Escolar Documentos

Profissional Documentos

Cultura Documentos

Tensile Test Upvc

Enviado por

Aloka KarunarathneDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Tensile Test Upvc

Enviado por

Aloka KarunarathneDireitos autorais:

Formatos disponíveis

DETERMINATION OF TENSILE PROPERTIES

Industrial Technology Institute

TEST CODE : ML

Materials laboratory

Revision No : Issue Date : 2017.

Method Manual

1.0 SCOPE

1.1 This test method determines the tensile properties of u PVC pipes.

1.2 This method is specified according to the methods given in SLS 147 :2013 ,SLS ISO

6259-1:2013 and SLS ISO 6259-2:2013

2.0 REFERENCE DOCUMENTS

2.1.SLS 147:2013 Specification for unplasticized Poly(Vinyl Chloride) Pipes for water supply

and for buried and above ground drainage and sewerage under pressure (Third Edition)

2.2 SLS ISO 6259-1:2013 Thermoplastics pipes -Determination of tensile properties - Part 1:

General test method

2.3. SLS ISO 6259-2:2013 Thermoplastics pipes - Determination of tensile properties-Part 2:

Pipes made of unplasticized poly(vinyl chloride) (PVC-U), chlorinated poly (vinyl chloride)

(PVC-C) and high-impact poly (vinyl chloride) (PVC-HI)

2.4. Record sheet for u PVC

3.0 INSTRUMENTS AND APPARATUS

3.1 Tensile Testing Machine

Specifications

Grips- for holding the test piece and attached to the machine so that the major axis of the test

piece coincides with the direction of pull through the centreline of the assembly by using

centering pins in the grips.The clamping system shall not cause premature fracture at the

grips.

3.2 Load indicator

3.3 Extensometer scale , suitable for determining the gauge length of the test piece at any

moment during the test.

3.4 Vernier caliper capable of reading to 0,01 mm or less and suitable for measuring

Prepared by: P.A. Aloka Karunarathne Approved by:

Page 1 of 3

DETERMINATION OF TENSILE PROPERTIES

Industrial Technology Institute

TEST CODE : ML

Materials laboratory

Revision No : Issue Date : 2017.

Method Manual

width of the test piece.

3.5 Thickness Gauge capable of reading to 0,01 mm or less

3.6 Cutting die, conforming to the relevant profile in ISO 6259-2 or ISO 6259-3, as

applicable.

3.7 Milling machine and cutter, capable of producing the test piece specified in ISO 6259-2

or ISO 6259-3, as applicable.

3.8 Oven cable of maintain temperature between 1250C and 1300C

4.0 TEST PIECES

4.1 Sampling

4.2 Dimension

Depending on the method by which they are prepared (see 4.2), the shape and dimensions of

the test pieces shall conform to table 1 and figure 1 or table 2 and figure 2, as applicable.

4.3 Preparation of test pices

4.4

5.0 TEST PROCEDURE

5.1 Sampling

5.2 Determination of Thickness

Select instrument or device for measuring wall thickness so that the accuracy of the result

is within the limits given in Table 1.

a) Maximum and minimum wall thicknesses

Move the measuring device until the positions of the maximum and/or minimum wall

thicknesses in the selected cross-sections

b) Mean wall thickness

Prepared by: P.A. Aloka Karunarathne Approved by:

Page 2 of 3

DETERMINATION OF TENSILE PROPERTIES

Industrial Technology Institute

TEST CODE : ML

Materials laboratory

Revision No : Issue Date : 2017.

Method Manual

In each selected cross-section, take at least six measurements of the wall thickness at regular

intervals around the circumference.

.

5.0. CALCULATIONS

From the values obtained, calculate the arithmetic mean value of wall thickness,

6.0. REPORT

The reporting of observed value shall be as follows.

a) Maximum and Minimum Thickness

Record the observed value(s) in accordance with the accuracy mentioned in Table 1.

b) Mean wall Thickness

Round off the measured thickness values in accordance with Table 2 and record the answer as

the mean wall thickness, em.

Wall thickness Round arithmetic mean

value to the nearest :a

10 0.05

>10 and 30 0.1

>30 0.1

a

Exactly intermediate values shall be rounded up.

Prepared by: P.A. Aloka Karunarathne Approved by:

Page 3 of 3

Você também pode gostar

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNo EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsAinda não há avaliações

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingNo EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghAinda não há avaliações

- Tensile Test UpvcDocumento3 páginasTensile Test UpvcAloka KarunarathneAinda não há avaliações

- Method Manual: Revision No: Issue Date: 2017Documento2 páginasMethod Manual: Revision No: Issue Date: 2017Aloka KarunarathneAinda não há avaliações

- P-003 Ultrasonic Testing ProcedureDocumento24 páginasP-003 Ultrasonic Testing ProcedureSaheb Yadav100% (2)

- Process Piping Guide R2Documento12 páginasProcess Piping Guide R2Edson Araga100% (1)

- Ultrasonic Testing Procedure for WeldsDocumento19 páginasUltrasonic Testing Procedure for Weldsparag wadekarAinda não há avaliações

- Ultrasonic Exam Procedure for Welds & ConnectionsDocumento17 páginasUltrasonic Exam Procedure for Welds & ConnectionsMohanadAinda não há avaliações

- QC - 08 PTCDocumento5 páginasQC - 08 PTCmahendraAinda não há avaliações

- AWSD1.1 Procedure UtDocumento19 páginasAWSD1.1 Procedure Utkevin desai50% (2)

- AWSD1 1 Procedure UtDocumento19 páginasAWSD1 1 Procedure UtGhilman0529Ainda não há avaliações

- Micro - ASTM E384-16 Standard Test Method For Microindentation Hardness of MaterialsDocumento28 páginasMicro - ASTM E384-16 Standard Test Method For Microindentation Hardness of MaterialsMOHD SAZALI BIN SALLEHAinda não há avaliações

- MT ProcedureDocumento8 páginasMT Procedureshabbir626100% (1)

- Methods of Test For Unplasticized PVC Pipes For Potable Water SuppliesDocumento20 páginasMethods of Test For Unplasticized PVC Pipes For Potable Water SuppliesPerkresht PawarAinda não há avaliações

- Expt 3 Brinell Hardness TestDocumento19 páginasExpt 3 Brinell Hardness TestDan Joshua EspinaAinda não há avaliações

- Atomic Technologies Ultrasonic Thickness ProcedureDocumento7 páginasAtomic Technologies Ultrasonic Thickness Procedurerajeshh294Ainda não há avaliações

- UT Procedure Rev.0Documento32 páginasUT Procedure Rev.0Goutam Kumar Deb100% (2)

- UT PROCEDURE NewDocumento10 páginasUT PROCEDURE NewMeet Patel100% (3)

- Astm D 732 - 02 PDFDocumento4 páginasAstm D 732 - 02 PDFJimmyJohanTapiaVasquez100% (1)

- Ensaios Dos MateriaisDocumento28 páginasEnsaios Dos Materiaisjoao pauloAinda não há avaliações

- UT TEST PROCEDURE LAMINATIONSDocumento8 páginasUT TEST PROCEDURE LAMINATIONSperogami100% (1)

- Measuring Ultrasonic Velocity in Advanced Ceramics With Broadband Pulse-Echo Cross-Correlation MethodDocumento8 páginasMeasuring Ultrasonic Velocity in Advanced Ceramics With Broadband Pulse-Echo Cross-Correlation Methodalejandro.morales.mAinda não há avaliações

- Procedure For UT TestingDocumento13 páginasProcedure For UT TestingKarrar TalibAinda não há avaliações

- Woven Sound Acoustic Ceiling-BS476 Test ReportDocumento7 páginasWoven Sound Acoustic Ceiling-BS476 Test ReportjrvaughnAinda não há avaliações

- MTRD Report on Foot Bridge TestingDocumento32 páginasMTRD Report on Foot Bridge TestingSimon Gikonyo100% (1)

- Proc SopDocumento90 páginasProc SopJohn Dolan100% (1)

- Ultrasonic Testing Procedure for Steel Weld InspectionDocumento24 páginasUltrasonic Testing Procedure for Steel Weld Inspectionbalakumar rajaram100% (1)

- FAT Report FOCDocumento19 páginasFAT Report FOCmahboob alamAinda não há avaliações

- PO 04-091 UT (En) R00 (ISO11666 - TDW)Documento17 páginasPO 04-091 UT (En) R00 (ISO11666 - TDW)Paolo AmaniAinda não há avaliações

- PTC Ar UtDocumento31 páginasPTC Ar UtSang Nguyen QuangAinda não há avaliações

- Ut6mm PDFDocumento16 páginasUt6mm PDFvrkots100% (2)

- SMC MFL ProcedureDocumento7 páginasSMC MFL ProcedureKuppan Srinivasan100% (2)

- PAUT Procedure for Butt Weld JointsDocumento22 páginasPAUT Procedure for Butt Weld Jointsrupam100% (5)

- Hardness TestDocumento20 páginasHardness TestJake Tee Hon YiAinda não há avaliações

- The Estimation of Uncertainties in Hardness Measurements - GABAUERDocumento18 páginasThe Estimation of Uncertainties in Hardness Measurements - GABAUERSuta VijayaAinda não há avaliações

- C 886 - 98 - QZG4NGDocumento2 páginasC 886 - 98 - QZG4NGneophymenAinda não há avaliações

- Astm C-743Documento4 páginasAstm C-743IyaadanAinda não há avaliações

- Astm B 244 2009Documento4 páginasAstm B 244 2009egemetsatisAinda não há avaliações

- Examining Unclad and Metal-Clad MaterialsDocumento1 páginaExamining Unclad and Metal-Clad MaterialsApinan NamkanisornAinda não há avaliações

- Ut ProcedureDocumento12 páginasUt ProcedurerohithAinda não há avaliações

- BMMP 3523 MIG Lab 1 (G1)Documento10 páginasBMMP 3523 MIG Lab 1 (G1)Zuly AidaAinda não há avaliações

- ASTM B499-09 (Coating Thickness Test)Documento5 páginasASTM B499-09 (Coating Thickness Test)bishoyAinda não há avaliações

- Procedure For ULTRASONIC THICKNESSDocumento4 páginasProcedure For ULTRASONIC THICKNESSKarrar TalibAinda não há avaliações

- Porphory Stone Testing For KOMDocumento11 páginasPorphory Stone Testing For KOMgouseyaAinda não há avaliações

- Safss 01 02aDocumento12 páginasSafss 01 02aJasminka Vilotijevic BozinovicAinda não há avaliações

- QA-NDT-12 ET DNV Classification Note 7Documento13 páginasQA-NDT-12 ET DNV Classification Note 7Colin-James Lowe100% (1)

- D1474Documento5 páginasD1474hdanyealAinda não há avaliações

- Microindentation Hardness of Materials: Standard Test Method ForDocumento28 páginasMicroindentation Hardness of Materials: Standard Test Method ForSarvesh MishraAinda não há avaliações

- Ut Procedure AwsDocumento23 páginasUt Procedure AwsKrishna Vacha80% (10)

- BMT LAB NEW Final111111 PDFDocumento85 páginasBMT LAB NEW Final111111 PDFmohanAinda não há avaliações

- PAUT Procedure - MRU Adsorber PCI Rev. 0 (Thickness 83-88 MM)Documento0 páginaPAUT Procedure - MRU Adsorber PCI Rev. 0 (Thickness 83-88 MM)bonnie_fajrie100% (1)

- Procedure For Hardness TestingDocumento8 páginasProcedure For Hardness TestingVinayaga MoorthiAinda não há avaliações

- Astm C886Documento2 páginasAstm C886정호철Ainda não há avaliações

- TWI-UT-Forgings Procedure For Level 3Documento9 páginasTWI-UT-Forgings Procedure For Level 3willypumphandle_5309100% (1)

- Ansaldo NDT Specifications 22GRKW v1 0Documento117 páginasAnsaldo NDT Specifications 22GRKW v1 0pvssrh9929Ainda não há avaliações

- Aalco Datasheet Al Test CertificatesDocumento7 páginasAalco Datasheet Al Test CertificatesPJOE81Ainda não há avaliações

- The Determination of Uncertainties in Plane Strain Fracture Toughness (K) TestingDocumento23 páginasThe Determination of Uncertainties in Plane Strain Fracture Toughness (K) TestingAnkur gaurAinda não há avaliações

- MTR - 830208 - Cui L 20 GR 3.5M - 10047403 - 000 - 00Documento6 páginasMTR - 830208 - Cui L 20 GR 3.5M - 10047403 - 000 - 00Brendan StackAinda não há avaliações

- Astm D2583-95Documento4 páginasAstm D2583-95Resanto25Ainda não há avaliações

- Design and Implementation of Portable Impedance AnalyzersNo EverandDesign and Implementation of Portable Impedance AnalyzersAinda não há avaliações

- Thickness Measurement of Flexible Packaging MaterialDocumento4 páginasThickness Measurement of Flexible Packaging MaterialAloka KarunarathneAinda não há avaliações

- D 2732 - 03 PDFDocumento5 páginasD 2732 - 03 PDFItzel EscobarAinda não há avaliações

- Densyl Tape: Composition ApplicationDocumento1 páginaDensyl Tape: Composition ApplicationAloka KarunarathneAinda não há avaliações

- Denso PVC Self-Adhesive Tape 200: Composition ApplicationDocumento1 páginaDenso PVC Self-Adhesive Tape 200: Composition ApplicationAloka KarunarathneAinda não há avaliações

- ASTM D 5630-01, Standard Test Method For Ash Content in Plastics PDFDocumento5 páginasASTM D 5630-01, Standard Test Method For Ash Content in Plastics PDFJose Cepeda0% (2)

- Denso Paste: Composition Surface PreparationDocumento1 páginaDenso Paste: Composition Surface PreparationAloka KarunarathneAinda não há avaliações

- Astm D792 PDFDocumento5 páginasAstm D792 PDFHector Hidalgo100% (1)

- En 71-1 2011 PDFDocumento128 páginasEn 71-1 2011 PDFroures76Ainda não há avaliações

- BSI Standards Publication: Safety of ToysDocumento62 páginasBSI Standards Publication: Safety of ToysAloka KarunarathneAinda não há avaliações

- Draft Uganda Standard: Standard Test Method For Volatile Content of CoatingsDocumento11 páginasDraft Uganda Standard: Standard Test Method For Volatile Content of CoatingsAloka KarunarathneAinda não há avaliações

- Densyl Mastic: Composition PrimerDocumento2 páginasDensyl Mastic: Composition PrimerAloka KarunarathneAinda não há avaliações

- Denso Paste: Composition Surface PreparationDocumento1 páginaDenso Paste: Composition Surface PreparationAloka KarunarathneAinda não há avaliações

- Astm D792 PDFDocumento5 páginasAstm D792 PDFHector Hidalgo100% (1)

- Denso Paste: Composition Surface PreparationDocumento1 páginaDenso Paste: Composition Surface PreparationAloka KarunarathneAinda não há avaliações

- Astm D43 2014Documento7 páginasAstm D43 2014Engineering TasblockAinda não há avaliações

- Iso 6721 10 2015Documento11 páginasIso 6721 10 2015Aloka KarunarathneAinda não há avaliações

- Physical and Chemical Properties of Industry Reference Materials (IRM)Documento4 páginasPhysical and Chemical Properties of Industry Reference Materials (IRM)Aloka KarunarathneAinda não há avaliações

- Astm D792 PDFDocumento5 páginasAstm D792 PDFHector Hidalgo100% (1)

- Rubber Compounding Materials-Determination of Particle Size Distribution of Recycled Vulcanizate Particulate RubberDocumento4 páginasRubber Compounding Materials-Determination of Particle Size Distribution of Recycled Vulcanizate Particulate RubberAloka KarunarathneAinda não há avaliações

- ASTM D882 - 10 Standard Test Method For Tensile Properties of Thin Plastic SheetingDocumento10 páginasASTM D882 - 10 Standard Test Method For Tensile Properties of Thin Plastic SheetingCarlotta C.Ainda não há avaliações

- Fire Service Manual - Volume 1 - Fire Service Technology Equipment and Media - Firefighting Foam - TechnicalDocumento52 páginasFire Service Manual - Volume 1 - Fire Service Technology Equipment and Media - Firefighting Foam - TechnicalAloka KarunarathneAinda não há avaliações

- Package Yield of Plastic Film: Standard Test Method ForDocumento3 páginasPackage Yield of Plastic Film: Standard Test Method ForDavid PachonAinda não há avaliações

- Is 3087Documento18 páginasIs 3087Dhruv GuptaAinda não há avaliações

- BS en 71-2-2011+a1-2014Documento26 páginasBS en 71-2-2011+a1-2014Aloka KarunarathneAinda não há avaliações

- Is 2645 2003 PDFDocumento16 páginasIs 2645 2003 PDFlittle gloryAinda não há avaliações

- BS 476 Part 6 PDFDocumento22 páginasBS 476 Part 6 PDFAloka KarunarathneAinda não há avaliações

- BS en 71-2-2011+a1-2014Documento26 páginasBS en 71-2-2011+a1-2014Aloka KarunarathneAinda não há avaliações

- Astm D 6980Documento5 páginasAstm D 6980Samuel Gaytan Ramirez100% (5)

- BS 476 Part 6 PDFDocumento22 páginasBS 476 Part 6 PDFAloka KarunarathneAinda não há avaliações

- Fire Test Methods: Astm Nfpa UL ISO IEC Astm E05Documento13 páginasFire Test Methods: Astm Nfpa UL ISO IEC Astm E05Aloka KarunarathneAinda não há avaliações

- Usa Easa 145Documento31 páginasUsa Easa 145Surya VenkatAinda não há avaliações

- Chapter 3: Elements of Demand and SupplyDocumento19 páginasChapter 3: Elements of Demand and SupplySerrano EUAinda não há avaliações

- Photoshop Tools and Toolbar OverviewDocumento11 páginasPhotoshop Tools and Toolbar OverviewMcheaven NojramAinda não há avaliações

- Ice Cream Cost Benefit AnalysisDocumento12 páginasIce Cream Cost Benefit AnalysischarlotteAinda não há avaliações

- Expert Business Analyst Darryl Cropper Seeks New OpportunityDocumento8 páginasExpert Business Analyst Darryl Cropper Seeks New OpportunityRajan GuptaAinda não há avaliações

- Variable Displacement Closed Circuit: Model 70160 Model 70360Documento56 páginasVariable Displacement Closed Circuit: Model 70160 Model 70360michael bossa alisteAinda não há avaliações

- Chill - Lease NotesDocumento19 páginasChill - Lease Notesbellinabarrow100% (4)

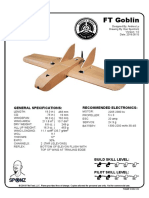

- FT Goblin Full SizeDocumento7 páginasFT Goblin Full SizeDeakon Frost100% (1)

- Conplast SP430 0407Documento4 páginasConplast SP430 0407Harz IndAinda não há avaliações

- Haryana Retial GarmentsDocumento8 páginasHaryana Retial Garmentssudesh.samastAinda não há avaliações

- Portable dual-input thermometer with RS232 connectivityDocumento2 páginasPortable dual-input thermometer with RS232 connectivityTaha OpedAinda não há avaliações

- Analytical DataDocumento176 páginasAnalytical DataAsep KusnaliAinda não há avaliações

- SyllabusDocumento4 páginasSyllabusapi-105955784Ainda não há avaliações

- Assignment-2: MCA204 Financial Accounting and ManagementDocumento6 páginasAssignment-2: MCA204 Financial Accounting and ManagementrashAinda não há avaliações

- MATH2070 Computer Project: Organise Porject FoldDocumento4 páginasMATH2070 Computer Project: Organise Porject FoldAbdul Muqsait KenyeAinda não há avaliações

- BlueDocumento18 páginasBluekarishma nairAinda não há avaliações

- Mba Assignment SampleDocumento5 páginasMba Assignment Sampleabdallah abdAinda não há avaliações

- Project The Ant Ranch Ponzi Scheme JDDocumento7 páginasProject The Ant Ranch Ponzi Scheme JDmorraz360Ainda não há avaliações

- Information Pack For Indonesian Candidate 23.06.2023Documento6 páginasInformation Pack For Indonesian Candidate 23.06.2023Serevinna DewitaAinda não há avaliações

- Khadi Natural Company ProfileDocumento18 páginasKhadi Natural Company ProfileKleiton FontesAinda não há avaliações

- Pig PDFDocumento74 páginasPig PDFNasron NasirAinda não há avaliações

- Basic Electrical Design of A PLC Panel (Wiring Diagrams) - EEPDocumento6 páginasBasic Electrical Design of A PLC Panel (Wiring Diagrams) - EEPRobert GalarzaAinda não há avaliações

- Legal Techniques (2nd Set)Documento152 páginasLegal Techniques (2nd Set)Karl Marxcuz ReyesAinda não há avaliações

- Internship Report Recruitment & Performance Appraisal of Rancon Motorbikes LTD, Suzuki Bangladesh BUS 400Documento59 páginasInternship Report Recruitment & Performance Appraisal of Rancon Motorbikes LTD, Suzuki Bangladesh BUS 400Mohammad Shafaet JamilAinda não há avaliações

- Instrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1ZDocumento24 páginasInstrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1Zmicmarley2012Ainda não há avaliações

- AHP for Car SelectionDocumento41 páginasAHP for Car SelectionNguyên BùiAinda não há avaliações

- Self-Assessment On Accountability: I. QuestionsDocumento2 páginasSelf-Assessment On Accountability: I. QuestionsAjit Kumar SahuAinda não há avaliações

- Debentures Issued Are SecuritiesDocumento8 páginasDebentures Issued Are Securitiesarthimalla priyankaAinda não há avaliações

- Binaural Recording Technology: A Historical Review and Possible Future DevelopmentsDocumento22 páginasBinaural Recording Technology: A Historical Review and Possible Future DevelopmentsNery BorgesAinda não há avaliações

- Database Chapter 11 MCQs and True/FalseDocumento2 páginasDatabase Chapter 11 MCQs and True/FalseGauravAinda não há avaliações