Escolar Documentos

Profissional Documentos

Cultura Documentos

SPEC For Chilled Water Pipework and Fittings

Enviado por

onspsnons0 notas0% acharam este documento útil (0 voto)

222 visualizações4 páginasWWW

Título original

SPEC for Chilled Water Pipework and Fittings

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoWWW

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

222 visualizações4 páginasSPEC For Chilled Water Pipework and Fittings

Enviado por

onspsnonsWWW

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 4

CHILLED WATER PIPEWORK AND FITTINGS

18.1.1 General

a) The Contractor shall be responsible for the supply and

installation of all chilled water and condensate drainage

pipe work as indicated on the Drawings and detailed in this

Specification.

b) The Contractor's attention is also drawn to the relevant

clauses in the General Section of this Specification.

c) All chilled water pipe work shall be standard black medium

weight quality seamless mild steel tube to BS 3600:1997

together with its cross references.

d) All condensate pipe work shall be as materials specified for

hot and cold water services and shall incorporate a water

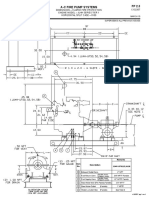

seal on the outlet from each unit. Refer to Sketch

AIRCOND/039 for depth of seal calculation.

e) Pipe work connections to each item of plant shall be

installed in such a manner as to allow removal of the item

without dismantling the pipe work, by means of flanges or

unions. Unions shall be used on pipe work up to and

including 40mm diameter and flanges shall be used on pipe

work 50mm diameter and above, unless specified

otherwise on the Drawings.

18.1.2 Provision for Expansion

a) Adequate provision shall be made for expansion and

contraction of the pipe work.

b) Provision shall be made to take up expansion by means of

diversions in the pipe runs and branches shall be taken-of

in a manner to allow expansion to take place without

unduly stressing the joints or tubulars.

c) Special attention shall be given to pipe work crossing

building expansion joints. In these cases, purpose made

flexible sections, shall be installed either side or across the

building movement joint. They shall be supplied and

installed in complete accordance with the manufacturer's

recommendations for the particular application and shall be

approved by the Engineer, prior to order for the equipment

being placed.

d) Supports shall be designed to allow correct expansion of

the pipe work and where necessary, spring loaded supports

shall be provided to accommodate expansion in vertical

pipeline.

e) The pipe work and hangers shall be arranged so that no

undue strain is placed upon any component due to

expansion and contraction of the pipe work.

18.1.3 Air Vents

a) At all high points or elsewhere as directed by the Engineer,

an air bottle shall be fitted with an automatic air eliminator,

as manufactured by Charles Winn, 70 Warwick Street,

Birmingham B12 OWC telex U.K. 338100, type 'B', with lock

shield shut-of valve. The discharge connection from the

vent valve shall be neatly run in copper tube to discharge

in a convenient position over the nearest gully or other

approved location.

b) The bottle shall be of the same bore as the pipe to which it

is fitted, but not more than 50mm and not less than

150mm high.

18.1.4 Drains

a) Emptying cocks shall be provided at all low points and on

the 'dead' side of all isolating valves to facilitate emptying

down. These valves shall be gunmetal draining types, with

lock shield cover and outlet serrated for hose connection.

The size shall be determined from the adjacent system up

to a maximum of 65mm.

b) All low points of the system shall be fitted with drain valves

to permit the complete drainage of the system. Bottoms of

all risers shall have dirt pockets the size of the riser and at

least be 300mm long complete with a drain level.

18.1.5 Valves

Isolating valves shall be fitted on the distribution mains as

indicated on the Drawings or noted in the Specification and

regulating valves shall be provided for permanently proportioning

the flow of water to each sub-circuit.

18.1.6 Strainers

a) Approved strainers shall be fitted where indicated on the

Drawings. All strainers shall be suitable for pressure of the

system concerned and are to be inspected and pressure

tested at works.

b) All strainers shall be of the 'Y' type, Class 150 and shall be

bronze, screwed or flanged, as applicable, upto 50mm

diameter and cast iron flanged 65mm and over.

c) All strainers shall be cast iron or bronze bodied of ample

strength for the pressure to which they shall be subjected

and with suitable flanges or tapings to connect with the

piping they serve. Strainer basket screens shall be

stainless steel and shall be ample strength to prevent

collapsing of the basket under shock loading.

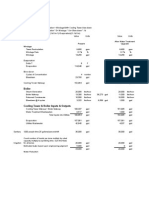

Perforations shall be in accordance with the following table:

Pipe Size Perforation No. of

Perforations

Size per

mm2

Up to 32mm pipe 0.4 mm 1.50

40mm to 100mm pipe 0.8 mm 0.65

18.1.7 Underground Chilled Water Pipe work

a) All underground chilled water lines shall be pre-insulated

steel as follows:

i) Steel pipe shall be manufactured in accordance with

BS EN 253:1995 and BS 489:1999.

ii) Outer casing shall be of hard polyurethane H.D.P.E.

iii) Insulation shall be of rigid polyurethane foam with

average density of 80-100Kg/m3.

b) All pipes and fittings shall be as manufactured by I.C.

Moeller, 191 Treldevej, DK 7000 Frederica, Denmark or

equal and approved.

c) All pipe work shall be installed, handled and stored strictly

in accordance with Code of Practice BS 7572:1992 and the

suppliers' written instructions. Copies of these instructions

shall be kept on site at all times.

d) For details of trench bedding backfill see Drainage Section

of this Specification.

e) When welding, Alu-shields shall be fitted on the pipe ends

to avoid flame damage to the polyurethane foam.

Você também pode gostar

- Adequacy of Materials For Civil WorksDocumento25 páginasAdequacy of Materials For Civil Workshari vAinda não há avaliações

- Air Distribution Basics and Duct DesignDocumento46 páginasAir Distribution Basics and Duct DesignVali GheorghisorAinda não há avaliações

- Hvac Duct Air Leakage 9 12 19Documento7 páginasHvac Duct Air Leakage 9 12 19Marinos GounaridisAinda não há avaliações

- HVAC Ductwork SpecificationDocumento4 páginasHVAC Ductwork SpecificationhvacwallyAinda não há avaliações

- Venturi Scrubber Unit. Operator's Manual (Ecom) (Techne 02-2007) (41s) PDFDocumento41 páginasVenturi Scrubber Unit. Operator's Manual (Ecom) (Techne 02-2007) (41s) PDFR_M_M_Ainda não há avaliações

- Design Building WoodWorks Case StudyDocumento12 páginasDesign Building WoodWorks Case StudyRT1234Ainda não há avaliações

- Bor11999 QLD Manual Bk12Documento58 páginasBor11999 QLD Manual Bk12Vinh DuongAinda não há avaliações

- Nfpa 13 Chapter 1Documento34 páginasNfpa 13 Chapter 1hmayordomo100% (1)

- Ahu 01 (STD)Documento5 páginasAhu 01 (STD)onspsnonsAinda não há avaliações

- Piping Design, Layout and Stress AnalysisDocumento2 páginasPiping Design, Layout and Stress AnalysisSharun SureshAinda não há avaliações

- PartitionDocumento2 páginasPartitionSyed IhyaAinda não há avaliações

- Chapter 8 Steam PipingDocumento14 páginasChapter 8 Steam PipingChen WsAinda não há avaliações

- Detailed Specification of PlumbingDocumento7 páginasDetailed Specification of PlumbingNava PavanAinda não há avaliações

- How To Install and Erect TrunkingDocumento13 páginasHow To Install and Erect TrunkingDaniel Madulu CharlesAinda não há avaliações

- Technical Specifications For Fire Suppression System PipesDocumento14 páginasTechnical Specifications For Fire Suppression System PipesHarikrishnaAinda não há avaliações

- Basic Engineering SpecificationDocumento16 páginasBasic Engineering SpecificationOvaisAinda não há avaliações

- PLUMBIM GB-High Definition PDFDocumento74 páginasPLUMBIM GB-High Definition PDFMARIA DEL VALLE rodriguez leonAinda não há avaliações

- Pipe Wall Thickness (ASME B31.3)Documento12 páginasPipe Wall Thickness (ASME B31.3)Rachmad HidayatAinda não há avaliações

- Vibration in Pumps PDFDocumento5 páginasVibration in Pumps PDFonspsnonsAinda não há avaliações

- Section 3.5 Fume Cupboard SpecDocumento14 páginasSection 3.5 Fume Cupboard SpecBiggie ColdAngelAinda não há avaliações

- Testing Precommissioning & Commissioning of FCUsDocumento7 páginasTesting Precommissioning & Commissioning of FCUsFinito TheEndAinda não há avaliações

- 00 BLANK - Hot and Cold Water LU Calculation SheetDocumento17 páginas00 BLANK - Hot and Cold Water LU Calculation SheetmaxmorekAinda não há avaliações

- Selecting Laboratory Exhaust SystemsDocumento3 páginasSelecting Laboratory Exhaust SystemsAnonymous 1zdRSWskhgAinda não há avaliações

- Project Standard Specification: Split-System Air-Conditioning Units 15738 - Page 1/6Documento6 páginasProject Standard Specification: Split-System Air-Conditioning Units 15738 - Page 1/6adel rihanaAinda não há avaliações

- Architectural Building MaterialsDocumento14 páginasArchitectural Building MaterialsGio PadillaAinda não há avaliações

- Pipe Stress and Deflection AppDocumento2 páginasPipe Stress and Deflection AppFahmi AliAinda não há avaliações

- Deluge Sprinkler SystemsDocumento3 páginasDeluge Sprinkler Systemsfalconcrest320% (1)

- Ngineering ATA: Temperature & Altitude Effects On FansDocumento3 páginasNgineering ATA: Temperature & Altitude Effects On FansMohamed TahounAinda não há avaliações

- Flushing and Cleanning of Fire Fighting Piping SystemsDocumento6 páginasFlushing and Cleanning of Fire Fighting Piping Systemsbani alsharifAinda não há avaliações

- Plaster and Render - Autonopedia PDFDocumento12 páginasPlaster and Render - Autonopedia PDFIgnacio Luis Reig MataixAinda não há avaliações

- Pressure Surges and Air Valve Specification PDFDocumento22 páginasPressure Surges and Air Valve Specification PDFTONAinda não há avaliações

- HT Tank Insulation SystemsDocumento2 páginasHT Tank Insulation SystemssabinAinda não há avaliações

- Sample Mechanical Basis of Design For UW - Chiller SystemsDocumento4 páginasSample Mechanical Basis of Design For UW - Chiller SystemsdaveleyconsAinda não há avaliações

- Standard Dimension Ratio (SDR) : HDPE Pressure Pipes According To EN 12201, EN 13244 and DIN 8074/75Documento1 páginaStandard Dimension Ratio (SDR) : HDPE Pressure Pipes According To EN 12201, EN 13244 and DIN 8074/75Arunprasad MurugesanAinda não há avaliações

- 0983 03 Method Statement For Installation Testing of Fire Fighting PipesDocumento3 páginas0983 03 Method Statement For Installation Testing of Fire Fighting PipesAnkit KumarAinda não há avaliações

- Cleaning Balls PDFDocumento8 páginasCleaning Balls PDFAlexandruNicolaAinda não há avaliações

- Raw Water System - Flushing Procedure 1Documento4 páginasRaw Water System - Flushing Procedure 1AdelAinda não há avaliações

- BOSS™ Pressurisation Units and Expansion Vessels PDFDocumento16 páginasBOSS™ Pressurisation Units and Expansion Vessels PDFRIFASAinda não há avaliações

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDocumento1 página200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajAinda não há avaliações

- LaMOT RD CatalogDocumento20 páginasLaMOT RD CatalogSasan Abbasi0% (1)

- Technical SpecificationDocumento12 páginasTechnical SpecificationYousuf KamalAinda não há avaliações

- Diesel Fire Pump (6x4x12F-M CW JU4H-UF54)Documento2 páginasDiesel Fire Pump (6x4x12F-M CW JU4H-UF54)ariefra100% (1)

- Saving Energy in Lab Exhaust SystemsDocumento11 páginasSaving Energy in Lab Exhaust Systemspal_stephenAinda não há avaliações

- Getting The Most Out of Your Rupture Disc: March 2009Documento4 páginasGetting The Most Out of Your Rupture Disc: March 2009madbakingAinda não há avaliações

- Scheme 1369551Documento936 páginasScheme 1369551Mihai CostacheAinda não há avaliações

- Nist TN 1887 v3202 2 PDFDocumento334 páginasNist TN 1887 v3202 2 PDFBegets BegetsAinda não há avaliações

- SE StandardDocumento51 páginasSE StandarddhairyasheelAinda não há avaliações

- AIIR For TB PDFDocumento25 páginasAIIR For TB PDFSyamz AzrinAinda não há avaliações

- Fire Alarm SpecificationsDocumento13 páginasFire Alarm SpecificationsDyeri FloresAinda não há avaliações

- Project Standard Specification: Condensers) (Integral Air-Cooled Condensers)Documento6 páginasProject Standard Specification: Condensers) (Integral Air-Cooled Condensers)adel rihanaAinda não há avaliações

- 04 - How Does Altitude Affect HVAC UnitsDocumento2 páginas04 - How Does Altitude Affect HVAC UnitsMaiccoll OlmAinda não há avaliações

- Vav Box Reheat Selection: Krueger KruegerDocumento5 páginasVav Box Reheat Selection: Krueger KruegerKia KhosraviAinda não há avaliações

- Chemicalfumehoods VUDocumento8 páginasChemicalfumehoods VUZuhair MasedAinda não há avaliações

- WRD Ot Clarifier Calculations 445211 7Documento118 páginasWRD Ot Clarifier Calculations 445211 7royal inAinda não há avaliações

- CFAST SampleDocumento112 páginasCFAST SampleReinhart85Ainda não há avaliações

- ATTMA TSL2 Issue 1 PDFDocumento32 páginasATTMA TSL2 Issue 1 PDFDenise Koh Chin HuiAinda não há avaliações

- 2a. Specs For Valves - IADocumento4 páginas2a. Specs For Valves - IAPraveen KasrottaranAinda não há avaliações

- PVC Duct DesignDocumento10 páginasPVC Duct DesigncitramuaraAinda não há avaliações

- High-Rise Fan - Coil - EngineerDocumento15 páginasHigh-Rise Fan - Coil - EngineerMIN GUIAinda não há avaliações

- NR-310304 - Dynamics of MachineryDocumento8 páginasNR-310304 - Dynamics of MachinerySrinivasa Rao GAinda não há avaliações

- Deluge Valve ADocumento14 páginasDeluge Valve APatel MehulkumarAinda não há avaliações

- Sample Bid SpecificationDocumento5 páginasSample Bid SpecificationChesterMercadoAinda não há avaliações

- Pipeline Inspection: Pipe RackDocumento4 páginasPipeline Inspection: Pipe RackAnushi DahariaAinda não há avaliações

- DESCRIPTIONS Garbage ChuteDocumento12 páginasDESCRIPTIONS Garbage ChuteYasser Fathy AlyAinda não há avaliações

- Combined Sprinkler and Standpipe AssemblyDocumento1 páginaCombined Sprinkler and Standpipe Assemblydesign sseAinda não há avaliações

- Nonmetal Ducts - Guide Specification - Updated 6-2019Documento17 páginasNonmetal Ducts - Guide Specification - Updated 6-2019abdullah amanullahAinda não há avaliações

- AHU CHW Coil ConnectionDocumento1 páginaAHU CHW Coil ConnectionMULTIKARTHI07100% (1)

- PP and FRPDocumento3 páginasPP and FRPAnonymous r3MoX2ZMTAinda não há avaliações

- Technical SpecificationsDocumento6 páginasTechnical Specificationspradeep reddyAinda não há avaliações

- Plumbing SpecsDocumento15 páginasPlumbing SpecssakeedfaheedAinda não há avaliações

- TSS Building MethodDocumento7 páginasTSS Building MethodAnubhav Hem Kumar JainAinda não há avaliações

- Kohinoor Square ProjectDocumento12 páginasKohinoor Square ProjectAnonymous zIYeDYU7zoAinda não há avaliações

- Basics of Refrigeration CycleDocumento2 páginasBasics of Refrigeration CyclePradeep SukumaranAinda não há avaliações

- 0014-Cpr-001 Concept Phase Report 170409bDocumento15 páginas0014-Cpr-001 Concept Phase Report 170409bonspsnonsAinda não há avaliações

- Ashraed2830120060711Documento6 páginasAshraed2830120060711kabardeyAinda não há avaliações

- PDO SMO Buildings - Site Visit ReportDocumento9 páginasPDO SMO Buildings - Site Visit ReportonspsnonsAinda não há avaliações

- Balancing and Vibration LimitsDocumento3 páginasBalancing and Vibration Limitsramamoorthy_sAinda não há avaliações

- A O Smith Residential Water Heater CatalogDocumento24 páginasA O Smith Residential Water Heater CatalogonspsnonsAinda não há avaliações

- Fire Damper Installation DetailsDocumento1 páginaFire Damper Installation DetailsonspsnonsAinda não há avaliações

- WaStop SS - PVC - PE International Version 2014Documento2 páginasWaStop SS - PVC - PE International Version 2014onspsnonsAinda não há avaliações

- CalculationsDocumento2 páginasCalculationsAliAliAinda não há avaliações

- Drainge&Waste WaterDocumento43 páginasDrainge&Waste WatermohdnazirAinda não há avaliações

- Cib HDocumento1 páginaCib HonspsnonsAinda não há avaliações

- ECO V - CatalogueDocumento5 páginasECO V - CatalogueonspsnonsAinda não há avaliações

- Cooling Tower ArticleDocumento7 páginasCooling Tower ArticleAudrey Patrick KallaAinda não há avaliações

- 3/5/8 (Soft/standard/hard Membrane) : To Be Updated With The Requirement of The Installation/purposeDocumento1 página3/5/8 (Soft/standard/hard Membrane) : To Be Updated With The Requirement of The Installation/purposeonspsnonsAinda não há avaliações

- FDS B 4 - CoilDocumento1 páginaFDS B 4 - CoilonspsnonsAinda não há avaliações

- FLM SpecificationsDocumento2 páginasFLM SpecificationsonspsnonsAinda não há avaliações

- Icw SpecDocumento3 páginasIcw SpeconspsnonsAinda não há avaliações

- Icc SpecDocumento2 páginasIcc SpeconspsnonsAinda não há avaliações

- Chiller Barrier Wall SpecificationDocumento2 páginasChiller Barrier Wall SpecificationonspsnonsAinda não há avaliações

- High TonesDocumento2 páginasHigh TonesonspsnonsAinda não há avaliações

- Commercial STL HTL Panels SpecificationDocumento4 páginasCommercial STL HTL Panels SpecificationonspsnonsAinda não há avaliações

- Barrier Wall SystemsDocumento2 páginasBarrier Wall SystemsonspsnonsAinda não há avaliações

- High Impact Hard SideDocumento2 páginasHigh Impact Hard SideonspsnonsAinda não há avaliações

- Hard Side Cloud SystemDocumento2 páginasHard Side Cloud SystemonspsnonsAinda não há avaliações

- Types of ConcreteDocumento64 páginasTypes of ConcreteAbhishek GoundAinda não há avaliações

- BUILDING UTILITIES 2 Building HVAC SystemsDocumento142 páginasBUILDING UTILITIES 2 Building HVAC Systemsjona serranoAinda não há avaliações

- Shoring Failure 384 794Documento2 páginasShoring Failure 384 794Ahmed Y. AlsahharAinda não há avaliações

- Ventiloconvector PDFDocumento2 páginasVentiloconvector PDFMihai STANAinda não há avaliações

- SdsDocumento4 páginasSdsMark Lester Brosas TorreonAinda não há avaliações

- A Report On Reinforced Cement Concrete FloorsDocumento7 páginasA Report On Reinforced Cement Concrete FloorsAshish PandeyAinda não há avaliações

- Svendsen 1967 Drained PE Joint Wall Principles of One-Stage and Two-Stage SealsDocumento4 páginasSvendsen 1967 Drained PE Joint Wall Principles of One-Stage and Two-Stage SealsJohn StraubeAinda não há avaliações

- Fisherman Village Draft Cover Book FinalDocumento43 páginasFisherman Village Draft Cover Book FinalGandham Kiran Ji67% (3)

- TankCalculator Ferro Cement TankDocumento22 páginasTankCalculator Ferro Cement TankAnonymous f5gNPeZDCAinda não há avaliações

- Bracing System Table of ContentsDocumento10 páginasBracing System Table of ContentsNyein ZawAinda não há avaliações

- Chemdrain Chemical Waste Drainage System Recommended Short Form SpecificationDocumento2 páginasChemdrain Chemical Waste Drainage System Recommended Short Form SpecificationGreg FarzettaAinda não há avaliações

- Module 1 - Single-Storey Non-Cyclonic - Test PDFDocumento16 páginasModule 1 - Single-Storey Non-Cyclonic - Test PDFSaiful IslamAinda não há avaliações

- Modern Methods of ConstructionDocumento19 páginasModern Methods of ConstructionYogesh KhanapurAinda não há avaliações

- AC Hotels by Marriott Design Standards Module 15 HVACDocumento12 páginasAC Hotels by Marriott Design Standards Module 15 HVACIan OsorioAinda não há avaliações

- DOYMA Delivery Programme PDFDocumento72 páginasDOYMA Delivery Programme PDFTEIUSANUAinda não há avaliações

- 5bd08978d8a19838e92d2dcf - Document - AR-130-T (1000Lbs) - Anchoring Structure - F-07Documento1 página5bd08978d8a19838e92d2dcf - Document - AR-130-T (1000Lbs) - Anchoring Structure - F-07olivier.bigouretAinda não há avaliações

- ABC-BI-10-00966 - DAILY RFI FORM-5 Nov22Documento1 páginaABC-BI-10-00966 - DAILY RFI FORM-5 Nov22Shahid BhattiAinda não há avaliações

- Item Description Quantity Unit Rate Amount Unit Rate Sheeting HTDocumento6 páginasItem Description Quantity Unit Rate Amount Unit Rate Sheeting HTimteaz00Ainda não há avaliações

- Engineered Wood13 PDFDocumento96 páginasEngineered Wood13 PDFartika sembiringAinda não há avaliações

- Structural DesignDocumento12 páginasStructural DesignAlexander PiniliAinda não há avaliações

- Clopay Modern Steel Literature 1Documento4 páginasClopay Modern Steel Literature 1api-281109629Ainda não há avaliações

- Chapter 16 - Structural DesignDocumento38 páginasChapter 16 - Structural DesignBud MannAinda não há avaliações

- New Directions Post Tension Ing Vol 4Documento34 páginasNew Directions Post Tension Ing Vol 4Jessie Radaza Tutor100% (1)