Escolar Documentos

Profissional Documentos

Cultura Documentos

Magna Cement 2016

Enviado por

Amine Ait ElaasriDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Magna Cement 2016

Enviado por

Amine Ait ElaasriDireitos autorais:

Formatos disponíveis

About ITW

ITW (NYSE:ITW) is a Fortune 200 global multi-industrial

Magna Welding Alloys uses high purity core wire generally having a much higher content of noble or semi-noble manufacturing leader.The companys seven industry-leading

How Magna Welding Alloys Benefits You metals such as nickel, molybdenum, columbium, cobalt etc. than ordinary electrodes. Also our electrodes are coated

segments leverage the unique ITW Business Model to drive solid

growth with best-in-class margins and returns in markets where

Magna Welding Alloys, a Division of ITW PP & F Koera Limited, has been pioneering the concept of with the state of the art - " Magna Flux Coating'' technology specially formulated for maintenance welding. highly innovative, customer-focused solutions are required. ITW

has nearly 50,000 dedicated colleagues in operations around the

" Total Maintenance Welding Solution" since 1968 for Cement Plants and other industries in order to

world who thrive in the companys unique decentralized and

achieve the following objectives: Please check with your local Magna Welding Alloys Distributor for a comprehensive list of welding solutions that will entrepreneurial culture. To learn more about the company and

the ITW Business Model, visit www.itw.com.

Reduce inventories exceed your expectations.

Minimise labour cost To offer the best service to each market segment, ITW PP & F

Specialist Welding Electrodes for Cement Plants Korea Limited operates the following divisions that are branded

Improve equipment availability uniquely for the most prominent recognition by users and

Shorten shutdowns and quicken start-ups customers:

Magna 303 GOLD Ferrite Balanced Super-Strength Non-Cracking Alloy for All Steels

Stretch overhaul intervals

Magna 303 is a maintenance electrode that welds all steels including high alloy steels. It provides excellent heat and OMEGA Ultimate Lubricants

Specializing in lubrication solutions - greases,

corrosion resistance. Magna 303 is excellent for welding and rebuilding of worn parts of Kiln Tyre, Hydraulic Cylinder oils and additives

Research and Development:

Housing, Axles, Pressure Pipes, Roller Shaft / Frames, Buckets, Girth Gear, Pinions, Bull Gears and Swivel Rings.

Magna Technical Research team is dedicated to working in close partnership with its Distributors and

MAGNA Welding Alloys

Customers to provide a premium quality and comprehensive product range with complete technical Specializing in gas and arc welding

back up service. Magna 400 Special Alloy for Crushing Equipment consumables for maintenance

Magna Crusher Rod 400 is a high chrome super metal formulated with rare earth compounds and special metals to

provide an unprecedented shock absorbing quality. It is ideal for hardfacing Bucket Teeth, Hammer Crusher and CORIUM Industrial Chemicals

Network of Distributors: Specializing in industrial & commercial

Crusher Jaws. chemicals and adhesives

The competitive advantage of Magna Welding Alloys lies in its ability to satisfy Customers' application Magna

needs and supply products quickly through its extensive network of Distributors around the world.

Magna 401 Universal Hard Facing Electrode ZETALUBE Lubricants

A new lubricity dimension evolved from

We l d i n g A l l o y s

Magna 401 does not crack even if applied in volume or welded rapidly without cushioning. Ideal for rebuilding on worn

Environmental Policy: experience

parts on Lifting Arms & Rollers, Mill Gear / Drive Pinions found in Crushers and Ball Mill. It provides supreme quality

Magna Welding Alloys envisions environmental protection as an integral part of its business activities. hardfacing for Bulldozers and Diaphragm of Cement Mill. WE SUPPLY SUPERIOR PRODUCTS THAT MAKE MAINTENANCE:

We have an environmental policy aiming to minimize impact on our customers, employees and the

FASTER SAFER MORE RELIABLE

community. Objectives set within the policy are directed at conserving natural resources and reducing Magna 402 Impact-Resistant Alloy for Manganese Steel

Our products are engineered to:

waste. Magna 402 is an electrode, which is austenitic in structure and non-cracking. It can withstand extreme shock, loading

Lower costs Reduce downtime Cut wastage

and impact. It is ideal for overlays and rebuilding of Hammers, Shovel Bucket & Lips, Toggle Bearing Plates, Hammer

Internet and Intranet site: Arms & Shafts etc. in Crusher and Ball Mill. At ITW PP & F Korea Limited we are fully committed to a proactive approach to

Magna Welding Consultants and its Distributors at various cities utilize updated information system safety, health, environment and product improvement. Our commitment is well

Welding & Brazing Solutions

and internet technology to feedback to Customers' queries speedily. Magna 403 Hard Facing Electrode for High Stress Abrasion reflected in:

Magna 403 is designed to resist both extreme high stress and low stress abrasion. This electrode has a balanced arc Our continuous Research and Developments

Personal Service from our Technical Specialist: transfer and a high deposition rate. It is easy to apply with no spatter or pin holes when rebuilding Crane Grabs, Coal

Pipe Bends and I.D. Fans in the Cement Mill.

Our on-going in-house Training and our in-house Training Facilities

Magna Welding Alloy's highly trained Distribution Representatives and Welding Consultants are Our comprehensive range of Quality Products

available to provide a complete package (ask for details from your local representative) to determine Our many long-term Repeat Customers.

Magna 404 Hard Facing Electrode for Extreme Abrasion

Contact Us

your individual welding needs which includes the following:

for Maintenance Repairs

Magna 404 contains hard tungsten cobalt carbides in a tough alloy steel matrix. This special formulation is designed to

resist severe grinding abrasion and extreme wear. The electrode can be applied using either torch or arc welding Distributor:

Customer Support Service: equipment. Ideal for rebuilding Burners (inner & outer Stainless Steel pipes) located in Kilns.

Proactive investigation on problems and complaints

Recommendations on base metal applications Magna 405 Superior Build-up Electrode

Complete solutions to technical enquiries Magna 405 is recommended for use in building up of worn parts for machining later. It is excellent for flame hardening

in Cement Plants

or pack hardening.

In-House Training Program:

Trained Representatives can conduct seminars and presentations on a continuous basis, covering Magna 770 High-Strength Non-Cracking Machinable Electrode for Cast Iron 13th floor, Unit B, We reserve the right to modify or change products for purposes of

subjects such as cost savings, product applications and health and safety requirements. Magna 770 is specially designed to weld all types of cast iron encountered in maintenance applications. It requires PAX Tower, 609 Eonju-ro, improving performance characteristics. 2016 ITW PP & F Korea Limited

little or no preheating. It is ideal for repairing and rebuilding of Engine Housings, Water Pump Housings, Compressor Gangnam-gu, Seoul, The OMEGA, MAGNA, CORIUM & ZETALUBE Trade Marks are the properties

In-house training programs are customised on request Korea 06108

of ITW Inc., and are used under licence by ITW PP & F Korea Limited

Cylinder Block Housings, Couplings of Kiln and Gear Box Housings. The information contained in this publication supersedes all relevant information

email: enquirygroup@magnagroup.com previously released and is to the best of our knowledge and accurate at the time of

MPL 038 Eng Version

issue on June, 2016.

On Site Visits:

Magna 777 Generation II Machinable Electrode for Cast Iron

Regular on sites visits conducted by Welding Consultants and Distribution Representatives

Request of on-site visits by Welding Consultants are welcomed

Superior design enables economical use on virtually all types of cast iron. High-tech "controlled blast" pulse action

automatically burns off surface contaminants before weld metal transfer. This machinable electrode delivers superior

VISIT OUR WEB SITE AT: WWW.MAGNAGROUP.COM

On-site demonstrations can be conducted by Distribution Representatives on request weld and protection for Engine Housings of heavy vehicles at quarry, Bearing Housings in Cement Mill and Couplings

ITW PP & F Korea Limited is a business unit of Illinois Tool Works Inc. (ITW), U.S.A.

in Raw Mill and Kiln.

2016 ITW PP & F Korea Limited. All rights reserved.

Some Application Examples of Magna Welding Alloys

Typical Process Flow of Ordinary Portland Cement

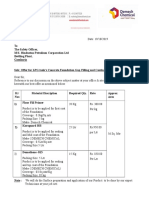

Equipment Particular Locations Base Material Common Problems Magna Solutions Why Magna is better?

LIMESTONE QUARRY

(* = Overlay) 2 LIMESTONE CRUSHING PLANT 1

(1) QUARRY

Hydraulic shovels Bucket teeth Manganese Steel Severe Impact & M402 Withstands extreme shock and impact LIMESTONE

Abrasion M400 Provides a high deposit rate with little or STORAGE DUMPING CAR CABLEWAY

no spatter.

OR BELT CONVEYOR

Outstanding resistance to sand and stone wear 3 DUMPER

Cement is second only to water as the most consumed substance on earth, with nearly Engine Housings Cast Iron Cracks M770 / M777 Specially designed for welding all types of

ELECTROSTATIC

three tons used annually for each person on the planet. Cement is the critical ingredient cast irons CONVEYOR BELT

Chassis Bucket Body Manganese Steel Cracks, Punctures M303 Gold Provides superior corrosion resistance and

RECLAIMER PRECIPITATOR

in concrete, therefore an indispensable part of meeting society's needs for housing and CLAY

basic infrastructure such as bridges, roads, water treatment facilities, schools and heat resistance MIXING BLENDING

WEIGHING AND STORAGE SILO

Dumpers Hydraulic Cylinder Alloy Steel Cracks M303 Gold Ditto + Delivers high tensile strength, yield strength

hospitals. FEEDERS

Housing & holding power

Chassis Alloy Steel Cracks M303 Gold Ditto + Excellent for all position welding CLAY RAW MILL

And it is the hundreds of Cement Plants located all over the world that Magna Welding STORAGE

Bulldozer Dozer Sprockets Manganese Steel Friction M402 Withstands extreme shock, loading and impact

Alloys is committed to serve. With its use in construction of shelter and other assets of

millions, cement is manufactured to strict standards. Based on the same philosophy,

Impact IMPACT CRUSHER 5

Wear *M401 *Engineered to resist heavy abrasion and wear

Magna Welding Alloys has been standing behind Cement Plants' most demanding SILICA

Track Link & Pin Manganese Steel Friction M402 Withstands extreme shock and impact SILICA SAND

maintenance needs with its proven solutions and cost-effectiveness over the years. BAG FILTER

Track Roller Impact *M401 *Crack-free deposit even with large volume SAND STORAGE

application

In the production of cement, there are many stages involving the crushing and grinding of WEIGHING

Front Blade Mild Steel & Abrasion, Friction M402 Ideal for shock & impact resisting build-ups

raw materials like limestone and coal as well as semi-finished cement at the later stage of FEEDER

production. These harsh processes cause wear and tear to key components through

Manganese Steel *M403 *Hardfacing for high stress abrasion

PYRITE

4

Engine Housings Cast Iron Cracks M770 / M777 Offers machinable and non-cracking welds PYRITE CINDER

impact, abrasion, corrosion and high temperatures induced on equipment such as the M100 Chamfers, grooves & gouges metals with no CINDER STORAGE

earthmoving equipment, crushers, roller presses, grinding tables, kiln trunions, etc. special skills required

Crushers Hammer Crusher Manganese Steel Impact, Friction M402 Withstands extreme shock, loading and impact WEIGHING NEW SUSPENSION

With spiralling costs of maintenance, labour and expensive new parts challenging *M400 *Specially engineered for crushers with FEEDER COAL MEAL BIN

Cement Plants today, scraping or replacing of parts is not a satisfactory answer. The COAL PREHEATER

ultra-resistance to impact and abrasion COAL COAL MILL WITH PRECALCINER

alternative is to salvage expensive parts by a comprehensive wear management Crusher Jaws Alloy Steel Friction, Abrasion M402 / *M400 Ditto + Can be applied using either stringer bead STORAGE

system. The most reliable way is to rebuild and reclaim equipment with or weave techniques

maintenance welding solutions. Extending the life of equipment parts through the

WASTE HEAT

Toggle Plate Austenitic Wear M402 Withstands shock and impact

use of electrodes is the most preferred and economic method.

RECOVERY PLANT

Manganese Steel NOTE:

Toggle Seal Manganese Steel Wear M402 Works rapidly, hardens to great depth and resists

However, maintenance engineers understand the conditions for production welding excessive shock and impact

are entirely different from conditions for maintenance welding. In production welding *M400 *Outstanding resistance to stone and sand wear FUEL OIL TANK ELECTROSTATIC MATERIAL FLOW

the base metal is known, welding environments are ideal and projects are repetitive. Blow Bars Manganese Steel Impact, Abrasion M402 / *M400 Excellent for equipment build-ups and *overlays PRECIPITATOR

In maintenance welding the base metals are unknown, welding conditions are less (4) RAW MILL

than ideal and repairs often are carried out on rusty and dirty parts. Raw Mill Girth Gear Alloy Steel Wear M303 Gold High ease-of-application, welds all kinds of steels GAS FLOW

Girth Gear Drive Alloy Steel Wear M303 Gold Machinable weld deposit

The challenge now is not to prove welding as the preferred solution, but to identify a truly preferred solutions provider. Pinion Work hardens to high hardness

Diaphragm Manganese Steel Impact & Abrasion M402 Withstands extreme shock & impact CEMENT BIN

Whether you are the Owner of a Cement Plant, the Plant Operation Manager, Maintenance Manager, or Maintenance Engineer, *M401 *Resists heavy abrasion

your day-to-day challenge is to maximize the return on every dollar you invest in your assets and maintenance jobs. You need Couplings Cast Iron Cracks M770 / M777 Welds most kinds of cast iron CLINKER

a reliable and professional partner who can offer you a genuine wear management system. Magna Welding Alloys is your Crack-free deposit 7 STORAGE

ROTARY KILN

ultimate answer.

Kiln Kiln Tyre Cast Steel

(6) CLINKER PRODUCTION

Wear M303 Gold Offers high versatility for repairing unknown or WASTE HEAT 6 BULK CEMENT

Magna Welding Alloys' Wear Management System offers Complete Solutions to the following dissimilar steels RECOVERY PLANT CLINKER

Key Equipment and Machinery of Cement Plants GRATE COOLER

Highly ductile weld metal with very high UTS

1. Quarries 3. Homogenization 6. Clinker fabrication 8. Additives Roller Shaft Carbon Steel Wear M303 Gold Weld deposits are machinable BULK CEMENT

Shovel loader Reclaimer Kiln Silo HIGH EFFICIENCY CEMENT TRAIN LOADING

Bulldozer Excavator Preheater Drying plant

Burner inner S.S. Steel Abrasion M303 Gold Excellent resistance to corrosion GYPSUM WEIGHING SEPERATOR SILO

Drilling equipment Traveling crane Grinder (coal) Metering system & Outer pipe *M404 Highest resistance to abrasion

FEEDERS BULK CEMENT

Reclaimer Metering system Cooler Drag chain Couplings Cast Iron Cracks M770 / M777 Produces crack-free and machinable weld SHIP LOADING

Tractor Planetary cooler Weighing feeder

Truck 4. Raw mill Ventilator deposits GYPSUM BAG FILTER

Funnel Vertical mill Dust extraction 9. Cement fabrication (9) CEMENT PRODUCTION

Dragline excavator

Conveyor belt

Ball mill

Tube mill

Filter

Clinker crusher

Ball mill

Vertical mill

Cement Mill Main Bearing Cast Iron Wear M770 / M777 Gives perfect machinable welds on cast irons and

STORAGE 9 ROTARY

Scalper Roller mill Hammer crusher Separator Housing no preheating is required IMPACT CRUSHER PACKER

Cone crusher Roller press Ventilator Girth Gear Drive Alloy Steel Wear M303 Gold Gives super strength as well as high precision

Hammer crusher Separator 7. Clinker storage Pipeline

Pinion weld

CEMENT

Bar crusher Drag chain Cement silo

Double roll crusher 5. Meal transport and Bucket elevator Pneumatic trough Work hardens to high hardness

MILL

Jaw crusher

Screening machine

homogenization

Bucket elevator

Belt conveyor

Traveling crane

conveyor

Diaphragm Manganese Steel Impact & Abrasion M402 Produces perfect build-up and *hardfacing to 8 PACKED CEMENT

Weighing Feeder Storage silo 10. Delivery *M401 ensure ultra protection

2.

Clay / stone transport

Screw conveyor

Fuller pump

Pipe-line

Storage dome Rotary Packer

Pump Trunion and Cast Steel Cracks M303 Gold Welds all kinds of steels 10

Slurry pump Sacking I.D. Fans Highly ductile weld metal with exceptional tensile

Conveyor belt Filter strength

* Please refer to Typical Process Flow of Ordinary Portland Cement on opposite page

Você também pode gostar

- Final - Metex GroupDocumento37 páginasFinal - Metex GroupVeluri HemanthAinda não há avaliações

- A TEC Leaflet HURRICLON PDFDocumento2 páginasA TEC Leaflet HURRICLON PDFthanh100% (1)

- Bechem Berutox M 21 KN 9007601 (GB)Documento1 páginaBechem Berutox M 21 KN 9007601 (GB)Luciano de Carvalho100% (2)

- 2 SpecificationDocumento20 páginas2 Specificationprithvi614710Ainda não há avaliações

- Klueberquiet BQH 72 102-EnDocumento2 páginasKlueberquiet BQH 72 102-Enвлад камрAinda não há avaliações

- High Performance Lubricants: Molykote Molykote MolykoteDocumento4 páginasHigh Performance Lubricants: Molykote Molykote Molykoteestebang956Ainda não há avaliações

- BELZONA 1111 Product Specification SheetDocumento2 páginasBELZONA 1111 Product Specification Sheetsibi_s_rajAinda não há avaliações

- Mobilgrease XHP 460Documento3 páginasMobilgrease XHP 460Jaime Miloz Masle JaksicAinda não há avaliações

- Training Report FINAL0000 RajatDocumento50 páginasTraining Report FINAL0000 Rajatrajat sharmaAinda não há avaliações

- Cement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Documento20 páginasCement Manufacturing: (Alan Gee-Lehigh Hanson Cement)NomanAinda não há avaliações

- Belzona 3111Documento2 páginasBelzona 3111Bobby SatheesanAinda não há avaliações

- Firex EC-43 DemoDocumento10 páginasFirex EC-43 DemoBanani SahuAinda não há avaliações

- 26 Core SolutionsDocumento32 páginas26 Core SolutionsSunil SinghAinda não há avaliações

- Aditivi Materiale PlasticeDocumento4 páginasAditivi Materiale PlasticeLavinia CalinAinda não há avaliações

- Belzona 5892 - BrochureDocumento2 páginasBelzona 5892 - BrochureANIBALLOPEZVEGAAinda não há avaliações

- Why Superon SteelDocumento83 páginasWhy Superon SteelArdh0072Ainda não há avaliações

- Installation of Rail Line Lubricator in EOT Crane For Rail & Wheels Wear ProtectionDocumento5 páginasInstallation of Rail Line Lubricator in EOT Crane For Rail & Wheels Wear ProtectionijsretAinda não há avaliações

- Preheater Calciner SystemsDocumento8 páginasPreheater Calciner SystemsDanni SulaimanAinda não há avaliações

- Workshop All AnnexuresDocumento18 páginasWorkshop All AnnexuresLavee ChandrakarAinda não há avaliações

- Document List: The Document List Contains Links To All Files of The Manual. Click On The Green Text To Open A FileDocumento4 páginasDocument List: The Document List Contains Links To All Files of The Manual. Click On The Green Text To Open A FilemkpqAinda não há avaliações

- Coating Handout PDFDocumento2 páginasCoating Handout PDFVictoria MirkoAinda não há avaliações

- Heavy-Duty, Reinforced Range Heavy-Duty, Reinforced Range Heavy-Duty, Reinforced RangeDocumento8 páginasHeavy-Duty, Reinforced Range Heavy-Duty, Reinforced Range Heavy-Duty, Reinforced RangeengindmecAinda não há avaliações

- High Temperature Solid LubricantDocumento19 páginasHigh Temperature Solid Lubricantgcytd65e756c56e765rAinda não há avaliações

- Krytox Typical Properties GPL 227Documento2 páginasKrytox Typical Properties GPL 227Ramu NallathambiAinda não há avaliações

- Chapter 5 Final A5 EditDocumento8 páginasChapter 5 Final A5 EditkINGAinda não há avaliações

- Belzona - Cold Curing WrapsDocumento4 páginasBelzona - Cold Curing WrapsNay ThihaAinda não há avaliações

- of NE Railway Summer TrainingDocumento18 páginasof NE Railway Summer TrainingAkhilesh Singh80% (5)

- Kirloskar Corrocoat GFC CaseStudyDocumento35 páginasKirloskar Corrocoat GFC CaseStudyAbhishek SharmaAinda não há avaliações

- HKR ProfileDocumento28 páginasHKR ProfileTariq AhmedAinda não há avaliações

- Belzona 4111Documento2 páginasBelzona 4111Bobby SatheesanAinda não há avaliações

- FAQ - What Is The Procedure For Welding En24 (Subsequently Known As 817M40 and 1.6582 34CrNiMo6), A 0.4% C, 1.25% CR, 0.3% Mo LowDocumento2 páginasFAQ - What Is The Procedure For Welding En24 (Subsequently Known As 817M40 and 1.6582 34CrNiMo6), A 0.4% C, 1.25% CR, 0.3% Mo LowSubhra S SanyalAinda não há avaliações

- Belzona 1391 T (Flyer)Documento2 páginasBelzona 1391 T (Flyer)Bobby SatheesanAinda não há avaliações

- Awst 11 07Documento8 páginasAwst 11 07Herd ImanAinda não há avaliações

- PILLARD AKTUEL Progressive BurningDocumento3 páginasPILLARD AKTUEL Progressive BurningSteveih100% (1)

- Coal BurnerDocumento11 páginasCoal BurnerGeorge Markas50% (2)

- Bechem Lubricants For High Load and High TemperatureDocumento3 páginasBechem Lubricants For High Load and High TemperatureShukor AzAinda não há avaliações

- Fls - Cfi SiloDocumento4 páginasFls - Cfi SiloNicolás CanelliAinda não há avaliações

- TB - T 2843-2007Documento21 páginasTB - T 2843-2007erdemAinda não há avaliações

- High Pressure Blowers 1Documento11 páginasHigh Pressure Blowers 1Miroslav Aleksic100% (1)

- Epilux-78 Primer-Base (MSDS) PDFDocumento4 páginasEpilux-78 Primer-Base (MSDS) PDFAkhtar aliAinda não há avaliações

- Lucky Internship ReportDocumento29 páginasLucky Internship Reportسید عاصم علی شاہAinda não há avaliações

- Clinker CoolerDocumento5 páginasClinker CoolerManish VermaAinda não há avaliações

- Offer For HPCLDocumento2 páginasOffer For HPCLhello tumAinda não há avaliações

- Combustion HandbookDocumento31 páginasCombustion HandbookJavier RiveraAinda não há avaliações

- Loctite Solutions For Power PlantsDocumento14 páginasLoctite Solutions For Power PlantsHusen TaufiqAinda não há avaliações

- Epoxy Injection Welds Cracks Back TogetherDocumento4 páginasEpoxy Injection Welds Cracks Back Togethergonzalez_m_aAinda não há avaliações

- Conformal Coating Curing and Drying Technical Bulletin Apr 09Documento2 páginasConformal Coating Curing and Drying Technical Bulletin Apr 09Lee HitchensAinda não há avaliações

- Belzona 1391Documento2 páginasBelzona 1391AsadAliAinda não há avaliações

- Dokumen - Tips - Castables and Refractories For Cement Dri Sponge Iron Kiln CoolerDocumento8 páginasDokumen - Tips - Castables and Refractories For Cement Dri Sponge Iron Kiln CoolerjulianoducaAinda não há avaliações

- CementDocumento59 páginasCementkamal21Ainda não há avaliações

- Speciality Lubricants For The Railway Industry B090000102 PDFDocumento11 páginasSpeciality Lubricants For The Railway Industry B090000102 PDFJavier Alejandro Muralles ReyesAinda não há avaliações

- Bestway Cement Annual 15 AccountsDocumento49 páginasBestway Cement Annual 15 AccountsM Umar FarooqAinda não há avaliações

- Final Draft 1 Abhishek VermaDocumento60 páginasFinal Draft 1 Abhishek VermaMasir SinghAinda não há avaliações

- Jetflex - Highlights ArticleDocumento2 páginasJetflex - Highlights Articlenagendra51Ainda não há avaliações

- Add Sector: ANTOML/MI/ME/MUDocumento129 páginasAdd Sector: ANTOML/MI/ME/MUshashank.prajapati9389Ainda não há avaliações

- MIS - Wipro LimitedDocumento7 páginasMIS - Wipro LimitedMehul DevatwalAinda não há avaliações

- CC-Link & CC-Link - LT CatalogDocumento119 páginasCC-Link & CC-Link - LT Catalogkhonghohenk6Ainda não há avaliações

- Resume AnkushDocumento3 páginasResume AnkushouchityaAinda não há avaliações

- DISCIPLINESPECS - 20170810 - Standard Specifications For IT Network Configur.... PDF - DOC634349Documento21 páginasDISCIPLINESPECS - 20170810 - Standard Specifications For IT Network Configur.... PDF - DOC634349Todd EAinda não há avaliações

- Product Data Sheets: Communications SystemDocumento11 páginasProduct Data Sheets: Communications SystemjenkahAinda não há avaliações

- MRF100201 De2Documento110 páginasMRF100201 De2Petros TsenesAinda não há avaliações

- Artificial Intelligence/Search/Heuristic Search/astar SearchDocumento6 páginasArtificial Intelligence/Search/Heuristic Search/astar SearchAjay VermaAinda não há avaliações

- BrochureDocumento8 páginasBrochurevacmanilaAinda não há avaliações

- GG&G 2012 CatDocumento111 páginasGG&G 2012 Cattyrant88Ainda não há avaliações

- Dahua Video Conferencing SolutionDocumento16 páginasDahua Video Conferencing SolutionDennis DubeAinda não há avaliações

- Incident Log - TemplateDocumento10 páginasIncident Log - TemplateRajaAinda não há avaliações

- Vbulletin 5 Connect: Quick Start Guide (Ver 1.0)Documento21 páginasVbulletin 5 Connect: Quick Start Guide (Ver 1.0)dantevasquezAinda não há avaliações

- Ge Washing Machine ManualDocumento52 páginasGe Washing Machine Manuallillith1723Ainda não há avaliações

- School MemoDocumento1 páginaSchool MemoBellaAinda não há avaliações

- Honeywell Aquatrol 2000 PDFDocumento60 páginasHoneywell Aquatrol 2000 PDFvsilickasAinda não há avaliações

- Micromagnetic Simulation of Magnetic SystemsDocumento12 páginasMicromagnetic Simulation of Magnetic SystemsImri SsAinda não há avaliações

- EAU 2022 - Prostate CancerDocumento229 páginasEAU 2022 - Prostate Cancerpablo penguinAinda não há avaliações

- St10 Flasher DLL: Stmicroelectronics ConfidentialDocumento10 páginasSt10 Flasher DLL: Stmicroelectronics Confidentialeshwarp sysargusAinda não há avaliações

- How To Apply For The UpcatDocumento3 páginasHow To Apply For The UpcatAaron ReyesAinda não há avaliações

- W6 Lesson 7 Find, Evaluate, and Use Online Information ResourcesDocumento14 páginasW6 Lesson 7 Find, Evaluate, and Use Online Information Resourcescharimaine hernandezAinda não há avaliações

- Eco SPARDocumento3 páginasEco SPARMohammad LabinAinda não há avaliações

- Ch08 Project SchedulingDocumento51 páginasCh08 Project SchedulingTimothy Jones100% (1)

- BPV ApproachDocumento13 páginasBPV ApproachfwfsdAinda não há avaliações

- CHAPTER 22-Audit Evidence EvaluationDocumento27 páginasCHAPTER 22-Audit Evidence EvaluationIryne Kim PalatanAinda não há avaliações

- LTE ID RNP StandardizationDocumento9 páginasLTE ID RNP Standardizationahdanizar100% (1)

- White Paper - Data Communication in Substation Automation System SAS - Part 1 Original 23353Documento5 páginasWhite Paper - Data Communication in Substation Automation System SAS - Part 1 Original 23353sabrahimaAinda não há avaliações

- Pricelist Jan 2023Documento7 páginasPricelist Jan 2023Rahmat FadilAinda não há avaliações

- SIConitDocumento2 páginasSIConitJosueAinda não há avaliações

- PepsiCo Strategic Plan Design PDFDocumento71 páginasPepsiCo Strategic Plan Design PDFdemereAinda não há avaliações

- Mortal Kombat XDocumento24 páginasMortal Kombat XMindSpaceApocalypseAinda não há avaliações

- Vishnu Institute of Technology: V2V CommunicationsDocumento22 páginasVishnu Institute of Technology: V2V CommunicationsBhanu PrakashAinda não há avaliações

- National School Building Inventory (NSBI) Encoding For SY 2021-2022Documento31 páginasNational School Building Inventory (NSBI) Encoding For SY 2021-2022Renato Rivera100% (1)

- Sydney Boys 2017 2U Accelerated Prelim Yearly & SolutionsDocumento26 páginasSydney Boys 2017 2U Accelerated Prelim Yearly & Solutions黄心娥Ainda não há avaliações

- Procter & Gamble Global Geothermal Screening Study FINAL 9 Feb 2023Documento56 páginasProcter & Gamble Global Geothermal Screening Study FINAL 9 Feb 2023Mohammad Syahir JamaluddinAinda não há avaliações

- RRB NTPC Previous Year Paper 20: WWW - Careerpower.inDocumento16 páginasRRB NTPC Previous Year Paper 20: WWW - Careerpower.inSudarshan MaliAinda não há avaliações