Escolar Documentos

Profissional Documentos

Cultura Documentos

ABB Load Shedding CB

Enviado por

kalos stratiotesDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

ABB Load Shedding CB

Enviado por

kalos stratiotesDireitos autorais:

Formatos disponíveis

White paper - "Preliminary"

Emax 2, all-in-one innovation

Load Shedding

Emax 2

Load Shedding innovation

Index

Introduction....................................................................... 2

Emax 2, all-in-one innovation............................................ 3

Benefits............................................................................. 4

Service continuity .......................................................... 4

Space saving .................................................................. 6

Ease of use .................................................................... 8

How it works...................................................................... 9

Basic Load Shedding..................................................... 10

Operating principle..................................................... 11

Adaptive Load Shedding................................................ 12

Operating principle..................................................... 12

Ekip Connect 3.0 commissioning tool............................. 14

Application example of Adaptive Load Shedding.. .......... 20

Industry......................................................................... 20

Building......................................................................... 22

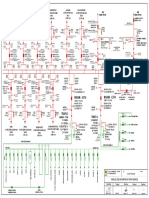

Electrical diagrams.......................................................... 24

Shopping List.................................................................. 28

ABB | Emax 2 - Load Shedding 1

Emax 2

Load Shedding innovation

Introduction

Power supply reliability is one of the main topic in all the market segments. Not only critical facilities like hospitals, banks or data centers,

but also ships, remote communities and industries are very sensitive to service continuity, since even one blackout means a long non-

productive time (NPT) with a consequent waste of productivity in their processes. Some cases are due to weak grids that are not able

to satisfy 24/7/365 continuous operation for overload or fault reasons. Other critical conditions are related to environmental contingenci-

es, like hurricane events or earthquakes that increase enormously the number of power outages.

Grid resiliency is the answer to this request in terms of electrical distribution reinforcement and generation safeguard. This means huge

investments for utilities and heavy modification of plant design for facility owners to get more reliability.

Microgrids are the next level approach in low voltage meshed networks which fully meet these expectations, using their capability to

define power absorption and to move from grid-connected to islanded operation mode quickly and without stress. On one hand, the

power demand definition is able to avoid overwork situations that can compromise the electrical stability. On the other hand, the bump-

less transition gives the chance for the plant to remain power supplied even off-grid, when the main grid is down.

Microgrids are the tangible result of the grid evolution, adding automation pillar in the energy distribution. This new network paradigm

cuts the investments necessary to improve the grid stability, ensuring savings for both utilities and end users. Based on this speed-up

concept, the low voltage distribution is continuously hunting for flexible solutions, able to reduce space in the switchgear for panel

builders and simply upgrade old pants using advanced solutions, which do not require a high engineering and customization effort for

consultants and system integrators. The electronic intelligence can now face all the challenges enabling software solutions to be prota-

gonist of the Microgrid control, giving flexibility for O&Ms manufacturer.

The circuit breaker becomes smart and able to protect the Microgrids under every conditions, ensuring service continuity, space savings

and ease of use.

2 Emax 2 - Load Shedding | ABB

Emax 2, all-in-one innovation

ABB Emax 2, the all-in-one smart circuit breaker, integrates innovative algorithms to safeguard the Microgrids and manage their

resources maximizing the efficiency. It embeds patented functions based on load shedding which reduces the Microgrid stress

in all situations.

Emax 2 is the main circuit breaker of the low voltage Microgrid located at the interface point with the medium voltage grid, able

to control the plant in every circumstances.

1) Microgrid in islanding operation

After the Emax 2 circuit breaker opening, because of interface protection systems intervention or external command, the Microgrid

should transit from on-grid to off-grid state with bumpless transition. When it is standalone, the power absorption from the main

grid ceases, so that the Microgrid loads remains supplied by the local generation, like diesel GenSet or energy storage systems.

This Microgrid generation can be always active or started up by an automatic transfer switching (ATS) logic after the disconnection

from the main grid, depending on the plant configuration. During the islanding transition, it is very important to avoid the frequency

drop, otherwise the generation protections could trip jeopardizing the Microgrid stability with consequently a long downtime.

Emax 2, employing the embedded voltage current and voltage measurements, integrates two different fast load shedding logics to

reduce this blackout risk, protecting the Microgrid during the intentional or unintentional islanding operation:

a) Basic Load Shedding, simple logic able to recognize the Microgrid disconnection event and shed a group of not priority loads

thus ensuring a fast time response and power balance.

b) Adaptive Load Shedding, the advanced algorithm available with Emax 2 as an enhancement of the basic version. The intelligent

software embedded in the circuit breaker sheds very quickly the not priority loads according to the Microgrid power consumption

and frequency measurements. Moreover, such software has a dedicated configuration for backup generation related to ATS and

the software itself is even able to estimate the energy produced by a solar plant based on plant-geography settings.

2) Microgrid in grid-connected operation

During normal circumstances, the microgrid point is generally connected to the Utility in order to inject/adsorb the surplus

or the lacking energy. During this situation, with Emax 2 as main circuit breaker installed immediately downstream the MV/LV

transformer in closed status, power overload should be avoided not to stress too much the plant elements. In order to satisfy

this, the circuit breaker embeds a patented load shedding algorithm:

a) Predictive Load Shedding, slow disconnection of loads based on the limit of the average power flow towards the Microgrid

according to the transformer size designed for the power peak profile.

All the versions are available on Emax 2 platform for both the Microgrid situations, sharing some information about the loads

under control in the plant.

The scope of this White Paper is to explain how Emax 2 manages the Microgrid transition from on-grid to off-grid, based on

fast load shedding logics. For Microgrid connected case, please refer to 1SDC007410G0202. In the Emax 2 commissioning

SW - Ekip Connect 3.0 - there is a dedicated tool where it is possible to enable the Predictive Load Shedding thanks to the SW

license available with this commercial code 1SDA082922R1.

ABB | Emax 2 - Load Shedding 3

Emax 2

Load Shedding innovation

Benefits

Service continuity

Emax 2 with load shedding features becomes the first circuit breaker that enables intentional or unintentional islanding and

avoid consequent blackouts. Indeed, when a plant remain disconnected from the Utility grid, even if there is active local pro-

duction, there is a significant stress that turns off all the generators with consequent blackout.

In any business, a lack of power supply always causes loss of money. For instance, on average, total annual downtime for automotive

industry is 700h, which represents a cost avg of 1b USD (22kUSD per minute); for F&B industry is about 500h annually; for a data center

the average cost of power outage is 8000 USD per minute, 600 KUSD per event; for a drill ship NPT means an average of $12 million/

year lost.

For all these reasons, it is very important to reduce the unplanned interruptions and speed up the recovery phase1. Thanks to

its load shedding function, Emax 2 not only improves the service continuity but also enhances the lifetime of the spinning gen-

erators.

1

See White Paper 1SDC007118G0201 Synchro Reclosing.

Figure 1: Microgrid hospital without Emax 2 Load Shedding Figure 2: Microgrid hospital with Emax 2 Load Shedding

function function

4 Emax 2 - Load Shedding | ABB

In detail, the load shedding protects the Microgrid from a quick significant frequency drop, which disconnects the local genera-

tion as shown in Figure 3 for machine protection trips. The plant remains live and can work in a stand-alone state, with priority

loads all time supplied and annual interruptions reduced.

Figure 3

f [Hz]

50

49

48

47

0 with Load Shedding

without Load Shedding

0.0 0.5 1.0 1.5 2.0 2.5 3.0 t [s]

ABB | Emax 2 - Load Shedding 5

Emax 2

Load Shedding innovation

Space saving

Neither PLC neither external relays are needed as Emax 2 has embedded the intelligence to realize the load shedding logic,

taking advantage of the internal current and voltage sensors for electrical parameter measurements.

In addition, static converters for low voltage photovoltaic production have typically anti-islanding protections: this implies an-

other power deficit to be added to the main grid contribution lost during the Microgrid disconnection.

Emax 2 is the first circuit breaker that estimates solar production requiring very few input data to face also this power unbal-

ance issue. Neither fieldbus network nor metering devices are needed for the function architecture, reducing components and

mistakes in wiring installation.

Figure 4: load shedding layout without Emax 2 Figure 5: load shedding layout with Emax 2

+

Traditional

Circuit-breaker

Ekip Supply

Signalling

Ekip

PLC

Yo/Yc

Yo/Yc

+

Loads Renewables Generator

Loads Renewables Generator

The load shedding algorithm embedded in Emax 2 is suitable with automatic transfer switch logics between switching devices.

When the back-up generator is tailored to supply only priority loads, the ATS units are designed with three switching device

configuration, like main bus tie gen. The bus tie switch disconnector distinguishes fundamental loads from the others, divid-

ing the low voltage Microgrid busbar in two parts, adding a constraint in the plant design.

Thanks to load shedding inside Emax 2, where feasible, bus-tie switch disconnector is no longer required yet and this means

less constraint for consultants and time for the electrical plant installation, besides a significant space saving up to 50% in the

power distribution switchgear. ATS unit should manage only two sources, without interlock, logic programming and wiring con-

nections for the third switch disconnector. In addition to this, using the Adaptive Load Shedding, the non-priority loads are not

preset, but dynamically chosen in the right amount among a group of controllable ones, as the algorithm is self-tuned with the

specific power unbalance identification.

6 Emax 2 - Load Shedding | ABB

Figure 6: electrical diagram and switchgear without load Figure 7: electrical diagram and switchgear with load shedding

shedding embedded in Emax 2 embedded in Emax 2

G G

G G

Saving

ABB | Emax 2 - Load Shedding 7

Emax 2

Load Shedding innovation

Ease of use

Load Shedding logics are generally set with high engineering skills and customization effort with devices as programmable logic

controllers. Emax 2 ensures ease of use thanks to predefined templates and the user-friendly graphic interface in the SW com-

missioning tool. This reduces a lot the programming time, so as to speed up the Microgrid projects without this possible barrier.

Figure 8: load shedding commissioning without Emax 2

Figure 9: load shedding commissioning with Emax 2

Besides, after the loads have been shed, no technician is needed to restore them, because Emax 2 automatically reconnects

every load in a cyclical way, without risk of simultaneous start up. This features guarantees reliability without waste of person-

hours in facility management.

8 Emax 2 - Load Shedding | ABB

How it works

Load Shedding functions are adopted to protect Microgrids during islanding operation. The application scenarios with just one

smart circuit breaker are:

Grid-connected plants with running GenSets, which contribute to the self-consumption together with potential renewable sources

and support the load power supply in emergency conditions. It is the case of hybrid PV-diesel remote communities connected to

weak distribution-grids where there are a lot of daily faults, or of facilities located in geographical areas where there are frequent

environmental events, for example hurricanes or earthquakes.

Grid-connected plants with back-up GenSets started up after main - gen transfer switching logics that require high reliability. For

example, hospitals, banks or data centers need redundancy and continuous operation, so it is important to avoid blackouts when

the emergency GenSets join the plant.

Figure 10: example of plant layout with Emax 2, Load Shedding

Main

Grid

Gensets Renewables

G

EMAX 2, all-in-one

with load shedding

ATS

Not-priority loads Priority loads

Even if Microgrids with diesel GenSets are the most common, they can be replaced with energy storage systems where the

inertia of the plant remains guaranteed.

As an extension situation, also standalone Microgrids are suitable to adopt load shedding logics embedded in Emax 2, which

becomes the main generator protection circuit breaker. In that scenario, like in marine applications, the generator is the main

power source instead of the distribution-grid.

ABB | Emax 2 - Load Shedding 9

Emax 2

Load Shedding innovation

Basic Load Shedding

Figure 11 shows the circuit breaker at the point of common coupling (PCC): when the circuit breaker opens, the Microgrid

is disconnected. Because of this, an unwanted balance condition generally occurs, so Emax 2 realizes the load shedding of

a group of non priority loads to restore power balance and, consequently, avoid a frequency reduction with the consequent

downtime due to generator protection tripping. When the Microgrid reconnects to the medium voltage grid, Emax 2 returns in

closed position, and the loads can be automatically closed again in a cyclical loop.

Figure 11: possible situation of fault that disconnects the Microgrid

Main

Grid

10 Emax 2 - Load Shedding | ABB

Operating principle

Figure 12 illustrates all the logic steps for Basic Load Shedding.

Figure 12: the logic steps for Basic Load Shedding

START

1. Microgrid islanding

Emax 2

open

2. Load shedding

Load shedding

3. Load reconnection

Emax 2

closed

Load reconnection

END

1. Microgrid islanding

The main circuit breaker, Emax 2, opens for fault events or remote/manual operation, for example due to substation maintenance or

Microgrid pricing strategy to enhance self consumption.

2. Load Shedding

After the main circuit breaker opening, a group of N controlled load (maximum 15 loads) are simultaneously open by the same I/O

contact. An alert output contact signals if the status of the load devices is not coherent with the commands sent.

3. Load reconnecting

After the Microgrid reconnection to the main grid, it is recommended to automatic reclose the loads shed for network stabilization.

This is realized only for the loads open without release tripped signal. Each n-load will be gradually reconnected in order to avoid a

stressing transient using I/O contacts and closing commands. A time delay is defined for the reconnecting loop.

ABB | Emax 2 - Load Shedding 11

Emax 2

Load Shedding innovation

Adaptive Load Shedding

The scenario is the same described for Basic Load Shedding, but Adaptive Load Shedding is a more sophisticated algorithm

that sheds loads according to power flow evaluation. The circuit breaker understands which is the reason for the plant island-

ing, recognizes the emergency condition with advanced measurements and quickly acts load disconnection. In addition, it

memorizes Microgrid instantaneous power absorption, parametrically characterizes load consumptions and estimates real-time

solar production.

All these calculations make the load shedding tuned to each specific case. As in Basic Load Shedding, when the Microgrid

returns to on-grid operation, the loads are automatically reconnected.

Besides, ATS logics are completely suitable with Adaptive Load Shedding. The back-up generator is connected to the grid

according to transfer switching logics, so this amount of power, indicated by the user, is not considered in the analysis of not

priority loads to be shed. This capability avoids the bus-tie switch disconnector installation, if used to separate non priority

loads from priority ones.

Operating principle

Figure 13 shows the main steps for the Adaptive Load Shedding algorithm built-in Emax 2 trip unit.

Figure 13: Adaptive Load Shedding logics

START

1. Microgrid islanding

Emax 2 open

Grid power

measurement

Yes No

Grid fault ?

Freq slope

& UF1

2. Load shedding

Solar power

estimation

Load shedding

ATS N

power estimation PSHED = P n sn PGrid +Psolar Pgen_ATS

n=1

Load

power estimation

UF2

Back-up load

shedding

3. Load reconnection

Emax 2 closed

Load reconnection

END

12 Emax 2 - Load Shedding | ABB

1. Microgrid islanding

The islanding operation starts on the main circuit breaker - Emax 2 opening event. The circuit breaker bi-directionally measures the

power flow of the Microgrid and identifies if the plant is consuming more than producing or vice-versa before the opening. In the first

case, load shedding sequence evaluation is initiated.

Emax 2 understands if the opening has been due to fault events in the main grid or to other reasons, like maintenance, inter-tripping

with medium voltage switching device or pricing logics identified by optimization systems to enhance self-consumption. If there has

been a grid fault, the circuit breaker trips for interface protections2, otherwise it opens for local/remote opening command.

In case of fault, the grid voltage value decreases significantly, so usually the loads adsorb less power and the generators produce

more power. As a result, the dynamic of the transient is slower than in the other situations. Having more time to take actions, Emax 2

sees the frequency trend after the fault and starts load shedding only if detects the frequency slope exceedance of the first under-fre-

quency (UF1) threshold. Having both frequency slope detection and under frequency limit makes the load shedding sensitive neither

for short-time disturbance nor for emergency conditions.

In other cases, the frequency decreases with high speed, so there is not any more time for Emax 2 to understand how the Microgrid

is evolving with running generation. This is also the case of ATS: when the back-up generator reconnects to the Microgrid, it has to

face all the loads, even if it is sized for a plant load percentage.

2

See White Paper 1SDC007117G0201 Interface Protection System and Interface Device

2. Load Shedding

If the triggers have been detected, the loads are fast shed according to Equation 1.

Equation 1

N

PSHED = Pn sn PGrid +Psolar Pgen_ATS

n=1

- PSHED is the amount of load power to be shed, adapted to the load-flow scenario. In particular, it is equal to the sum of the

power of the minimum number (N) of loads that can cover the load shedding power request. In other words, it is the result of

power unbalance calculation.

- PGrid is the measured power that has been absorbed from the grid before the opening event. Emax 2 is configured top-bottom,

so it uses the load convention.

- Psolar is the estimated power of the photovoltaic plant in the Microgrid. It can be disconnected after the islanding for internal pro-

tections of the static converters, so there is a power gap in the system.

The solar power calculation is based on a few details edited by the user during commissioning (see 5) :

- Geographic position

- Date and time

- Solar panels inclination and orientation

- Solar plant size

Emax 2 analyzes this information and gives a conservative sunny daily power profile.

- Pgen_ATS is the power of the back-up generator in the main gen ATS architectures, or energy storage systems in general. This is a

parameter inserted by the user during commissioning (see 5)).

- Pn is the usage power of the n-load. It is obtained as the product of the nominal power and the usage factor depending on the

kind of loads. These are not priority loads, possible to be turned off in emergency situations, for example thermal loads like air

conditioning units, ovens, freezing cells or pumps, air compressors, chillers, non-emergency lights.

- sn is the status (open/closed) of the n-load device. For instance, if it is open, it is set to zero since it is not involved in the power to

be shed calculation.

Whenever frequency continues to decrease and a back-up under second under frequency threshold (UF2) is exceeded, Emax 2 dis-

connects all the controlled loads not previously open in order to avoid as well as possible a blackout.

3. Load reconnecting

It is the same procedure of Basic Load Shedding (see 4.1.1).

ABB | Emax 2 - Load Shedding 13

Emax 2

Load Shedding innovation

Ekip Connect 3.0 commissioning tool

Ekip Connect 3.0 simplifies complex programming, which is an emblematic barrier for the adoption of advanced functions with

other devices.

The user can find load shedding functions inside the Tools section and select the desidered setup. It is possible to configure

the load shedding function even if the SW license has not been already bought, so as to let the user make practice and see if

the algorithm fits with the requirements prescribed for the Microgrid. On the other side, there is the chance to save projects in

dedicated files and upload them for other people and in other plants, leaving the greater flexibility for every application.

Basic Load Shedding is available with in Emax 2 circuit breaker, so it is possible to boost performances with Adaptive Load

Shedding.

Figure 14: select load shedding function

14 Emax 2 - Load Shedding | ABB

Figure 15: if Basic Load Shedding has been selected, it is continuously possible to try Adaptive Load Shedding

The Ekip Connect tool have two sessions for load shedding: one for the commissioning stage and another for supervising when

the plant is running.

During commissioning, if other compatible tools are already enabled, some parameters are already acquired, without repeating

twice the same configuration.

Figure 16: commissioning of Adaptive Load Shedding with some loads shared with other tools

ABB | Emax 2 - Load Shedding 15

Emax 2

Load Shedding innovation

Adaptive Load Shedding setup is divided into 2 steps:

1) Configuration of Emax 2 settings for load shedding

Figure 17: main settings of Emax 2, Adaptive Load Shedding

Figure 18: solar plant estimation parameters

16 Emax 2 - Load Shedding | ABB

Figure 19: ATS back-up generation definition1

3

If it set as 0 kW, it means there is not any ATS back up generation in the Microgrid.

2) Configuration of controlled loads

Figure 20: general classification with time constraints

ABB | Emax 2 - Load Shedding 17

Emax 2

Load Shedding innovation

Figure 21: signal status definition

Figure 22: command to each load device settings

18 Emax 2 - Load Shedding | ABB

After commissioning, the logics can be easily transferred to the circuit breaker, if the SW license has already been purchased

and there is the possibility to see how it works with the supervising widgets. They represent the controlled loads, the yearly

peak solar power estimation and the real-time Microgrid frequency values.

Figure 23: transfer of Adaptive Load Shedding logics to Emax 2

Figure 24: supervising widget

ABB | Emax 2 - Load Shedding 19

Emax 2

Load Shedding innovation

Application example of Adaptive Load Shedding

Industry

This application example refers to an industry connected to the MV Utility through a MV/LV transformer (15kV/400V). As shown

in Figure 24, in such plant there are a GenSet (An = 625 kVA, Pn = 500 kW) and a PV plant (Pn = 100 kW) which are in parallel

with the Utility during the grid-connected operation. The total active power consumed by the loads is 1000kW, so the power

absorbed from the grid in a sunny day is equal to 400kW. As a result, the total power of the non-priority loads must be at least

500 kW (sum of the power flowing from the grid with the PV plant nominal power4).

The main circuit breaker Emax 2 - installed immediately downstream of the MV/LV transformer and equipped with Interface

Protection System feature is an E1.2C Iu = 800 A.

There are two production lines: Line 1 and 2. Line 1 feeds the priority loads belonging to a continuous production process, so

they cannot be controlled by the Load Shedding during islanding operation. Instead, Line 2 feeds non-priority loads which can

be managed by the Load Shedding by means of contactors, installed on the power circuit of the corresponding asynchronous

motors. Moreover, in the warehouse, there are several loads (e.g lighting and HVAC) that can be controlled by the Load Shed-

ding by means of circuit breakers.

4

As said before, it is assumed that the PV plant stops its power delivering during islanding operation due to the inverter stand-by self-protection.

Figure 25

GEN.

SET

3

PV PLANT

LINE 1 OFFICES LINE 2 WAREHOUSE POWER FACTOR

CORRECTION

ASYNCHRONOUS ASYNCHRONOUS ASYNCHRONOUS LIGHTING SOCKET LIGHTING HVAC

MOTOR MOTOR MOTOR

M M M

3 3 3

20 Emax 2 - Load Shedding | ABB

The reconnection priority and the controlled devices chosen by the Customer are shown in Table 1:

Table 1

Reconnection Load Nominal Load Total Power Controlled

Priority Power [kW] Factor [kW] device

1 HVAC 3 x 50 0.8 120 MCCB

2 Lighting 3 x 30 1 90 MCB

3 Conveyor belt Asynchronous motor 100 0.9 90 Contactor

4 Air compressor 1 Asynchronous motor 140 0.8 112 Contactor

5 Air compressor 2 Asynchronous motor 120 0.8 96 Contactor

508

Figure 26 shows the frequency variation diagrams during the islanding operation in the following two cases:

without load shedding feature (Red Line)

with load shedding feature (Blue Line)

As it can be seen, in the first case, moving from grid-connected to islanding operation, there is a frequency reduction due to a

power absorption by the passive loads higher than the power produced by the GenSet. As a result, as soon as the frequency

reaches the undervoltage threshold of the circuit breaker installed on the generator feeder, there will be a shutdown of the

whole microgrid.

Instead, in the second case and thanks to the Load Shedding feature, as soon as the main circuit breaker Emax 2 opens,

the algorithm disconnects a number of non-priority in order to have a power balance between the power absorbed and local

generated. As a result, the frequency decrease is reduced and stopped to a value higher than in the previous case. Hence, the

frequency protection does not trip and the Microgrid remains live.

Then, when the main circuit breaker Emax 2 recloses, the Load Shedding feature will reconnect all the loads according to the

priority list.

Figure 26

105

104

103

Microgrid frequency [%]

102

101

100

99

98

97

96

Trip generator

95

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.30 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0

with load shedding Time [s]

without load shedding

ABB | Emax 2 - Load Shedding 21

Emax 2

Load Shedding innovation

Building

This application example refers to an office building connected to the MV Utility through a MV/LV transformer (15kV/400V). As

shown in Figure 26, in such plant there is a PV plant (Pn = 100 kW) connected in parallel with the Utility during the grid-con-

nected operation. There is also a GenSet (An = 625 kVA, Pn = 500 kW) which is connected by the ATS when the main circuit

breaker Emax 2, installed immediately downstream of the MV/LV transformer, opens. The total active power adsorbed by the

loads is 1000kW; therefore, the power adsorbed from the grid in a sunny day is equal to 900kW. As a result, the total power

of the non-priority loads must be at least 500 kW (difference between the total power of the loads and the nominal generator

power5).

5

Even in this case, it is assumed that the PV plant stops power delivering during islanding operation due to the inverter stand-by.

Figure 27

GEN.

SET

3

PV PLANT

PRIORITY WASTE CLEAN WATER HVAC 1 HVAC 2 PRIORITY OFFICES POWER FACTOR FREEZER ELECTRIC

LOAD WATER PUMPS PUMPS LOAD CORRECTION OVENS

M M

3 3

The reconnection priority of the non-priority loads and the controlled devices chosen by the Customer are shown in Table 2.

Table 2

Reconnection Load Nominal Load Total Power Controlled

Priority Power [kW] Factor [kW] device

1 HVAC1 3 x 50 0.7 105 MCCB

2 HVAC2 3 x 50 0.7 105 MCCB

3 Clean water pumps Asynchronous motor 170 0.8 136 Contactor

4 Waste water pumps Asynchronous motor 170 0.8 136 Contactor

5 Freezer 12 0.9 10.8 MCB

6 Electric ovens 12 0.9 10.8 MCB

503.6

22 Emax 2 - Load Shedding | ABB

Figure 28 shows the frequency variation diagrams during islanding operation in the following two cases:

without load shedding feature (Red Line)

with the load shedding feature (Black Line)

As it can be seen, in the first case, moving from grid-connected to islanding operation, there is a short time interval during

which the loads are not supplied until the ATS has activated the GenSet. Nevertheless, even if the GenSet starts to deliver its

maximum power, the frequency decreases due to a power absorption by the passive loads higher than the power produced. As

a result, as soon as the frequency reaches the undervoltage threshold of the circuit breaker installed on the generator feeder,

there will be a shutdown of the whole microgrid.

Instead, in the second case, after the brief power interruption, the algorithm disconnects a number of non-priority loads to

ensure power balance between the power absorbed and local generated. As a result, the frequency decrease is reduced and

stopped at a value higher than in the previous case. Hence, the frequency protection does not trip and the Microgrid remains

active.

Then, when the main circuit breaker Emax 2 recloses, the Load Shedding feature reconnects all the loads according to the

priority list.

Figure 28

104

103

102

101

Microgrid frequency [%]

100

99

98

97

96

95

trip generator

94

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10

Time [s]

with load shedding

without load shedding

ABB | Emax 2 - Load Shedding 23

Emax 2

Load Shedding innovation

Electrical diagrams

In the algorithm architecture, Emax 2 sends inputs to the non-priority load devices to realize the load shedding and outputs to

each one for their reconnection. From the other side, it receives the load status and tripped indication, where available, from the

load devices.

The connection among Emax 2 and the load devices is realized by traditional wiring using Ekip Signalling modules. The num-

ber of Ekip Signalling depends on the number of loads controlled. The load devices that can be shed are those of the Table 3,

either if ABB product or not.

Table 3: load device controlled

Product family Accessory required Emax 2 I/O used

Molded case circuit breaker Motor operator, open/closed contact, 2

ABB example: Tmax XT, Tmax T equipped with MOD or MOE released tripped contact

Air circuit breaker Charging coil motor, opening/closing 2

ABB example: Emax, Emax 2 coil, status contact, release tripped

contact

Contactors ABB example: AF Auxiliary contact 1

Switches ABB example:: OTM Motor operator, auxiliary contact 1

Miniature circuit breaker Auxiliary power supply, motor op- 1

ABB example:: S200 equipped with S2C-CM, DS200 erator, open/closed contact (if not

equipped with DS2C-CM, S800 equipped with S800-RSU-H included in the motor).

I/O interface Digital input contact 1

Example: drives

If the loads under control are many and therefore the integrated I/O are not enough or if they are far from the Emax 2 cabinet, it

is possible to connect them through Ekip Signalling 10K. This Din-rail module is connected to Emax 2 either by the local bus for

short distance or by Ekip Link, using standardized Ethernet cable in case of long distances.

24 Emax 2 - Load Shedding | ABB

Figure 28: example of switchboard design for Emax 2 Load Shedding

110-240 Vac

Ekip Supply

Ekip Link

Emax 2 Ekip Signalling 10k

Load Shedding

Emax 2 Drive Emax 2 Tmax XT + MOE Tmax XT + MOE

Ekip MS

Q/1 S51 Q/1 S51

Ekip TM

S51 Q/1

M

M Q/1 YO

YO YC

YC

Figure 28 shows a schematic circuit diagram with an example of the load shedding architecture. Emax 2 equipped with the

load shedding is the main circuit breaker that controls four circuit breakers (two air circuit breakers and two molded case circuit

breakers) and one drives on the load side. These ones are commanded by traditional wirings using Ekip Signalling 10k, that is

peer-to-peer Ethernet wired to the Ekip Link cartridge module of Emax 2.

ABB | Emax 2 - Load Shedding 25

Emax 2

Load Shedding innovation

Figure 29: example of electrical diagram for Emax 2 Load Shedding

Q2 - Emax 2 Q1 - Emax 2 + Adaptive Load Shedding

(A) (B)

(LOCAL BUS)

S75I/5

Ekip Link

K51

COM

n

BUS 1

26 Emax 2 - Load Shedding | ABB

Q3 - Tmax XT + MOE

ABB | Emax 2 - Load Shedding 27

Emax 2

Load Shedding innovation

Shopping List

The load shedding algorithms can be easily used Emax 2 thanks to a plug&play business model.

The Basic Load Shedding is always available in the circuit breaker equipped with the right hardware and can be configured

directly by Ekip Connect.

The Adaptive Load Shedding can be ordered directly for new breaker or uploaded for upgrade switchgear already commis-

sioned. In this case, the SW license present in the USB key unlocks the settings transfer to the breaker by Ekip Connect 3.0.

Table 4: shopping list for Emax 2 Load Shedding

Description Product Commercial Codes Notes 6

Trip unit Ekip Touch + Ekip Measuring Embedded in Emax 2 Otherwise, Ekip Hi Touch, Ekip G

circuit breaker Touch, Ekip G Hi Touch family

Power supply Ekip Supply 110-240V AC/DC 1SDA074172R1 As an alternative Ekip Supply 24-48V

DC (1SDA074173R1)

I/O contacts Ekip Signalling 10k 1SDA074171R1 As an alternative, depending on

the number of I/O required in

the architecture, Ekip Signal-

ling 4k (1SDA074170R1) 7 or Ekip

Signalling 2k 8 (1SDA074167R1,

1SDA074168R1, 1SDA074169R1)

Ethernet communication Ekip Link 1SDA074163R1 Optional if used with Ekip Signalling

10k with Ekip Link interface

SW license USB key Basic Load Shedding Already installed in Emax 2

SW license USB key Adaptive Load Shedding 1SDA082921R1

6

For every commercial codes, see 1SDC200023D0204 for IEC and 1SDC200039D0201 for UL.

7

Available for E2.2-E6-2 frames.

8

Up to 2 modules for frame E1.2, up to 3 modules for frame E2.2-E6.2.

28 Emax 2 - Load Shedding | ABB

ABB | Emax 2 - Load Shedding 29

Contact us

For more information please contact: The data and illustrations are not binding. We reserve

1SDC007119G0201 - 10/2016

the right to modify the contents of this document on

ABB SACE the basis of technical development of the products,

without prior notice.

A division of ABB S.p.A.

L.V. Breakers Copyright 2016 ABB. All rights reserved.

Via Pescaria, 5

24123 Bergamo - Italy

Tel.: +39 035 395 111

Fax: +39 035 395306-433

www.abb.com

Você também pode gostar

- Voltage Stability Improvement Using FACTS Devices: Prepared By: Supervised byDocumento28 páginasVoltage Stability Improvement Using FACTS Devices: Prepared By: Supervised byAditya Tiwari100% (1)

- Saudi Aramco 2616 document analysisDocumento290 páginasSaudi Aramco 2616 document analysisbillAinda não há avaliações

- Modeling and Simulation of Reverse PowerDocumento6 páginasModeling and Simulation of Reverse PowergusgifAinda não há avaliações

- NGR Technical InformationDocumento6 páginasNGR Technical InformationPrabakar PAinda não há avaliações

- Technical Complementary Guide 2013Documento256 páginasTechnical Complementary Guide 2013brightstardustAinda não há avaliações

- 12kV Air Insulated Metal Clad Switchgear PanelDocumento2 páginas12kV Air Insulated Metal Clad Switchgear PanelHarmanPreetAinda não há avaliações

- Power Flow and Protection Study of Compressor Gas StationDocumento87 páginasPower Flow and Protection Study of Compressor Gas StationmazzoffaAinda não há avaliações

- Study Report - GLS FoilDocumento64 páginasStudy Report - GLS FoilNeeraj SinghAinda não há avaliações

- MasterThesis Basem Idlbi (Documento119 páginasMasterThesis Basem Idlbi (GuruxyzAinda não há avaliações

- Advanced Inverter Report 2013 FinalDocumento16 páginasAdvanced Inverter Report 2013 FinalLaurence MichaelAinda não há avaliações

- A Stand Alone Solar Energy Plant by Using PV ModulesDocumento5 páginasA Stand Alone Solar Energy Plant by Using PV ModulesKing khanAinda não há avaliações

- IAS28P4Documento8 páginasIAS28P4anexi01Ainda não há avaliações

- Section Vi Sow PDFDocumento109 páginasSection Vi Sow PDFbacuoc.nguyen356Ainda não há avaliações

- Power transmission network 220kV and above in IndiaDocumento1 páginaPower transmission network 220kV and above in IndiaBarnidhar Singh0% (1)

- Over Load Protection For TransformerDocumento45 páginasOver Load Protection For Transformerupender_kalwaAinda não há avaliações

- Report To CB Ph1Documento22 páginasReport To CB Ph1ramesh cuppuAinda não há avaliações

- eVD4 - Breaker Integrated Protection RBX615 - Engineering Manual PDFDocumento100 páginaseVD4 - Breaker Integrated Protection RBX615 - Engineering Manual PDFHans MortenAinda não há avaliações

- Motor Protection Principles: Arijit Banerjee, Arvind Tiwari-GE Global Research Jakov Vico, Craig Wester - GE MultilinDocumento35 páginasMotor Protection Principles: Arijit Banerjee, Arvind Tiwari-GE Global Research Jakov Vico, Craig Wester - GE Multilinvaradarajanrengasamy100% (1)

- 5MW Solar Power Project Report by Twin Hickory Pvt LtdDocumento44 páginas5MW Solar Power Project Report by Twin Hickory Pvt LtdShyamSunderAinda não há avaliações

- 7-AZN-PDS-3501 - (20kV Switchgear (PDS) ) GA & SLD 24kV Switchgear SM6 - As BuiltDocumento40 páginas7-AZN-PDS-3501 - (20kV Switchgear (PDS) ) GA & SLD 24kV Switchgear SM6 - As BuiltRingoAinda não há avaliações

- Power System Restoration WithDocumento5 páginasPower System Restoration WithSandhya ShyamasundarAinda não há avaliações

- Rajasthan Rajya Vidyut Utpadan Nigam Limited 2 X 660 MW Suratgarh Supercritical Tps Unit # 7 & 8Documento41 páginasRajasthan Rajya Vidyut Utpadan Nigam Limited 2 X 660 MW Suratgarh Supercritical Tps Unit # 7 & 8rohitctppAinda não há avaliações

- Effect of Load Shedding Strategy On Interconnected Power Systems Stability When A Blackout OccursDocumento6 páginasEffect of Load Shedding Strategy On Interconnected Power Systems Stability When A Blackout OccursMoon3pellAinda não há avaliações

- Load Flow AnalysisDocumento79 páginasLoad Flow AnalysisKeshav ChanjalAinda não há avaliações

- User Manual Ecu Test Bench 2020Documento24 páginasUser Manual Ecu Test Bench 2020jhoan maestreAinda não há avaliações

- SLD of WTGDocumento1 páginaSLD of WTGbhargavram1987Ainda não há avaliações

- Toshiba n5ss Chassis Training Manual (Et)Documento173 páginasToshiba n5ss Chassis Training Manual (Et)Jose Domingo Maltez VallecilloAinda não há avaliações

- 1 11 FR 11 Substation Lightning ProtectionDocumento12 páginas1 11 FR 11 Substation Lightning Protectionkhaldoun sami100% (1)

- Transmission Distribution Services LNT SNL PDFDocumento23 páginasTransmission Distribution Services LNT SNL PDFsunjeyAinda não há avaliações

- AAR Substation Meskerem 2013 Peak LoadDocumento42 páginasAAR Substation Meskerem 2013 Peak LoadAddisu MengeshaAinda não há avaliações

- Line Differential Protection and Control Red615 Ansi: Application ManualDocumento120 páginasLine Differential Protection and Control Red615 Ansi: Application ManualMir MuhammadAinda não há avaliações

- Nissin - Gt14 Nissin - Gt14: BUS 150 KV (2000A) Bus A Bus BDocumento1 páginaNissin - Gt14 Nissin - Gt14: BUS 150 KV (2000A) Bus A Bus BirfanAinda não há avaliações

- Design and Modelling of Hybrid PV-Micro Hydro Power Generation Case Study Jimma ZoneDocumento9 páginasDesign and Modelling of Hybrid PV-Micro Hydro Power Generation Case Study Jimma ZoneDanang KimoAinda não há avaliações

- Electrical System Earthing Design Philosophy: Prelude Floating LNG PROJECTDocumento28 páginasElectrical System Earthing Design Philosophy: Prelude Floating LNG PROJECTStefano FavaroAinda não há avaliações

- Siemens Vacuum Switching Technology Meets Medium-Voltage RequirementsDocumento32 páginasSiemens Vacuum Switching Technology Meets Medium-Voltage RequirementsSaurav BhattaraiAinda não há avaliações

- White Paper - Resistive Load Banks: AESPL - Ahuja Engineering Services Pvt. LTDDocumento10 páginasWhite Paper - Resistive Load Banks: AESPL - Ahuja Engineering Services Pvt. LTDsinanbalbanAinda não há avaliações

- Intelligent Load SheddingDocumento29 páginasIntelligent Load Sheddingarjun c chandrathil100% (2)

- Overview of Grid Code and Operational Requirements of Grid-Connected Solar PV Power Plants-NOTA TECNICADocumento7 páginasOverview of Grid Code and Operational Requirements of Grid-Connected Solar PV Power Plants-NOTA TECNICAEdgardo Kat ReyesAinda não há avaliações

- Edsa PaladinDocumento52 páginasEdsa PaladinIulian PârjoleanuAinda não há avaliações

- E01 & E02+wr1Documento134 páginasE01 & E02+wr1faqihu rizkyAinda não há avaliações

- Wind Plant Collector SystemDocumento16 páginasWind Plant Collector SystemDaniel DelaFuenteAinda não há avaliações

- ABB PV ReferencesDocumento48 páginasABB PV Referencesahmetgumus1902Ainda não há avaliações

- Annexe 2 - ESKOM Cost Estimate Letter No IPP293459467 - Legoko 3 PV PlantDocumento46 páginasAnnexe 2 - ESKOM Cost Estimate Letter No IPP293459467 - Legoko 3 PV PlantalfredoAinda não há avaliações

- 500 - SET19294-03-Generator Technical SpecificationDocumento20 páginas500 - SET19294-03-Generator Technical SpecificationAndres DAinda não há avaliações

- An Intelligent Load Shedding Ils System Application in A Large IDocumento9 páginasAn Intelligent Load Shedding Ils System Application in A Large IManoj RAinda não há avaliações

- VCB 06 (1) .07.07 PDFDocumento56 páginasVCB 06 (1) .07.07 PDFrazvansasuAinda não há avaliações

- Automatic Power Supply Control: Eit-MDocumento7 páginasAutomatic Power Supply Control: Eit-MsamuelAinda não há avaliações

- CAB-15-003 Issue 8 With DrawingsDocumento23 páginasCAB-15-003 Issue 8 With DrawingsmuratucobanAinda não há avaliações

- Arc Flash Exercise 5: SetupDocumento2 páginasArc Flash Exercise 5: SetuppvenkyAinda não há avaliações

- Selective Coordination Breaker Application ChartDocumento5 páginasSelective Coordination Breaker Application Charthanner90Ainda não há avaliações

- S Gen Lightning 00Documento15 páginasS Gen Lightning 00raviaggrawalla8727Ainda não há avaliações

- Model User Guide For Generic Renewable Energy System ModelsDocumento74 páginasModel User Guide For Generic Renewable Energy System ModelsLidiaLuengoAinda não há avaliações

- Safelink CB: Gas Insulated Ring Main UnitDocumento2 páginasSafelink CB: Gas Insulated Ring Main UnitABCDAinda não há avaliações

- REF615 Appl 756378 ENt PDFDocumento404 páginasREF615 Appl 756378 ENt PDFBishnu RegmiAinda não há avaliações

- Recommended Bass Reflex Enclosure DesignDocumento1 páginaRecommended Bass Reflex Enclosure DesignOrçun GünaydınAinda não há avaliações

- Decentralized Inverter Guide for Large Solar PlantsDocumento48 páginasDecentralized Inverter Guide for Large Solar PlantsPablo Omar Luz PedemonteAinda não há avaliações

- Moulded Case Circuit Breakers GuideDocumento84 páginasMoulded Case Circuit Breakers GuideKishore Krishna92% (13)

- ABB - Generator Protections GuideDocumento45 páginasABB - Generator Protections GuideAyesha ShaikhAinda não há avaliações

- StatcomDocumento16 páginasStatcomksg9731100% (1)

- Power System Protection 25Documento235 páginasPower System Protection 25mishra.satyam9874100% (1)

- DOC3 Software InstructionDocumento32 páginasDOC3 Software Instructionkalos stratiotesAinda não há avaliações

- HKIEDocumento2 páginasHKIEkalos stratiotesAinda não há avaliações

- Cu0212 An Measuring Earth Resistance v1 PDFDocumento31 páginasCu0212 An Measuring Earth Resistance v1 PDFkalos stratiotesAinda não há avaliações

- Individual MembershipsDocumento3 páginasIndividual Membershipskalos stratiotesAinda não há avaliações

- Technologist Qualifications For Associate Membership - Exemption From Assessment (A14343)Documento2 páginasTechnologist Qualifications For Associate Membership - Exemption From Assessment (A14343)kalos stratiotesAinda não há avaliações

- PRC QC Qualification FormDocumento2 páginasPRC QC Qualification Formkalos stratiotesAinda não há avaliações

- Cu0120 An Earthing Systems Fundamentals v3 PDFDocumento16 páginasCu0120 An Earthing Systems Fundamentals v3 PDFkalos stratiotesAinda não há avaliações

- ASEAN MRA On Engineering Services PDFDocumento35 páginasASEAN MRA On Engineering Services PDFkalos stratiotesAinda não há avaliações

- Medium Voltage Drives in The Sugar Industry - SIT 2005 PDFDocumento11 páginasMedium Voltage Drives in The Sugar Industry - SIT 2005 PDFkalos stratiotesAinda não há avaliações

- Distribution Automation Handbook Section 8.3 Elements of Power Distribution System PDFDocumento120 páginasDistribution Automation Handbook Section 8.3 Elements of Power Distribution System PDFHans MortenAinda não há avaliações

- Schneider Protection GuideDocumento76 páginasSchneider Protection GuideahmedhamzehAinda não há avaliações

- No. NS Answer: Coaching: GEAS Group Name: TUP-TaguigDocumento7 páginasNo. NS Answer: Coaching: GEAS Group Name: TUP-Taguigkalos stratiotesAinda não há avaliações

- Geas - Coaching 5 Team SluDocumento2 páginasGeas - Coaching 5 Team Slukalos stratiotesAinda não há avaliações

- Geas Coaching7 Tip&TupDocumento6 páginasGeas Coaching7 Tip&Tupkalos stratiotesAinda não há avaliações

- Geas Coaching6 Tup&TipDocumento6 páginasGeas Coaching6 Tup&Tipkalos stratiotesAinda não há avaliações

- Excel GEAS Coaching 4 (More)Documento4 páginasExcel GEAS Coaching 4 (More)kalos stratiotesAinda não há avaliações

- Geas Coaching6 Team Assorted 06apr13Documento20 páginasGeas Coaching6 Team Assorted 06apr13kalos stratiotesAinda não há avaliações

- Geas Final CoachingDocumento2 páginasGeas Final Coachingkalos stratiotesAinda não há avaliações

- ELEX - Module 30Documento5 páginasELEX - Module 30Cullado Christian JosephAinda não há avaliações

- Module 07Documento3 páginasModule 07Denaiya Watton LeehAinda não há avaliações

- Wire Size (MM) Cable Ampacity (Copper) Size AWG or Kcmil: 600 V, 75 C@30 C AmbientDocumento6 páginasWire Size (MM) Cable Ampacity (Copper) Size AWG or Kcmil: 600 V, 75 C@30 C Ambientkalos stratiotesAinda não há avaliações

- Module 05Documento3 páginasModule 05kalos stratiotesAinda não há avaliações

- Optimal Investment Analysis of P100K Across 5 Bond OptionsDocumento7 páginasOptimal Investment Analysis of P100K Across 5 Bond Optionskalos stratiotesAinda não há avaliações

- Electronics - Module 06Documento3 páginasElectronics - Module 06Cullado Christian JosephAinda não há avaliações

- Module 02Documento7 páginasModule 02Denaiya Watton LeehAinda não há avaliações

- RA 7920 and IRRDocumento19 páginasRA 7920 and IRRCamilla AlbaAinda não há avaliações

- Module 04 DC Armature Winding QuestionsDocumento3 páginasModule 04 DC Armature Winding Questionskalos stratiotesAinda não há avaliações

- Module 03Documento8 páginasModule 03Denaiya Watton LeehAinda não há avaliações

- Perform Test Data After Midlife Log EDG NCP2 NPU - 21 Feb 20Documento1 páginaPerform Test Data After Midlife Log EDG NCP2 NPU - 21 Feb 20MR BEAAinda não há avaliações

- Marine Gas Turbine: PerformanceDocumento2 páginasMarine Gas Turbine: Performancefrdn100% (1)

- Diesel Generator QSK78Documento4 páginasDiesel Generator QSK78Gerard Phillippe LeguatAinda não há avaliações

- 3516B TaDocumento6 páginas3516B TaGeovanny Chasi PesantezAinda não há avaliações

- Pramac GSW110IDocumento10 páginasPramac GSW110IJanko GardaševićAinda não há avaliações

- Dvigatel Perkins 4016 61trg3Documento14 páginasDvigatel Perkins 4016 61trg3mohammed khadrAinda não há avaliações

- New 20 Years Monpura Mini-Grid Research English FinalDocumento17 páginasNew 20 Years Monpura Mini-Grid Research English Finalfi_523916200Ainda não há avaliações

- Caterpillar 750Documento5 páginasCaterpillar 750esilva2021Ainda não há avaliações

- D.G Size Calculation (22.8.12)Documento1 páginaD.G Size Calculation (22.8.12)eng_zidAinda não há avaliações

- Mitsubishi Marine Product GuideDocumento108 páginasMitsubishi Marine Product GuideAlbertoAinda não há avaliações

- Genset Price ListDocumento1 páginaGenset Price Listandry wicaksanaAinda não há avaliações

- SO-1136-d Part 1 Engine Room Simulator MAN B&W 5L90MC-L11Documento22 páginasSO-1136-d Part 1 Engine Room Simulator MAN B&W 5L90MC-L11Stipe TurićAinda não há avaliações

- AM ElectricalDocumento2 páginasAM Electrical3J Solutions BDAinda não há avaliações

- Electric Power AP1000 Design Control Document: Section TitleDocumento3 páginasElectric Power AP1000 Design Control Document: Section TitlehafizgAinda não há avaliações

- Man l32 44Documento274 páginasMan l32 44Tran Duy NamAinda não há avaliações

- XZ53500000252 - Deif - Marathon - BR2000Documento35 páginasXZ53500000252 - Deif - Marathon - BR2000GiangDoAinda não há avaliações

- Technical Data Perkins 1506a - E88tag5Documento5 páginasTechnical Data Perkins 1506a - E88tag5misterahmads100% (1)

- QSB6.7 Series: Diesel Generator SetDocumento4 páginasQSB6.7 Series: Diesel Generator SetVIET TRIEU HUYNHAinda não há avaliações

- 250kva Diesel Generator SetDocumento4 páginas250kva Diesel Generator SetZez SamuelAinda não há avaliações

- B3.9 Series: Diesel Generator SetDocumento4 páginasB3.9 Series: Diesel Generator Setkumar aAinda não há avaliações

- C2000D6Documento4 páginasC2000D6Gestión del Talento Humano GEMRAAinda não há avaliações

- Nsets H25-33VDocumento1 páginaNsets H25-33VM. ShaatAinda não há avaliações

- Caterpillar 1.563MVA GeneratorDocumento6 páginasCaterpillar 1.563MVA Generatoromh129Ainda não há avaliações

- Diesel Generator Sizing - REV0Documento8 páginasDiesel Generator Sizing - REV0alinaghib100% (2)

- Diesel Generator Safety and Operation ManualDocumento39 páginasDiesel Generator Safety and Operation ManualEli Marsee100% (1)

- Electrical Engineer Seeking New OpportunityDocumento3 páginasElectrical Engineer Seeking New OpportunityMohsin YasinAinda não há avaliações

- Diesel Generator n14 PDFDocumento4 páginasDiesel Generator n14 PDFRobles Jmr100% (1)

- QSK60 Spec SheetDocumento6 páginasQSK60 Spec Sheetbacuoc.nguyen356Ainda não há avaliações

- Acoustic Insulation DG Generator Canopy HSD TankDocumento16 páginasAcoustic Insulation DG Generator Canopy HSD TankAnonymous sWqPozhJAinda não há avaliações

- Cummins Sales and Service: Central States Diesel GeneratorsDocumento46 páginasCummins Sales and Service: Central States Diesel GeneratorsTheronAinda não há avaliações