Escolar Documentos

Profissional Documentos

Cultura Documentos

Synchro Izer

Enviado por

Karthigaiselvan ShanmuganathanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Synchro Izer

Enviado por

Karthigaiselvan ShanmuganathanDireitos autorais:

Formatos disponíveis

Synchronizers1.

qxd 4/11/03 12:44 PM Page 36

How

Synchronizers

Work Blocking Rings

by Steve Bodofsky

T

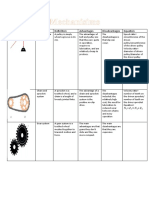

he other day I was talking to a Synchronizers consist of three All three of these components

technician about a manual main components: work together to adjust the speed of the

transmission problem that he 1. Slider shafts, and align the gears so the slider

was dealing with. The trans was grind- 2. Keys (usually three of them) can link two of the shafts together.

ing going into 2nd gear. He was sure 3. Blocking Rings (usually brass)

the synchronizer was the problem. But

when I opened the trans, he said, the

teeth on the blocking rings looked

fine.

He was right: The synchronizer

was bad. The problem was that he did-

nt really understand how a synchroniz-

er worked, so he didnt know what to Slider

look for.

That might sound surprising to

you, but Ive talked to a number of

techs over the years that didnt really

have a good grasp on the subject. In

fact, I wasnt completely comfortable

with them myself until I was asked to

write a manual on the subject a few

years ago. And as anyone whos ever

been there before will tell you, if you

really want to understand a subject, try

teaching it to someone else. Key

So lets take a look at synchroniz-

ers and see how they work. Once you

understand the principles of synchro-

nizer operation, youll find diagnosis

and repair a snap.

What Are Synchronizers?

Synchronizers are devices used in

manual transmissions to allow the

transmission to shift from gear to gear

without grinding. They do this by

adjusting the rotation of the shafts with-

in the transmission, so that the gears

remain aligned throughout the shift.

36 GEARS May-June 2003

Synchronizers1.qxd 4/11/03 12:44 PM Page 38

Overview of a Manual wheels. Now you want to shift into sec-

Transmission ond.

In most manual transmissions, all You press the clutch pedal to the

of the gears ride freely on the output Most shift forks floor: This releases the clutch from the

shaft. And theyre all constantly flywheel. Now the only thing driving

meshed with the transmission counter- and sliders will the transmission shafts is the rotation of

fit in either

shaft. To lock the transmission into a the wheels, which drives the output

single gear, the slider has to slide over shaft. Since the slider still has first gear,

the teeth on one of the gears, locking the output shaft is still turning the coun-

that gear to the output shaft. This com- direction, but theyll tershaft and input shaft.

only work properly

pletes the powerflow through the trans- You slide the gearshift out of first:

mission, from the engine to the wheels. This separates the output shaft from the

So youre driving along in first countershaft. Now the two halves of the

gear. The clutch is applied to the fly- facing one way. transmission are still turning at the

wheel, and the powerflow is complete same speeds, but separately. You want

through the trans, driving through to the to shift the unit into second gear, but

second gear is smaller than first gear, so

the second gear teeth are moving by

Get Ready to faster than the slider teeth. Which

means that second gear, the counter-

shaft, and the input shaft are all turning

Shift Gears! too fast. If you tried to move the slider

over the second gear, itd grind.

Thats why we have synchronizers:

To adjust the speed of the gear, coun-

tershaft and input shaft, so theyre all

REMIUMS THAT WILL turning at the same speed as the output

shaft during the shift.

Synchronizer Operation

EDUCE YOUR INSURANCE COSTS,

As you continue to pull on the

FROM A shifter, the slider first pushes against

the synchronizer keys. These keys, in

turn, push against the blocking ring,

which pushes the blocking ring into the

EWLY ENDORSED BROKER, cone-shaped part of the gear. The

READY TO

blocking ring acts as a brake, grabbing

the gear, forcing it to slow down (or

speed up, depending on whether youre

ELIVER PRICE & SERVICE upshifting or downshifting).

The two halves of the transmission

are now linked together by friction; not

enough of a link to drive the vehicle,

YOUR TRANSMISSION BUSINESS. but enough to keep the two shafts turn-

ing at the same speed while you com-

plete the shift.

At the same time, the keys and the

IABILITY, PROPERTY, AUTO notches in the blocking ring have

COVERAGES & MORE! aligned the teeth on the blocking ring

with the teeth on the gear. Now, as you

continue to push the shifter into gear,

the slider rides along the teeth on the

blocking ring, using them as ramps to

align the teeth on the slider with the

gear teeth. This prevents a misalign-

For more information and a quote ment problem, so the shifter slides into

call Brant Watson, Rachel Lavin or Erin Heffernan Insurance gear easily and consistently.

Brokers License #

Trevethan, Toll Free at 1-800-234-6787. 0564249 Once you have the shifter pushed

38 GEARS May-June 2003

Synchronizers1.qxd 4/11/03 12:44 PM Page 39

all the way into gear, you release the ring in proper alignment with the teeth ment and direction will go a long way

clutch. The two halves of the transmis- on the gear. So you could have a gear toward avoiding assembly problems

sion are now locked in second gear, and clash during the shift. later.

you can continue driving along until Of course, you also have to make As you can see, theres a lot that

youre ready to shift into third, and the sure the slider and hub are in good goes on in a manual transmission dur-

process begins all over again. shape, and theres no noticeable wear ing a shift. And its amazing how little

As you can see, there are a lot of on the cone-shaped area of the gear. wear or damage is necessary to cause a

mechanical processes involved with Any wear in any of these locations problem. Remember the processes

synchronizer operation: Pushing, grab- could cause a problem during shifting. involved with synchronizer operation

bing, aligning, holding sounds like Last of all, check your assembly: the next time youre facing a transmis-

shopping the week before Christmas! Most shift forks and sliders will fit in sion that grinds going into gear.

So lets see what we need to check to either direction, but theyll only work

make sure the synchronizers working properly facing one way. The best way

right. to avoid problems during assembly is to

mark these components before disas-

Synchronizer Checks sembly. A little notch indicating place-

When you push on the shifter, the

slider pushes the keys into the blocking

ring. So the keys have to be in good

shape, and the springs that hold them

out against the slider have to be strong. Be a winner.

If the springs are weak, the keys will

drop out of the way, and wont put the

appropriate pressure against the block- Shift to Rockland Standard Gear.

ing ring.

Next the blocking ring: Yes, the

teeth are important for proper align- We road test our parts at 190 mph.

ment, but even more important - and

more likely to wear - is the inside of the

synchronizer. This cone-shaped area

has to grab the gear, holding it to the

slider as the shift begins. If the inside

area is worn out, the synchronizer

wont grab the gear, so the gear will

grind during the shift.

This is why most manufacturers

provide a clearance spec between the

blocking ring and the gear. They want

you to place the blocking ring down

onto the gear, and then check for prop-

er clearance using a feeler gauge. If Huge Inventory of OEM Quality Parts

there isnt enough clearance, the block-

ing ring is sitting too low on the gear, so New & Reman Transmissions & Transfer Cases

it wont grab onto the gear during the

shift.

Toll Free Technical Support

What they often dont tell you is Same Day Shipping

that its possible for the blocking ring to

have adequate clearance, but still not

grab the gear surface. So you should AWA-AISIN BORG WARNER DAIKIN CLUTCH DANA DODGE

also check for proper friction. Press the

EATON EXEDY SPORT CLUTCH FORD ISUZU JEEP LuK CLUTCH

blocking ring onto the gear surface, and

see if the blocking ring turns freely: It MITSUBISHI MORSE CHAIN NEW PROCESS NEW VENTURE

shouldnt. The blocking ring should NISSAN TTC-SPICER TTC-TREMEC TOYOTA ZF

grab onto the gear and hold it firmly as

you press down.

And check the notches on the Call 1-800-227-1523 1-845-753-2005 (alt.)

blocking ring. If theyre worn, they Fax 1-877-774-3294 (toll free)

wont hold the teeth on the blocking Or email rsggear@aol.com Shipping 8:30 AM - 5:30 PM EST, M-F

GEARS May-June 2003 39

Você também pode gostar

- Assig.6 1.CuevaS - Mechanicalvibrations2023Documento16 páginasAssig.6 1.CuevaS - Mechanicalvibrations2023SamuelAndresAinda não há avaliações

- Final Drive and DifferentialDocumento9 páginasFinal Drive and DifferentialVasantha SeelanAinda não há avaliações

- GearsDocumento4 páginasGearsYadanaAinda não há avaliações

- Synchromesh Coupling MechanismDocumento17 páginasSynchromesh Coupling MechanismTung NguyenAinda não há avaliações

- 2.00AJ / 16.00AJ Exploring Sea, Space, & Earth: Fundamentals of Engineering DesignDocumento22 páginas2.00AJ / 16.00AJ Exploring Sea, Space, & Earth: Fundamentals of Engineering DesignL11r1Ainda não há avaliações

- MechanisimsDocumento5 páginasMechanisimsIván AguirreAinda não há avaliações

- How Manual Gearboxes WorkDocumento5 páginasHow Manual Gearboxes Workloihua2002Ainda não há avaliações

- Transmission 1 Transmission 1: Group 3Documento30 páginasTransmission 1 Transmission 1: Group 3Edwin Anugrah EffendyAinda não há avaliações

- How To Shift The Spicer PRO-SHIFT 18 Speed Transmission: Starting Vehicle From A StopDocumento2 páginasHow To Shift The Spicer PRO-SHIFT 18 Speed Transmission: Starting Vehicle From A StopMA RIOAinda não há avaliações

- Activities of Mechanisms (3º ESO C Technology) : Eva e IbtisamDocumento7 páginasActivities of Mechanisms (3º ESO C Technology) : Eva e IbtisamLola Jiménez BlancoAinda não há avaliações

- 0.rahat Sir AutomobileDocumento157 páginas0.rahat Sir AutomobileTahammul Islam IbonAinda não há avaliações

- Gear Drive, Belt and Chain Drive - Lecture NotesDocumento26 páginasGear Drive, Belt and Chain Drive - Lecture NotesVarun KavvampalliAinda não há avaliações

- Automobile Engineering - Mechanical EngineeringDocumento7 páginasAutomobile Engineering - Mechanical EngineeringMusa Karim ShuvoAinda não há avaliações

- Robotics: - Prabhat Chandra BajpaiDocumento26 páginasRobotics: - Prabhat Chandra BajpaiPrabhat BajpaiAinda não há avaliações

- How Manual Transmissions WorkDocumento7 páginasHow Manual Transmissions Workbishal.sonarAinda não há avaliações

- Transmission Paper Short QuestionsDocumento18 páginasTransmission Paper Short QuestionsAbdurrehman HashmiAinda não há avaliações

- Planetary Gear Unit-PPT 3Documento24 páginasPlanetary Gear Unit-PPT 3Gemechu DemeAinda não há avaliações

- Mechanical Basics PDFDocumento15 páginasMechanical Basics PDFZeyadAinda não há avaliações

- Gearboxes Design Guide PDFDocumento26 páginasGearboxes Design Guide PDFDracoRodriguezAinda não há avaliações

- Gearboxes: Motion Design GuideDocumento26 páginasGearboxes: Motion Design GuideMohana Rao VabbilireddiAinda não há avaliações

- A305 Mesleki 2 Motor Erdem UzunsoyDocumento37 páginasA305 Mesleki 2 Motor Erdem Uzunsoyburhan1065Ainda não há avaliações

- Workshops Pressure, GearDocumento6 páginasWorkshops Pressure, GearShubham PopliAinda não há avaliações

- Workshops Pressure, GearDocumento6 páginasWorkshops Pressure, GearShubham PopliAinda não há avaliações

- Simpson Planetary Gear Unit: Section 3Documento25 páginasSimpson Planetary Gear Unit: Section 3rabitosanAinda não há avaliações

- Transmission Paper Short QuestionsDocumento5 páginasTransmission Paper Short QuestionsAtif SultanAinda não há avaliações

- MEC 130 Module 4 - PDF 1 Types of ClutchesDocumento12 páginasMEC 130 Module 4 - PDF 1 Types of ClutchesvijayAinda não há avaliações

- Automatic Transmission Problems and SolutionsDocumento3 páginasAutomatic Transmission Problems and SolutionsMakuetewo EmmanuelAinda não há avaliações

- Document 2 TDe9 12082018Documento8 páginasDocument 2 TDe9 12082018RoshanAinda não há avaliações

- DL 2602gb IngDocumento11 páginasDL 2602gb IngKamanziAinda não há avaliações

- SPT Attach MagDocumento6 páginasSPT Attach MagAnonymous Clyy9NAinda não há avaliações

- 15 Ishan BajpaiDocumento2 páginas15 Ishan BajpaiKylo RenAinda não há avaliações

- Power Transmission: Rotational PulleyDocumento19 páginasPower Transmission: Rotational PulleyQim SvAinda não há avaliações

- Mechanics and Statics 2Documento25 páginasMechanics and Statics 2Aggelos VelegrakisAinda não há avaliações

- Synchromesh Gearbox - Construction, Working Principle, Advantages, Disadvantages, and Applications (PDF)Documento7 páginasSynchromesh Gearbox - Construction, Working Principle, Advantages, Disadvantages, and Applications (PDF)Kyle LabileAinda não há avaliações

- Manual Transaxle Training GuideDocumento127 páginasManual Transaxle Training GuideLojan Coronel José Humberto100% (1)

- ClutchesDocumento24 páginasClutchesRom XenonAinda não há avaliações

- CrankshaftDocumento7 páginasCrankshaftJhesa Mae DesengañoAinda não há avaliações

- Borg Warner R10 Wiring Instruction: Originally Posted OnDocumento5 páginasBorg Warner R10 Wiring Instruction: Originally Posted OnRob WolfeAinda não há avaliações

- Transmission WordDocumento7 páginasTransmission WordfatmafarahAinda não há avaliações

- 4motion PDFDocumento16 páginas4motion PDFJan Svein HammerAinda não há avaliações

- DifferentialsDocumento48 páginasDifferentialsEngine Tuning UpAinda não há avaliações

- Differentials (Open, Locked, Limited Slip, EDL, Quattro)Documento9 páginasDifferentials (Open, Locked, Limited Slip, EDL, Quattro)stefanovicana1Ainda não há avaliações

- Manual TransmissionDocumento11 páginasManual Transmissionagus baharudinAinda não há avaliações

- Drive TrainDocumento41 páginasDrive TrainMuhammed HussainAinda não há avaliações

- Chapter 1 - Powertrains SystemDocumento36 páginasChapter 1 - Powertrains Systemahmad kamalAinda não há avaliações

- Pulleys 1 Rotary Cams 1 Gears 2: Pulleys Are Used To Transfer Rotating Motion, Via A BeltDocumento17 páginasPulleys 1 Rotary Cams 1 Gears 2: Pulleys Are Used To Transfer Rotating Motion, Via A BeltRentu PhiliposeAinda não há avaliações

- Limited-Slip Differential WikiDocumento7 páginasLimited-Slip Differential WikiMariano MartinAinda não há avaliações

- ManualTransmissionPartsandFunction (PDF) PDF 1669757620326Documento16 páginasManualTransmissionPartsandFunction (PDF) PDF 1669757620326Muganyizi Hillary932Ainda não há avaliações

- 4.0 Gears: Introduction: The Slip and Creep in The Belt or Rope Drives Is A Common Phenomenon, in TheDocumento50 páginas4.0 Gears: Introduction: The Slip and Creep in The Belt or Rope Drives Is A Common Phenomenon, in TheSham SundarAinda não há avaliações

- Chapter 2-Gear SystemDocumento26 páginasChapter 2-Gear SystemNui Yuhu KuwAinda não há avaliações

- Definition of Synchromesh Gear BoxDocumento13 páginasDefinition of Synchromesh Gear BoxAmol Rasane100% (1)

- Transmission SystemDocumento51 páginasTransmission SystemPethurajAinda não há avaliações

- Unit-III Transmission SysytemDocumento168 páginasUnit-III Transmission Sysytemriyaz ahmedAinda não há avaliações

- Mechanical Toy Booklet AltDocumento11 páginasMechanical Toy Booklet AltPranav BISUMBHER100% (1)

- MKT PDFDocumento29 páginasMKT PDFelgauchoandresAinda não há avaliações

- Gear Box BasicsDocumento7 páginasGear Box BasicsVelshankar MJ100% (1)

- Kinematic of Machines - Gear 1Documento8 páginasKinematic of Machines - Gear 1Safdar Ali NiaziAinda não há avaliações

- Toyota Training Automatic Transmission BasicsDocumento20 páginasToyota Training Automatic Transmission Basicsnorman100% (34)

- MECH3030 06 Gear PDFDocumento88 páginasMECH3030 06 Gear PDFHei Kan ChengAinda não há avaliações

- B E AutomobileDocumento348 páginasB E AutomobileMr Nelson PremkumarAinda não há avaliações

- Mechanical DetailsDocumento1 páginaMechanical DetailsKarthigaiselvan ShanmuganathanAinda não há avaliações

- Automobile Car Seat Head Rest PositionDocumento8 páginasAutomobile Car Seat Head Rest PositionKarthigaiselvan ShanmuganathanAinda não há avaliações

- Good Habits To Follow - r1Documento1 páginaGood Habits To Follow - r1Karthigaiselvan ShanmuganathanAinda não há avaliações

- Mechanical DetailsDocumento1 páginaMechanical DetailsKarthigaiselvan ShanmuganathanAinda não há avaliações

- 2017 Excel Calendar Planner 12Documento24 páginas2017 Excel Calendar Planner 12Jib CollantesAinda não há avaliações

- 2017 Excel Calendar Planner 12Documento24 páginas2017 Excel Calendar Planner 12Jib CollantesAinda não há avaliações

- 2016 06 03 Bertrandt Motorrad Flyer en FinalDocumento8 páginas2016 06 03 Bertrandt Motorrad Flyer en FinalKarthigaiselvan ShanmuganathanAinda não há avaliações

- N1 Regular Cab and Cab Chassis Bro CombinedDocumento2 páginasN1 Regular Cab and Cab Chassis Bro CombinedKarthigaiselvan ShanmuganathanAinda não há avaliações

- Brochure NewDusterPh2 EnglishDocumento11 páginasBrochure NewDusterPh2 EnglishKarthigaiselvan ShanmuganathanAinda não há avaliações

- 1Documento1 página1Karthigaiselvan ShanmuganathanAinda não há avaliações

- 2016 06 03 Bertrandt Motorrad Flyer en FinalDocumento8 páginas2016 06 03 Bertrandt Motorrad Flyer en FinalKarthigaiselvan ShanmuganathanAinda não há avaliações

- Automotive India PresentationDocumento36 páginasAutomotive India PresentationKarthigaiselvan ShanmuganathanAinda não há avaliações

- BillDesk Payment GatewayDocumento1 páginaBillDesk Payment GatewayKarthigaiselvan ShanmuganathanAinda não há avaliações

- MD Id Proof Tin Certificate Photo Purchase Order Rental AgreementDocumento1 páginaMD Id Proof Tin Certificate Photo Purchase Order Rental AgreementKarthigaiselvan ShanmuganathanAinda não há avaliações

- Drum Brake CalculationDocumento3 páginasDrum Brake CalculationKarthigaiselvan Shanmuganathan100% (1)

- A Low Cost Vehicle Concept For The U.S. MarketDocumento86 páginasA Low Cost Vehicle Concept For The U.S. MarketAnneJacinthAinda não há avaliações

- List of IncubatorsDocumento41 páginasList of IncubatorsKarthigaiselvan ShanmuganathanAinda não há avaliações

- Feedback FormDocumento4 páginasFeedback FormKarthigaiselvan ShanmuganathanAinda não há avaliações

- Atm WorkingDocumento4 páginasAtm WorkingKarthigaiselvan ShanmuganathanAinda não há avaliações

- SimplelessonsDocumento64 páginasSimplelessonsKarthigaiselvan ShanmuganathanAinda não há avaliações

- Design and Development of Automatic Start Stop System For Two WheelerDocumento10 páginasDesign and Development of Automatic Start Stop System For Two WheelerKarthigaiselvan ShanmuganathanAinda não há avaliações

- SimplelessonsDocumento64 páginasSimplelessonsKarthigaiselvan ShanmuganathanAinda não há avaliações

- MOHANDocumento30 páginasMOHANKarthigaiselvan ShanmuganathanAinda não há avaliações

- Ncert 3Documento8 páginasNcert 3Karthigaiselvan ShanmuganathanAinda não há avaliações

- Mock PrenstationDocumento7 páginasMock PrenstationKarthigaiselvan ShanmuganathanAinda não há avaliações

- English Through TamilDocumento90 páginasEnglish Through TamilKhalifullah100% (1)

- IgnitionDocumento64 páginasIgnitionKarthigaiselvan Shanmuganathan100% (6)

- 16F877ADocumento234 páginas16F877AMarius PauletAinda não há avaliações

- 8 - Field Inspectors (CQA) Certification ProgramDocumento7 páginas8 - Field Inspectors (CQA) Certification Program齐左Ainda não há avaliações

- Sonali MondalDocumento2 páginasSonali MondalSonali MondalAinda não há avaliações

- 7) Progress PaymentDocumento5 páginas7) Progress Paymentkerwin jayAinda não há avaliações

- Course Objective and Outcome FormDocumento2 páginasCourse Objective and Outcome FormSajedur Rahman MishukAinda não há avaliações

- Tate Airflow Tate Airflow Isoflospec3Documento2 páginasTate Airflow Tate Airflow Isoflospec3oscarbogadoAinda não há avaliações

- Emi 2018Documento72 páginasEmi 2018Pushpendra Pratap Singh0% (1)

- Phy 109 PDFDocumento1 páginaPhy 109 PDFsohamAinda não há avaliações

- Galvanic Cathodic Protection For Power Transmission Tower Grillage FoundationsDocumento6 páginasGalvanic Cathodic Protection For Power Transmission Tower Grillage FoundationsMA100% (1)

- Casting DefectsDocumento22 páginasCasting DefectsDeepakKaushik100% (1)

- Road Note 06Documento32 páginasRoad Note 06hessian123Ainda não há avaliações

- 077 Mining Challenge at El SoldadoDocumento6 páginas077 Mining Challenge at El SoldadoKenny CasillaAinda não há avaliações

- Breakwater Vertical BarriersDocumento10 páginasBreakwater Vertical BarriersAlbert PranataAinda não há avaliações

- TR-7551 Wiring & Typical Connection DiagramDocumento1 páginaTR-7551 Wiring & Typical Connection Diagramlakshitha sandaruwanAinda não há avaliações

- Equipment Damage Curves TransformersDocumento8 páginasEquipment Damage Curves TransformersrobertoseniorAinda não há avaliações

- Unit - 2 Diff Amp Objective QuestionsDocumento3 páginasUnit - 2 Diff Amp Objective QuestionsRaviAinda não há avaliações

- Dtu-30 09 2019 PDFDocumento15 páginasDtu-30 09 2019 PDFRameo majumderAinda não há avaliações

- Drip Legs Definition Purpose Configuration Selection Installation and Sizing PDFDocumento4 páginasDrip Legs Definition Purpose Configuration Selection Installation and Sizing PDFFaizal KhanAinda não há avaliações

- Charpy Impact Test - STP 1072Documento219 páginasCharpy Impact Test - STP 1072biancogallazzi100% (3)

- Cloud Infrastructure and ServicesDocumento3 páginasCloud Infrastructure and ServicesShobha RaniAinda não há avaliações

- Nse Past Questions and AnswersDocumento10 páginasNse Past Questions and Answersadesloop85% (13)

- SG Series NewDocumento2 páginasSG Series NewSantosh ChaudharyAinda não há avaliações

- Aircraft Refuelling HoseDocumento4 páginasAircraft Refuelling HoseBimo IndroAinda não há avaliações

- TP5 W9 S9 R0Documento2 páginasTP5 W9 S9 R0DickiEffendy0% (1)

- Aspen Manual v11.1Documento112 páginasAspen Manual v11.1api-3750488100% (6)

- Credazone 6 GiudeDocumento3 páginasCredazone 6 Giudeguddu84Ainda não há avaliações

- Perry 02Documento2 páginasPerry 02Thaly MejiaAinda não há avaliações

- Oracle IdeasDocumento45 páginasOracle Ideashamdy2001Ainda não há avaliações

- Proiectarea Asistata de Calculator Pentru Avionica: Elemente de Limbaj C - II Aplicatii de Calcul ComplexeDocumento21 páginasProiectarea Asistata de Calculator Pentru Avionica: Elemente de Limbaj C - II Aplicatii de Calcul ComplexeAna BaumAinda não há avaliações

- International MasterDocumento21 páginasInternational MasterminhbmtsAinda não há avaliações

- KICH MKT PVT LTD Project Report-Prince DudhatraDocumento93 páginasKICH MKT PVT LTD Project Report-Prince DudhatrapRiNcE DuDhAtRa67% (3)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesNo EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesNota: 5 de 5 estrelas5/5 (1)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsNo EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsNota: 3.5 de 5 estrelas3.5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeNo EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeNota: 4.5 de 5 estrelas4.5/5 (9)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosNo EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosNota: 5 de 5 estrelas5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNo EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNota: 4.5 de 5 estrelas4.5/5 (27)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialNo EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialNota: 3.5 de 5 estrelas3.5/5 (3)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonNo EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonNota: 5 de 5 estrelas5/5 (2)

- Teach Yourself Electricity and Electronics, 6th EditionNo EverandTeach Yourself Electricity and Electronics, 6th EditionNota: 3.5 de 5 estrelas3.5/5 (15)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesNo EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesNota: 5 de 5 estrelas5/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceNo EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceAinda não há avaliações

- Heat Transfer Engineering: Fundamentals and TechniquesNo EverandHeat Transfer Engineering: Fundamentals and TechniquesNota: 4 de 5 estrelas4/5 (1)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)No EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)Ainda não há avaliações

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)No EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Nota: 4.5 de 5 estrelas4.5/5 (2)

- Power Electronics Diploma Interview Q&A: Career GuideNo EverandPower Electronics Diploma Interview Q&A: Career GuideAinda não há avaliações

- Practical Reservoir Engineering and CharacterizationNo EverandPractical Reservoir Engineering and CharacterizationNota: 4.5 de 5 estrelas4.5/5 (3)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionNo EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionNota: 4.5 de 5 estrelas4.5/5 (543)