the

order listed for proper results to be obtained,

Press rotor.

. Set $91 to clear.

. Press S108 (reset) for 3 seconds and release.

ioe

Set $91 to test.

GENERAL ELECTRIC MEDICAL SYSTEMS AMX-3 X-RAY UNIT

Reve ‘SM A0654F

F. Verity that voltage at TP9 reads .600 VDC + .006 —_7. Set switch positions as follows:

vec: swiTcH SWITCH

G. Adjust F107 i necessary and repeat steps A 90-8320 $104~ On

through F until correct voltage is obtained: Re- S91~See below $110 ~ On

eee $92-Cal Sit - off

DS 109-O8F $108 See Below

5. Set switch posttions as folows: mipe

SWITCH switch B. Set S91 to clear.

‘390-64 - 6.4 $104 On

sotesiees sce on C. Press $108 (reset) for 3 seconds and release.

$92--Cal Sit1~On Breet

DS 109-OfF S108 ~ See Below Sout

E, Verity that vottage at TP@ reads .66 VDC =

.01 Vb.

‘A. Attach DVM from TP9 (+) to TP8 (GND).

B, Press rotor. fb aes

©. Set S91 to clear. veneers 8 Seed

D. Press $108 (reset) for 3 seconds and release. * fee ee

388

E, Set $91 to test. 6 Bee

F. Verify that voltage at TP9 reads 6.60 VDC = SS See

01 De. ie

3

6. Set switch positions as follows:

SWITCH ‘SWITCH

‘$90-6-64 ‘$104 — On,

'$91~-See below $110 ~ Off

$92--Cal 8111 On

DS 109--Off $108~ See Below

Press rotor.

Set $91 to clear.

. Press S108 (reset) for 3 seconds.

. Set $91 to test.

mo 9 @ >

Verify that voltage at TP9 reads .66 VDC +

01 VDC.

FIGURE 3-14

3:23 Copyright® 1985, 1986 by General Electric Co.

GENERAL ELECTRIC MEDICAL SYSTEMS

AMX-3 X-RAY UNIT

REVS

44 indicates Change

mAs Integrator Operation

1. Plug the 342 board into the calibrated mAs integra-

tor, Switch $92 to the integrate (INT) position. Post

tion “mAs RANGE” switch such that desired riAs is

within that range. Attach a DVM to integrator output

TP8 (—) and TP9 (+). Depress the rotor switch and

ero outputby pushing reset switch (S108). Take an

X-ray exposure and read mAs output on DVM

‘according to Table 3-1A. The rotor switch must be

depressed in order to maintain value. Take mAs

readings within 10 seconds of exposure termination.

CAUTION: Allow 1 minute between exposures

for tube rotor to cool.

TABLE 314

mAs Range Scale Factor

£454 1Vimas

86+ O.1VimAs:

80-320 O.01VimAS

Examples: On the 8-64 mAs scale, an output of

0.80 volt corresponds to 8.0 mAs. On the 80-320

mAs scale, an output of 3.20 volts corresponds to

320 mAs.

412-2 Final mAs and Load Checks

‘* Tum keyswitch and circuit breaker OFF.

‘¢ Shield tube unit and block X-ray port.

‘* Insert calibrated mAs integrator board in series with

the 3A2 board per Section 12-1

1. Tum circuit breaker and keyswitch ON.

2. Connect scope leads to mAs integrator (+) to TP7

(mA+) and (—) to TP6 (mA~) or remove jumper from

‘STB1-mA+ to 3TB1-mA~, connect a 100 resistor

between STB1-mA+ and mA~ and connect scope

‘across this resistor. This voltage waveform will be

representative of the mA waveform. Use scope set-

tings of 1 voltidiv if using the mAs integrator connec-

tions and 2 volts/div if using the 3TB1 connections

with the 100 © resistor.

Copyright® 1985, 1986 by General Electr Co,

3:24

‘SM AD6S4F

Select 80 kVp, 10 mAs. Take an exposure and, if

necessary, adjust 3A2R114 fora fat waveform dur-

ing the first 30 ms of exposure. This yields a flat mA

and kVp response.

Select 80 kVp, 100 mAs. Make an exposure, and

vetify that actual mAs is between 97 and 103 mAs.

Adjust 3A1R7 if necessary.

Select 80 kVp, 10 mAs. Make an exposure, and

verify that actual mAs is between 9.5 and 10.5 mAs.

If tisn't, something is defective, and should be re-

paired before continuing.

Select 80 kVp, .64 mAs. Make an exposure and

‘observe kVp waveform. The mAs meter should read

.58 to .70 MAS. Check mAs at 50, 80 and 120 kVp,

recording mAs values on Form F3382. “Observe

waveform for each exposure, andi necessary, adjust

‘3A1R9 to yield a consistent number of pulses for all 3

waveforms. Tolerance of mAs must be per Table

3B.

. Take exposures at 50, 80 and 120kVp, at 10 and 100

mAs each. Record mAs values on F3382. Toler-

ances of mAs values shall be per Table 3-1B.

TABLE 318

‘mAs | Min.mAs | Max mAs

kp Selection | Allowed | Allowed

50 4 5 73

80 84 55 73

110 4 35 73

50 10 90 11.0

80 10 35 105

110 10 90 11.0

50 100 4 106

80 100 7 103

110 100 94 106

. Tum Keyswitch and main circuit breaker OFF.

. Remove mAs integrator board. Reinstall 3A2 board,

CAUTION: Some resistors on the 3A2 board may

be hot.

If the 100 ohm resistor was used in Step 2 above,

remove the resistor and replace the jumper between

3TBI-mA+ and mA~

GENERAL ELECTRIC MEDICAL SYSTEMS

AMX-3 X-RAY UNIT

REVS

SECTION 13 — MODIFICATIONS

Record collimator information on F3382 Test 6-1-4 at

this time. :

131 Collimator Functional Checks and Modifica-

tions

1. Ifinstallation requires metric field size scale, perform

the scale label modifications per Chapter 6, Sec-

tion 23-1.

‘The field light timer is factory set for 15 to 20 sec-

nds. f the user requests.a shorter time setting, refer

‘SM AD654F

to Adjustment Procedure per Chapter 6, Sec-

tion 23-2,

13-2. Canadian Warning Label

The warning label located at the bottom of the operator's.

control pane! must be replaced for Canadian units.

‘A waming label (46-212949P1) written in French has

been supplied with Canadian units.

Locate this label and use it to replace the existing

‘warning by removing the backing of the French label

and sticking this label over the existing waming.

Copyright @ 1965 by Genera Electric Co

GENERAL ELECTRIC MEDICAL SYSTEMS.

REV7

4 Indicates Change

SECTION 14 — COLLIMATOR CHECKS

General

‘The collimator blade and shutter assemblies have been

factory aligned. The following adjustments, however,

should be checked and readjusted if necessary.

NOTE: The mirror should NEVER be moved.

4141 Cross Hair Position Check and Adjustment

This does not normally need to be checked, but if

service is required, see Section 29 of Chapter 6.

142 Extension Cylinder (Optional Accessory)

Alignment Check

1. Slide the extension cylinder into the tracks at the

bottom of the collimator until the cylinder latch snaps

into the slot on the right-hand track.

Darken the room and energize the field light. The

illuminated area on the cassette should show equal

sectors of light on either side of the cross hair

shadows. See Figure 3-15.

FIGURE 9-15

22004020

Copyright © 1985 by General Electric Co,

3-26

AMX-3 X-RAY UNIT

‘SM A0654F-O

3. If adjustment is necessary, proceed as follows:

‘a. Loosen the eight cone track screws.

. Shift and/or shim the tracks as necessary.

cc. Retighten the screws.

. Recheck the alignment.

4. Remove the extension cylinder by pressing the latch,

WARNING: SOME OF THE FOLLOWING PROCE-

DURES REQUIRE THAT RADIOGRAPHS BE

‘TAKEN. OBSERVE RADIATION SAFETY RULES. A

LEAD PROTECTIVE SCREEN, LEAD APRON UNIT,

OR OTHER PROTECTIVE MEDIUM SHOULD BE

USED.

GENERAL ELECTRIC MEDICAL SYSTEMS

AMX-3 X-RAY UNIT

REV7

14-3 Large Field Size Check

1

Position a loaded 14” x 17” (95.5 om x 43.2 cm)

cassette under the colimator (17" (43.2 cm) dimen-

sion transverse to the axis of the tube unit). Using the

collimator measuring tape, set the source-to-image

distance at 40° (1.016 m).

. Adjust the blades to yield a field size of 14” x 17”

(85.5 om x 43.2 cm). Place a coin on the cassette to

identify the anode front comer of the X-ray field. See

Figure 3-16.

anone| |caTHone |

FIGURE 3.16

3. Make a 50 kVp, 1 mAs exposure and develop the

film,

4. If cutoff in the transverse direction is observed, lead

finger spacing of the collimator should be checked.

3-27

‘SM AD654F-O

Copyright © 1985 by General Electric Co

GENERAL ELECTRIC MEDICAL SYSTEMS

AMX-3 X-RAY UNIT

REV 8

14-4 Field Lamp Voltage Check

To meet HHS requirements, the voltage at the coll-

‘ator lamp socket must be at least 19.6VAG (RMS) at a

‘minimum battery voltage of 140VDC. This is an indirect

test of ilumination level.

1. Remove the blade control knobs and the collimator

front nameplate. See Figure 3-17.

‘SM AOBS4F

TABLE 92

Win, Colimator Lamp Volage

Notoed | ‘easured wit Beckman 3000 RMS

Bat. Vott or Fluke 80304,

128 228

126 226

124 23

122 220

120 217

118 213

116 209

14 205

42 20.1

+10 196

OO

FIGURE 3-17

a. Loosen two 6-32 UNC x 1/4" hex socket set

screws at the top front of the collimator frame.

. Tilt the nameplate forward enough to clear the

knob shafts and lift out,

2. Tum circuit breaker and keyswitch ON. Measure and

record no-load battery voltage using the digital vol-

meter, Beckman 3030 RMS or Fluke 8030A, across

3TB1-19 (+) and STB1-5 (—).

3. Tum circuit breaker and keyswitch OFF. Disconnect

digital voltmeter from 3181-19 and 3TB1-5. Turn

Circuit breaker and keyswitch ON.

4. With the field ight energized, measure and record

the voltage across the lamp socket terminals using

the digital voltmeter.

5. Compare no-load battery voltage with collimator

lamp voltage. To provide required illumination, lamp

voltage must be no less than value listed in Table

3-2. Too high a vottage will reduce lamp life.

Copyright®) 1985, 1988 by General Electric Co,

6. If necessary, shift secondary taps on 8TS1 to pro-

Vide required collimator lamp voltage. Carefully pry

cover over the 8 panel

‘The secondary of 811 is factory connected. A shift to

an adjacent tap will change lamp voltage by approxi-

mately 0.5V RMS. Select the lowest voltage tap of

8T1 that provides at least the minimum voltage re-

quired BUT NOT MORE THAN 1V OVER.

7. Replace nameplate and knobs after verifying that the

collimator lamp is operating in a proper voltage

range.

‘8. Record collimator lamp voltage and battery voltage

on F3382, Test Set 6-3.

21276.040

FIGURE 2:18

3-28

GENERAL ELECTRIC MEDICAL SYSTEMS

REV9 > Indicates Change

SECTION 15 — COLLIMATOR BEAM ALIGNMENT

CHECKS

‘To meet HHS requirements:

Perform by using one of the following two methods:

>

Method 1 — (Section 15-1) is preferred if the “Light

Field to X-Ray Field Test Pattern”, 46-198466P1,

from a newer 46-177372G1 kit is available (46-

198466P1 can also be ordered separately from PRO,

by number 46-194427P209.

Method 2 ~ (Section 15-2) with RAT kit assembly

must be used if the “Light Field to X-Ray Field Test

Pattern” is not available,

151 Method 1— With “Light Field to X-ray Field

Test Pattern” (Preferred)

1. The total misalignment of the edges of the ight field

with the respective edges of the X-ray field along

either the length or width shall not exceed 1.8% of

SID when the field is perpendicular to the X-ray

beam

2, Field size indicators of length and width on colimator

shall each agree with actual X-ray field size at the

receptor to within 1.8% of SID when beam axis is

perpendicular to the plane of the fim.

‘¢ Tum main power circuit breaker ON.

Tum X-ray generator keyswitch ON.

« Retract charger cord.

1. Load a 14” x 17" (95.5 om x 43.2 om) cassette and

place on floor. Place the “Light Field to X-ray Field

Test Pattern”, 46-198466P1, centered on the

cassette. Position tube unit and collimator for a

vertical Xray beam at a SID of 40" (1.016 m). Use

colimator light to carefully center X-ray beam per-

pencicularly on cassette and test patter.

sio

arr

| 1.016 mi3.83 m

om |

AMX-3 X-RAY UNIT

‘SM A0654F

NOTE: The measuring tape buit into the collimator

housing is used to measure source-to-image distance

{SID). The correct SID is indicated by having the bottom

Of the colimator housing even with the marking on the

tape which corresponds to the desired source-to-image

distance. For accurate measurements, have the tape

tab on the end of the tape straight down, not perpendic-

ular to the tape,

2. Carefully adjust collimator field indicators to 8" x 10”

(20.3 cm x 25.4 om).

3. Using collimator light, note and record where edges

of light field appear on test pattern.

—

oun 320

rest

text rn Pare

estuzason Gurus

arena.

gAACEMENTS

¥ L

¥

¥

r T

votre L JE

oatacevents somo

FIGURE 921

3-29

GENERAL ELECTRIC MEDICAL SYSTEMS

Revs

4, Expose and develop film (recommend 4 mAs at 50

kVp for par speed film with medium screens at 40°

(1.016 m) and 16 mAs at 72" (1.83 m).

5. Measure X-ray image length and width. Each must

agree withthe numerical indicator settings (Step 2)

within 1.8% of SID, .72" at 40° SID (18.3 mm at

1.016 m) or 1.9" at 72” SID (83 mm at 1.83 m),

6. Mark light field (Step 3) in relation to X-ray field on

film. Measure misalignment et each of the four

edges. Total misalignment of either the two length

oF two width edges must not exceed 1.8% of SID.

7. Repeat Steps 1 through 6 for a SID of 72" (1.83 m).

8. If edge-to-edge light field to X-ray field alignment

exceeds 1.8% of SID, adjust as follows:

‘a. Remove the blade control knobs and collimator

front nameplate.

FIGURE 3.22

Copyright®) 1985, 1986 by General Electr Co.

AMX.3 X-RAY UNIT

‘SM ADGS4F

b. With nameplate removed, temporarily reinstall

knobs and adjust field size to same setting as in

Step 2.

©. Slightly loosen the two light housing mounting

screws. See Figure 3-22.

4d. Shift ight housing so that light field aligns with

the test pattem of the X-ray field from Step 3.

€. Retighten the two light housing mounting

screws and replace the nameplate and control

knobs.

1. Repeat the alignment check from Step 6.

Ifthe indicated versus actual field size does not fll

within specifications, adjust the appropriate pointer

or pointers as follows:

‘@. Remove the blade control knobs and the name-

Plate.

b. Gently bend the pointer sideways to make the

necessary adjustment.

©. Replace the nameplate and the knobs.

4d. Repeat the alignment check from Step 5.

10. Record collimator beam alignment on F3382, Test

3-80

62-4,

GENERAL ELECTRIC MEDICAL SYSTEMS

REV7

15-2 Method 2— Using RAT Kit Assembly

1. The total misalignment of the edges of the light field

with the respective edges of the X-ray field along

either the length or width shall not exceed 1.8% of

‘SID when the field is perpendicular to the X-ray

beam.

2. Field size indicators of length and width on collimator

shall each agree with actual X-ray field size at the

receptor to within 1.8% of SID when beam axis is

perpendicular to the plane of the film.

‘¢ Tum main power circuit breaker ON.

‘¢ Tum X-ray generator keyswitch ON.

‘¢ Retract charger cord.

1. Load a 14” x 17" (35.5 om x 43.2 om) cassette and

place on floor. Position tube unit and collimator for a

vertical X-ray beam at a SID of 40" (1.016 m). Use

collimator ight to carefully center X-ray beam per-

pendicularly on cassette.

NOTE: The measuring tape built into the collimator

housing is used to measure source-to-image distance

(SID). The correct SID is indicated by having the bottom

Cf the collimator housing even with the marking on the

tape which corresponds to the desired source-to-image

distance. For accurate measurements, have the tape

tab on the end of the tape straight down, not perpendic-

ular to the tape.

siD

aire"

| 1.016 mit.83.m

\ oy

(04.8 Mm)

FIGURE 3-22

3-308

AMX-3 X-RAY UNIT

‘SM A0654F-O

2. Carefully adjust collimator field indicators to a com-

‘mon field site smaller than the cassette — use 12” x

12" (804.8 mm) for a 14” x 17" (35.5 om x 43.2 om)

cassette. Place acoin on the cassette in the anode~

front comer of the light field for reference.

3. Assemble and attach Receptor Alignment Too!

(RAT) to collimator using RAT holding fixture.

4, Using colimator light, note and record where edges

of light field appear on RAT grid pattern.

1 RAT

(A

FIGURE 3-228

2907-020

RAT

1417 FILM PATTERN

(955 0M x 43.2 OM) ‘ON FILM

\_/

_L

LATERAL

DISPLACEMENTS

¥

aH

T

¥

T

LIGHT FIELD: | hee | be

ee)

DISPLACEMENTS peo

FIGURE 3.220

Copyright © 1985 by General Electric Co,

GENERAL ELECTRIC MEDICAL SYSTEMS

REVS

5. Expose and develop film (recommend 4 mAs at

'50 kVp for par speed film with medium screens at

40" (1.016 m) and 16 mAs at 72" (1.83 m)).

6. Measure X-ray image length and width. Each'must

agree with the numerical indicator settings (Step 2)

within 1.8% of SID, .72" at 40° SID (18.3 mm at

1.016 m) or 1.3" at 72" SID (33 mm at 1.83 m).

7. Mark light field (Step 4) in relation to X-ray field on

film. Measure misalignment at each of the four

‘edges. Total misalignment of either the two length

‘or two width edges must not exceed 1.8% of SID.

8. Repeat Steps 1 through 7 for a SID of 72" (1.83 m).

9. If edge-to-edge light field to X-ray field alignment

exceeds 1.8% of SID, adjust as follows:

a. Remove the blade control knobs and collimator

front nameplate.

b. With nameplate removed, temporarily reinstall

knobs and adjust field size to same setting as in

Step 2.

cc. Slightly loosen the two light housing mounting

screws. See Figure 3-220.

FIGURE $220

Copyright® 1985, 1988 by General Electric Co,

10.

1

AMX-3 X-RAY UNIT

SM A0654F

. With RAT in holding fixture beneath colimator,

shift light housing so that light field aligns with

the grid pattem of the X-ray field from Step 4.

. Retighten the two light housing mounting

screws and replace the nameplate and control

knobs.

{, Repeat the alignment check from Step 7.

Ifthe indicated versus actual field size does not fall

within specifications, adjust the appropriate pointer

oF pointers as follows:

a. Remove the blade control knobs and the name-

plate.

b. Gently bend the pointer sideways to make the

necessary adjustment.

©. Replace the nameplate and the knobs.

4d. Repeat the alignment check from Step 6.

Record colimator beam alignment on F3382, Test

6-2-4,

GENERAL ELECTRIC MEDICAL SYSTEMS

AMX-3 X-RAY UNIT

REV8

‘SECTION 16— DIAGNOSTIC SOURCE ASSEMBLY

— INHERENT FILTRATION

‘To meet HHS requirements, the half-value layer of the

useful beam at 80 kVp shall be not less than 2.3 mm,

aluminum.

NOTE:

test must be performed on interational

units.

This test does not have to be done at installation

‘on domestic (U.S.) units (except for replace-

ment of tube unit, insert, collimator mirror, or

‘other absorption between source and patient).

‘The reason is that this check is performed be-

{fore shipment, and tube/collimator pairs are not

split thereatter for domestic units.

NOTE: Refer to Direction 13894, Section 2-4, "Radia-

tion Instruments” for specific information on diferent

types of instruments.

1. Position radiation probe of an integrating radiation

measuring instrument so that the center of the

‘active probe area is 12 inches (304.8 mm) from the

fend of the collimator and centered in the useful

beam. Collimate down to area of probe using light

beam.

Keep other equipment at least 4” (101.6 mm) away

from probe to prevent radiation scatter errors.

Remove the 1.0 and 2.0 mm selective filters from

collimator.

Use technic factors of 80 kVp, 20 to 48 mAs. The

mAs should be adjusted so that the reading in Step

4 is approximately 3/4 scale.

|. Make an exposure and measure radiation (total R)

with no added fiters. This represents 100% trans-

mission level. Record readings.

Place standard absorber 46-173632G1 in beam.

Absorber must be in collimator accessory rails.

Repeat exposure and record reading.

‘SM AD654F

6. Divide reading in Step 5 by reading in Step 4.

If ratios less than 0.5, then fixed fitrtion must

be added (mandatory).

. IH the ratiois above 0.87, the 1/4 or 1/8 mm fiers

may be removed. The X-ray beam to light field

will require adjusting after removing one or both

of these fiers

7. The 0.5 minimum ratio is mandatory. I fitration must

be adjusted, refer to Direction 13894, Test 4-1,

Beam Quality

8. Record data on F3382, Test 4-1

DIAGNOSTIC SOURCE ASSEMBLY

[STANDARD

resonoen FF T

PROBE }

FIGURE 3-23,

331 Copyright © 1996 by General Bectc Co.

GENERAL ELECTRIC MEDICAL SYSTEMS

5-2083

‘SECTON 17 — MOTOR DRIVE SYSTEM

‘¢ Tum main power circuit breaker ON.

¢ Tum X-ray generator keyswitch OFF.

‘¢ Disconnect charger cord.

17-1 Motor Drive Controls and Safety interlocks

1. Check speed control knob. The drive motor speed

control knob should rotate freely and spring return.

2. Place direction selector in FORWARD position.

Depress brake handle and advance speed control

knob. The siow speed should begin with some pre~

travel of the speed lever.

B. DIRECTION

SELECTOR

SWITCH

. DRIVE ASSIST

C, BRAKE HANOLE

AMX-3 X-RAY UNIT

‘SM A0654F

3. Check brake handle. The brake handle limit switch

should be actuated when the brake handle is de-

pressed within 3/8” (9.53 mm) of its bottom, brake

released, position.

4. Check front safety bumper. The bumper should de-

press completely without binding and spring return.

‘The drive power should be deenergized when the

bumper is depressed approximately 1/4 inch

(6.35 mm).

5. Tum circuit breaker OFF.

17-2 Motor Drive Calibration

Motor drive calibration depends on battery voltage. AS

battery voltage is lowered, the AMX drive speed will be

reduced. This adjustment is set at the factory and

should not need changing during installation. If adjust-

ment becomes necessary, refer to Chapter 6.

A. MAIN POWER,

SWITCH

s26s1-00t

. SPEED CONTROL

FIGURE 324

3-32

GENERAL ELECTRIC MEDICAL SYSTEMS

REVS

4 Indicates Change

‘4 SECTION 18 — REPRODUCIBILITY OF EXPOSURE

Follow the test procedure of Direction 13894, “System

‘Test for HHS,” Section 3-6, with the following three

modifications, and record results on F382:

1. Battery must be fully charged and in good condition.

2. Select 80 kVp, 10 mAs to get nominal 0.1 second,

exposure time.

3. Do not make any exposure prior to the Wait light

going out.

AMX-3 X-RAY UNIT

‘SM A0654F

SECTION 19 — RECHARGE BATTERY

Charge battery after completion of all prior sections or

any time the “Recharge Immediately” indicator is lit.

3.33 Copyright® 1985, 1986 by General Electric Co.

GENERAL ELECTRIC MEDICAL SYSTEMS

AMX-3 X-RAY UNIT

REVS

‘SECTION 20 — COMPLETING THE INSTALLATION.

20-1 Complete Paper Work

1. PMS Data Record — AMX-3 Mobile Unit

2. HHS Field Tests, F382.