Escolar Documentos

Profissional Documentos

Cultura Documentos

Operation V N P T I 75

Enviado por

Dhiraj SatyamTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Operation V N P T I 75

Enviado por

Dhiraj SatyamDireitos autorais:

Formatos disponíveis

Sudden decrease in firing rate Increase feeding range of running mills.

e.g. tripping of the running mills

B.F.P. scoop tube position suddenly Check differential pressure across feed control

increased valve and maintain 5 Kg/cm2 by adjusting scoop

tube position.

2.11.5 Flame Failure At an Elewation

Closing of trip valves on H.O., : Do not attempt to introduce ignitors or oil guns at

W.U. Oil/Ignitor (Causing loss of elevation where "No flame" condition persist.

ignition support energy) Where F.O.

is being used as support fuel or when

only oil is being used.

Sudden decrease of mill feeder : Trip out the coal mills of feeding elevation where

speeds to minimum "No flame" condition is persisting. Allow sometime

for purging then introduce oil support adjacent to

working mills until furnace flame is stabilised.

Too low or too high windbox Check that secondary air windbox dampers are

pressure causing unstable modulating to maintain about 80mm windbox to

combustion furnace differential pressure.

Water wall tube failure Check furnace for tube failure.

Malfunction of flame scanners due If two elevations scanners show "No flame" trip the

to supply failure or scanner air boiler manually

failure, slag or soot on scanner

lenses etc.

Burner tilt mechanism negative : Check burner tilt keep it between +10.

extreme due to air failure to

power cylinders.

Rapid load changes without : Check furnace flame condition.

adjusting air flow leading to

improper combustion.

2.11.6.One Fan Trips (Other in Service)

It is presumed that I.D./F.D./P.A. fan de-interlocking switches are on "Interlock" position.

Fan Bearing temperature high : i) Take draft control or manual,

and/or and/or increase the loading on running fan

and maintain furnace draft.

Fan motor Bearing temperature high ii) Check corresponding fan is tripped through

and/or interlock

71

Você também pode gostar

- Boiler EmergancyDocumento35 páginasBoiler EmergancyAshok RasekarAinda não há avaliações

- Boiler Emergency OperationsDocumento55 páginasBoiler Emergency OperationsbajrangAinda não há avaliações

- If One F.D. Fan TripsDocumento9 páginasIf One F.D. Fan TripsAhemad100% (1)

- Operation V N P T I 109Documento1 páginaOperation V N P T I 109Dhiraj SatyamAinda não há avaliações

- TG EmergenciesDocumento15 páginasTG EmergenciessasibhushanAinda não há avaliações

- Emergency in Power PlantDocumento12 páginasEmergency in Power PlantCo-gen ManagerAinda não há avaliações

- Boiler EmergencyDocumento41 páginasBoiler Emergencysubrata guhaAinda não há avaliações

- Handling of Turbine During EmergencyDocumento17 páginasHandling of Turbine During EmergencyManohar TatwawadiAinda não há avaliações

- Start/stop of The Boiler: 1 GeneralDocumento4 páginasStart/stop of The Boiler: 1 GeneralphuocAinda não há avaliações

- New Microsoft Word DocumentDocumento25 páginasNew Microsoft Word DocumentRathin KukrejaAinda não há avaliações

- Section11 ROUTINE OPERATION.Documento37 páginasSection11 ROUTINE OPERATION.Mithilesh YadavAinda não há avaliações

- Trouble Shooting GuideDocumento26 páginasTrouble Shooting GuideArun S100% (1)

- Operation V N P T I 108Documento1 páginaOperation V N P T I 108Dhiraj SatyamAinda não há avaliações

- Operation and Maintenance: Start/stop of BoilerDocumento24 páginasOperation and Maintenance: Start/stop of BoilerAlexander BaziotisAinda não há avaliações

- Boiler EmergenciesDocumento21 páginasBoiler EmergenciesRama ReddyAinda não há avaliações

- Standard Operating Procedure - KilnDocumento7 páginasStandard Operating Procedure - KilnJCS100% (2)

- Warm StartupDocumento3 páginasWarm StartupRahul KurmiAinda não há avaliações

- Manual Boiler Feed IND 12 PDFDocumento1 páginaManual Boiler Feed IND 12 PDFHicham IdrisiAinda não há avaliações

- Starting A Boiler From Dead Ship ConditionsDocumento21 páginasStarting A Boiler From Dead Ship ConditionsrickAinda não há avaliações

- Boiler Cooling MethodDocumento7 páginasBoiler Cooling Methodjp mishra100% (1)

- Chiller SafetyDocumento51 páginasChiller SafetyChesya Sera De ClaresyaAinda não há avaliações

- Turbine Emergency - Thermal Power Plant A-ZDocumento5 páginasTurbine Emergency - Thermal Power Plant A-ZSiva Kulanji100% (1)

- BoilerDocumento21 páginasBoilerIrawan SutionoAinda não há avaliações

- 140 Boiler EmergenciesDocumento32 páginas140 Boiler EmergenciesSudip Guthe100% (2)

- LC 54Documento16 páginasLC 54Christos ChristofiAinda não há avaliações

- Turbine Start UpDocumento15 páginasTurbine Start UprobiansahAinda não há avaliações

- DCU Heater Mod.Documento36 páginasDCU Heater Mod.Varun Gupta100% (1)

- Experiment 2-Performance of Steam PlantDocumento8 páginasExperiment 2-Performance of Steam PlantAhmad DanialAinda não há avaliações

- pp1 Lab 2Documento7 páginaspp1 Lab 2Mian KaleemAinda não há avaliações

- Boiler-Steam Generator Protection PDFDocumento12 páginasBoiler-Steam Generator Protection PDFأمير حارث100% (1)

- C&I Part of SCDocumento28 páginasC&I Part of SCLakshmi Narayan100% (1)

- 1553002416-ABB - VDU - Module 2 - PDFsDocumento28 páginas1553002416-ABB - VDU - Module 2 - PDFsNew TonAinda não há avaliações

- Steam Turbine Fast Cooling Down of The Turbine OperationDocumento1 páginaSteam Turbine Fast Cooling Down of The Turbine Operationparthibanemails5779Ainda não há avaliações

- Powr PlantDocumento10 páginasPowr PlantSajjad Ibraheem100% (1)

- Handling of Turbine During Emergency: Emergencies in Turbine and AuxiliariesDocumento3 páginasHandling of Turbine During Emergency: Emergencies in Turbine and Auxiliariesron1234567890Ainda não há avaliações

- Scanboilerr TextDocumento7 páginasScanboilerr TextAntonio AvilesAinda não há avaliações

- Op Eff 16 12 2023Documento45 páginasOp Eff 16 12 2023Sharath BogaAinda não há avaliações

- Heavy Oil or Similar Firing Systems With Rotary Cup Atomizer BurnersDocumento2 páginasHeavy Oil or Similar Firing Systems With Rotary Cup Atomizer Burners徐玉坤Ainda não há avaliações

- 5 Boiler OperationDocumento12 páginas5 Boiler OperationAllen AnyayahanAinda não há avaliações

- Chapter 21-40-00 Enviromental System - HeatingDocumento38 páginasChapter 21-40-00 Enviromental System - HeatingAnggarda Bagus SejatiAinda não há avaliações

- AQ9 Boiler PDFDocumento26 páginasAQ9 Boiler PDFВиталий РунцивAinda não há avaliações

- Rankine CycleDocumento12 páginasRankine CycleVishant GuliaAinda não há avaliações

- EXPERIMENT 2a-PERFORMANCE OF STEAM PLANT Thermo PDFDocumento8 páginasEXPERIMENT 2a-PERFORMANCE OF STEAM PLANT Thermo PDFNurul MardhatiAinda não há avaliações

- 使用说明书Documento23 páginas使用说明书huutinhAinda não há avaliações

- April 2017 Tip SheetDocumento1 páginaApril 2017 Tip Sheetsaka dewaAinda não há avaliações

- Boiler Turbine Protection,,,EHC, Hydraullic-2Documento21 páginasBoiler Turbine Protection,,,EHC, Hydraullic-2Balvir GangarAinda não há avaliações

- Turbine Shutting Down From Full LoadDocumento7 páginasTurbine Shutting Down From Full Loadrohit_0123100% (1)

- Flagro Fvo 400 Heater Operations and TroubleshootingDocumento30 páginasFlagro Fvo 400 Heater Operations and TroubleshootingJocelyn DuteauAinda não há avaliações

- ATTEMPERATIONDocumento13 páginasATTEMPERATIONRajashekarBheemaAinda não há avaliações

- Thermo 4Documento9 páginasThermo 4Emran MuhammadAinda não há avaliações

- Boiler EmergenciesDocumento5 páginasBoiler Emergenciesshantanu_scribdAinda não há avaliações

- Section F CFBC Startup Procedure R00Documento8 páginasSection F CFBC Startup Procedure R00purvgargAinda não há avaliações

- Heat 029143 1Documento4 páginasHeat 029143 1khairnarsayali257Ainda não há avaliações

- Ultra Series 3 Boiler ManualDocumento108 páginasUltra Series 3 Boiler ManualEnfant PerduAinda não há avaliações

- 1 - DMX9402 - Unit 2 - Lect 5 - Boiler Op - Eff - 16 - 12 - 2023Documento51 páginas1 - DMX9402 - Unit 2 - Lect 5 - Boiler Op - Eff - 16 - 12 - 2023Sharath BogaAinda não há avaliações

- Operation and Control of Crude Oil Refining Process Using Atmospheric Distillation Column With PLCDocumento5 páginasOperation and Control of Crude Oil Refining Process Using Atmospheric Distillation Column With PLCBihina HamanAinda não há avaliações

- Harpuneet Refrigeration Assignment 4Documento12 páginasHarpuneet Refrigeration Assignment 4hpsingh0078Ainda não há avaliações

- Rankine CycleDocumento6 páginasRankine CyclenabeelAinda não há avaliações

- Experiment No. 2-To Study The Mountings and Accessories in BoilersDocumento10 páginasExperiment No. 2-To Study The Mountings and Accessories in BoilersShahed100% (1)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SAinda não há avaliações

- Super Critical Power - Part91Documento1 páginaSuper Critical Power - Part91Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part88Documento1 páginaSuper Critical Power - Part88Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part92Documento1 páginaSuper Critical Power - Part92Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part85Documento1 páginaSuper Critical Power - Part85Dhiraj SatyamAinda não há avaliações

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocumento1 páginaChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamAinda não há avaliações

- Super Critical Power - Part80Documento1 páginaSuper Critical Power - Part80Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part83Documento1 páginaSuper Critical Power - Part83Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part76Documento1 páginaSuper Critical Power - Part76Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part77Documento1 páginaSuper Critical Power - Part77Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part86Documento1 páginaSuper Critical Power - Part86Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part81Documento1 páginaSuper Critical Power - Part81Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part62Documento1 páginaSuper Critical Power - Part62Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part41Documento1 páginaSuper Critical Power - Part41Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part56Documento1 páginaSuper Critical Power - Part56Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part60Documento1 páginaSuper Critical Power - Part60Dhiraj SatyamAinda não há avaliações

- Suitable For Remote Manual OperationDocumento1 páginaSuitable For Remote Manual OperationDhiraj SatyamAinda não há avaliações

- Super Critical Power - Part59Documento1 páginaSuper Critical Power - Part59Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part57Documento1 páginaSuper Critical Power - Part57Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part58Documento1 páginaSuper Critical Power - Part58Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part48Documento1 páginaSuper Critical Power - Part48Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part47Documento1 páginaSuper Critical Power - Part47Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part46Documento1 páginaSuper Critical Power - Part46Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part42Documento1 páginaSuper Critical Power - Part42Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part34Documento1 páginaSuper Critical Power - Part34Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part40Documento1 páginaSuper Critical Power - Part40Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part37Documento1 páginaSuper Critical Power - Part37Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part38Documento1 páginaSuper Critical Power - Part38Dhiraj SatyamAinda não há avaliações

- Super Critical Power - Part35Documento1 páginaSuper Critical Power - Part35Dhiraj SatyamAinda não há avaliações

- WME01 01 Que 20200305Documento24 páginasWME01 01 Que 20200305Ahmad BatranAinda não há avaliações

- Compaction and Pressureless Sintering of ZirconiaDocumento9 páginasCompaction and Pressureless Sintering of ZirconiaWalaa Hassan Salem Abd El KareemAinda não há avaliações

- Opt Encoder 62SDocumento2 páginasOpt Encoder 62SShelton HodzieszAinda não há avaliações

- 765 KV & 400 KV Isolators - SpecificationDocumento23 páginas765 KV & 400 KV Isolators - Specificationbalaeee123Ainda não há avaliações

- Gujarat Technological UniversityDocumento2 páginasGujarat Technological UniversityShivam PanchalAinda não há avaliações

- Necessary and Sufficient Conditions For Riemann and Riemann-Stieltjes IntegrabilityDocumento10 páginasNecessary and Sufficient Conditions For Riemann and Riemann-Stieltjes IntegrabilityAloyana Couto da SilvaAinda não há avaliações

- Simulation of Forward Osmosis Using CFDDocumento7 páginasSimulation of Forward Osmosis Using CFDMohammadreza NaghaviAinda não há avaliações

- Specification For Pressure Vessel Plates, Alloy Steel, High-Strength, Quenched and TemperedDocumento4 páginasSpecification For Pressure Vessel Plates, Alloy Steel, High-Strength, Quenched and TemperededwinbadajosAinda não há avaliações

- Coordinate Measuring MachineDocumento5 páginasCoordinate Measuring MachineMuhammad UsmanAinda não há avaliações

- L4b Rate Law and Stoichiometry Example ProblemsDocumento18 páginasL4b Rate Law and Stoichiometry Example ProblemsĐỗ Quyết NguyễnAinda não há avaliações

- Mechanical Behavior of Aluminum Metal Matrix Composite Reinforcement With Graphene Nano FillersDocumento11 páginasMechanical Behavior of Aluminum Metal Matrix Composite Reinforcement With Graphene Nano FillersInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Lectrocount : Standard Bulk Truck System Standard Bulk Truck System Installation Procedures Installation ProceduresDocumento44 páginasLectrocount : Standard Bulk Truck System Standard Bulk Truck System Installation Procedures Installation ProceduresPhilip HoferAinda não há avaliações

- AHLSTAR Process PumpsDocumento71 páginasAHLSTAR Process PumpsPascal Cote100% (2)

- Chapter 4 NEPHAR 201 - Analytical Chemistry II - Atomic Absorption and Emission Spectrometry - 13Documento40 páginasChapter 4 NEPHAR 201 - Analytical Chemistry II - Atomic Absorption and Emission Spectrometry - 13Negasso JiraAinda não há avaliações

- 2.6.3 Practice - Quadratic Functions (Practice)Documento10 páginas2.6.3 Practice - Quadratic Functions (Practice)HyounJoun KangAinda não há avaliações

- Unit 4 Problems On Combined Bending and TorsionDocumento8 páginasUnit 4 Problems On Combined Bending and TorsionAnonymous mRBbdopMKf100% (1)

- Periodic Table Research PaperDocumento8 páginasPeriodic Table Research Paperafnhlmluuaaymj100% (1)

- SMA Fuel Save Solution PresentationDocumento52 páginasSMA Fuel Save Solution Presentationootchay100% (2)

- Low-Cost Non-Destructive Inspection by Simplified Digital Speckle InterferometryDocumento8 páginasLow-Cost Non-Destructive Inspection by Simplified Digital Speckle InterferometryLuis Pujay MateoAinda não há avaliações

- Differentiation 2Documento87 páginasDifferentiation 2Ali SAinda não há avaliações

- Electrical Data: ML06 ApplicationsDocumento5 páginasElectrical Data: ML06 ApplicationsCarlos MeloAinda não há avaliações

- H O CO: CHEM1102 Worksheet 10 - Answers To Critical Thinking QuestionsDocumento4 páginasH O CO: CHEM1102 Worksheet 10 - Answers To Critical Thinking QuestionsJohn-dred BautistaAinda não há avaliações

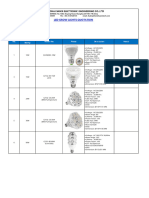

- LED Grow Lights List - Shanghai Sans - 3Documento4 páginasLED Grow Lights List - Shanghai Sans - 3asadakhter239Ainda não há avaliações

- CE405 - Experiment 3 - Determination of Specific Gravity and Water Absorption of AggregatesDocumento5 páginasCE405 - Experiment 3 - Determination of Specific Gravity and Water Absorption of AggregatesMel CoderesAinda não há avaliações

- Crystalin SolidDocumento51 páginasCrystalin SolidFebry YagamiAinda não há avaliações

- Allengers HF 49 Service ManualDocumento6 páginasAllengers HF 49 Service Manualdemon6592Ainda não há avaliações

- LAS No. 2Documento8 páginasLAS No. 2Eddie Lumaras Jr.Ainda não há avaliações

- Application of Jute Fiber in Soil StabilizationDocumento8 páginasApplication of Jute Fiber in Soil StabilizationMary Joy ManayagaAinda não há avaliações

- Chem Class 11 Notes For HydrogenDocumento8 páginasChem Class 11 Notes For HydrogenAishahAinda não há avaliações

- Wind LoadDocumento34 páginasWind LoadArah Louise ApostolAinda não há avaliações