Escolar Documentos

Profissional Documentos

Cultura Documentos

CIV - 10 Manchester Hanger

Enviado por

adventmanurungTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CIV - 10 Manchester Hanger

Enviado por

adventmanurungDireitos autorais:

Formatos disponíveis

Airport Hangar Roof Lifting,

Manchester Airport

www.fagioli.com

info@fagioli.com

CIVIL 10

There are numerous advantages in

fabricating roof trusses at ground level

and lifting the completed sections to

their final position using strand jacking

techniques.

At Manchester Airport, Qualitair

Aviation contracted Costain to build a

new 15m hangar of a size big enough

to house four A300 Airbuses. The roof,

dimensioned at 108 metres long and

100 metres wide, was fabricated in 4

sections, the heaviest section

weighing 330 tonnes.

Steelwork Contractor Robert Watson

decided to use this erection method

and contracted Fagioli to provide the

lifting service to raise the sections to

their final height of 23 metres. 8 No.

L50 lifting jacks, each jack using 3 No.

18mm dia cables, were positioned on

top of the columns. Using an L9/7.5D

power pack, the roof sections were

raised at a rate of 13 metres/hour by

the jacks automatically synchronised

by the control module.

The hangar is typical of the size of

structure that Fagioli can help in offering

cost effective alternatives to traditional

erection methods.

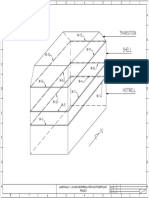

Above: Four of the eight L50 strand jacks arranged on one side wall connected to the roof

panel below. All eight jacks in the jacking system were synchronized by one power pack

placed at ground level.

Você também pode gostar

- TG20 13 User GuideDocumento30 páginasTG20 13 User GuideMalik Aldmour100% (1)

- Standard Specification Webbing For Slings WB-1Documento10 páginasStandard Specification Webbing For Slings WB-1adventmanurung100% (1)

- 111 - The Design and Construction of Cliffsend UnderpassDocumento4 páginas111 - The Design and Construction of Cliffsend UnderpassYash SinghAinda não há avaliações

- 2014 Jacquard tc207 Foundations by Prestressing Anchors of The "Villa Mediterranee enDocumento5 páginas2014 Jacquard tc207 Foundations by Prestressing Anchors of The "Villa Mediterranee enLucas HoodAinda não há avaliações

- Bahrain World Trade CenterDocumento11 páginasBahrain World Trade CenterKashif AfridiAinda não há avaliações

- Excellent Notes For Intact and Damage StabilityDocumento15 páginasExcellent Notes For Intact and Damage Stabilitynishant100% (2)

- Stainless Steel Socket-Set Screws: Standard Specification ForDocumento5 páginasStainless Steel Socket-Set Screws: Standard Specification FormsbarretosAinda não há avaliações

- Security ManualDocumento80 páginasSecurity Manualcristian181100% (7)

- Residential Lease or Rental Agreement CA NEWDocumento4 páginasResidential Lease or Rental Agreement CA NEWSeasoned_SolAinda não há avaliações

- Plant LayoutDocumento42 páginasPlant LayoutAnjali Narayan100% (4)

- CIV - 09 Fab Hall RoofDocumento1 páginaCIV - 09 Fab Hall RoofadventmanurungAinda não há avaliações

- 2828 Burj Khalifa Dubai UaeDocumento3 páginas2828 Burj Khalifa Dubai Uaearii_setiawanAinda não há avaliações

- Flying BeltDocumento2 páginasFlying Beltshazz_28Ainda não há avaliações

- Concrete Construction Article PDF - Precast Concrete Forms The Backbone of The Channel TunnelDocumento2 páginasConcrete Construction Article PDF - Precast Concrete Forms The Backbone of The Channel TunnelAnithaAinda não há avaliações

- Six Rows of High Capacity Removable Anchors Support Deep Soil Mix Cofferdam Barley Payne Mcbarron European Conference Amsterdam 1999Documento7 páginasSix Rows of High Capacity Removable Anchors Support Deep Soil Mix Cofferdam Barley Payne Mcbarron European Conference Amsterdam 1999Kenny CasillaAinda não há avaliações

- Innovations in Mechanised Track MaintenanceDocumento14 páginasInnovations in Mechanised Track MaintenanceKai OracleAinda não há avaliações

- EOT CraneDocumento3 páginasEOT CraneHusain BaradAinda não há avaliações

- Microtunneling: MGM College of Engineering and Technology, Kamothe, Navi Mumbai, IndiaDocumento3 páginasMicrotunneling: MGM College of Engineering and Technology, Kamothe, Navi Mumbai, IndiaHarshith Y HarshAinda não há avaliações

- Feeder StackerDocumento2 páginasFeeder StackerСтоян МитевAinda não há avaliações

- Lift Boat Blue TitaniumDocumento2 páginasLift Boat Blue TitaniumbobsikalAinda não há avaliações

- Gatwick Air BridgeDocumento7 páginasGatwick Air BridgemrasdanAinda não há avaliações

- Toll Road Project - Specifications Section 9 - PavementsDocumento32 páginasToll Road Project - Specifications Section 9 - PavementsadhystiraAinda não há avaliações

- A Case Study of Multi-Use Platform: Aquaculture in Offshore Wind FarmsDocumento1 páginaA Case Study of Multi-Use Platform: Aquaculture in Offshore Wind FarmsaseAinda não há avaliações

- TBM Carboniferous Rock PajaresDocumento7 páginasTBM Carboniferous Rock PajaresThomasCamusAinda não há avaliações

- Single Girder, Double Truss CranesDocumento2 páginasSingle Girder, Double Truss CranesGogyAinda não há avaliações

- Construction Planning, Equipment, Arid Methods Cranes: Bridge ProjectDocumento3 páginasConstruction Planning, Equipment, Arid Methods Cranes: Bridge ProjectYusril HadiAinda não há avaliações

- CIV - 31 Virgin Hangar 2pagerDocumento2 páginasCIV - 31 Virgin Hangar 2pageradventmanurungAinda não há avaliações

- C 3 Project Des PDFDocumento30 páginasC 3 Project Des PDFLRHENGAinda não há avaliações

- MMT - Onshore Wind ServiceDocumento11 páginasMMT - Onshore Wind ServiceYossef Sami El DidiAinda não há avaliações

- Space For Electrical and Mechanical Services in BuildingsDocumento19 páginasSpace For Electrical and Mechanical Services in BuildingscharuAinda não há avaliações

- M.E. Laws, Contracts and Ethics PresentationDocumento28 páginasM.E. Laws, Contracts and Ethics PresentationLeo Paulo Del Rosario0% (1)

- AddtiX Airport PDF (1) - 1 PDFDocumento7 páginasAddtiX Airport PDF (1) - 1 PDFSyahrul PasaribuAinda não há avaliações

- 08-001 - Sea-2000Documento1 página08-001 - Sea-2000jmScriAinda não há avaliações

- 14 Access For Future Strengthening and For Inspection and MaintenanceDocumento2 páginas14 Access For Future Strengthening and For Inspection and Maintenancem_zaman76Ainda não há avaliações

- Control of Yenka Runway Project: Operation ManagemnetDocumento4 páginasControl of Yenka Runway Project: Operation ManagemnetRajnish PandeyAinda não há avaliações

- Parsifal 2263Documento2 páginasParsifal 2263maritim2k16Ainda não há avaliações

- EOT Spec RefDocumento22 páginasEOT Spec RefSantoshkota123Ainda não há avaliações

- A Reinforced Soil Mix Wall Cofferdam Supported by High Capacity Removable Soil AnchorsDocumento9 páginasA Reinforced Soil Mix Wall Cofferdam Supported by High Capacity Removable Soil AnchorsHüseyin EkiciAinda não há avaliações

- (052 58) Shop8 14Documento7 páginas(052 58) Shop8 14Jame ColesAinda não há avaliações

- Brochure Camara Refugio Strata (Usa)Documento9 páginasBrochure Camara Refugio Strata (Usa)JOSE HUAMANIAinda não há avaliações

- Ijftr 19 (3) 172-176 PDFDocumento5 páginasIjftr 19 (3) 172-176 PDFKathirrveluSubramainan100% (1)

- Technology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemDocumento8 páginasTechnology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemShanmuga SundaramAinda não há avaliações

- Beumer Apron ConveyorDocumento8 páginasBeumer Apron ConveyortranceinttAinda não há avaliações

- Stal9781614996569 1185Documento5 páginasStal9781614996569 1185Vignesh VenkatasubramanianAinda não há avaliações

- IMG - 0103 PSME Code 2008 94Documento1 páginaIMG - 0103 PSME Code 2008 94Master JaguarAinda não há avaliações

- Seaway - Alfa Lift-300dpi - Pdf.downloadasset PDFDocumento2 páginasSeaway - Alfa Lift-300dpi - Pdf.downloadasset PDFДимаAinda não há avaliações

- Leonardo Da Vinci Datasheet V3defDocumento3 páginasLeonardo Da Vinci Datasheet V3defSarvesh SangleAinda não há avaliações

- Design Constructionof CUBICSpace Frame RoofDocumento10 páginasDesign Constructionof CUBICSpace Frame RoofJuanCruzAinda não há avaliações

- Floating Windmill: Mohammad Moin 1RG07EE026 Final Year EEEDocumento18 páginasFloating Windmill: Mohammad Moin 1RG07EE026 Final Year EEEcrimsonmoinAinda não há avaliações

- AC60 Training Manual Intranet1.3 PDFDocumento954 páginasAC60 Training Manual Intranet1.3 PDFDemagUral50% (2)

- The New Closed Circuit Wind Tunnel of The Aircraft Laboratory of University of São Paulo, BrazilDocumento8 páginasThe New Closed Circuit Wind Tunnel of The Aircraft Laboratory of University of São Paulo, Brazilreza mohammedAinda não há avaliações

- Precast ConcreteDocumento6 páginasPrecast ConcreteMagdy BakryAinda não há avaliações

- Leaflet Winches Sheer Leg - Dubai Dry Docks - PDFDocumento1 páginaLeaflet Winches Sheer Leg - Dubai Dry Docks - PDFGhyd ArtiagaAinda não há avaliações

- Guyed Wind Turbine Tower Concept Low ResDocumento2 páginasGuyed Wind Turbine Tower Concept Low ResTiago CunhaAinda não há avaliações

- 1400/75/F28ALR Combined Aerial and Pumping ApplianceDocumento2 páginas1400/75/F28ALR Combined Aerial and Pumping ApplianceoussemaAinda não há avaliações

- Beumer Belt Bucket Elevator en 06Documento8 páginasBeumer Belt Bucket Elevator en 06mathiAinda não há avaliações

- Worlds Longest Single Flight Conventional Overland Belt ConveyorDocumento10 páginasWorlds Longest Single Flight Conventional Overland Belt ConveyorTrần Quang MinhAinda não há avaliações

- Atlantic London Specs GA - Updated 26.01.18Documento3 páginasAtlantic London Specs GA - Updated 26.01.18RiccoAinda não há avaliações

- Brochura LineageDocumento6 páginasBrochura LineageFAQMD2Ainda não há avaliações

- Embraer Lineage1000E BrochureDocumento6 páginasEmbraer Lineage1000E BrochureNaili Bourhane Aboudou RahimeAinda não há avaliações

- Intrebari SCaffoldfinalDocumento14 páginasIntrebari SCaffoldfinalMadalina FoteaAinda não há avaliações

- Highly Repeatable Rope Winch Design With MultipleDocumento19 páginasHighly Repeatable Rope Winch Design With MultipleKhalil homraniAinda não há avaliações

- Cable Laying 3FGKFGJDocumento4 páginasCable Laying 3FGKFGJSyed Zuber AhmedAinda não há avaliações

- Sumaia EatiDocumento26 páginasSumaia EatiSabbir AhmedAinda não há avaliações

- A Guide to Some of the Equations used in Constructing a Suspension BridgeNo EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeAinda não há avaliações

- PT - Jel KPI & Calender Compliance 2019Documento10 páginasPT - Jel KPI & Calender Compliance 2019adventmanurung100% (1)

- GENERATOR ITEM - Delivery Equipment Equipment - 01Documento1 páginaGENERATOR ITEM - Delivery Equipment Equipment - 01adventmanurungAinda não há avaliações

- STD Report PDFDocumento11 páginasSTD Report PDFadventmanurungAinda não há avaliações

- Grove RT890E Load Chart 75% Load ChartDocumento28 páginasGrove RT890E Load Chart 75% Load ChartadventmanurungAinda não há avaliações

- Environment Aspect ImpactDocumento8 páginasEnvironment Aspect ImpactadventmanurungAinda não há avaliações

- TURBINE ITEM - Delivery Equipment Steam Turbine - 01Documento1 páginaTURBINE ITEM - Delivery Equipment Steam Turbine - 01adventmanurungAinda não há avaliações

- Request of Tool No.7Documento1 páginaRequest of Tool No.7adventmanurungAinda não há avaliações

- Mechanical Trades SOPDocumento5 páginasMechanical Trades SOPadventmanurungAinda não há avaliações

- Manual Wa 5000 PDFDocumento20 páginasManual Wa 5000 PDFadventmanurungAinda não há avaliações

- Safety Data Sheet SDS For HIT-RE 500-SD Epoxy Adhesive Documentation ASSET DOC APPROVAL 0638Documento9 páginasSafety Data Sheet SDS For HIT-RE 500-SD Epoxy Adhesive Documentation ASSET DOC APPROVAL 0638adventmanurungAinda não há avaliações

- Calculation ReportDocumento21 páginasCalculation ReportadventmanurungAinda não há avaliações

- Mechanical Properties of Metric FastenersDocumento10 páginasMechanical Properties of Metric FastenersadventmanurungAinda não há avaliações

- (Eng) Tutorial Shell 2009.0.1Documento1 página(Eng) Tutorial Shell 2009.0.1adventmanurungAinda não há avaliações

- Eurocodes in Scia EngineerDocumento2 páginasEurocodes in Scia EngineeradventmanurungAinda não há avaliações

- 1.over RallDocumento1 página1.over RalladventmanurungAinda não há avaliações

- Scia Engineer Result 3D PDFDocumento3 páginasScia Engineer Result 3D PDFadventmanurungAinda não há avaliações

- Method Statement For Ug Piping 6423dp420 00 00200 00 Rev03 PDFDocumento20 páginasMethod Statement For Ug Piping 6423dp420 00 00200 00 Rev03 PDFadventmanurungAinda não há avaliações

- Web Sling StandardsDocumento2 páginasWeb Sling StandardsadventmanurungAinda não há avaliações

- Making Plastic Canopies From Soda BottlesDocumento3 páginasMaking Plastic Canopies From Soda BottlesJohnny Warhawk ONeillAinda não há avaliações

- A320 NEO and Forthcoming NoveltiesDocumento44 páginasA320 NEO and Forthcoming Noveltiescwzjhon100% (1)

- DowelDocumento3 páginasDowelganeshl08Ainda não há avaliações

- Sika Carbodur S Pds enDocumento5 páginasSika Carbodur S Pds enHarnawan Satya W ArsitekAinda não há avaliações

- Const TimberDocumento25 páginasConst TimberRemya R. Kumar50% (4)

- AnirudhDocumento81 páginasAnirudhbalki123Ainda não há avaliações

- Acft Operating Lease Redelivery Considerations (Aircarft Monitor)Documento39 páginasAcft Operating Lease Redelivery Considerations (Aircarft Monitor)sazalirsAinda não há avaliações

- Electrochemical MachiningDocumento16 páginasElectrochemical MachiningParthiban SoundarrajanAinda não há avaliações

- Bill of QuantitiesDocumento6 páginasBill of QuantitiesSidney Musonda100% (1)

- Loading and UnloadingDocumento3 páginasLoading and UnloadingMargaret FordAinda não há avaliações

- A 210Documento1 páginaA 210AnuranjanAinda não há avaliações

- Case Study - Hot Tap, Stopple and By-PassDocumento2 páginasCase Study - Hot Tap, Stopple and By-Passowenh796Ainda não há avaliações

- Supply Chain ManagementDocumento16 páginasSupply Chain ManagementSnigdho Shokal100% (1)

- Alwasy Step Ahead in TechnologyDocumento4 páginasAlwasy Step Ahead in TechnologyjtpmlAinda não há avaliações

- 01-Samss-039 18122016Documento14 páginas01-Samss-039 18122016ELNA83Ainda não há avaliações

- July 2015 Master Plumber Terms IncludedDocumento5 páginasJuly 2015 Master Plumber Terms Includedzenzen1100% (1)

- Dar DirectoryDocumento104 páginasDar DirectoryJayant GhawalkarAinda não há avaliações

- ENG STD 1602 Cold InsulDocumento32 páginasENG STD 1602 Cold Insuldarrybr52Ainda não há avaliações

- Piping StopplerDocumento3 páginasPiping Stoppleranusaan2007Ainda não há avaliações

- RHI CatalogueDocumento104 páginasRHI CatalogueRenaissance Heavy IndustriesAinda não há avaliações

- Mobil Product Guide South Pacific May09Documento23 páginasMobil Product Guide South Pacific May09Arimbi GembiekAinda não há avaliações

- Helicopter Hoist Rescue PDFDocumento13 páginasHelicopter Hoist Rescue PDFTomas Gaviria Martinez100% (1)

- The History of Dunelm, Now PendennickDocumento35 páginasThe History of Dunelm, Now PendennickAnthony RentonAinda não há avaliações

- LEMLJENJEDocumento24 páginasLEMLJENJEAnte NinićAinda não há avaliações