Escolar Documentos

Profissional Documentos

Cultura Documentos

DR - Safaa El-Gamal: Chemistry of Cement For Third Year Students Major Chemistry

Enviado por

Ahmed Awad100%(1)100% acharam este documento útil (1 voto)

51 visualizações25 páginasThis document provides information about the chemistry of cement for third year chemistry students studying major chemistry. It discusses the types, manufacture, properties, hydration, and mechanisms of various cements including Portland cement, blast furnace slag cement, and super sulphated cement. The key points covered include the composition, phases, specifications, hydration processes, and factors that influence the strength and curing of different cements. Diagrams illustrate the chemical reactions and mechanisms involved.

Descrição original:

cement hydration and chemistry

Título original

chemistryofcementformajorchemistry-140624171540-phpapp02

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThis document provides information about the chemistry of cement for third year chemistry students studying major chemistry. It discusses the types, manufacture, properties, hydration, and mechanisms of various cements including Portland cement, blast furnace slag cement, and super sulphated cement. The key points covered include the composition, phases, specifications, hydration processes, and factors that influence the strength and curing of different cements. Diagrams illustrate the chemical reactions and mechanisms involved.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(1)100% acharam este documento útil (1 voto)

51 visualizações25 páginasDR - Safaa El-Gamal: Chemistry of Cement For Third Year Students Major Chemistry

Enviado por

Ahmed AwadThis document provides information about the chemistry of cement for third year chemistry students studying major chemistry. It discusses the types, manufacture, properties, hydration, and mechanisms of various cements including Portland cement, blast furnace slag cement, and super sulphated cement. The key points covered include the composition, phases, specifications, hydration processes, and factors that influence the strength and curing of different cements. Diagrams illustrate the chemical reactions and mechanisms involved.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 25

CHEMISTRY of CEMENT

for THIRD YEAR STUDENTS

MAJOR CHEMISTRY

Dr. Safaa El-gamal

introduction

Cement: given to a substances which can be used to

bind together sand and any form of aggregate. (eg.

broken stone).

Primitive cement is Ca(OH)2 (hydrated lime).

Hydraulic cement: is the cement that not only react

with water ,it also form water resistant products.

Cement can be

used as

Paste Mortar Concrete

Some important Terms:

1-Setting 2-Hardening

3-Hydration reaction. 4-Curing condition.

Cement chemical nomenclature

Oxide Abbreviation Compound Abbreviation

CaO C 3 CaO.SiO2 C3S

SiO2 S 2 CaO.SiO2 C2S

Al2O3 A 3 CaO.Al2O3 C3A

Fe2O3 F 4 CaO.Al2O3.Fe2O3 C4AF

MgO M 4 CaO.2Al2O3.SO3 C4A2S

SO3 S 3 CaO.2 SiO2.3 H2O C3S2H3

H2O H CaSO4.2 H2O CSH2

C3S = Tri Calcium Silicate, C2S = Di Calcium Silicate

Manufacture of Portland Cement

Lime stone (CaCO3) +Clay (or other compounds

with similar bulk composition)heating to about

1450 oC partial fusion clinker(67%C, 22%S,

5%A, 3% F+ 3% other component) grinding and

mixed with few %gypsum (Ca SO4.2 H2O)

Portland cement

Main phases of PC clinker:

1) C3S 2) C2S 3)C3A 4) C4AF

Rule of each phase in the Hydration

characteristics of Portland Cement

Percentage and the rule of each phase in PCC

I) Compressive strength:

C3A,C4AF give little strength compared to C3 S, -C2S.

II)Evolution of heat:hydration of PC is an exothermic

process(C3S and C3A) make large contribution to heat

of hydration.

III) Sulphate resistant: some ground water and sea

water contains enough sulphate to attack PC and

causes its expansion and disintegration.

Sulphate attack depends on C3A content, and formation

of ettringite (C3A.3 CaSO4.32H2O).

Types of Portland Cement according to ASTM Classification

ASTM type Composition ( % ) Characteristic

and name s

C3S C2S C3A C4AF

I (Ordinary 42- 10- 0-17 6-18 no special

Portland 65 30 requirements.

cement)

II ( 35- 15- 0-8 6-18 moderate sulfate

Modified 60 35 resistance,

moderate heat

Portland

of hydration.

cement)

III ( High - early 45-70 10- 0-15 6-18 higher

strength 30 strength

Portland soon after

cement) pouring.

IV ( Low - heat 20-30 50- 3-6 8-15 low heat of

Portland 55 hydration.

cement)

V ( Sulfate - 40-60 15- 0-5 10- high sulfate

resistant 40 18 resistance.

Portland

cement)

Specification of PC is based on

1)Test on unhydrated cement.

2)Test on behaviour of cement

during hydration.

3)Test on the hardened pastes.

White cement (other Type of Portland Cement):

made from iron free materials (e.g lime stone and

china clay), they contain C3A,C3S and C2S.

non Portland cement:

I) Aluminous cement:

Lime stone +bauxite (heating) complete fusion

aluminous cement.

Properties of Aluminous cement

1)set and harden quickly compared to PC

2)High early strength.

3)High resistant to sulphate attack.

II) Slag cement:

a) blastfurnace slag b)supersulphated cement.

III- Pozzolanic Cement:

Pozzalanas: are substances which are not in

themselves cementitious, but reacts with Ca(OH)2 in

presence of water and act as cement.

Expansive cement: cement that give paste which

expand slightly on hydration.

Mechanism of cementing action

1)Reactivity of anhydrous compounds

1)C3S ,CA react rapidly with water and strongly

hydraulic.

2)-C2S reacts slowly with water and strongly

hydraulic, but -C2S is inert.

3)C3A,C4AF reacts rapidly with water, but they are

weakly hydraulic.

b)-C2S reacts slowly with water and strongly

hydraulic, but -C2S is inert.

c)C3A,C4AF reacts rapidly with water, but they are

weakly hydraulic.

Explanation

i) many compounds are stable at room temperature

when (Ca) atoms coordinated to six oxygen. In

compounds formed at high temperature the

coordination number of (Ca) is less than (6) and

the reactivity is attributed to tendency of (Ca) to

attain (6) CO.NO.

ii) Also irregularity in arrangement of coordinated

oxygen was an important factor

iii) Finally presence of minor impurities may be a

reason for reactivity.

2-product formed on hydration

i) Chemical nature of it.

ii) Particle size and particle shape.

iii)Surface structure: hydraulic reactivity is high for

compounds have surfaces in which coordination

of ions or atoms are unsatisfactory.

iv-Condition of formation of hydration products

a) If the hydration product occurs under conditions

which do not causes disruption of the pre-existing

structure it give strength.

b) If the reverse of (a) occurs it will causes low

strength.

v-Condition of formation of hydration products

a) If the hydration product occurs under conditions

which do not causes disruption of the pre-existing

structure it give strength.

b) If the reverse of (a) occurs it will causes low

strength.

Theories of setting and hardening

1) Crystallization hypothesis (by Lechatelier):

Cement+H2Osolution(supersaturated relative to

hydration products) precipitation of hydration

products as crystals, interlocked with each other

hardened mass .

2) Gel hypothesis (by Michaels):

He attributed the hardening of hydraulic cement

due to formation of gel.

a) Gel is soft and contains much water.

b) Unreacted cement particles which still present

absorbs this water from this gel and use it for

hydration

c) The gel becomes hard and impermeable

3-Modern Views

a) Cement +H2O dispersion system (cement grains not

close packed)

b) Large amount of hydration products (of colloidal

dimension) were formed on the surface of grains.

c) After few hours amount of hydration increase and

extended to meet each other, so that give gel in the space

between the grains (setting stage).

d)(after few days), the colloidal particles between the

cement grains becomes densely packed, give

hardened materials, also the gel becomes closely

packed in some regions and less dense in other,

which give pores (hardening stage)

Hydration of Portland Cement

a) Through solution mechanism:-

Reactants dissolves gives ions in solution

ions combined giving products precipitate from

solution.

b) Topochemical mechanism:- reaction occurs directly on

surface of solid.

1)hydration of C3S

2 C3S +6H C3S2H3 +3 Ca(OH)2

2)hydration of C2S

2 C2S +4H C3S2H3 + Ca(OH)2

3)Hydration of C3A

a)C3A+excessH2O(C4AH19+C4AH8 ) these are metastable

hydrates by time C3 AH6(more stable and less soluble)

b) C3A+less H2O and room temp.C3 AH6

3)Hydration of C4AF:

C4AF +CaSO4.2H2O +Ca(OH)2 3CaO(Al2O3.Fe2

O3).3CaSO4(aq)

Role of gypsum in setting and hardening

It added to cement to delay its setting.

Mechanism of hydration

1)pre-induction period (first minutes) (fast hydration).

induction period : the rate is slow down. dormant

period (period of relative inactivity) lasting 1-2 hours.

3)acceleration period: (3-12 hours after mixing) due to

break up CSH coating and continuation of

hydration process).

4)post acceleration: in this period the rate of

hydration is slow down gradually as the amount of

unhydrated materials decreases.

Blast-Furnace Slag Cement (BFC)

BFS is by-product obtained in manufacture of pig-

iron in the blast furnace as molten at 1400-1500 oC.

then cooling may be:

a) Slow cooling which give grey crystalline ,stony

material known as dense slag.

b) Rapid cooling using limited amount of water ,

giving light weight materials called foamed slag

and after cursing and grinding used as light weight

aggregates.

a) very rapid cooling of the slag by pouring into

excess water

b)or by very rapid cooling using jets of water or of air

and water.

The product known as granulated slag.

Reaction of blast-furnace slag with water

It react very slowly with water but without

Setting

. But when some Ca(OH)2 is added to it

,setting and hardening reactions occurs,

similar to PC but with slower rate.

The products formed are: CSH (tobermorite),

C4AH13

Reaction of blast-furnace slag with

water

It react very slowly with water but without

setting.

But when some Ca(OH)2 is added to it

,setting and hardening reactions occurs,

similar to PC but with slower rate.

The products formed are: CSH (tobermorite),

C4AH13

What is the rule of activator (e.g. Ca(OH)2 , NaOH or

KOH)?

Mechanism of hydration of slag in

slag cement mixture

1)Fast hydration reaction from time of mixing with water(0.5

h) (pre-dormant period).

2)first dormant period, this period( ended at 0.5 day of

hydration). Very slow stage of hydration (due to initially

formed hydrates with high amorphous character)

3)first acceleration period ends at 3 days of hydration.

4) Second dormant period (after 3-days) the hydration is

slow down.

5)Second acceleration period (after 28-day) . In this

period a marked decrease in free lime and free slag

were observed up to 180 days

The beginning and duration of each stage :

depends on

a) Fineness

b) Composition of the original slag cement mixture.

Super sulphate Cement

It made from (80-85%)of granulated blast furnace

slag + CaSO4 (as activator)+5% PC

Super sulphate Cement

It made from (80-85%)of granulated blast

furnace slag + CaSO4 (as activator)+5%

PC

Você também pode gostar

- IELTS Writing VocabularyDocumento5 páginasIELTS Writing VocabularyAhmed Awad100% (1)

- Proportioning Concrete MixesDocumento54 páginasProportioning Concrete Mixesgman444Ainda não há avaliações

- Disclosure To Promote The Right To Information: IS 4351 (2003) : Steel Door Frames - (CED 11: Doors, Windows and Shutter)Documento14 páginasDisclosure To Promote The Right To Information: IS 4351 (2003) : Steel Door Frames - (CED 11: Doors, Windows and Shutter)Rachel IngramAinda não há avaliações

- It's A Product of An Intimate Mixture of Correctly ProportionedDocumento28 páginasIt's A Product of An Intimate Mixture of Correctly ProportionedshahriarAinda não há avaliações

- Rocket Motor Construction TutorialDocumento19 páginasRocket Motor Construction TutorialAzher Uddin100% (1)

- Polyurethane Chemistry1Documento7 páginasPolyurethane Chemistry1Ahmed AwadAinda não há avaliações

- New BSR 16-02-2010Documento818 páginasNew BSR 16-02-2010Charith SachindraAinda não há avaliações

- 7 - Concrete-1 PDFDocumento73 páginas7 - Concrete-1 PDFjinnaAinda não há avaliações

- Gourd CraftsDocumento81 páginasGourd CraftsJeKa Art67% (3)

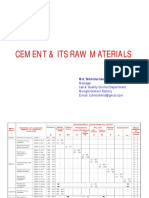

- Cement Raw MaterialsDocumento9 páginasCement Raw MaterialsTuhin TahmidAinda não há avaliações

- WeatherBarriers PDFDocumento15 páginasWeatherBarriers PDFcolawariAinda não há avaliações

- 1-Con TechDocumento37 páginas1-Con TechZELALEM100% (1)

- Clinker Coolers PDFDocumento22 páginasClinker Coolers PDFAhmed AwadAinda não há avaliações

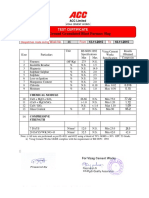

- Ground Granulated Blast Furnace Slag: Test CertificateDocumento2 páginasGround Granulated Blast Furnace Slag: Test CertificatenoumanAinda não há avaliações

- Tests On Portland Cement: CompositionDocumento27 páginasTests On Portland Cement: CompositionIrma NurrohmahAinda não há avaliações

- Industrial Waste As Alternative Fuel in Cement Industry: Its Impact On EnvironmentDocumento7 páginasIndustrial Waste As Alternative Fuel in Cement Industry: Its Impact On EnvironmentBilal El YoussoufiAinda não há avaliações

- CementDocumento55 páginasCementSajjad AhmadAinda não há avaliações

- D1P3-Mill Feed CharacteristicsDocumento23 páginasD1P3-Mill Feed CharacteristicsYhaneAinda não há avaliações

- Maxillofacial MaterialsDocumento52 páginasMaxillofacial MaterialsDr_Abhishek1990100% (2)

- Influence of Grinding Method and Particle Size Distribution On The Properties of Portland-Limestone CementsDocumento11 páginasInfluence of Grinding Method and Particle Size Distribution On The Properties of Portland-Limestone CementsJohn GiannakopoulosAinda não há avaliações

- Guidelines COPROCEM LowDocumento136 páginasGuidelines COPROCEM LowDekeukelaere Anne100% (1)

- Modelled Fate of Sulphur and Chlorine in Rotary Kilns Part I PDFDocumento10 páginasModelled Fate of Sulphur and Chlorine in Rotary Kilns Part I PDFJohn GiannakopoulosAinda não há avaliações

- The Role of Gypsum in CementDocumento30 páginasThe Role of Gypsum in Cementsafwat hassanAinda não há avaliações

- Cement: EN 197-1 States That, Cement Is A Hydraulic Binder, I.E. A Finely Ground Inorganic Material WhichDocumento33 páginasCement: EN 197-1 States That, Cement Is A Hydraulic Binder, I.E. A Finely Ground Inorganic Material WhichPrantoAinda não há avaliações

- Alodine® 1200 Two Component Brush-On Process: Translation of The German Technical Process BulletinDocumento3 páginasAlodine® 1200 Two Component Brush-On Process: Translation of The German Technical Process BulletinDumitru MoldovanAinda não há avaliações

- Concrete TechnologyDocumento23 páginasConcrete TechnologyM NANDITHA CIVIL STAFF100% (1)

- Influence of Clinker So 3 On The Cement CharacteristicsDocumento9 páginasInfluence of Clinker So 3 On The Cement CharacteristicsShakti Singh100% (1)

- Clinker Formation ConceptsDocumento28 páginasClinker Formation ConceptspashaAinda não há avaliações

- 7 Quality Management and Control of Cement Production - Ó+ Í - + - +ÝËÙ+ÏÍãDocumento88 páginas7 Quality Management and Control of Cement Production - Ó+ Í - + - +ÝËÙ+ÏÍãNova HeriAinda não há avaliações

- Lecture Cement IndustryDocumento65 páginasLecture Cement IndustryUsman AliAinda não há avaliações

- Chapter 3 - Cement Hydration and AAR in ConcreteDocumento65 páginasChapter 3 - Cement Hydration and AAR in Concreteaddis zewd100% (1)

- Compression Molding: Neslihan Yağmur 11/12/2012Documento17 páginasCompression Molding: Neslihan Yağmur 11/12/2012Not-Not MarkonotAinda não há avaliações

- 10 Sulfate HydrationDocumento30 páginas10 Sulfate HydrationMohamed SaadAinda não há avaliações

- Product SurveyDocumento26 páginasProduct SurveyAdnan PervaizAinda não há avaliações

- Training - Cga ApplicationDocumento34 páginasTraining - Cga ApplicationSubhan MuhammadAinda não há avaliações

- Catalysis (From Royal Society of Chemistry)Documento217 páginasCatalysis (From Royal Society of Chemistry)Ahmed AwadAinda não há avaliações

- Life Is Full of Challenges So Be Brave & Face ItDocumento48 páginasLife Is Full of Challenges So Be Brave & Face Itrams221209Ainda não há avaliações

- Types of Welding ElectrodesDocumento2 páginasTypes of Welding Electrodessinghanimesh12345Ainda não há avaliações

- Quailty Assurance of CementDocumento30 páginasQuailty Assurance of Cementabdullah100% (3)

- Cement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 1 - Session 6Documento0 páginaCement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 1 - Session 6breyes25Ainda não há avaliações

- Hydration of CementDocumento37 páginasHydration of CementZaid KhanAinda não há avaliações

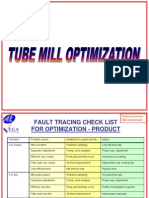

- Tube Mill OptimisationDocumento7 páginasTube Mill OptimisationJoko DewotoAinda não há avaliações

- Chemical Technology Subject Code: CH2001Documento13 páginasChemical Technology Subject Code: CH2001U SANKAR TEJOAinda não há avaliações

- Role of Gypsum in Cement GrindingDocumento13 páginasRole of Gypsum in Cement GrindingMinh Tien LeAinda não há avaliações

- Mineralisation PDFDocumento11 páginasMineralisation PDFElwathig BakhietAinda não há avaliações

- Cement Kiln Process Chemistry: Cemnet Training - Course Ckpc01Documento10 páginasCement Kiln Process Chemistry: Cemnet Training - Course Ckpc01Elwathig BakhietAinda não há avaliações

- Perimeter Curtain Wall Revised 1Documento63 páginasPerimeter Curtain Wall Revised 1shuweAinda não há avaliações

- Textbook 3 Cementproduction v31Documento8 páginasTextbook 3 Cementproduction v31Mohammad Awais NazirAinda não há avaliações

- Typical Raw Minerals 202.1Documento2 páginasTypical Raw Minerals 202.1Mohammed AbdoAinda não há avaliações

- Department of Chemical Engineering: Analysis & Comparison of Cheaper Binder For Coal FinesDocumento26 páginasDepartment of Chemical Engineering: Analysis & Comparison of Cheaper Binder For Coal FinesVijaya GosuAinda não há avaliações

- 6-FGD Chemistry ModuleDocumento68 páginas6-FGD Chemistry ModuleclesncronAinda não há avaliações

- Tf1 - Co2 Protocol v3Documento80 páginasTf1 - Co2 Protocol v3indrabudhiAinda não há avaliações

- SOx Emmissions Absortion FLSDocumento14 páginasSOx Emmissions Absortion FLSMartha Carolina Gomez MartinezAinda não há avaliações

- Variation of Feed Chemical Composition and Its Effect On Clinker Formation PDFDocumento7 páginasVariation of Feed Chemical Composition and Its Effect On Clinker Formation PDFs_prasy6540Ainda não há avaliações

- DRI Charging in EAFDocumento3 páginasDRI Charging in EAFMuhammad NbAinda não há avaliações

- The Effect of Coal Ash On Synthesis and Properties of C3SDocumento6 páginasThe Effect of Coal Ash On Synthesis and Properties of C3SNam HuynhAinda não há avaliações

- Grinding and Milling in Cement Manufacturing: 1.2 Fineness RequirementsDocumento6 páginasGrinding and Milling in Cement Manufacturing: 1.2 Fineness RequirementsJosé UrdayAinda não há avaliações

- CementDocumento42 páginasCementMadhavanIceAinda não há avaliações

- Minor ElementsDocumento50 páginasMinor ElementsnaldsonAinda não há avaliações

- Unit 2 - CementDocumento55 páginasUnit 2 - CementSaharsha GadariAinda não há avaliações

- Loss On Ignition (L.O.I) : Concrete Technology (I) Lecture 3Documento10 páginasLoss On Ignition (L.O.I) : Concrete Technology (I) Lecture 3Mahmoud HosnyAinda não há avaliações

- Cement PropertiesDocumento4 páginasCement PropertiesDebendra Dev KhanalAinda não há avaliações

- Seaa2112 l2 CementDocumento70 páginasSeaa2112 l2 Cementrawk hahihu100% (1)

- 8-Lecture 8Documento45 páginas8-Lecture 8mustafAinda não há avaliações

- BasicCementChem - CIL2Documento30 páginasBasicCementChem - CIL2D'izmi D'barcaAinda não há avaliações

- The Cement Grinding Office: Home About Us Services Mining Area Links and ContactDocumento2 páginasThe Cement Grinding Office: Home About Us Services Mining Area Links and ContactVisnu SankarAinda não há avaliações

- Clinker Coolers: By: Oliver Christian D. DeyparineDocumento26 páginasClinker Coolers: By: Oliver Christian D. Deyparinemoonbright27Ainda não há avaliações

- Blast Furnace Slag Weathering StudyDocumento8 páginasBlast Furnace Slag Weathering StudyARNALDO BATTAGIN100% (3)

- Cement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Documento14 páginasCement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Senthilkumar PragasamAinda não há avaliações

- Usage of Cement Kiln Dust in Cement Products - Research ReviewDocumento7 páginasUsage of Cement Kiln Dust in Cement Products - Research ReviewhawdinAinda não há avaliações

- Cement Chemistry Notation and Mineral NamesDocumento2 páginasCement Chemistry Notation and Mineral NamesAfqan B-vAinda não há avaliações

- Influence of The Clinker SO3 On The Cement CharacteristicsDocumento1 páginaInfluence of The Clinker SO3 On The Cement Characteristicsroshan_geo078896Ainda não há avaliações

- Rockwool 2Documento8 páginasRockwool 2leroniusAinda não há avaliações

- Role of Gypsum in Cement and Its EffectsDocumento3 páginasRole of Gypsum in Cement and Its Effectsvenkateswara rao pothinaAinda não há avaliações

- The - 10 Basic Facts On ClinkerDocumento1 páginaThe - 10 Basic Facts On ClinkerParesh GohelAinda não há avaliações

- 1.1 Program KymoreDocumento2 páginas1.1 Program Kymoresaji kumarAinda não há avaliações

- CementDocumento36 páginasCementVignesh RamalingamAinda não há avaliações

- Some Questions and Answers of CEMENT Rotary KilnDocumento4 páginasSome Questions and Answers of CEMENT Rotary KilnSalud Y SucesosAinda não há avaliações

- Lab Chemist Ahmed Awad Updated 25-12-2018Documento2 páginasLab Chemist Ahmed Awad Updated 25-12-2018Ahmed AwadAinda não há avaliações

- Recent Task 2 Essay Questions 2Documento28 páginasRecent Task 2 Essay Questions 2esraaalhajAinda não há avaliações

- How To Do Body Paragraphs QuizDocumento2 páginasHow To Do Body Paragraphs QuizAhmed AwadAinda não há avaliações

- IT With AnswerDocumento256 páginasIT With AnswerAhmed AwadAinda não há avaliações

- Catalysis Sec 3 No 8Documento12 páginasCatalysis Sec 3 No 8Ahmed AwadAinda não há avaliações

- Chemistry Course Work 2Documento10 páginasChemistry Course Work 2Ahmed AwadAinda não há avaliações

- Qaulitative AnalysisDocumento65 páginasQaulitative AnalysisAhmed AwadAinda não há avaliações

- Alkali ContentDocumento1 páginaAlkali ContentAhmed AwadAinda não há avaliações

- Polymer Chemistry ReviewDocumento15 páginasPolymer Chemistry RevieweduingeAinda não há avaliações

- The Specification Requirerments of GGBS: - 5% Glass ContentDocumento2 páginasThe Specification Requirerments of GGBS: - 5% Glass ContentAhmed AwadAinda não há avaliações

- Chemseal - KR: Product DataDocumento3 páginasChemseal - KR: Product DataghazanfarAinda não há avaliações

- C 18150Documento2 páginasC 1815003sri03Ainda não há avaliações

- 11 - Meher Prasad - Tech For Mass HousingDocumento35 páginas11 - Meher Prasad - Tech For Mass HousingKiran KoraddiAinda não há avaliações

- Stone Cladding Fixation 1Documento3 páginasStone Cladding Fixation 1wadyspring100% (2)

- SSG1022E Edition 8 PDFDocumento5 páginasSSG1022E Edition 8 PDFHarold Gill100% (1)

- 2011-01-25 HLEOA-AG08D3-Exterior Doors PDFDocumento14 páginas2011-01-25 HLEOA-AG08D3-Exterior Doors PDFgeowozAinda não há avaliações

- Draft Discussions On 4TH Amendment of Is 456Documento6 páginasDraft Discussions On 4TH Amendment of Is 456Santhosh Kumar BaswaAinda não há avaliações

- Technical Data Sheet: EPIKURE™ Curing Agent 3274Documento4 páginasTechnical Data Sheet: EPIKURE™ Curing Agent 3274Kelvin Allan Soler LopezAinda não há avaliações

- Building SSR 2011-12Documento403 páginasBuilding SSR 2011-12Guru Prasad0% (1)

- Ajay Vikram PPP On MsDocumento13 páginasAjay Vikram PPP On MsSunil YadavAinda não há avaliações

- 3M Adhesive 08115Documento4 páginas3M Adhesive 08115Syavash EnshaAinda não há avaliações

- GulfSea Hyperbar LCM2 PDFDocumento2 páginasGulfSea Hyperbar LCM2 PDFObydur RahmanAinda não há avaliações

- Shotcrete PresentationDocumento21 páginasShotcrete Presentationparth patel100% (1)

- Gyprock 949 Strata Wall 201202Documento24 páginasGyprock 949 Strata Wall 201202duckeAinda não há avaliações

- Building Materials - Ferrous and Non-FerrousDocumento24 páginasBuilding Materials - Ferrous and Non-FerrousDevansh MehtaAinda não há avaliações

- MaterialData 11916 2Documento1 páginaMaterialData 11916 2Muhammad Shena GumilangAinda não há avaliações