Escolar Documentos

Profissional Documentos

Cultura Documentos

Formulation Development and Evaluation of Orodispersible Tablet of Cinnarizine Solid Dispersion

Enviado por

Baru Chandrasekhar RaoTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Formulation Development and Evaluation of Orodispersible Tablet of Cinnarizine Solid Dispersion

Enviado por

Baru Chandrasekhar RaoDireitos autorais:

Formatos disponíveis

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.

Patil et al ISSN 2349-7750

CODEN (USA): IAJPBB ISSN: 2349-7750

INDO AMERICAN JOURNAL OF

PHARMACEUTICAL SCIENCES

http://doi.org/10.5281/zenodo.556750

Available online at: http://www.iajps.com Research Article

FORMULATION DEVELOPMENT AND EVALUATION OF

ORODISPERSIBLE TABLET OF CINNARIZINE SOLID

DISPERSION

Dhananjay M. Patil*, Kaveri R. Wagh, Sapna S. Chaudhari, Vinod A. Bairagi,

Valmik R Patil

Department of Pharmaceutics-K.B.H.S.S Institute of Pharmacy, Malegaon, Nasik-423203.

Received: 11 April 2017 Accepted: 20 April 2017

Abstract:

The objective of present study was to formulate directly compressible orodispersible tablets of Cinnarizine with

improved solubility and bioavailability by using solid dispersion technique. Cinnarizine is a H1 receptor

antagonist and widely used in the treatment of motion sickness, vomiting and vertigo disorder. Solid dispersion

of Cinnarizine was prepared by Solvent evaporation method and physical mixture using novel polymer soluplus

as carrier. 1:1, 1:2 and 1:3 these three different weight ratios of drug and carrier respectively were taken.

Saturation solubility of drug was determined in physical mixture and solid dispersion formulation. The prepared

solid dispersion formulations were further characterized by drug contents, FTIR spectroscopy, DSC and in-vitro

drug release. From that crystalline form of Cinnarizine is converted into amorphous state during formulation of

solid dispersion. Solid dispersion by solvent evaporation method in 1:3 ratios showed better results than other

formulations. Orodispersible tablets of Cinnarizine were compressed using selected solid dispersion 1:3

formulation and excipients with kyron T 314 as a superdisintegrant. Orodispersible tablet shows disintegration

time 13 seconds and in-vitro drug release 99.75 %, which is better as compare to marketed conventional tablet

66.92 % within 15 minutes. Thus formulation of orodispersible tablet of Cinnarizine solid dispersion showed

increased solubility and bioavailability with patient complies and convenience.

Keywords: Cinnarizine, Soluplus, Kyron T-314, Solid dispersion, Orodispersible tablet, Solubility.

Corresponding author:

Dhananjay M. patil, QR code

Department Of Pharmaceutics,

K.B.H.S.S Trust Institute of Pharmacy

Bhaygoan Road Opp, Jajuwadi Malegoan Camp,

Nasik-423203,

Email-drdhananjaypatil@hotmail.com

Mob No-09823385304

Please cite this article in press as Dhananjay M. patil et al, Formulation Development and Evaluation of

Orodispersible Tablet of Cinnarizine Solid Dispersion, Indo Am. J. P. Sci, 2017; 4(04).

www.iajps.com Page 910

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

INTRODUCTION: antagonist of T-type voltage-operated calcium ion

Limited and variable drug absorption resulting in channels, because its binding blocks the channels

poor bioavailability is the major problem that can and keeps them inert. In treatment of nausea

be encountered when delivering an active agent via motion sickness and vertigo Cinnarizine exerts its

oral route. Bioavailability of the drug is one critical effects by inhibiting the calcium currents in voltage

parameter for determining the efficacy of gated channels in type II vestibular hair cells within

pharmaceutical formulations[1-2]. Drug absorption the inner ear. Cinnarizine is BCS class II drug

from GIT can be limited and varied by a variety of (Low solubility and high permeability). Cinnarizine

factors with most significant contributors being is practically insoluble in water, low and invariably

poor aqueous solubility and/or membrane bioavailability and thus delays onset of action. It is

permeability of the drug molecule. The well established fact that, dissolution is the rate

therapeutically effective amount of a medicine in a limiting step in the absorption process.

composition should be made available to the Consequently, numerous attempts have been made

organism, with optimum blood concentrations of to modify the dissolution characteristics of

the active ingredients reached within the shortest insoluble drugs in an attempt to attain fast and

possible time. Since the development cost of a new more complete dissolution[10,11]. In an attempt to

chemical entity is very high, the pharmaceutical enhance the solubility, dissolution rate and

companies are focusing on the development of new bioavailability of slightly soluble drugs, solid

drug delivery systems for existing drug with an dispersion by using novel polymer soluplus has

improved efficacy and bioavailability together with been extensively applicable.

reduced dosing frequency to minimize side Many patients find it difficult to swallow tablets

effects[3-5]. Solubility enhancement of poorly and hard gelatin capsules and thus not comply with

water soluble drugs are needed. Solid dispersion prescription that results in high incidence of non-

technique is extensively used to increase the compliance and ineffective therapy. Orodispersible

solubility of poorly soluble drug [6]. tablets are gaining prominence as new drug

For the past two decades, there has been enhanced delivery systems. These dosage forms dissolves or

demand for more patient compliance dosage disintegrate in oral cavity within a minute without

forms. As a result, the demand for their the need of water or chewing before

technologies has been increasing three-fold swallowing[12]. Kyron T-314 is used as

annually. Solid dosage forms like tablets and superdisintegrant in given formulation to achieve

capsules are more popular and preferred drug fast disintegration of tablet and patient compliance

delivery system because they have, accurate and convenience[13].

dosing, good physical and chemical stability. But

the most evident drawback of the commonly used MATERIALS AND METHODS:

oral dosage forms like tablets and capsules is Materials:

difficulty in swallowing, leading to patients Cinnarize and Soluplus were obtained as gift

incompliance particularly in case of pediatric and sample from Glenmark pharma Nasik, and BASF,

geriatric patients, but it also applies to people who The chemical company Germany respectively.

are ill in bed and to those active working patients Kyron T-314 was obtained as gift sample from

who are busy or traveling, especially those who Corel Pharma, Ahmadabad. All other ingredients

have no access to water[7]. are of pharmaceutical and analytical grades.

Difficulty in swallowing (dysphasia) is a common

problem of all age groups, especially the elderly Methods:

and pediatrics, because of physiological changes Preparation of solid dispersion of Cinnarizine

associated with these groups[8,9]. Other categories with Soluplus:

that experience problems in using conventional oral Preparation of physical mixtures (PMs):

dosage forms include the mentally ill, The physical mixtures were prepared by mixing the

uncooperative and patients suffering from required amount of Cinnarizine and Soluplus in the

nausea, motion sickness, sudden episodes of ratio of 1:1, 1:2, 1:3 for 15 min in a mortar with

allergic attack or coughing. It is estimated that pestle until a homogeneous mixture was obtained.

35-50% of the population is affected by this This resulting mixture was sieved through a 40

problems. Recent advances in Novel Drug mesh screen. The powder was stored in a dessicator

Delivery Systems aim to enhance safety and until further evaluation.

efficacy of drug molecule by formulating a

convenient dosage form for administration and to Preparation solvent evaporation method

achieve better patient compliance. One such dispersions (SDs)[14]:

approach is to enhance the solubility of drug by Accurately weighed quantities of Cinnarizine and

solid dispersion technique and further to formulate Soluplus in the ratio of 1:1 1:2, 1:3 by weight were

orodispersible tablet[9]. dissolved in acetone in a porcelain dish. The

Cinnarizine is a piperazine derivative, H1 receptor solvent was evaporated by occasional stirring and

antagonist. Cinnarizine is classified as a selective wet mass was kept in hot air oven at 50oC for

www.iajps.com Page 911

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

drying. The dried mass was sieved through 40 Formulation of tablets using Solid dispersion of

mesh screen. The solid dispersion was stored in a Cinnarizine

dessicator until further evaluation. Tablets containing equivalent to 25 mg of

Cinnarizine solid dispersion were prepared by

Characterization of solid dispersion direct compression. The blend was compressed on

Saturation solubility studies[15]: a 10 station rotary machine using round shaped,

Excess quantity of pure Cinnarizine and its all concave punches. The composition of tablet is

prepared physical mixtures and solid dispersions given in following table.

with Soluplus were added in a 50 ml of glass Table 1: Composition of tablet

stoppered volumetric flasks containing 25 ml of Ingredients F1 F2 F3 F4

solvent (pH 1.2 buffer solution and phosphate

(mg) (mg) (mg) (mg)

buffer pH 6.8 separately). The flasks were sealed,

placed on mechanical shaker and agitated for 24 Solid Dispersion 100 100 100 100

hrs at 280C 0.20C. After 24 hrs, the samples were Kyron T 314 2 4 6 8

then filtered through Whatman filter paper, diluted Aspartame 1.2 1.2 1.2 1.2

suitably and absorbance was measured at 254 nm. Magnesium 0.6 0.6 0.6 0.6

stearate

Drug content [15]: Talc 0.6 0.6 0.6 0.6

The content of Cinnarizine in each physical

Microcrystalline 95.6 93.6 91.6 89.6

mixture and solid dispersions was determined using

cellulose pH 102

by UV spectroscopy. Accurately weighed physical

mixture or solid dispersion equivalent to 25 mg of Total 200 200 200 200

Cinnarizine was transferred to 100 ml volumetric

flask containing 10 ml of methanol and dissolved. Evaluation

The volume was made up to 100 ml with methanol. Physical evaluation of tablet blend

The solution was filter through Whatman filter Angle of repose[19]:

paper. 1 ml of this solution was diluted 10 times The angle of repose of each powder blend was

with methanol to achieve 25 g/ml and the determined by glass funnel method by using the

absorbance was measured at 254 nm. following equation

tan = h/r

Infrared spectroscopy[16,17]: Where,

IR spectra were obtained by KBr disk method h = height of cone

using Fourier- transform infrared (FTIR) r = radius of powder cone

spectrometer (8400 S Shimadzu). KBr disks

prepared using hydrostatic press a thrust of 5 Bulk density[19]:

tons/cm2 for 5 min. The scanning range was 400 to Bulk density of solid dispersion granules were

4000 cm-1. determined by pouring gently 25 gm of sample

through a glass funnel into a 100 ml graduated

Differential scanning calorimetry[16,17]: cylinder. The powder was carefully leveled without

The DSC measurements were performed on a compacting it and the apparent volume was

Differential Scanning Calorimetry (Shimadzu-DSC measured (Vo). Bulk density was calculated as

60) with a thermal analyzer. All accurately below-

weighed samples (5 mg) were placed in sealed Bulk density = M/Vo

aluminum pans, before heating under nitrogen flow Where,

(10 ml/min) at a scanning rate of 10C/min. from M = mass of powder

35C- 300C. An empty aluminum pan was used as Vo = apparent unstirred volume

reference.

Dissolution studies[15,18]: Tapped density[19]:

The pure drug, physical mixtures and solid The tapped density was determined by pouring 25

dispersions equivalent to 25 mg of Cinnarizine gm sample (solid dispersion with excipients)

were subjected to the dissolution study using USP through a glass funnel into a 100 ml graduated

dissolution apparatus type II (Paddle) maintained at cylinder. The cylinder was tapped from height of 2

37 0.5oC and 50 rpm. Dissolution medium used is inches until a constant volume obtained. Volume

pH 1.2 buffer 900ml. occupied by the sample after tapping was recorded

Samples of 5 ml were withdrawn at regular interval and tapped density was calculated.

of 3 min. The volume withdrawn was replaced by

fresh volume of dissolution medium to maintain

constant volume of medium. The filtered samples Carrs index[19]:

were analyzed spectrophotometrically at 254 nm. It is also one of the simple method to evaluate flow

property of a powder by comparing the bulk

www.iajps.com Page 912

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

density and tapped density. Carrs index is also In-vitro disintegration study[18,20]:

known compressibility index and which was The process of breakdown of a tablet into smaller

calculated. particles is called as disintegration.

The in-vitro disintegration time of a tablet was

determined using disintegration test apparatus. The

disintegration test was carried out using USP

disintegration test apparatus-II. Tablets were placed

Hausners ratio[19]: individually in each tube of disintegration test

It provides an indication of the degree of apparatus and discs were placed over each tablet.

densification that could result from vibration of Distilled water (900 ml) was used as the medium

feed hopper. Lower the hausner ratio better is the which is maintained at 37 2C and the time taken

flowability. for each tablet to disintegrate completely was

Tapped density recorded.

Hausner ratio

Bulk density Hardness[20]:

Evaluation of tablets Tablet hardness and resistance to powder and

The tablets were evaluated for the following test friability are necessary requisites for acceptance.

parameters, The Pfizer hardness tester was used for hardness

testing. Generally 4 kg/cm2 hardness is considered

Weight variation test[18]: as acceptable for uncoated tablets.

Twenty tablets of each formulation were weighed

individually using an electronic balance. The Wetting time[21,22]:

average weight was calculated and individual tablet A piece of tissue paper folded twice was kept in

was compared with the average value and the petri dish (internal diameter 5.5 cm) containing 10

deviation was recovered. ml of distilled water. A tablet having a small

amount of amaranth powder on the upper surface

Content uniformity of tablets[15]: was placed on the tissue paper. The time required

Ten tablets were weighed and crushed in a small to develop a red color on the upper surface of the

mortar. The fine powder equivalent to 25 mg of tablet was recorded as wetting time.

Cinnarizine was transferred to 100 ml volumetric

flask containing 10 ml of methanol and dissolved. Water absorption ratio[21,22]:

The volume was made up to 100 ml with methanol. A piece of tissue paper folded twice was placed in

The solution was filter through Whatman filter a small Petri dish (5 cm diameter) containing 6 ml

paper. 1 ml of this solution was diluted 10 times of water. A tablet was put on the tissue paper and

with methanol to achieve 25 g/ml and the allowed to wet completely. The wetted tablet was

absorbance was measured at 254 nm. then weighed and the water absorption ratio R

was determined by using following equation.

Thickness:

Twenty tablets were randomly selected from R = Wb - Wa x 100

formulations and thickness was measured Wa

individually. It was expressed in millimeter and Where,

average was calculated. Wa= weight of tablet before water absorption

Wb = weight of tablet after water absorption.

Friability test[18]:

Friability test is performed to assess the effect of In-vitro dispersion time[23]:

friction and shocks, which may often cause tablet to In-vitro dispersion time of prepared tablet was done

chip, cap or break. Roche friabilator was used for the by dropping the tablet in 10 ml measuring cylinder

purpose. (according to USP monograph 1216 - containing 6 ml of simulated salivary fluid (pH

tablets with a unit weight equal to or less than 650 6.8). Time required for complete dispersion of

mg, take a sample of whole tablets corresponding as tablet was measured.

near as possible to 6.5 gm.) Pre weighed sample of

tablets was placed in the friabilator, which was then

operated for 100 revolutions/min. Tablets were Dissolution study[18]:

dusted and reweighed. The percentage friability was In order to study prepared tablet subjected to the

calculated by, dissolution study using USP dissolution apparatus

type II (Paddle) maintained at 37 0.5oC and 50

W initial W final rpm. Dissolution medium used is pH 1.2 buffer

F= ------------------- 100 900ml. Samples of 5 ml were withdrawn at regular

W final interval of 3 min. The volume withdrawn was

Percentage weight loss was calculated. A loss of replaced by fresh volume of dissolution medium to

less than 0.5 to 1 % in weight was generally maintain constant volume of medium. The filtered

acceptable.

www.iajps.com Page 913

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

samples were analyzed spectrophotometrically at drug content, and in-vitro dissolution were

254 nm. evaluated according to the procedure described as

above.

Stability studies[24]: RESULTS AND DISCUSSIONS:

In the present study, the stability studies were Characterization of solid dispersion system

carried out as per ICH guidelines at 40C 2C/75 Saturation solubility studies:

% 5% RH for the selected formulation (F4) for 3

month. After specified time intervals, parameters

like hardness, dispersion time, disintegration time,

Table.2: Saturation solubility of PD (Cinnarizine), PMs and SDs in pH 1.2 buffer

Formulation code Saturation Solubility(mg/ml)

PD 0.632611.51

PM1:1 1.57651.79

PM1:2 2.3511.74

PM1:3 2.83520.658

SD1:1 3.700141.31

SD1:2 3.993241.084

SD1:3 4.846061.08

Mean, SD, n= 3

Fig 1: Saturation solubility of PD, PMs and SDs in pH 1.2 buffer

Table 3: Saturation solubility of PD, PMs and SDs in pH 6.8 phosphate buffer

Formulation Code Saturation Solubility(mg/ml)

PD 0.0039750.135

PM1:1 0.006720.3400

PM1:2 0.0099630.2064

PM1:3 0.0156390.4745

SD1:1 0.0205490.2064

SD1:2 0.0287930.3400

SD1:3 0.030684 0.2813

Mean, SD, n= 3

www.iajps.com Page 914

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

Fig 2: Saturation solubility of PD, PMs and SDs in pH 6.8 phosphate buffer

The saturation solubility profile for the pure Table 4: Results of drug content with Soluplus.

Cinnarizine and its all prepared physical mixture

and solid dispersion is shown in figure no.6.5 and Methods Drug Content Ratio

6.6. These figures indicate that Cinnarizine is (%)

having very low solubility i.e. 0.6326 mg/ml and Physical Method 1:1 98.78.8050

0.0039 mg/ml in pH 1.2 buffer solution and pH 6.8 (PMs) 1:2 99.19.8798

phosphate buffer respectively. Physical mixture 1:3 99.20.9814

and solid dispersion with Soluplus shows increase Solvent 1:1 99.23.3098

in solubility respectively as concentration of Evaporation 1:2 99.13.9226

polymer is increases. Method (SDs) 1:3 100.04.4000

The ratio 1:3 of solid dispersion gives the Mean, SD, n= 3

maximum saturation solubility among all the The drug content of Cinnarizine physical mixtures

physical mixture and solid dispersions i.e. 4.8460 and solid dispersions was found to be in range

mg/ml and 0.030684 mg/ml in pH 1.2 buffer 98.78 % to 100.04 % and these values are within

solutions and pH 6.8 phosphate buffer respectively. the acceptable range. Low values of standard

Analysis of drug content deviation with respect to drug content indicate

The percentage drug content of PMs and SDs are uniformity of drug distribution in all the physical

shown in table no 4. mixtures and solid dispersions of Cinnarizine.

30

%T

25

20

1029.92

15

1384.79

1596.95

1184.21

923.84

1371.29

10

1357.79

864.05

1076.21

2690.51

1305.72

2864.09

1278.72

1004.84

5

3022.25

2956.67

1490.87

964.34

1141.78

1448.44

2767.66

2810.09

4000 3600 3200 2800 2400 2000 1800 1600 1400 1200 1000 800 600

sample 1 1/cm

Fig .3: FTIR spectrum of Cinnarizine

14

%T

12

10

2156.27

8

2474.50

717.47

6

840.91

946.98

4

973.99

1024.13

1112.85

1197.71

2

1375.15

1481.23

1438.80

1242.07

1627.81

1739.67

2858.31

3537.20

2929.67

3600 3200 2800 2400 2000 1800 1600 1400 1200 1000 800

sample 2 1/cm

Fig 4: FTIR spectrum of Soluplus

www.iajps.com Page 915

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

45

%T

37.5

642.25

1868.89

1959.54

30

794.62

837.05

923.84

864.05

2362.64

1029.92

22.5

1336.58

1197.71

1076.21

3056.96

999.06

1371.29

3022.25

740.61

15

2864.09

1265.22

1490.87

964.34

1733.89

2958.60

1141.78

1635.52

2767.66

1448.44

7.5

2810.09

0

3600 3200 2800 2400 2000 1800 1600 1400 1200 1000 800

sample 5 1/cm

Fig 5: FTIR spectra of solid dispersion (1:3)

Fig 6: FTIR spectra of Kyron T-314

Fig 7: FTIR spectrum of orodispersible tablet (F4)

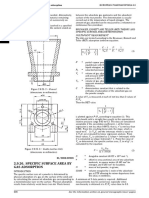

Fourier Transform Infra Red (FTIR) aliphatic C-H stretching occurs at 2956.67 cm-1, the

Spectroscopy: C=C stretching occurs at 1490.87 cm-1, C-N

Fourier transform infrared spectroscopy has been stretching occurs at 1141.78 cm-1. Soluplus shows

used to assess the interaction between carrier and the characteristic peaks O-H stretching at 3537.20

drug molecule. The FTIR spectrum of Cinnarizine, cm-1 , C-H stretching at 2929.67 cm-1 C=O

Soluplus and solid dispersion prepared by solvent stretching at 1627.81 cm-1, C-N at C-N stretching

evaporation method are as shown in figure no.6&7. 1197.71 cm-1 The peaks of solid dispersion of

Cinnarizine with Soluplus shows one additional

The FTIR studies were performed to detect the peak at 3537.20 cm-1 indicative of intermolecular

molecular interaction between drug and polymers. hydrogen bonding between Cinnarizine and

The FTIR spectra of Cinnarizine, Soluplus and Soluplus.

their solid dispersion are shown in the figure no. 3, The IR spectra of Kyron T 314the characteristic

4 and 5 respectively. In FTIR spectra of peak C=C stretching occur at 1480.34 cm-1 , C-H

Cinnarizine the characteristic absorption peaks, stretching occur at 2870 cm-1, and CH 2 bending

aromatic C-H bending occurs at 3022.25 cm-1, occur at 1465.45 cm-1. The IR spectra of F4

www.iajps.com Page 916

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

formulation blend show all characteristic peaks Differential scanning calorimetry study

Cinnarizine and solid dispersion and it indicates The DSC thermo gram of Cinna rizine, Soluplus,

that there is no interaction between solid dispersion solid dispersion prepared by solvent evaporation

and Kyron T 314. method and its overlapped as shown in figure

no.8-11 respectively

DSC T hermal Analysis Result of Cinnarizine

mW

0.00

Onset 0

25. 32x

C10

0

Endset 0

-104. 72x

C10 Peak 121.27x

C10

Onset 0

118.39x

C10

Trans it ion 0

1.50x

mW10

0 Endset 0

125.34x

C10

0.30x

mW10 / m g

0

Mid Point 0

25. 03x

C10 Heat -347. 58x

mJ10

-5.00 0

Height -13. 67x

mW10

-10.00

50.00 100.00

Temp [C]

Fig 8: DSC Thermogram of Cinnarizine

DSC T hermal Analysis Result of Soluplus

mW

-1.00

Onset 0

34. 28x

C10

-2.00 Endset 0

41. 93x

C10

0

Trans it ion 0.01x

mW10

0

0.00x

mW10 / m g

0

-3.00 Mid Point 36. 19x

C10

Peak 0

81. 03x

C10

0

Onset 72. 00x

C10

0

Endset 87. 91x

C10

-4.00 Heat 0

-31. 36x

mJ10

Height 0

-0. 48x

mW10

-5.00

-6.00

40.00 60.00 80.00 100.00

T emp [C]

Fig 9: DSC Thermogram of Soluplus

D SC Thermal Analysis Result of Cinnarizine-soluplus(solid dispersion1:3)

mW

0. 00

-2. 00

0

Peak 93.48x

C 10

Onset 0

87.77x

C 10

Endset 0

99.91x

C 10

-4. 00 H eat - 19.090

x10

mJ

0

Onset 38.13x

C 10 0

H eig ht - 0.40x

mW10

0

Endset 46.34x

C 10 Peak 0

115.95x

C 10

Tr ansition 0

0.73x

mW10 0

Onset 111.29x

C 10

0

0.15x

mW/mg

10 0

-6. 00 Endset 119.34x

C 10

M id Point 0

47.59x

C 10 H eat - 246.410

x10

mJ

H eig ht 0

- 7.82x

mW10

-8. 00

D SC

50.00 100. 00 150. 00

Tem p [C]

Fig 10: DSC Thermogram of solid dispersion (1:3)

www.iajps.com Page 917

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

D SC Thermal Analysis Result of Cinnarizine-soluplus 1:3 (Overlapped)

mW

0. 00

Onset 0

38.93x

C 10

-5. 00 0 Peak 0

115.95x

C 10

Endset 46.24x

C 10

0

Onset 111.26x

C 10 0

Tr ansition 0

0.64x

mW10 Peak 121.27x

C 10

0 Endset 0

119.39x

C 10

0.13x

mW/mg

10 Onset 0

118.36x

C 10

M id Point 0

46.47x

C 10 H eat - 241.310

x10

mJ 0

Endset 125.18x

C 10

H eig ht - 7.770

x10

mW

H eat - 344.210

x10

mJ

-10. 00 H eig ht - 13.630

x10

mW

M ixtur e D SC

C innar izine DSC

50.00 100. 00 150. 00

Tem p [ C ]

Fig 11: DSC Thermogram of Cinnarizine and solid dispersion (1:3) overlapped

From the figure no.8 the Cinnarizine showed the dissolution apparatus at 50 rpm in 900 ml pH 1.2

melting point at 121C, from figure no.9 Soluplus buffer solution as a dissolution medium.

showed the melting point at 81C, from figure Temperature of dissolution medium was

no.10 the solid dispersion showed the melting point maintained at 37 0.50C. PD 25 mg and PMs and

reduced to 115C from 121C and the intensity of SDs equivalent to 25 mg of Cinnarizine were added

the peak in pure drug is reduced. From the figure in each vessels. 5ml sample withdrawn at regular

no.11 it can be concluded that there is a formation time interval of 3 min and filtered through

of solid dispersion with conversion of drug Whatman filter paper. An equal volume of fresh

crystalline to amorphous form. dissolution medium was added in order to kept

total volume of dissolution medium constant.

Dissolution study Filtered samples absorbance was measured at 254

In order to investigate the release rate of PD, PMs nm and results are shown in table no 5-6and figure

and SDs with Soluplus in the ratio 1:1, 1:2 and 1:3 no12-13.

were subjected to dissolution study in USP type II

Table 5: Results of percentage cumulative drug release of PD, PMs with Soluplus

Time (min) PD PM 1:1 PM 1:2 PM 1:3

0 0 0 0 0

3 10.5460.5339 10.72230.1555 11.44650.3905 12.63610.4741

6 14.81640.4123 16.93710.3236 18.59630.4970 19.99940.3558

12 17.03590.8688 20.72690.4764 23.53030.5437 26.80150.3210

15 20.90660.6491 26.01061.1239 28.31720.8966 32.58631.118

18 25.78010.5563 33.55020.7962 34.85590.4669 38.66621.1249

21 31.14030.4715 39.73430.3302 40.68320.7665 44.66821.1813

24 35.91840.0784 44.86561.655 47.14131.5349 52.05031.2690

27 44.60761.005 55.53061.312 60.56881.1986 67.45070.6648

30 49.4320.4227 61.02570.9124 66.66990.8894 75.91670.4513

Mean, SD, n= 3

Fig 12: In-vitro dissolution profile of PD and PMs with Soluplus

www.iajps.com Page 918

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

Table 6: Results of percentage drug release of PD, SDs with Soluplus

Time (min) PD SD 1:1 SD 1:2 SD 1:3

0 0 0 0 0

3 10.54600.533 13.20910.268 21.73960.2687 26.34300.498

6 14.81640.412 20.36470.238 30.23960.5382 34.50661.092

9 17.03590.868 27.2740.544 38.85870.8584 45.01130.829

12 20.90660.649 33.26930.392 46.77990.9484 58.29400.689

15 31.14030.471 40.17640.698 58.62320.5696 72.47661.335

18 31.14030.471 47.2760.414 69.28960.2302 84.92601.235

21 35.91840.078 54.41390.235 79.59950.9607 96.97680.418

24 39.89050.454 61.27960.353 91.93301.0698 99.82960.399

27 44.60761.005 70.1990.564 98.89320.2632 -

30 49.43200.422 78.78340.366 - -

Mean, SD, n= 3

Fig 13: In-vitro dissolution profile of PD, SDs with Soluplus

From the table no.5 and figure no.12, it is observed dissolution medium and improved wetability of the

that the physical mixture of 1:3 shows the higher drug particles, significant reduction particle size

percent cumulative drug release after 30 min as during the formation of the solid dispersion and

compared to the other physical mixture of 1:1, 1:2 intrinsically higher rate of dissolution of the

ratio and pure drug. This is 75.9167 0.4513 % as selected soluble polymer, which could pull

compared to other physical mixture of 1:1, 1:2 ratio insoluble but finely mixed drug into the bulk of

and pure drug, which is 61.0257 0.9124 %, dissolution medium.

66.6699 0.8894 % and 49.43 0.4227 % The Cinnarizine solid dispersion prepared with

respectively after 30 min. Soluplus by solvent evaporation method in ratio 1:3

From the table no.6 and figure no.13, it is observed showed better percent cumulative drug release as

that the solid dispersion of 1:3 shows the higher compared to other solid dispersions, physical

percent cumulative drug release after 24 min as mixtures and pure drug. The percent cumulative

compared to the other solid dispersion of 1:1, 1:2 drug release rate of solid dispersion with ratio 1:3

ratio and pure drug. This is 99.82 0.3998 % as was 99.82 0.399 % in 24 min. and solid

compared to other solid dispersion of 1:1, 1:2 ratio dispersion 1:1, 1:2, physical mixture 1:1, 1:2, 1:3

and pure drug, which is 78.78 0.366 %, 98.89 and pure drug was 75.91 %, 98.89 %, 61.02 %,

0.2632 %, and 49.43 0.4227 % respectively after 66.66 %, 75.91 0.957 % and 49.43 0.422 % in

30 min. 30 min. in pH 1.2 buffer respectively. Among all

In order to investigate the drug release from the these formulation solid dispersion with 1:3 ratios is

prepared solid dispersion, in-vitro dissolution study best due to percent cumulative drug release that is

carried out in pH 1.2. The better dissolution 100.19 % in 24 min.

performance of solid dispersions was increased as From the results of dissolution studies, the solid

compared to the pure drug and physical mixture in dispersion with 1:3 ratio prepared by using

pH 1.2 in a particular time course. This may be Soluplus was selected for tablet formulation.

attributed to the higher solubility of Soluplus in

www.iajps.com Page 919

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

Evaluation of solid dispersion tablet parameters to study the flow properties of granules

Pre compression evaluation of tablet blend. angle of repose, mean bulk density, mean tapped

Formulations ready for compression containing density, carrs index, hausners ratio as shown in

solid dispersion of Cinnarizine and various table no.7

excipients were subjected for pre-compression

Table 7: Evaluation of precompression parameters of orodispersible tablets containing Cinnarizine solid

dispersion.

Formulation Angle of Bulk Density Tapped Density Carrs Index Hausners

Code Repose(0) (g/cm2) (g/cm2) (%) Ratio

F1 25.1033 0.8048 0.9260 13.08 1.1506

0.9042 0.0108 0.0102 0.3592 0.0047

F2 24.73 0.8217 0.9460 13.14 1.1514

0.4430 0.0232 0.0180 0.7950 0.0104

F3 23.9733 0.7954 0.9158 13.04 1.1500

0.9957 0.0113 0.0135 0.2655 0.035

F4 23.7833 0.7997 0.9158 12.68 1.1452

1.008 0.0157 0.0134 0.5167 0.0067

Mean, SD, n= 3

Formulation design: Post compression parameters:

The present study was carried out to develop The tablets prepared by direct compression

orodispersible tablets of Cinnarizine solid technique were subjected for evaluation according

dispersion (1:3) in order to improve patient to various official specifications and other

compliance and also to prepare user-friendly parameters like shape and color, thickness,

formulations. In this case, four formulations of diameter, hardness, friability, weight variation, in-

orodispersible tablets were prepared by direct vitro disintegration time, wetting time, water

compression method using superdisintegrant Kyron absorption ratio, dispersion time, drug content and

T 314. The detailed composition of each in- vitro dissolution studies as shown in table no.8

formulation is given in the table no.1. to 10 and figure no.14.

Table 8: Evaluation of post compression parameters of orodispersible tablets containing Cinnarizine solid

dispersion.

Formulation Hardness Thickness Weight Drug

Code (kg/cm 2) (mm) Diameter Friability Variation Content

n=5 n=20 (mm) (%) (mg) (%)

n=20 n=20 n=3

F1 3.90 4.94 7.49 0.5616 199.7 99.10

0.100 0.0228 0.0058 1.1742 0.6100

F2 3.78 4.96 7.49 0.4117 200.25 99.44

0.0836 0.0329 0.0044 1.4823 0.5086

F3 3.84 4.94 7.5 0.4723 200.15 99.60

0.1341 0.0290 0.0064 1.3518 0.4000

F4 3.86 4.96 7.49 0.4419 200 99.81

0.1140 0.0372 0.0075 1.0760 3987

Table 9: Evaluation of post compression parameters of orodispersible tablets containing Cinnarizine solid

dispersion.

Formulation code Wetting time (sec) Dispersion time Water absorption Disintegration time

(sec) ratio (%) (sec)

F1 31.330.5773 34.330.01 88.160.7636 26.160.7527

F2 24.661.1547 28.330.04 90.000.5000 21.50.8366

F3 19.660.5773 23.330.01 90.831.0408 16.830.7527

F4 14.01.000 19.330.01 94.661.0408 130.8944

Mean, SD, n=3

www.iajps.com Page 920

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

Dissolution study of formulated tablet min. The percent cumulative drug release rate of

The formulated tablets were subjected to formulation F1 was 99.14 0.4240 % in 24 min.

dissolution study in USP type II dissolution F2 was 99.49 0.4672 %in 21 min, 99.4461

apparatus at 50 rpm in 900 ml pH 1.2 buffer 0.2273 % in 18 min and F4 was 99.7582 0.6297

solution as a dissolution medium. Temperature of % in 15 min. Among all these formulations F4 is

dissolution medium was maintained at 37 0.50C. best due to percent cumulative drug release that is

Orodispersible tablet equivalent to 25 mg of 99.7582 % in 15 min.

Cinnarizine were added in each vessels. 5 ml From the results of dissolution studies, the

sample withdrawn at regular time interval of 3 min, formulation F4 is selected as a final formulation

filtered through Whatman filter paper. An equal and compared with marketed tablet.

volume of fresh dissolution medium was added in

order to kept total volume of dissolution medium

constant. Filtered samples absorbance was

measured at 254 nm and results are shown in table

no 10 and figure no14.

The orodispersible tablet containing Cinnarizine

solid dispersion prepared with Soluplus by solvent

evaporation method in ratio 1:3 showed better

percent cumulative drug release in less than 30

Table 10: Results of percentage cumulative drug release of orodispersible tablet formulations F1-F4

Mean, SD, n=3

Time (min) F1 F2 F3 F4

0 0 0 0 0

3 27.45250.2688 28.77410.3583 31.9810.4655 34.94650.3905

6 35.64790.4756 36.48590.2682 44.15860.7357 49.65230.2358

9 46.62620.2366 47.98430.6224 57.42830.4733 70.99950.4751

12 59.76270.9956 60.86960.3233 71.8480.4733 88.68551.013

15 73.07410.6237 76.11740.6058 84.75740.7862 99.75820.6297

18 86.40590.8609 88.0010.2340 99.44610.2273 -

21 96.60270.8748 99.4980.4672 - -

24 99.14750.4240 - - -

Fig 14: In-vitro dissolution profile of orodispersible tablet formulations F1-F4

www.iajps.com Page 921

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

Comparison between marketed Cinnarizine tablet (conventional) and selected

formulation F4

Table 11: Comparative result of marketed Cinnarizine tablet and formulation F4

Parameter Marketed Tablet Formulation F4

Weight Variation(n=20) 198.211.5301 200.001.0760

Hardness (Kg/cm2)(n=5) 4.31 0.7524 3.86 0.1140

Wetting Time (Sec.) 176.20.231 14.0 1.000

Friability (%) 0.7525 0.4419

Disintegration Time (Sec.) 305.53.526 13.00 0.894

Drug Content (%) 97.720.2350 99.810.3987

Mean, SD, n=3

Table 12: Results of percentage cumulative drug release of marketed tablet and formulation F4

Time (min) Marketed Tablet Formulation F4

0 0 0

3 24.42930.2370 34.94650.3905

6 36.20290.6258 9.65230.2358

9 44.75161.0082 70.99950.4751

12 56.06731.3602 88.68551.013

15 66.92720.2321 99.75820.6297

Mean, SD, n=3

Fig 15: In-vitro dissolution profile of marketed tablet and formulation F4

Comparative results between marketed Cinnarizine formulation show better results than conventional

tablet (conventional) and formulation F4 are marketed Cinnarizine tablet.

reported in table no 11-12 and figure no 15. Mouth

dissolving tablet of Cinnarizine is not available in Stability study

market. Percent cumulative drug release of The physical appearance of the samples kept for

marketed formulation in 15 min was 66.9272 stability studies were checked each month and

0.2321 % and F4 formulation was 99.7582 found that there was no difference in the

0.6297 %. appearance.

From the comparative study between marketed

tablet and formulation F4, it was concluded that F4

www.iajps.com Page 922

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

Table 13: Stability studies for orodispersible tablets (F4)

Parameter 40C 2C/75% 5% RH

30 Day 60 Day 90 Day

Hardness (Kg/cm 2) 3.89 0.4370 3.940.7590 4.930.2743

Dispersion time (sec) 19.630.4211 20.170.3871 20.180.1835

Disintegration time (sec.) 13.470.1457 13.641.3804 14.200.2752

Drug content (%) 99.440.2758 99.500.3620 98.980.1552

In-vitro Dissolution 99.320.5387 99.290.1575 98.920.1560

Mean, SD, n=3

After completion of three month stability study there was no any significance change occurred in formulation

F4.

SUMMARY AND CONCLUSION: 0.8050 % to 100.04 0.4000 % and these values

The enhancement of the oral bioavailability is are within the acceptable range. Low values of

currently one of the greatest challenge in the standard deviation with respect to drug content

development of poorly water soluble drugs. To indicate uniformity of drug distribution in all the

increase the solubility and hence the bioavailability physical mixtures and solid dispersions of

it is important to increase the dissolution of the Cinnarizine.

poorly water soluble drugs. One of the possible In FTIR study were peaks of SD1:3 shows one

way to overcome this limitation is the use of solid additional peak at 3537.20 cm-1 than pure

dispersion technique. Cinnarizine is a H1 receptor Cinnarizine peaks, which is indicative of

antagonist is mostly prescribed in treatment of intermolecular hydrogen bonding between

motion sickness, vomiting and vertigo. It is BCS Cinnarizine and Soluplus. In DSC study

class II drug having low solubility and high thermogram of Cinnarizine shows sharp endotherm

permeability, and shows variable bioavailability at 121C indicating melting point of Cinnarizine.

and delay in onset of action. It is well established The thermogram of Soluplus shows change in heat

fact that, dissolution is the rate limiting step in the capacity at 81C indicating melting point of

absorption process. Conventional tablet of Soluplus. In SD 1:3 thermogram shows the

Cinnarizine is available in markets which are not reduction in melting point from 1210C to 1150C

suitable where fast onset of action is needed. and intensity of peak also reduced. This decrease in

In order to overcome above problems, the present melting point of Cinnarizine may attribute to

study was carried out to develop orodispersible crystalline to amorphous nature in solid dispersion.

tablets containing Cinnarizine solid dispersion. In order to investigate in-vitro release of pure drug,

Solid dispersions of Cinnarizine were prepared by physical mixtures and solid dispersions with

using novel polymer Soluplus in different ratios by Soluplus were subjected to dissolution study in

physical mixture and solvent evaporation method. USP type II dissolution apparatus. PD, PM1:1, 1:2

The drug and polymer ratio of 1:1, 1:2, 1:3 were and 1:3 shows 49.432 0.4227 %, 61.025 0.9124

used in order to enhance solubility and dissolution %, 66.669 0.8894 % and 75.916 0.4513 % drug

rate. After formulation completed Cinnarizine, release respectively in 30 min. Solid dispersion

physical mixture and solvent evaporation method SD1:1, SD1:2 and 1:3 shows 75.916 0.9570 %,

dispersions were proceeds for its evaluation study 98.893 0.2632% and 99.829 0.3998 % drug

Saturation solubility of Cinnarizine was found to be release in 30 min, 27 min and 24 min respectively.

0.6326 mg/ml and 0.0039 mg/ml in pH 1.2 buffer It indicate that SD1:3 shows higher drug release

solution and pH 6.8 phosphate buffer respectively. 99.82 0.3998 % within 24 min compared to PD,

Physical mixture and solid dispersion with PMs and SD1:1, 1:2. From the results of

Soluplus shows increase in solubility respectively. dissolution studies SD1:3 is selected as best

The ratio 1:3 of solid dispersion gives the formulation for tablet formulation.

maximum saturation solubility among all the Orodispersible tablets of SD1:3 were prepared by

physical mixture and solid dispersions i.e. 4.8460 using Kyron T-314 as a superdisintegrant in

mg/ml and 0.030684 mg/ml in pH 1.2 buffer different concentration 1 %, 2 %, 3 % and 4 % by

solution and pH 6.8 phosphate buffer respectively. direct compression method. These formulations are

Drug content was found to be in range 98.78 coded as F1, F2, F3 and F4. In order to establish

www.iajps.com Page 923

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

compatibility study, the FTIR spectra of Formulation of orodispersible tablet by using solid

formulation blend shows all characteristic peaks of dispersion of Cinnarizine is unique technique by

Cinnarizine and SD1:3 and it indicates that there is which solubility and bioavailability of drug can be

no any significance interaction between SD1:3 and enhanced with improving patient compliance and

Kyron T 314. convenience.

The blends of all the formulations were evaluated It can be concluded that combination of solid

for pre-compression parameters like angle of dispersion and superdisintegrant is a promising

repose, bulk density, tapped density, carrs index approach to prepare efficient orodispersible tablet

and housners ratio. The results that are obtained of BCS class II drug (low solubility, high

for formulation F1-F4 shows good compression permeability).

and flow property. The prepared tablets were Standardized orodispersible tablet formulation F4

subjected for post-compression parameters. The was found to be stable after three month

results for all formulations possessed good accelerated stability study.

mechanical strength with sufficient hardness in the Thus, the objectives of the research work were

range of 3.78 to 3.90 kg/cm2. The percent friability successfully achieved.

was found to be 0.4117 to 0.5616 which is less than

1m% indicating tablets were mechanically stable. REFERENCES:

All formulations show 199.7 to 200.25 mg/tablet 1.Das Sanjoy Kumar, Roy Sudipta, Yuvaraja

weight, which complies with pharmacopeias limit. Kalimuthu, Khanam Jasmina, Nanda Arunabha.

Drug contents were found to be within Solid dispersions: An approach to enhance the

pharmacopeias limit. The wetting time, dispersion bioavailability of poorly water soluble drugs,

time, disintegration time for all formulations was International Journal of Pharmacology and

found to be 14.0 to 31.33 sec., 19.33 to 34.33 sec. Pharmaceutical Technology, Vol.-I, Issue-1, p.37-

and 13.0 to 26.16 sec. It is decreasing wetting, 46.

dispersion and disintegration time with increasing 2.Sharma D, Soni M, Kumar S, Gupta GD.

concentration of Kyron T-314. Solubility enhancement eminent role in poorly

The in-vitro dissolution profiles were indicates soluble drugs. Research Journal of Pharma and

faster and maximum drug release from all Tech, 2009; 2 (2), p. 220-224.

formulations F1 to F4. F1 shows 99.1475 0.4240 3.Patel T, Patel L, Patel T, Makwana S, Patel T.

% in 24 min., F2 shows 99.498 0.4672 % in 21 Enhancement of dissolution of Fenofibrate by solid

min., F3 shows 99.4461 0.2273 % in 18 min and dispersion technique. International Journal

F4 shows 99.7582 0.6297 % in 15 min. Based on Research and Pharm Science 2010; 1(2), p. 127-

obtained results, the formulation F4 is selected as a 132.

best formulation and which is compared with 4.IlseWeuts, Dieter Kempena, Geert Verreck,

marketed formulation. Percent drug release of JefPeeters, Marcus Brewster, Norbert Blaton,. Salt

marketed formulation in 15 min was 66.9272 formation in solid dispersions consisting of

0.2321 % and F4 formulation was 99.7582 polyacrylic acid as a carrier and three basic model

0.6297 %. compounds resulting in very high glass transition

The prepared orodispersible tablet of Cinnarizine temperatures and constant dissolution properties

solid dispersion has shown better release and upon storage. European Journal of Pharmaceutical

stability as compared to marketed formulation. Science, 2005; 25, p. 387393.

The conclusions from present research work are as 5.Bramhmankar DM, Jaiswal SB,

follows: Biopharmaceutics and Pharmacokinetics- A

The use of Soluplus for obtaining solid dispersion Treatise, Vallabh Prakashan, Second edition, p. 24-

of Cinnarizine proved successful. 30, 314-336.

The significance increase in solubility and 6.Dhirendra K, Lewis S, Udupa N. Solid

dissolution was observed from solid dispersion dispersions: A review, Pak Journal of

containing Cinnarizine and Soluplus in 1:3 ratio Pharmaceutical Science, Vol 22, April 2009; p.

prepared by solvent evaporation method as 234-246.

compared to pure drug, physical mixtures and other 7.Kuchekar BS, Aruagam VA. Review: Fast

solvent evaporation method dispersions. dissolving tablets. Indian Journal of Pharmaceutical

Soluplus as a solid dispersion carrier imparts good Education, 2001; 35, p. 150-152.

surface adsorbent property and leaves drug in 8.Lindgreen S, Janzon L. Dysphagia: Prevalence of

amorphous state that increases the surface area, due swallowing complaints and clinical findings.

to enhances the dissolution rate. Medical Clinic of North America. 1993; 77, p. 3-5.

Formulation of orodispersible tablet of Cinnarizine 9.Bangale GS, Shinde GV, Stephen B. New

solid dispersion (1:3) by using Kyron T- 314 generation of orodispersible tablets: recent

showed rapid in-vitro disintegration and dispersion advances and future prospects, International

time.

www.iajps.com Page 924

IAJPS 2017, 4 (04), 910- 925 Dhananjay M.Patil et al ISSN 2349-7750

Journal of Advances in Pharmaceutical Sciences, 2, 22.Khan S, Kataria P, Nakhat P, Yeole P. Taste

2011; p. 17-28. masking of Ondensetron hydrochloride by polymer

10.Patel Bipin, Patel Jayvadan, Thakor Rashmin, carrier system and formulation of rapid

Rajput Ganesh, Patel Kalpesh. Improvement of disintegrating tablet. AAPS Pharmceutical Science

solubility of Cinnarizine by using solid dispersion and Techchnology. 2007; 8(2), p. 238-243

technique, International Research Journal of 23.Gandhi B. R., Mundada A. S., Gandhi K. R.,

Pharmacy, 2010; 1(1), p. 127-131. Evaluation of Kyron T-314 (polacrillin potassium)

11.Suresh Preeti K, Sharma Sudhanshu. as a novel superdisintegrant, International Journal

Formulation and in-vitro characterization of self- of Drug Delivery, Vol. 3, 2011; p. 109-114.

nanoemulsifying drug delivery system of 24.Natalie MC, Clure. Stability studies in overview

Cinnarizine , International Journal of of ICH Guidelines for Drug Products. Matrix

Comprehensive Pharmacy, 2011; Vol. 02, Issue 09, Pharmaceutical Inc., 1997.

p 1-6. (http://www.mcclurenet.com).

12.Bangale GS, Shinde GV, Stephen B. New

generation of orodispersible tablets: recent

advances and future prospects, International

Journal of Advances in Pharmaceutical Sciences, 2,

2011; p. 17-28.

13.Gandhi B. R., Mundada A. S., Gandhi K. R.,

Evaluation of Kyron T-314 (polacrillin potassium)

as a novel superdisintegrant, International Journal

of Drug Delivery, Vol. 3, 2011; p. 109-114.

14.Tiwari Ruchi, Tiwari Gaurav, Srivastava

Brijendra, Rai Awani, Radke R. Development and

optimization of multi-unit solid dispersion systems

of poorly water soluble drug, Research Journal of

Pharm. and Tech. Oct-Dec 2008; 1(4), p. 444-449.

15.Shinde Sharad N, Satej S. Magdum, Kamla K.

Chandak, Mahesh R. Mishra, Smita S. Singhal.

Modification of solubility characteristics of

cinnarizine using -cyclodextrin, International

Imperial Journal Pharmaceutics & Cosmetology

2(1): May 2012; p. 30-36.

16.Pokharkar Varsha, Mendiratta Charu, Kadam

Vivek, Lansoprazole solid dispersion using a novel

amphiphilic polymer Soluplus, Journal of Chemical

and Pharmaceutical Research, 2011; 3(6), p. 536-

543.

17.Bahar Kalava, Muzeyyen Demirel, Yasemin

Yazan, Physicochemical characterization and

dissolution properties of Cinnarizine solid

dispersions, Turkish Journal of Pharmaceutical

Science Vol 2, 2005, p. 51-61.

18.The United State Pharmacopoeia 28 / The

National Formulary 23, Asian edition, The Official

Compendia of Standards, United State

Pharmacopoieal Conviction Inc. Rockville, 2004;

p. 2724-2725, 2412-14, 2379-2380, 2000,1675.

19.Remington. The science and practice of

pharmacy. 20th Ed: B.I. Publications Pvt. Ltd:

2000; 1, p. 858-862.

20.Lachman L. Libberman HA, Kanig JL. Theory

and Practice of Industrial Pharmacy. 3rd edition

Varghese publishingn house, 1990; p. 296-302

21.Yunxia B, Sunada H, Yonezawa Y, and Danjo

K. Evaluation of rapidly disintegrating tablets

prepared by direct compression method. Drug

Devlivery of Indian Pharma 1999; 25(5), p. 571-

581.

www.iajps.com Page 925

Você também pode gostar

- Assessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaDocumento7 páginasAssessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaBaru Chandrasekhar RaoAinda não há avaliações

- Parenteral Products: The Preparation and Quality Control of Products for InjectionNo EverandParenteral Products: The Preparation and Quality Control of Products for InjectionAinda não há avaliações

- EUV Lithography and Source TechnologyDocumento47 páginasEUV Lithography and Source TechnologyGabriel DonovanAinda não há avaliações

- Formulation and Evaluation of Cefixime Trihydrate Dispersible TabletsDocumento10 páginasFormulation and Evaluation of Cefixime Trihydrate Dispersible TabletsEditor IJTSRDAinda não há avaliações

- Physical Properties of Dental MaterialsDocumento87 páginasPhysical Properties of Dental MaterialsManiBernardHAinda não há avaliações

- Fuel Cell Lab ReportDocumento6 páginasFuel Cell Lab ReportSumeet RanuAinda não há avaliações

- The Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalDocumento11 páginasThe Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalBaru Chandrasekhar RaoAinda não há avaliações

- Engineering Chemistry Unit III(A) - Definition and Types of LubricantsDocumento25 páginasEngineering Chemistry Unit III(A) - Definition and Types of Lubricantssri aknth100% (1)

- 8 States of MatterDocumento4 páginas8 States of Matterrashmi_harryAinda não há avaliações

- 1440 - Magazine Chemical Engineering October 2012Documento76 páginas1440 - Magazine Chemical Engineering October 2012gh_ali110Ainda não há avaliações

- Handbook Milk Powder Manufacture PDFDocumento265 páginasHandbook Milk Powder Manufacture PDFWaqar Hassan100% (9)

- Data Sheets - UpdatedDocumento267 páginasData Sheets - Updateddurgesh82338114100% (1)

- Phytochemical Screening and TLC Fingerprinting Formulation and Evaluation of Fast Disintegrating Tablets of FenofibrateDocumento8 páginasPhytochemical Screening and TLC Fingerprinting Formulation and Evaluation of Fast Disintegrating Tablets of FenofibrateBaru Chandrasekhar RaoAinda não há avaliações

- Medicine ManagementDocumento7 páginasMedicine Managementimdad KURDIAinda não há avaliações

- 2 Vol.2 11 IJPSR RE 351 2011 Paper 2Documento14 páginas2 Vol.2 11 IJPSR RE 351 2011 Paper 2anomsawitriAinda não há avaliações

- Literature SurveyDocumento6 páginasLiterature SurveyVaibhav KaleAinda não há avaliações

- Review Oral StripsDocumento10 páginasReview Oral StripsRohit guptaAinda não há avaliações

- Oral Dispersible System A New Approach in Drug Del PDFDocumento6 páginasOral Dispersible System A New Approach in Drug Del PDFHaider SalahAinda não há avaliações

- 1745-Article Text-6947-2-10-20200624Documento14 páginas1745-Article Text-6947-2-10-20200624Gaurav AdhikariAinda não há avaliações

- MDIw MTMy MJ U5Documento5 páginasMDIw MTMy MJ U5Zeyad A AbdullahAinda não há avaliações

- Sustained Release Matrix Tablet of Diltiazem Hydrochloride It'S Formulation and EvaluationDocumento10 páginasSustained Release Matrix Tablet of Diltiazem Hydrochloride It'S Formulation and EvaluationruriAinda não há avaliações

- Formulation, Optimization and Evaluation of Eslicarbazepine AcetateDocumento6 páginasFormulation, Optimization and Evaluation of Eslicarbazepine AcetateBaru Chandrasekhar RaoAinda não há avaliações

- A Review On Dry Syrups For Paediatrics PDFDocumento7 páginasA Review On Dry Syrups For Paediatrics PDFPhani DeepthiAinda não há avaliações

- A Review On Dry Syrups For Paediatrics PDFDocumento7 páginasA Review On Dry Syrups For Paediatrics PDFAmaliyahNurAinda não há avaliações

- Formulation and Evaluation of Effervescent Tablets of ParacetamolDocumento30 páginasFormulation and Evaluation of Effervescent Tablets of ParacetamolAnonymous TjrM0BXkZAinda não há avaliações

- Inlay Tablets - A Novel Approach for Sustained Drug DeliveryDocumento10 páginasInlay Tablets - A Novel Approach for Sustained Drug DeliveryTakeshi MondaAinda não há avaliações

- Hindawi Publishing Corporation Journal of Pharmaceutics Volume 2014, Article ID 808167, 8 PagesDocumento14 páginasHindawi Publishing Corporation Journal of Pharmaceutics Volume 2014, Article ID 808167, 8 PagesnanangAinda não há avaliações

- A Review On Fast Dissolving Tablets FDTsDocumento10 páginasA Review On Fast Dissolving Tablets FDTsKamran AlamAinda não há avaliações

- SD Telmisartan 2016Documento9 páginasSD Telmisartan 2016Rifa sabrina SalsabilaAinda não há avaliações

- Formulation and Evaluation of Mouth Dissolving Oral Films and Mini Tablets of DomperidoneDocumento48 páginasFormulation and Evaluation of Mouth Dissolving Oral Films and Mini Tablets of DomperidoneINTERNATIONAL JOURNAL OF SCIENCE SCHOLARSAinda não há avaliações

- Ondansetron Formulation-Archives of Pharmacal ResearchDocumento13 páginasOndansetron Formulation-Archives of Pharmacal ResearchJenk JenkAinda não há avaliações

- Article 017Documento10 páginasArticle 017Digambar GondvaleAinda não há avaliações

- 4 Preeti PDFDocumento15 páginas4 Preeti PDFBaru Chandrasekhar RaoAinda não há avaliações

- Review of Literature on Fast Dissolving TabletsDocumento22 páginasReview of Literature on Fast Dissolving TabletsSunil ChaudharyAinda não há avaliações

- Formulation and in Vitro Evaluation of Fesoterodine Fumarate Sustained Release TabletsDocumento13 páginasFormulation and in Vitro Evaluation of Fesoterodine Fumarate Sustained Release TabletsBaru Chandrasekhar RaoAinda não há avaliações

- Formulation and Evaluation of Enteric CoatedDocumento13 páginasFormulation and Evaluation of Enteric Coatedvanvu buiAinda não há avaliações

- 2.review Article PDFDocumento11 páginas2.review Article PDFBaru Chandrasekhar RaoAinda não há avaliações

- Reconstitutable Oral Suspensions (Dry Syrups) : AnDocumento23 páginasReconstitutable Oral Suspensions (Dry Syrups) : Ananggunputriviona31Ainda não há avaliações

- Formulation and Evaluation of Mouth Dissolving Film Containing RofecoxibDocumento7 páginasFormulation and Evaluation of Mouth Dissolving Film Containing RofecoxibSathish SizzyAinda não há avaliações

- Article Wjpps 1408969434Documento20 páginasArticle Wjpps 1408969434guptaranjeet40Ainda não há avaliações

- 19 Iajps19062017 PDFDocumento9 páginas19 Iajps19062017 PDFBaru Chandrasekhar RaoAinda não há avaliações

- M.Pharm Dissertation Protocol: Formulation and Evaluation of Antihypertensive Orodispersible TabletsDocumento7 páginasM.Pharm Dissertation Protocol: Formulation and Evaluation of Antihypertensive Orodispersible TabletsFree Escort ServiceAinda não há avaliações

- Jchps 6 (4) 15 Page 286-292 MsreddyDocumento7 páginasJchps 6 (4) 15 Page 286-292 MsreddydwahyusafriAinda não há avaliações

- 61Documento4 páginas61Ta RaAinda não há avaliações

- Farm As EtikDocumento30 páginasFarm As EtikNadila AmaliaAinda não há avaliações

- Formulation and Evaluation of Orally Disintegrating Tablets of SertralineDocumento7 páginasFormulation and Evaluation of Orally Disintegrating Tablets of SertralineDinesh BabuAinda não há avaliações

- Beta-Cyclodextrin Solid DispersionDocumento30 páginasBeta-Cyclodextrin Solid Dispersiondarkarva84100% (1)

- Formulation and In-Vitro Evaluation of Fast Dissolving Tablets of TelmisartanDocumento6 páginasFormulation and In-Vitro Evaluation of Fast Dissolving Tablets of TelmisartanNIKUAinda não há avaliações

- V6I105 28 January 2021Documento9 páginasV6I105 28 January 2021Harrizul RivaiAinda não há avaliações

- Formulation and Evaluation of Multiunit Pellet System of Venlafaxine HydrochlorideDocumento12 páginasFormulation and Evaluation of Multiunit Pellet System of Venlafaxine HydrochloridevbadsAinda não há avaliações

- Formulation Development and in Vitro Evaluation of Capecitabine Immediate Release TabletsDocumento9 páginasFormulation Development and in Vitro Evaluation of Capecitabine Immediate Release TabletsEditor IJTSRDAinda não há avaliações

- Solubility Enhancement Techniques - A ReviewDocumento13 páginasSolubility Enhancement Techniques - A ReviewBaru Chandrasekhar RaoAinda não há avaliações

- Development of Fast Disintegration TableDocumento20 páginasDevelopment of Fast Disintegration TableKamran AlamAinda não há avaliações

- An Overview On Stability of Extemporaneously Prepared Pharmaceutical SuspensionDocumento4 páginasAn Overview On Stability of Extemporaneously Prepared Pharmaceutical SuspensionJesica Carine PoluanAinda não há avaliações

- 10 12991-Marupj 259883-226368Documento11 páginas10 12991-Marupj 259883-226368Nitesh MishraAinda não há avaliações

- Formulation Development and Evaluation of Cinnarizine Nasal SprayDocumento8 páginasFormulation Development and Evaluation of Cinnarizine Nasal SprayPutri BalgisAinda não há avaliações

- A Review of Formulation Technology For Recent Advancements in Fast Dissolving TabletsDocumento12 páginasA Review of Formulation Technology For Recent Advancements in Fast Dissolving TabletsInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- 2404-Article Text-7186-1-10-20190315 PDFDocumento7 páginas2404-Article Text-7186-1-10-20190315 PDFnelisaAinda não há avaliações

- Development of Fast Dissolving Oral Film ContaininDocumento14 páginasDevelopment of Fast Dissolving Oral Film ContaininLina WinartiAinda não há avaliações

- 2176-Article Text-6429-1-10-20190112Documento8 páginas2176-Article Text-6429-1-10-20190112Lenny NovitaAinda não há avaliações

- An Outlook On Nasal Drug Delivery SystemDocumento16 páginasAn Outlook On Nasal Drug Delivery SystemGopalasatheeskumar KAinda não há avaliações

- Formulation and Evaluation of Taste-Masked Ciprofloxacin Oral Reconstitutable Dry SyrupDocumento10 páginasFormulation and Evaluation of Taste-Masked Ciprofloxacin Oral Reconstitutable Dry SyrupdhilahAinda não há avaliações

- Paper 8695Documento9 páginasPaper 8695IJARSCT JournalAinda não há avaliações

- Jurnal CarbamazepinDocumento9 páginasJurnal CarbamazepinRosamaria Yuni UtamiAinda não há avaliações

- Controlled Injectable Drug Delivery OverviewDocumento11 páginasControlled Injectable Drug Delivery OverviewWandikbogweAinda não há avaliações

- International Journal of Pharmaceutics: A 1 A 1 A A A BDocumento10 páginasInternational Journal of Pharmaceutics: A 1 A 1 A A A BNurfaidah Ayu ApriliantiAinda não há avaliações

- Dispersible Tablet Current Trend and FutDocumento14 páginasDispersible Tablet Current Trend and FutKRISHNA RAJ JAinda não há avaliações

- Design and Development of Carvedilol Gastroretentive Floating Drug Delivery Systems Using Hydrophilic Polymers and in Vitro CharacterizationDocumento8 páginasDesign and Development of Carvedilol Gastroretentive Floating Drug Delivery Systems Using Hydrophilic Polymers and in Vitro CharacterizationPRASANTA KUMAR MOHAPATRAAinda não há avaliações

- Formulation and Evaluation of Orodispersible Tablets of CelecoxibDocumento8 páginasFormulation and Evaluation of Orodispersible Tablets of CelecoxibdadaAinda não há avaliações

- Development of Cell Culture System From Selected Tissues of Pangaius HypopthalmusDocumento6 páginasDevelopment of Cell Culture System From Selected Tissues of Pangaius HypopthalmusBaru Chandrasekhar RaoAinda não há avaliações

- Development and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormDocumento11 páginasDevelopment and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormBaru Chandrasekhar RaoAinda não há avaliações

- Genetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Documento5 páginasGenetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Baru Chandrasekhar RaoAinda não há avaliações

- Formulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleDocumento9 páginasFormulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleBaru Chandrasekhar RaoAinda não há avaliações

- Analytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationDocumento8 páginasAnalytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationBaru Chandrasekhar RaoAinda não há avaliações

- Non-Adherence in Hyppertensive Patients of Peshawar, PakistanDocumento13 páginasNon-Adherence in Hyppertensive Patients of Peshawar, PakistanBaru Chandrasekhar RaoAinda não há avaliações

- Gastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsDocumento7 páginasGastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsBaru Chandrasekhar RaoAinda não há avaliações

- Knowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyDocumento8 páginasKnowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyBaru Chandrasekhar RaoAinda não há avaliações

- The Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesDocumento8 páginasThe Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesBaru Chandrasekhar RaoAinda não há avaliações

- Simultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodDocumento6 páginasSimultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodBaru Chandrasekhar RaoAinda não há avaliações

- A Brief Review On YawsDocumento7 páginasA Brief Review On YawsBaru Chandrasekhar RaoAinda não há avaliações

- Preparation of Silver Nanoparticles From Herbal PlantDocumento9 páginasPreparation of Silver Nanoparticles From Herbal PlantBaru Chandrasekhar RaoAinda não há avaliações

- Nephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsDocumento12 páginasNephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsBaru Chandrasekhar RaoAinda não há avaliações

- Relationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityDocumento4 páginasRelationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityBaru Chandrasekhar RaoAinda não há avaliações

- Role of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenDocumento4 páginasRole of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenBaru Chandrasekhar RaoAinda não há avaliações

- An Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchDocumento6 páginasAn Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchBaru Chandrasekhar RaoAinda não há avaliações

- An Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsDocumento6 páginasAn Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsBaru Chandrasekhar RaoAinda não há avaliações

- Review On: Inventory ManagementDocumento8 páginasReview On: Inventory ManagementBaru Chandrasekhar RaoAinda não há avaliações

- Association of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyDocumento4 páginasAssociation of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyBaru Chandrasekhar RaoAinda não há avaliações

- Pharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoDocumento7 páginasPharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoBaru Chandrasekhar RaoAinda não há avaliações

- Study of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Documento6 páginasStudy of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Baru Chandrasekhar RaoAinda não há avaliações

- After Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsDocumento4 páginasAfter Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsBaru Chandrasekhar RaoAinda não há avaliações

- Descriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreDocumento4 páginasDescriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreBaru Chandrasekhar RaoAinda não há avaliações

- C-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsDocumento5 páginasC-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsBaru Chandrasekhar RaoAinda não há avaliações

- An Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentDocumento6 páginasAn Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentBaru Chandrasekhar RaoAinda não há avaliações

- Isolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Documento8 páginasIsolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Baru Chandrasekhar RaoAinda não há avaliações

- Oppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyDocumento10 páginasOppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyBaru Chandrasekhar RaoAinda não há avaliações

- A Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreDocumento8 páginasA Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreBaru Chandrasekhar RaoAinda não há avaliações

- Fundamentals of Thermodynamics Fundamentals of ThermodynamicsDocumento32 páginasFundamentals of Thermodynamics Fundamentals of ThermodynamicsYep IdidthisAinda não há avaliações

- 1 s2.0 S0360319922001793 MainDocumento17 páginas1 s2.0 S0360319922001793 MainAbhi KrishAinda não há avaliações

- Sustainable Energy: Linfeng ZhangDocumento39 páginasSustainable Energy: Linfeng ZhangLuli NikiAinda não há avaliações

- NHT Catalyst Activation ORC-I (Updated)Documento10 páginasNHT Catalyst Activation ORC-I (Updated)Clash with HBAinda não há avaliações

- Principles of Fluid Chillers: Design for Reliable OperationDocumento7 páginasPrinciples of Fluid Chillers: Design for Reliable OperationAzim AdamAinda não há avaliações

- 12U Chem Final June 05bDocumento14 páginas12U Chem Final June 05bedeceAinda não há avaliações

- Improving OLED Performance Via Semiconductor Dilution: Chris GiebinkDocumento11 páginasImproving OLED Performance Via Semiconductor Dilution: Chris GiebinkinzanerAinda não há avaliações

- Latent Heat: Click Here For More Content On CSEC PhysicsDocumento14 páginasLatent Heat: Click Here For More Content On CSEC PhysicsZae ZayAinda não há avaliações

- J Diamond 2005 09 007Documento4 páginasJ Diamond 2005 09 007Yohanes Fredy KartikoAinda não há avaliações

- Adhesives and Sealants 12 - 2018Documento6 páginasAdhesives and Sealants 12 - 2018Jose LopezAinda não há avaliações

- PMS Theory Chapter3Documento47 páginasPMS Theory Chapter3moulitechAinda não há avaliações

- Test Bank For Chemistry A Molecular Approach 4th Edition by Tro ISBN 0134112830 9780134112831Documento36 páginasTest Bank For Chemistry A Molecular Approach 4th Edition by Tro ISBN 0134112830 9780134112831shawnramirez06042001jzc100% (23)

- Volumetric Gas Adsorption Technique - Magnesium Stearate - EP6.0 - 01 - 231Documento4 páginasVolumetric Gas Adsorption Technique - Magnesium Stearate - EP6.0 - 01 - 231Debahis BoseAinda não há avaliações

- The Advantages of Uniform Particle Sized Ion Exchange ResinsDocumento10 páginasThe Advantages of Uniform Particle Sized Ion Exchange ResinsLUIS ENRIQUE VILCA ESPINOZAAinda não há avaliações

- Jurnal Tegangan Permukaan InggrisDocumento8 páginasJurnal Tegangan Permukaan InggrisDiyan PriyaniAinda não há avaliações

- Unit 5 - Test Questions Humss 1 & Abm 3Documento9 páginasUnit 5 - Test Questions Humss 1 & Abm 3Neil GabatoAinda não há avaliações

- Basics of Convection of Heat Transfer ModeDocumento105 páginasBasics of Convection of Heat Transfer ModeSamir YehyaAinda não há avaliações

- BiotechnologyDocumento2 páginasBiotechnologyLyka Mae Gemino TestaAinda não há avaliações

- 1 s2.0 S1674987123000919 MainDocumento21 páginas1 s2.0 S1674987123000919 MainMatteo MainoAinda não há avaliações

- Properties of Gaseous FuelsDocumento11 páginasProperties of Gaseous FuelsIan Dave OpaoAinda não há avaliações

- Atkins Physical Chemistry 2nd Law EntropyDocumento20 páginasAtkins Physical Chemistry 2nd Law Entropyfebiola silvia ningsihAinda não há avaliações

- Important Concepts in UV-Vis and IR SpectrosDocumento53 páginasImportant Concepts in UV-Vis and IR SpectrosmarkkkkkAinda não há avaliações