Escolar Documentos

Profissional Documentos

Cultura Documentos

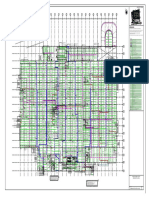

KCDC Ws 004 Thrust Blocks Concrete Block Details

Enviado por

Anonymous 1HFV185Sl4Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

KCDC Ws 004 Thrust Blocks Concrete Block Details

Enviado por

Anonymous 1HFV185Sl4Direitos autorais:

Formatos disponíveis

MAX

CORROSION

PRESSURE 1000 kPa (NOM. 100 m HEAD) PROTECTION

AS REQUIRED

SOIL CLASSIFICATION AND ALLOWABLE

FOR HORIZONTAL THRUST ON TRENCH

WALLS WHERE COVER OVER PIPES IS

HORIZONTAL BEARING PRESSURE OF

TEES AND DEAD ENDS

HORIZONTAL BENDS HORIZONTAL BENDS HORIZONTAL BENDS HORIZONTAL BENDS

CORROSION

PROTECTION

SAND/GRAVEL; DECOMPOSED

SAND/GRAVEL; DECOMPOSED

SAND/GRAVEL; DECOMPOSED

SAND/GRAVEL; DECOMPOSED

SAND/GRAVEL; DECOMPOSED

GROUND. SEE NOTE 3

STIFF CLAY; MEDIUM DENSE;

STIFF CLAY; MEDIUM DENSE;

STIFF CLAY; MEDIUM DENSE;

STIFF CLAY; MEDIUM DENSE;

STIFF CLAY; MEDIUM DENSE;

AS REQUIRED

HARD CLAY; SOUND ROCK

HARD CLAY; SOUND ROCK

HARD CLAY; SOUND ROCK

HARD CLAY; SOUND ROCK

HARD CLAY; SOUND ROCK

VERY STIFF CLAY; DENSE

VERY STIFF CLAY; DENSE

VERY STIFF CLAY; DENSE

VERY STIFF CLAY; DENSE

VERY STIFF CLAY; DENSE

450 OR GREATER

CLEAN SAND

CLEAN SAND

CLEAN SAND

CLEAN SAND

CLEAN SAND

ROCK

ROCK

ROCK

ROCK

ROCK

DI, GRP, OR DI, GRP, OR

150mm

PVC PIPE PVC PIPE

PLAN PLAN

250 MIN 250 MIN

PBH

(kPa) 50 100 200 50 100 200 50 100 200 50 100 200 50 100 200

100 0.34 0.17 N 0.18 N N N N N N N N 0.24 0.12 N CORROSION DN DN

NOMINAL DIAMETER OF

150 0.70 0.35 0.18 0.38 0.19 N 0.20 N N N N N 0.50 0.25 0.12 PROTECTION

200 1.20 0.60 0.30 0.64 0.32 0.16 0.34 0.17 N 0.16 N N 0.84 0.42 0.21 AS REQUIRED

FITTING (DN)

225 1.52 0.75 0.38 0.81 0.41 0.21 0.42 0.22 0.11 0.22 N N 1.06 0.53 0.27

250 1.80 0.91 0.45 0.98 0.49 0.25 0.50 0.25 0.12 0.26 0.13 N 1.28 0.64 0.32

300 2.66 1.33 0.66 1.44 0.72 0.36 0.74 0.37 0.18 0.36 0.18 N 1.88 0.94 0.47

375 4.04 2.02 1.01 2.18 1.09 0.55 1.12 0.56 0.28 0.56 0.28 0.14 2.86 1.43 0.72

100

225 5.71 2.86 0.73 3.09 1.55 0.40 1.58 0.79 0.20 1.58 0.79 0.20 4.04 2.02 0.52 SEE NOTE 7 SEE NOTE 7

250 6.98 3.49 0.89 3.78 1.89 0.49 1.93 0.98 0.25 1.93 0.98 0.25 4.93 2.37 0.63

300 9.89 4.95 1.27 5.36 2.68 0.68 2.73 1.36 0.35 2.73 1.36 0.35 6.90 3.50 0.89

375 15.16 7.58 1.94 8.21 4.10 1.05 4.19 2.10 0.53 4.19 2.10 0.53 10.72 5.36 1.37 ELEVATION (FOR HORIZONTAL THRUST) ELEVATION (FOR HORIZONTAL THRUST)

'N' DENOTES NOMINAL THRUST AREA - (SEE NOTES 4 & 5)

PBH - ALLOWABLE HORIZONTAL BEARING PRESSURE THRUST BLOCK FOR TEES THRUST BLOCK FOR BENDS

NOTE:

1. ALL DIMENSIONS IN MILLIMETRES UNLESS OTHERWISE SPECIFIED.

2. CAST THE THRUST AREA OF ALL THRUST BLOCKS AGAINST A CLEAN FACE OF UNDISTURBED NATURAL SOIL. 150 MIN

THRUST BLOCKS NOT TO INTERFERE WITH OTHER SERVICES USING 20MPa CONCRETE. HALF THRUST AREA

EACH SIDE SEE NOTE 7

BEARING AREA

3. DO NOT USE STANDARD THRUST BLOCKS AS SPECIFIED IN THIS DRAWING IN:

- VERY SOFT, SOFT, OR FIRM CLAY.

300 MIN

- LOOSE CLEAN SAND. CORROSION PROTECTION

50

AS REQUIRED

- UNCOMPACTED FILL OR REFUSE.

4. A GEOTECHNICAL ASSESSMENT AND INDIVIDUAL DESIGN IS REQUIRED FOR THESE SOILS.

DI, GRP OR

5. THE NOMINAL THRUST AREA 'N' TO BE ACHIEVED BY POURING CONCRETE THE FULL LENGTH OF THE FITTING AND

PVC PIPE

TO A DEPTH THAT ENSURES THE THRUST IS VERTICALLY AND HORIZONTALLY CENTRED ON THE RESULTING

THRUST BLOCK. SEE ALSO NOTE 7.

6. DESIGN PRESSURES OTHER THAN 1000 kPa REDUCE OR INCREASE THE MINIMUM THRUST AREA BY THE RATIO OF

THE DESIGN PRESSURES EXCEPT WHERE:

BEARING AREA

300 MIN

- 'N' APPEARS IN THE TABLE AND DESIGN PRESSURE IS ABOVE 1000 kPa. CALCULATE THE AREA.

7. FINISH THRUST BLOCKS APPROXIMATELY 100 ABOVE THE TOP OF THE FITTING OR BEARING PAD AND EXTEND TO SEE NOTE 7

10mm

THE FLOOR OF THE TRENCH OR DEEPER IF NECESSARY TO ACHIEVE THE REQUIRED THRUST AREA. MAXIMUM

8. THE MINIMUM THRUST AREA FOR TAPER THRUST BLOCKS TO BE EQUAL TO THE DIFFERENCE BETWEEN THE PLAN (FOR HORIZONTAL THRUST)

THRUST AREAS FOR DEAD ENDS OF EQUIVALENT DIAMETER TO THOSE EACH SIDE OF TAPER.

0

9. FOR DOWNWARD VERTICAL THRUST, THE ALLOWABLE BEARING PRESSURES FOR VARIOUS SOILS MAY BE TAKEN AS TAPER THRUST BLOCK

TWICE THAT FOR HORIZONTAL THRUST SHOWN.

10. WHEN POURING CONCRETE AGAINST FITTINGS PLACE A MEMBRANE OF POLYETHYLENE, PVC OR FELT BETWEEN

THE FITTING AND CONCRETE TO PREVENT DAMAGE TO THE FITTING. JOINTS TO BE CLEAR OF CONCRETE.

11. CONCRETE TO BE KEPT CLEAR OF BOLTS & FLANGES OR GIBAULT JOINTS TO ALLOW FITTINGS TO BE REMOVED

WITHOUT INTERFERING WITH ANCHOR BLOCK. Drawn Designed

STANDARD DETAILS S. TURKINGTON

Approved

J. SAXTON

Revision Date

Copyright Standards New Zealand 2011. Drawings from NZS 4404:2010 have been M. COLE OCTOBER 2015

reproduced with permission from Standards New Zealand under Copyright Licence 000904.

Refer to the complete Standard available for purchase from Standards New Zealand.

THRUST BLOCKS Scale Drawing No. Revision

KCDC AMENDMENTS TO NZS 4404:2010 SHOWN IN BOLD. CONCRETE BLOCK DETAILS NOT TO SCALE KCDC-WS-004 R1

Original Sheet Size A3 [297x420]

Você também pode gostar

- Topographical Survey Tech Specification - BHELDocumento12 páginasTopographical Survey Tech Specification - BHELvikalp161Ainda não há avaliações

- Pipelines Thrust Blocks and AnchorsDocumento14 páginasPipelines Thrust Blocks and AnchorsOsvaldo Junges BomfimAinda não há avaliações

- Topographical Survey Drawing ModelDocumento1 páginaTopographical Survey Drawing ModelArunashish MazumdarAinda não há avaliações

- 293-1-Spc-002 Specification For Grouting, Rev. ADocumento10 páginas293-1-Spc-002 Specification For Grouting, Rev. ABasitAinda não há avaliações

- Sa203 Structural DrawingDocumento50 páginasSa203 Structural DrawingChime MornAinda não há avaliações

- Modeling Finite Elements - TRNC03184Documento43 páginasModeling Finite Elements - TRNC03184Kidd TornoAinda não há avaliações

- Standard Penetration TestDocumento41 páginasStandard Penetration TestMohamedAinda não há avaliações

- 313 WEST 117th STREET New York, NyDocumento17 páginas313 WEST 117th STREET New York, NyGalo Delgado100% (1)

- The Lining of Irrigation CanalsDocumento30 páginasThe Lining of Irrigation CanalsGonzalo López0% (1)

- Em 1110-2-1601 PDFDocumento61 páginasEm 1110-2-1601 PDFransajeewaniAinda não há avaliações

- Typical Road and Paving DetailsDocumento1 páginaTypical Road and Paving Detailsahmed elesawyAinda não há avaliações

- CSR-2014-Sindh NHA PDFDocumento262 páginasCSR-2014-Sindh NHA PDFSohail Ahmed Khilji100% (1)

- STAAD GeneratorDocumento5 páginasSTAAD GeneratorSrikanth SikhaAinda não há avaliações

- Rectangular Column CalculationsDocumento1 páginaRectangular Column CalculationsSharif UddinAinda não há avaliações

- Maamoura and Baraka Development ProjectDocumento29 páginasMaamoura and Baraka Development ProjectAHMED AMIRAAinda não há avaliações

- And Fi Nally..Documento1 páginaAnd Fi Nally..Sara RamliAinda não há avaliações

- CanalsDocumento19 páginasCanalsFemeena P-vAinda não há avaliações

- 1.wind Guide 1Documento32 páginas1.wind Guide 1quaisarAinda não há avaliações

- Highway Miscallaneous DrawingsDocumento150 páginasHighway Miscallaneous Drawingsp09tp451Ainda não há avaliações

- 0000 REP JJ 0003 - Detailed Design Report & AppendicesDocumento172 páginas0000 REP JJ 0003 - Detailed Design Report & AppendicesHumberto Jose100% (1)

- Shop Drawing: National Water Supply and Drainage BoardDocumento1 páginaShop Drawing: National Water Supply and Drainage BoardsitheeqAinda não há avaliações

- Piping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Upper Deck / Main Deck System 53Documento1 páginaPiping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Upper Deck / Main Deck System 53Mohd KhaidirAinda não há avaliações

- Calculation Report For Fence Foundation Model HP3000: REV Description Engineering Approval Boss DateDocumento9 páginasCalculation Report For Fence Foundation Model HP3000: REV Description Engineering Approval Boss DateGerardo JoseAinda não há avaliações

- HEC-RAS 6.4 New FeaturesDocumento14 páginasHEC-RAS 6.4 New FeaturesAaron NicholsAinda não há avaliações

- PJNAB ATK FFS GFP P1 3023 Layout1Documento1 páginaPJNAB ATK FFS GFP P1 3023 Layout1waheedAinda não há avaliações

- Miscellaneous - 077154C 000 JSS 2000 003 - CDocumento7 páginasMiscellaneous - 077154C 000 JSS 2000 003 - CStructures ProductionAinda não há avaliações

- Indo/Nepal Border Rudhauli: Key PlanDocumento1 páginaIndo/Nepal Border Rudhauli: Key PlanMrinal KayalAinda não há avaliações

- GB1516 Sac 240 CV SP 0003 - ADocumento31 páginasGB1516 Sac 240 CV SP 0003 - AkkkkAinda não há avaliações

- Consideraciones Sismicas para Contenedores de LiquidoDocumento21 páginasConsideraciones Sismicas para Contenedores de Liquidodavid gonzalezAinda não há avaliações

- Structural Use of Bamboo. Part 4: Element Design Equations: SynopsisDocumento4 páginasStructural Use of Bamboo. Part 4: Element Design Equations: SynopsisVictor OmotoriogunAinda não há avaliações

- 03510E01Documento41 páginas03510E01fructoraAinda não há avaliações

- Method Statement For External Joint CoatingDocumento15 páginasMethod Statement For External Joint CoatingAbdullah AbdullahAinda não há avaliações

- !indx DWG IDocumento23 páginas!indx DWG IAmolAinda não há avaliações

- Appendix I PIPELINE SLOP STABLITY BAG GUNNYDocumento85 páginasAppendix I PIPELINE SLOP STABLITY BAG GUNNYMAHESH CHANDAinda não há avaliações

- SF Ground Improvement REVISED 0514041Documento3 páginasSF Ground Improvement REVISED 0514041amokhtaAinda não há avaliações

- Fqi MPR 2014 12Documento60 páginasFqi MPR 2014 12muneerpmhAinda não há avaliações

- Project Light Rail Transit (LRT) : Structure Calculation ReportDocumento37 páginasProject Light Rail Transit (LRT) : Structure Calculation ReportVansya PratamaAinda não há avaliações

- Evaluation of Suspension BridgeDocumento274 páginasEvaluation of Suspension BridgeUlises CastroAinda não há avaliações

- GB1516 Sac 240 CV RP 0004 - BDocumento69 páginasGB1516 Sac 240 CV RP 0004 - BkkkkAinda não há avaliações

- JJ Cruz + Associates S-02: Standard HooksDocumento1 páginaJJ Cruz + Associates S-02: Standard HooksCarlo GarciaAinda não há avaliações

- Peri - Catalogo de Componentes 2005Documento493 páginasPeri - Catalogo de Componentes 2005katherine CastellanosAinda não há avaliações

- Prosedur Proyek - Lifting-Rigging ProcedureDocumento32 páginasProsedur Proyek - Lifting-Rigging ProcedureNofrizal NofrizalAinda não há avaliações

- Kuta 15-Roof Top-03-06-2022-1Documento11 páginasKuta 15-Roof Top-03-06-2022-1dede kurniawanAinda não há avaliações

- DM001 F All MPS WPS DCC 400003 PDFDocumento109 páginasDM001 F All MPS WPS DCC 400003 PDFAshokAinda não há avaliações

- Comparison of Ground Motion Selsction Criteria For Seismic DesignDocumento14 páginasComparison of Ground Motion Selsction Criteria For Seismic Designanna_318857983Ainda não há avaliações

- Uk Drawing Jan09 PDFDocumento17 páginasUk Drawing Jan09 PDFMirko Flores Jimenez100% (1)

- GN - 1.04 - Bearing Guidance Notes-SCIDocumento7 páginasGN - 1.04 - Bearing Guidance Notes-SCIraaaaajjjjjAinda não há avaliações

- Progress Up To 231117Documento103 páginasProgress Up To 231117Anonymous UUw70xirblAinda não há avaliações

- Foundation Plan and Anchor Locations: Section CDocumento1 páginaFoundation Plan and Anchor Locations: Section CJavier Guerra TriviñoAinda não há avaliações

- A Civ Spe 000 30002 1Documento30 páginasA Civ Spe 000 30002 1ZaidiAinda não há avaliações

- Tripod Breasting Dolphin - Detail 1 PDFDocumento1 páginaTripod Breasting Dolphin - Detail 1 PDFToniAinda não há avaliações

- 5203 - 2008 LARUCP Plan Review List - Structural v1 0Documento14 páginas5203 - 2008 LARUCP Plan Review List - Structural v1 0Omer HayatAinda não há avaliações

- 08 Tech Spec LSTK D1003AM1 Annexure-4Documento26 páginas08 Tech Spec LSTK D1003AM1 Annexure-4Vikash Singh100% (1)

- Topographical SurveysDocumento27 páginasTopographical SurveysRomeo ZsurzsAinda não há avaliações

- Waterproofing Structures Installed Below Ground Level PDFDocumento50 páginasWaterproofing Structures Installed Below Ground Level PDFDirk BummAinda não há avaliações

- MS For Chemical Grouting (Typical Style) PDFDocumento20 páginasMS For Chemical Grouting (Typical Style) PDFHieu Nguyen Huu100% (2)

- Structural Calc Analysis of in Patient BLDG Facade Rev 03Documento121 páginasStructural Calc Analysis of in Patient BLDG Facade Rev 03عزة الإسلامAinda não há avaliações

- Major10640112x18.3pscgirder V6 Approve P13Documento1 páginaMajor10640112x18.3pscgirder V6 Approve P13rushi123Ainda não há avaliações

- 104 - Blast DoorDocumento1 página104 - Blast DoorMohammedAmmarSalamehAinda não há avaliações

- P20c30ug01prw Aecg Civugsdwg 34801 1 (A)Documento1 páginaP20c30ug01prw Aecg Civugsdwg 34801 1 (A)kaizen.hameshaAinda não há avaliações

- Proposed 3S Facilities For Sba at Al AmaratDocumento1 páginaProposed 3S Facilities For Sba at Al AmaratAnonymous 1HFV185Sl4Ainda não há avaliações

- 16-May-19 20-May-2019 11:12 Zone04 - 0.std: Job No Sheet No RevDocumento4 páginas16-May-19 20-May-2019 11:12 Zone04 - 0.std: Job No Sheet No RevAnonymous 1HFV185Sl4Ainda não há avaliações

- Report Zone 7 - Duct Only R0Documento104 páginasReport Zone 7 - Duct Only R0Anonymous 1HFV185Sl4Ainda não há avaliações

- Dymocks - Fundamentals of Engineering Fe Civil All-In-One Exam Guide by Indranil Goswami, 9781260011340, PaperBack BookDocumento4 páginasDymocks - Fundamentals of Engineering Fe Civil All-In-One Exam Guide by Indranil Goswami, 9781260011340, PaperBack BookAnonymous 1HFV185Sl4Ainda não há avaliações

- Devajith USA Visa FormDocumento5 páginasDevajith USA Visa FormAnonymous 1HFV185Sl4Ainda não há avaliações

- Crack Width Check BS5400 4Documento6 páginasCrack Width Check BS5400 4Anonymous 1HFV185Sl4Ainda não há avaliações

- 24-May-19 11-Jun-2019 00:57 Pipesupport4M - B.STD: Job No Sheet No RevDocumento6 páginas24-May-19 11-Jun-2019 00:57 Pipesupport4M - B.STD: Job No Sheet No RevAnonymous 1HFV185Sl4Ainda não há avaliações

- My 19 Aveo e Brochure enDocumento2 páginasMy 19 Aveo e Brochure enAnonymous 1HFV185Sl4Ainda não há avaliações

- Design CalculationDocumento228 páginasDesign CalculationAnonymous 1HFV185Sl4Ainda não há avaliações

- Sultanate of Oman: Foundation Reinforcement - Cross SectionDocumento2 páginasSultanate of Oman: Foundation Reinforcement - Cross SectionAnonymous 1HFV185Sl4Ainda não há avaliações

- Base Plate DesignDocumento4 páginasBase Plate DesignAnonymous 1HFV185Sl4Ainda não há avaliações

- Minutes of MeetingDocumento2 páginasMinutes of MeetingAnonymous 1HFV185Sl4Ainda não há avaliações

- Design Basis r0Documento31 páginasDesign Basis r0Anonymous 1HFV185Sl4100% (1)

- Report On Expansion Joint R-0Documento15 páginasReport On Expansion Joint R-0Anonymous 1HFV185Sl4Ainda não há avaliações

- 02-Jul-16 04-May-2019 01:30 Pole10m - 0.std: Job No Sheet No RevDocumento1 página02-Jul-16 04-May-2019 01:30 Pole10m - 0.std: Job No Sheet No RevAnonymous 1HFV185Sl4Ainda não há avaliações

- Structural Design Brief: PreambleDocumento6 páginasStructural Design Brief: PreambleAnonymous 1HFV185Sl4Ainda não há avaliações

- Column Design Check SummaryDocumento2 páginasColumn Design Check SummaryAnonymous 1HFV185Sl4Ainda não há avaliações

- Hilti PROFIS Rebar 2.4.12: 1. Loads 2. Drilling & Temperature 3. Material & SafetyDocumento5 páginasHilti PROFIS Rebar 2.4.12: 1. Loads 2. Drilling & Temperature 3. Material & SafetyAnonymous 1HFV185Sl4Ainda não há avaliações

- Oman Convention & Exhibition Center: Financial Status Statement (FSS) As atDocumento2 páginasOman Convention & Exhibition Center: Financial Status Statement (FSS) As atAnonymous 1HFV185Sl4Ainda não há avaliações

- 19 Thrust Block - Bearing 19-ModelDocumento1 página19 Thrust Block - Bearing 19-ModelAnonymous 1HFV185Sl4Ainda não há avaliações

- Computing Liquid-Vapor Phase Diagrams For Non-Ideal Binary MixturesDocumento22 páginasComputing Liquid-Vapor Phase Diagrams For Non-Ideal Binary Mixturesmurdanetap957Ainda não há avaliações

- 03 - 111141e - Kolliphor RH 40Documento6 páginas03 - 111141e - Kolliphor RH 40Karolina ChavkovAinda não há avaliações

- XPS (X Ray Photoemission Spectroscopy) /ESCA (Electron Spectroscopy For Chemical Analysis)Documento46 páginasXPS (X Ray Photoemission Spectroscopy) /ESCA (Electron Spectroscopy For Chemical Analysis)Serdar ArıcanAinda não há avaliações

- Spons Encyclopaedia of The Industrial Arts, Manufactures, and Commercial Products, Part 3Documento396 páginasSpons Encyclopaedia of The Industrial Arts, Manufactures, and Commercial Products, Part 3Books for the lotAinda não há avaliações

- Solubility CurveDocumento2 páginasSolubility CurveDanni SulaimanAinda não há avaliações

- Supercritical Uid Extraction of Spent Coffee Grounds - Measurement of Extraction Curves and Economic AnalysisDocumento10 páginasSupercritical Uid Extraction of Spent Coffee Grounds - Measurement of Extraction Curves and Economic AnalysisMarcelo MeloAinda não há avaliações

- Openstax - Chemistry - Answer Key (Odds)Documento75 páginasOpenstax - Chemistry - Answer Key (Odds)Windel AventuradoAinda não há avaliações

- Aphron Invasion Control System (ICS)Documento8 páginasAphron Invasion Control System (ICS)LoganBohannonAinda não há avaliações

- Why Slabs Curl - Part2Documento6 páginasWhy Slabs Curl - Part2Tim LinAinda não há avaliações

- An Improved Isolation of Trimyristin From Myristica Fragrans As A Renewable Feedstock With The Assistance of Novel Cationic Gemini SurfactantDocumento16 páginasAn Improved Isolation of Trimyristin From Myristica Fragrans As A Renewable Feedstock With The Assistance of Novel Cationic Gemini SurfactantNabila PutriAinda não há avaliações

- Ancient and Modern Paper CharacterizatioDocumento20 páginasAncient and Modern Paper CharacterizatioVornicu NicoletaAinda não há avaliações

- Equalization Tank-Homogenization TankDocumento16 páginasEqualization Tank-Homogenization TankAnusha GsAinda não há avaliações

- Protocol Hybridization Capture of Dna Libraries Using Xgen Lockdown Probes and Reagents Version 3Documento16 páginasProtocol Hybridization Capture of Dna Libraries Using Xgen Lockdown Probes and Reagents Version 3Rodger12Ainda não há avaliações

- Questionbank AS5640Documento9 páginasQuestionbank AS5640Saurav KumarAinda não há avaliações

- Websitecompanies NewDocumento33 páginasWebsitecompanies NewRajiv JulakantiAinda não há avaliações

- Cambridge O Level: Chemistry 5070/41 October/November 2020Documento9 páginasCambridge O Level: Chemistry 5070/41 October/November 2020Islamabad ALMA SchoolAinda não há avaliações

- Service: Residential/Commercial Generator SetsDocumento72 páginasService: Residential/Commercial Generator SetsJosé roberto PoblanoAinda não há avaliações

- Transflex BrochureDocumento7 páginasTransflex BrochureMickijevicAinda não há avaliações

- Msds Colateric Jbs (16 Section)Documento6 páginasMsds Colateric Jbs (16 Section)mndmattAinda não há avaliações

- Corrosion New Jul20Documento66 páginasCorrosion New Jul20hafiz aimanAinda não há avaliações

- Doosan Mitsubishi 2.4L - Product Overview Training PDFDocumento105 páginasDoosan Mitsubishi 2.4L - Product Overview Training PDFkhairul100% (1)

- 10 - Log Cement BondDocumento20 páginas10 - Log Cement BondMahardhyka PrakashaAinda não há avaliações

- CO Storage: 20 ASCO ISO Tank ContainersDocumento5 páginasCO Storage: 20 ASCO ISO Tank ContainersMB ManyauAinda não há avaliações

- Chapter 1 Introduction To The Study of GeneticsDocumento31 páginasChapter 1 Introduction To The Study of GeneticsCassieGrecoAinda não há avaliações

- Sathyabama University Department of Biomedical EngineeringDocumento21 páginasSathyabama University Department of Biomedical EngineeringMathavaraja JeyaramanAinda não há avaliações

- What Is Translocation in PlantsDocumento9 páginasWhat Is Translocation in PlantsZakia BariAinda não há avaliações

- Topic: Insects Pests Of: Cotton and Their IPMDocumento15 páginasTopic: Insects Pests Of: Cotton and Their IPMG Janardana ReddyAinda não há avaliações

- Project Report On Wire RodDocumento9 páginasProject Report On Wire RodEIRI Board of Consultants and Publishers100% (1)

- DSU D InstallDocumento2 páginasDSU D InstallstarykAinda não há avaliações

- Guide For Making A Condition Survey of Concrete in Service: ACI 201.1R-92Documento16 páginasGuide For Making A Condition Survey of Concrete in Service: ACI 201.1R-92malik jahan100% (1)