Escolar Documentos

Profissional Documentos

Cultura Documentos

H 14

Enviado por

CTN2010Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

H 14

Enviado por

CTN2010Direitos autorais:

Formatos disponíveis

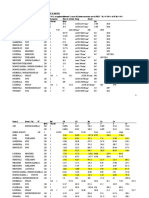

Upper threaded portion

formed out of round to

produce self-locking action.

., sJLv

AXIAL APPROX

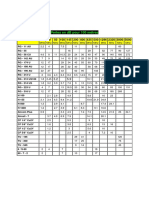

PART THREAD A C H S V W TENSILE WT

NUMBER (MIL-S-8879) MIN MIN MAX MIN REF STRENGTH LBS/100

LBS. MIN.

H14-06 .1380-32 UNJC-3B

I .244 .171 .141 .055 .032 .158-.150 1,670 .05

H14L06 .1380-32 UNJC-3B .244 .207 .141 .055 .032 .190-.181 1,670 .07

H14-08 .1640-32 UNJC-3B .290 .207 .170 .060 .035 .190-.181 2,590 .09

H14L08 .1640-32 UNJC-3B .290 .244 .170 .060 .035 .221-.213 2,590 .11

H14M3 .1900-32 UNJF-3B .330 .244 .188 .065 .035 .221-.213 3,470 .13

H14-3 .1900-32 UNJF-3B .330 .277 .188 .065 .035 .252-.243 3,470 .18

.420

H14M4 .2500-28 UNJF-3B

I .313 .219 .090 .045 .284-.274 6,200 .24

H14-4 .2500-28 UNJF-3B .420 .347 .219 .090 .045 .316-.304 6,200 .30

H14-5 .3125-24 UNJF-3B .520 .419 .266 .120 .050 .378-.367 9,820 .55

H14-6 .3750-24 UNJF-3B .620 .491 .282 .125 .060 .440-.430 15,200 .76

H14-7 .4375-20 UNJF-3B .720 .562 .328 .150 .070 .505-.494 20,600 1.26

H14-8 .5000-20 UNJF-3B .820 .633 .480 .220 .080 .566-.555 27,400 2.07

H14-9 .5625-18 UNJF-3B .922 .775 .540 .240 .090 .692-.680 34,800 3.26

H14-10 .6250-18 UNJF-3B 1.027 .846 .600 .250 .105 .755-.743 43,600 4.15

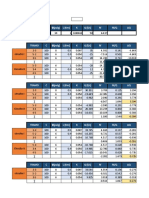

MATERIAL: 4037 alloy steel per AMS 6300 (UNS G40370) or 4340 alloy steel per AMS 6414 or

AMS 6415 (UNS A97050) or 8740 alloy steel per AMS 6322 (UNS G87400).

FINISH: Cadmium plate per QQ-P-416, Type II, Class 2 and Kaylube molybdenum disulfide dry

lubricant per MIL-L-4601 O.

PERFORMANCE: MIL-N-25027, except as follows:

a. Axial tensile strength as tabulated.

b. "C" and "W" dimensions apply before forming self-locking feature.

H14 SIX-POINT NUT H14

ALLOY STEEL, REDUCED HEIGHT

3/30/93 KY10C Revised 5M KAYNAR@ 2-3

Microdot Aerospace Limited

Você também pode gostar

- Programme Maths cm2Documento1 páginaProgramme Maths cm2gorguy100% (1)

- GEAI Info Special FR 32P 2 1290699927Documento32 páginasGEAI Info Special FR 32P 2 1290699927Cleaver BrightAinda não há avaliações

- Examen Corrigé Marketing - Questionnaire À Choix Multiple (QCM)Documento7 páginasExamen Corrigé Marketing - Questionnaire À Choix Multiple (QCM)Mar IemAinda não há avaliações

- Examen Blanc Physique Chimie Bac DDocumento4 páginasExamen Blanc Physique Chimie Bac Dkouassi hermann ulrich koffi100% (1)

- Lapter PerkerasanDocumento66 páginasLapter PerkerasanaxlAinda não há avaliações

- Método de Violino - CajatiDocumento41 páginasMétodo de Violino - CajatiWalmir PaiãoAinda não há avaliações

- World of Warcraft - Wrath of The Lich King - Arthas, My SonDocumento4 páginasWorld of Warcraft - Wrath of The Lich King - Arthas, My SonAdrian Angel LagrecaAinda não há avaliações

- Dépistage Des Anticorps Dirigés Contre Les Antigènes Nucléaires SolublesDocumento12 páginasDépistage Des Anticorps Dirigés Contre Les Antigènes Nucléaires SolublesCDM achiffaAinda não há avaliações

- Formation Technique - Ox360 - FR - V4Documento63 páginasFormation Technique - Ox360 - FR - V4Steev JanotAinda não há avaliações

- Rapport de Mission (Maintenance Équipements Médicaux)Documento13 páginasRapport de Mission (Maintenance Équipements Médicaux)Delor OulaAinda não há avaliações

- Axonlab Catalogue PDFDocumento96 páginasAxonlab Catalogue PDFyan benAinda não há avaliações

- Marqueurs Cardiaques DR RAAF Alger 2014Documento15 páginasMarqueurs Cardiaques DR RAAF Alger 2014Mohamed Lamine SadAinda não há avaliações

- CR Résultats D'examens Biologiques PDFDocumento1 páginaCR Résultats D'examens Biologiques PDFSonia MarchAinda não há avaliações

- Dosage de La Ferritine - 2014-03-13Documento25 páginasDosage de La Ferritine - 2014-03-13Abidi MohamedAinda não há avaliações

- 2da RedDocumento14 páginas2da RedSalvador Ignacio Garcia OrihuelaAinda não há avaliações

- C de Garde Fibre Op PDFDocumento8 páginasC de Garde Fibre Op PDFAnonymous ugneZ8ijAinda não há avaliações

- Tabela Revenda Março 2021Documento6 páginasTabela Revenda Março 2021William QueirozAinda não há avaliações

- Api Tubin 1Documento2 páginasApi Tubin 1Harolt Alexis Leon tripulAinda não há avaliações

- Analisa 1-5Documento1 páginaAnalisa 1-5KPH BaliAinda não há avaliações

- Perte Cable PDFDocumento4 páginasPerte Cable PDFcheikh196Ainda não há avaliações

- 07 585 Conversions Nuances Metalliques Et Caracteristiques Pour JointsDocumento1 página07 585 Conversions Nuances Metalliques Et Caracteristiques Pour Jointspascal.lebbrechtAinda não há avaliações

- Mass Datenblatt Updrive MCDocumento4 páginasMass Datenblatt Updrive MCIngo LießkeAinda não há avaliações

- Deber 3Documento7 páginasDeber 3Steven TorresAinda não há avaliações

- Medidas Bombas JetDocumento7 páginasMedidas Bombas JetdearsaAinda não há avaliações

- Volume Precast Façade Wall Gunung Sindur Type 36Documento1 páginaVolume Precast Façade Wall Gunung Sindur Type 36Muhammad FarhanAinda não há avaliações

- Stock Compression Spring CatalogDocumento845 páginasStock Compression Spring CatalogShahnawaz PathanAinda não há avaliações

- Torque - and - Makeup - Loss - Metric 3Documento3 páginasTorque - and - Makeup - Loss - Metric 3CRISTIANOAinda não há avaliações

- CSK 421Documento1 páginaCSK 421Muhammad FarhanAinda não há avaliações

- FP - VEM Unidirectionnel 001 VAP PDFDocumento1 páginaFP - VEM Unidirectionnel 001 VAP PDFOussamaAinda não há avaliações

- WerkstoffdatenDocumento21 páginasWerkstoffdatenersinAinda não há avaliações

- 2 Rodillos British StandardDocumento1 página2 Rodillos British StandardANGEL FERNANDO PANTOJAAinda não há avaliações

- Ipl 2023Documento43 páginasIpl 2023AravamudhanAinda não há avaliações

- Tabela de Preços DEZEMBRO - 2008Documento2 páginasTabela de Preços DEZEMBRO - 2008SergioAinda não há avaliações

- Alumex Price List 01.01.2024 - VAT - 18%Documento17 páginasAlumex Price List 01.01.2024 - VAT - 18%jayadushAinda não há avaliações

- BUZONESDocumento1 páginaBUZONESpephn01Ainda não há avaliações

- Analisa 1-30Documento1 páginaAnalisa 1-30KPH BaliAinda não há avaliações

- Brosur CKE Axial FanDocumento2 páginasBrosur CKE Axial Fansalman alfarisiAinda não há avaliações

- 605-Overband FR PDFDocumento2 páginas605-Overband FR PDFUlrich ToukamAinda não há avaliações

- Data Raw JeparaDocumento104 páginasData Raw JeparaExen DesigngraphicAinda não há avaliações

- Copie de Usure Engin-PL-VLDocumento4 páginasCopie de Usure Engin-PL-VLmessaoudiAinda não há avaliações

- Copie de RoulmentDocumento5 páginasCopie de Roulmentattoil mohammdAinda não há avaliações

- Assainissement Raffana - Reseaux - Métrés Par TronçonsDocumento7 páginasAssainissement Raffana - Reseaux - Métrés Par TronçonsMed CthAinda não há avaliações

- ABARTHDocumento1 páginaABARTHisrael.anedisAinda não há avaliações

- Catalogue Pieces Cat Tractopelles Maj 01 Bd04Documento24 páginasCatalogue Pieces Cat Tractopelles Maj 01 Bd04Boumediene CHIKHAOUIAinda não há avaliações

- Tri TechDocumento1 páginaTri TechHidramarin TecnicoAinda não há avaliações

- Hardy Cross ExcelDocumento14 páginasHardy Cross ExcelBrayamAinda não há avaliações

- RT EngineeringDataDocumento17 páginasRT EngineeringDataCristian Contreras PerezAinda não há avaliações

- EatoncambiosDocumento3 páginasEatoncambiosPedro MelloAinda não há avaliações

- CASO 3 DEMANDA ALTA - SA2S - Summary-1-12Documento12 páginasCASO 3 DEMANDA ALTA - SA2S - Summary-1-12Diego Guerrero DiazAinda não há avaliações

- OD Size Weight Wall Grade Make-Up Torque Fractional Decimal Min. Opt. Max. in in LBS/FT in Ft-Lbs Ft-Lbs Ft-LbsDocumento3 páginasOD Size Weight Wall Grade Make-Up Torque Fractional Decimal Min. Opt. Max. in in LBS/FT in Ft-Lbs Ft-Lbs Ft-Lbsfernando velascoAinda não há avaliações

- (Inc PPN) Daftar New Price List Maret 2021 Sea YogyaDocumento2 páginas(Inc PPN) Daftar New Price List Maret 2021 Sea YogyaMuhammad JawadAinda não há avaliações

- PDF &presentationtype 3&lang Es&tablename 6 1 1&startnum 2&mDocumento1 páginaPDF &presentationtype 3&lang Es&tablename 6 1 1&startnum 2&mgiovannivargas83939Ainda não há avaliações

- Anexo Lista 1 - 122317Documento5 páginasAnexo Lista 1 - 122317Humberto SaavedraAinda não há avaliações

- Alumoweld Wire and StrandDocumento1 páginaAlumoweld Wire and StrandmapsouzaAinda não há avaliações

- Nom 5 102 793Documento12 páginasNom 5 102 793Леонид СтепановAinda não há avaliações

- Standard Internal Retaining RingsDocumento2 páginasStandard Internal Retaining RingsendangsubarnaAinda não há avaliações

- Pascua, K. Ce41s2 MDMDocumento37 páginasPascua, K. Ce41s2 MDMJD Cabrera AbastillasAinda não há avaliações

- Euronorm en 10025Documento7 páginasEuronorm en 10025paulapanaitAinda não há avaliações

- CASO 2 ALTA ERV - SA2S - Summary-1-12Documento12 páginasCASO 2 ALTA ERV - SA2S - Summary-1-12Diego Guerrero DiazAinda não há avaliações

- Caractéristiques Techniques Systeme Electriq Ue - CongoBDocumento6 páginasCaractéristiques Techniques Systeme Electriq Ue - CongoBzkd77Ainda não há avaliações

- Acewood Ikolo Bordereau de Chargement: Total Clis: 6 PCS: 420 Cubage/m3: 16.310Documento2 páginasAcewood Ikolo Bordereau de Chargement: Total Clis: 6 PCS: 420 Cubage/m3: 16.310Fawziat MikailouAinda não há avaliações

- AISATo BrokerDocumento4 páginasAISATo BrokerAgusAinda não há avaliações

- Informe 4 AnalisisDocumento13 páginasInforme 4 AnalisisJose Huamani gallardoAinda não há avaliações

- M2CP Brochure PDFDocumento16 páginasM2CP Brochure PDFmarklaforestAinda não há avaliações

- CorrespondênciasDocumento5 páginasCorrespondênciasTTaddictAinda não há avaliações

- CH1 (Introduction Au SI) PDFDocumento17 páginasCH1 (Introduction Au SI) PDFEL OUAZZANI PRINTAinda não há avaliações

- 2M120 TD 2016 ch1 Codes CorrecteursDocumento2 páginas2M120 TD 2016 ch1 Codes CorrecteurskokiAinda não há avaliações

- ProjetDocumento4 páginasProjetEya AwadiAinda não há avaliações

- Brochure Nissan Urvan N350 15 PlacesDocumento14 páginasBrochure Nissan Urvan N350 15 PlaceskoneAinda não há avaliações

- 5-Focales-Episode-2-Planification Et RégulationDocumento42 páginas5-Focales-Episode-2-Planification Et RégulationTaffyd MaertinsAinda não há avaliações

- Corrige Serie5Documento4 páginasCorrige Serie5Chef FatimaAinda não há avaliações

- DRAFT - Cours OCO - Part1Documento32 páginasDRAFT - Cours OCO - Part1Khennoune WissamAinda não há avaliações

- 1 - Cours2 Hydraulique Et Pneumatique (2éme Année Électromécanique)Documento16 páginas1 - Cours2 Hydraulique Et Pneumatique (2éme Année Électromécanique)Mohamed Hechmi JERIDIAinda não há avaliações

- Laboratoire Biolab Bamako - Recherche GoogleDocumento1 páginaLaboratoire Biolab Bamako - Recherche GoogleAlou CoulibalyAinda não há avaliações

- Biochimie 08 - Réplication Et Réparation Des Erreurs AssociéesDocumento14 páginasBiochimie 08 - Réplication Et Réparation Des Erreurs AssociéesNathan CohenAinda não há avaliações

- Catalogue OKOFEN 2018 2019Documento68 páginasCatalogue OKOFEN 2018 2019joseph38Ainda não há avaliações

- ContexteDocumento2 páginasContextehibaouafi502Ainda não há avaliações

- Chapitre 3 Ressources Réserves PlanificationDocumento10 páginasChapitre 3 Ressources Réserves PlanificationAdlaneAinda não há avaliações

- TP Controle Optimal PDFDocumento29 páginasTP Controle Optimal PDFHamza El-houariAinda não há avaliações

- RIB CopieDocumento1 páginaRIB CopieAbdoulaye CisséAinda não há avaliações

- Formation - PDF - Robotique - Mécatronique PDFDocumento9 páginasFormation - PDF - Robotique - Mécatronique PDFHachicha SaberAinda não há avaliações

- Serveur D'impression Sous Windows 2003Documento6 páginasServeur D'impression Sous Windows 2003Issam BammouAinda não há avaliações

- Exercice 3Documento1 páginaExercice 3test lili100% (1)

- MicrobiologieDocumento5 páginasMicrobiologieInes FirasAinda não há avaliações

- Phrases À Remettre Dans L'ordreDocumento9 páginasPhrases À Remettre Dans L'ordreSylvie DinisAinda não há avaliações

- Manuel C2Documento140 páginasManuel C2Daniel AndriamananaAinda não há avaliações

- Laddition Des Nombres Entiers CM2Documento8 páginasLaddition Des Nombres Entiers CM2chantal.aboujaoudehAinda não há avaliações

- Cevap AnahtarıDocumento1 páginaCevap AnahtarıVeliAinda não há avaliações

- Transformateurs MonophasésDocumento51 páginasTransformateurs MonophasésDo OuAinda não há avaliações

- Les Corriges Essai District Kanel Jan 2024 - 061004Documento8 páginasLes Corriges Essai District Kanel Jan 2024 - 061004souleymanehousnaAinda não há avaliações