Escolar Documentos

Profissional Documentos

Cultura Documentos

Wel 01 B

Enviado por

Willy UioTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Wel 01 B

Enviado por

Willy UioDireitos autorais:

Formatos disponíveis

example, the ability to join metals with nonmetallic ma-

terials is the subject of much effort. As industry expands

and improves its technology, new welding processes will

play an indispensable part in progress.

Currently, five welding associations provide guidance

and standards related to the welding industry.

American National Standards Institute (ANSI)

American Petroleum Institute (API)

American Society of Mechanical Engineers (ASME)

American Welding Society (AWS)

American Bureau of Shipping (ABS)

Welding as an Occupation

A student needs to learn all phases of the trade. Welding,

reading drawings, math, and computer knowledge will se-

cure a successful career. Many qualified welders are cer-

tified by the AWS, ASME, and API. The tests are difficult

and require many hours of practice.

Because welders hold key positions in the major indus-

tries, they are important to the economic welfare of our Fig. 1-5 Welding is generally considered a nontraditional

country. Without welding, the metal industry would be occupation for women. However, it can be a very lucrative and

seriously restricted; many of the scientific feats of the past in-demand skill for those women choosing this career path. A proce-

dure is being used setting up a plasma arc gouging operation.

and the future would be impossible. As long as there are Andersen Ross/Iconica/Getty Images

metal products, welders will be needed to fabricate and

repair them.

Keep in mind that the field of welding can offer you

prestige and security. It can offer you a future of continu-

JOB T I P ous employment with steady advancement at wages that

are equal to other skilled trades and are better than aver-

Job Hunting age. It can offer you employment in practically any indus-

Looking for a job is a job! When you begin, try you choose and travel to all parts of the world. It is

make a list of what you plan to do in the next week. As- an expanding industry, and your chances for advancement

sess what kind of job you want. As you complete items on are excellent. Welders have the opportunity to participate

your list, you not only will be closer to your goal, but you

in many phases of industrial processes, thus giving them

also will be in control of the job-hunting process and will

be less stressed. the broad knowledge of the field necessary for advance-

ment to supervisory or technical positions.

Welding is gender friendly, Fig. 1-5. Thousands of

Industrial Welding Applications

women are employed throughout the industry. Many women Welding is not a simple operation. The more than 90 dif-

find the work highly satisfying and are paid well at a rate ferent welding processes are divided into three major

equivalent to that of men. types: arc, gas, and resistance welding. A number of other

Welding is done in every civilized country in the world. types such as induction, forge, thermit, flow welding, and

You may wish to work in the oil fields of the Near East or brazing are used to a somewhat lesser extent.

in our own country. You may wish to work in some jungle Resistance welding includes spot welding, seam weld-

area of South America or Africa, constructing buildings, ing, flash welding, projection welding, and other similar

power plants, pipelines, or bridges. Our many military processes that are performed on machines. These welding

installations throughout the world offer jobs for civilian areas are not the subject of this text. Because of the special-

workers. Employment opportunities for welders are plen- ized nature of the machines, operators are usually taught

tiful in all parts of the United States. on the job. They are semiskilled workers who do not need

History of Welding Chapter 1 7

Fig. 1-7 Instructor observing students practicing for a 5G position pipe

weld test. The welder is working out of the overhead position on the pipe

and getting into the vertical position. The progression of the weld is uphill.

The flux cored arc welding process is being used and is being applied in a

semiautomatic fashion. Miller Electric Mfg. Co.

Fig. 1-6 Welding in the vertical position. Miller

Electric Mfg. Co.

specific hands-on welding skills. The arc and gas welding

processes will be extensively covered later in this text.

In a sense, welders are both artists and scientists. Arc

and gas welders have almost complete control of the pro-

cess. Much of their work demands manipulative skill and

independent judgment that can be gained only through

training and a wide variety of job experience. They must

know the properties of the metals they weld; which weld

process to use; and how to plan, measure, and fabricate

their work. They must use visualization skills and be pre-

cise, logical, and able to use their heads as well as their

hands. Most welders are expected to be able to weld in the

vertical and overhead positions, Figs. 1-6 and 1-7, as well Fig. 1-8 Using a method of weld inspection known as

magnetic-particle testing in pipe fabrication. This non-destructive

as in the flat and horizontal positions.

method followed by radiograph and/or ultrasonic testing assures

Gas welders may specialize in oxyacetylene or GTAW weld soundness for critical pipe welds. Location: Piping Systems Inc.

processes. Some welders are skilled in all the processes. McGraw-Hill Education/Mark A. Dierker, photographer

You should acquire competence in shielded metal arc

SMAW, GTAW, and GMAW processes for both plates

and pipes. work is inspected, Figs. 1-8 and 1-9. Welders are required

to pass periodic qualification tests established by vari-

Qualifications and Personal Characteristics ous code authorities, insurance companies, the military,

The standards are high in welding. In doing work in and other governmental inspection agencies. Certifica-

which lives may depend on the quality of the welding tions are issued according to the kind and gauge of metal

high-rise buildings, bridges, tanks and pressure vessels and the specific welding process, technique, or procedure

of all kinds, aircraft, spacecraft, and pipelineswelders used. Some welders hold several different certifications

must be certified for their ability to do the work, and their simultaneously.

8 Chapter 1 History of Welding

Fig. 1-9 Workers using a crane to lift a cask filled with highly Fig. 1-10 A large amount of art metalwork is done with welding

radioactive fuel bundles at a Hanford, Washington, nuclear facility. processes. Leon Werdinger/Alamy Stock Photo

The construction of this type of vessel relies heavily upon welding.

U.S. Department of Energy/AP Images

The welder must perform certain basic tasks and pos-

SH OP TA L K

sess certain technical information in order to perform the

welding operation. In making a gas weld, the welder at- Medical Alert

taches the proper tip to the torch and adjusts the weld- The technology of medical heart pacemak-

ing regulators for the proper volume and pressure of the ers continues to change. Some pacemakers are less likely

gases. The welder must also regulate the flame according to be prone to interference by electromagnetic fields.

to the needs of the job. People who weld and have pacemakers are safer if there

For electric arc welding, the welder must be able to reg- are other people nearby to help if they have problems.

Waiting 10 seconds between each weld may be a good

ulate the welding machine for the proper welding current

strategy for those with pacemakers.

and select the proper electrode size and type, as well as

the right shielding gas.

Welding requires a steady hand. The welder must hold

the torch or electrode at the proper angle, a uniform dis- pressure vessels requiring 4-inch plate to the delicate

tance from the work, and move it along the line of weld at welding of silver and gold, the welds are of the highest

a uniform speed. quality and can be depended upon to meet the require-

During the welding process, the welder should use vi- ments of the job.

sualization skills to form a mental picture of how the weld The following welding occupations require a high

will be created. Although much of the work is single pass, school education:

welds made on heavy material often require a number of Welding operator

passes side by side and in layers according to the specified Welder fitter

weld procedure. Combination welder

Welders must also be able to cut metals with the Master welder

oxyacetylene cutting torch and with the various cut- Welding supervisor

ting procedures involving the plasma arc cutting ma- Welding analyst

chine. Flame cutting is often the only practical method Inspector

for cutting parts or repairing steel plate and pipe. Welding foreman

Plasma arc cutting is used to cut all types of m etals. Welding superintendent

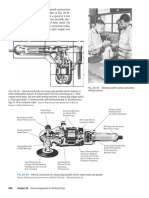

Proper use of an electric or pneumatic grinder will save Equipment sales

many hours in the welding process. Sales demonstrator

The master welder is a master craftsperson, Fig.1-10. Sales troubleshooter

Such a person is able to weld all the steels and their al- Welding instructor

loys, as well as nickel, aluminum, tantalum, titanium, Robotics welder operator

zirconium, and their alloys and claddings. From heavy Job or fabrication shop owner

History of Welding Chapter 1 9

A large number of unsafe situations must be

of concern to the welder who is conscious of the

need to work in a safe environment. Very often

accidents are caused as a result of some small, rel-

atively unimportant condition. Extremely danger-

ous hazards usually get the attention of the welder

and are, therefore, rarely a cause of accidents.

Job hazards may include fire danger, burns,

sunburn from electric arcs, noxious fumes from

materials vaporized at high temperatures, eye-

strain, welders flash, and electric shock. These

hazards can be minimized or eliminated by the

use of the proper protective clothing and safety

shoes, welding hood, face shields, goggles, respi-

ratory equipment, and adequate ventilation. When

performing jobs, welders always take precaution-

Fig. 1-11 Welders in the construction industries are called upon to ary measures for their own safety and the safety of

weld in many unusual positions. Here, a welder and a helper are making others in the area.

an attachment to a building beam in the overhead position. The shielded

metal arc welding process is being used and is being applied in the

You are encouraged to study the various safety

typical manual fashion. Note the safety gear and fall protection devices. practices and regulations presented in this text.

Vicki Silbert/PhotoEdit Safety precautions related to specific processes are

presented in the principle chapters (Chapters 16,

10, 11, 12, 18, 21, 2532). Safe welding technique and the

Certain welding occupations also require a college safe use of equipment are given in the practice chapters

education: (Chapters 710, 1317, 19, 20, 2224). Before you begin

Welding engineer (metallurgical) to practice welding, you should read Chapter32, Safety,

Welding development engineer which summarizes the safety measures described else-

Welding research engineer where and presents the precautions to be followed both in

Welding engineer the school shop and in industry.

Technical editor There are several ways of helping to secure your place

Welding professor in this fast-paced field. These methods can assist you in

Certified welding inspector (AWS/CWI) staying current with the most recent changes in technol-

Corporation executive ogy and help you network with other professionals.

Owner of welding business 1. Read trade journals, service manuals, textbooks,

Sales engineer and trade catalogs.

2. Join associations such as the American Welding

Many people in the welding occupations listed entered

Society.

the industry as welders and were able to improve their

3. Research topics on the Internet.

positions by attending evening classes at a university or

4. Trade tips with your peers.

community college.

Safety and Working Conditions

Welders work on many kinds of jobs in almost any envi- A B OU T WEL DIN G

ronment. They may do light or heavy welding, indoors or

outdoors, in spacious surroundings or cramped quarters. Welding Processes

Often they work in awkward positions in boiler shops, The welding process using elec-

shipyards, tanks, and piping systems. The work may be ex- tron beams was first developed in the 1950s by the

French Atomic Energy Commission, by J. A. Stohr.

tremely noisy (hearing protection will be necessary), and During this same time, the Russians were perfecting

welders may have to work on scaffolds high off the ground a method of solid-state joining called friction welding.

(necessitating the use of a safety harness), Fig. 1-11. On In the United States, General Motors started using an

some jobs there may be considerable lifting, tugging, and electroslag welding process.

pushing as equipment and materials are placed in position.

10 Chapter 1 History of Welding

CHAPTER 1 REVIEW

Multiple Choice b. 18901900

Choose the letter of the correct answer. c. 19301942

d. 19501965

1. When did humans learn the art of welding?

9. Using American Welding Society Standards,

(Obj.1-1)

name four popular welding processes in use

a. Early 1990s

today. (Obj. 1-2)

b. Around the birth of Christ

a. SMAW, GTAW, GMAW, ESW

c. Between 3000 and 2000 b.c.

b. MCAW, CAW, EBW, OHW, LBW, ARTW

d. Welding started between World Wars I and II

c. SSW, ROW, FLB, AAW

2. Name four metals that were used by early metal- d. GLUEW, STKW, GASW, MIGW

workers. (Obj. 1-1)

10. When was a patent issued for the GTAW process?

a. Copper, bronze, silver, gold

(Obj. 1-2)

b. Zinc, pewter, aluminum, lead

a. 1936

c. Silver, mercury, vanadium, gold

b. 1942

d. Cast iron, steel, brass, tin

c. 1948

3. Which metal was probably the first to be worked by d. 1965

early metalworkers? (Obj. 1-1)

11. When was a patent issued for the GMAW process?

a. Pewter

(Obj. 1-2)

b. Gold

a. 1936

c. Copper

b. 1942

d. Tin

c. 1948

4. When was fusion welding, as we know it, first d. 1965

developed? (Obj. 1-1)

12. What is welding? (Obj. 1-3)

a. In 1888 by a Russian

a. Hammering two pieces of metal together until

b. In 1892 by C. L. Coffin

they become one

c. In 1881 by Auguste de Meritens

b. Using rivets or screws to attach metal

d. In 1930 by Hobart & Devers

c. Bending and shaping metal

5. Electric arc welding using an electrode was devel- d. Joining together two pieces of metal by heating

oped around what period? (Obj. 1-1) to a temperature high enough to cause soften-

a. 18801900 ing or melting, with or without the applica-

b. 19301942 tion of pressure and with or without the use of

c. 17501765 filler metal

d. 19501965

13. Welding is ______ and there are many jobs avail-

6. In what country was a patent first issued for electric able for both men and women. (Obj. 1-3)

arc welding? (Obj. 1-1) a. Gender friendly

a. France b. Nonskilled

b. China c. Easy learning

c. Russia d. Filler type

d. United States

14. In electric arc welding, which of the following does

7. What invention gave the electric arc welding pro- the welder not have to regulate? (Obj. 1-4)

cess its greatest boost? (Obj. 1-1) a. Cruise control

a. Covered electrodes b. Welding current

b. Oxyacetylene gas mixture c. Electrode

c. Workable electric generating devices d. Shielding gas

d. Both a and c

15. Even with the proper equipment, which of the fol-

8. Oxyacetylene welding was developed around what lowing would be very difficult to weld? (Obj. 1-4)

period? (Obj. 1-1) a. Aluminum

a. 17201740 b. Magnesium

History of Welding Chapter 1 11

c. Stainless steel 21. Which of the following is not a trade association re-

d. All of these lated to the welding industry? (Obj. 1-9)

16. Which of the following lists classifications of weld- a. AWS

ing occupations? (Obj. 1-5) b. ASME

a. Combination welder, welder fitter, welding in- c. AUPS

spector, welding instructor, welding engineer d. API

b. Junk yard welder, wanna-be welder, art welder, 22. Establishing goals such as ______ will help secure

stick welder your achievement as a skilled welder. (Obj. 1-10)

c. Inside welder, outside welder, underwater a. Join a professional organization

welder, upside-down welder b. Nonstop classroom work

d. Flat welder, vertical welder, horizontal welder, c. Friendly equipment

overhead welder d. Trade vocation

17. Which of the following is not a welding occupation?

Review Questions

(Obj. 1-5)

a. Certified welding inspector Write the answers in your own words.

b. Pilot technician 23. Is welding a recent industrial process? Explain.

c. Instructor (Obj. 1-1)

d. Technical editor 24. Name four metals that were used by early metal-

18. Welders are required to pass periodic qualification workers. Which metal was the first to be worked?

tests established by various ______. (Obj. 1-6) (Obj. 1-1)

a. Code authorities 25. When did the manufacture of steel begin? (Obj. 1-1)

b. Training agencies 26. In what country was the patent for electric arc weld-

c. Insurance companies ing first issued? (Obj. 1-2)

d. Both a and c

27. What invention gave electric arc welding its greatest

19. If you are a competent welder, you need to know boost? (Obj. 1-2)

______ skills. (Obj. 1-7)

28. Name four important welding processes. (Obj. 1-4)

a. Drawing

b. Math 29. Is it true that industry uses MIG/MAG welding only

c. Layout skills for special applications because of its instability?

d. All of these Explain. (Obj. 1-4)

20. Job hazards can be minimized or eliminated by the 30. Name 10 occupational classifications in the welding

use of ______. (Obj. 1-8) industry. (Obj. 1-5)

a. Protective clothing 31. Name three welding occupations that require a col-

b. Face shields lege degree. (Obj. 1-5)

c. Adequate ventilation 32. Which welding process contributed most to alumi-

d. All of these num welding? (Obj. 1-10)

INTERNET ACTIVITIES

Internet Activity A

Search on the Web for books about welding at Englands Cambridge International

Science Publishing. Make a list of books that sounds interesting to you.

Internet Activity B

Using the Internet, search for safety and health guidelines for welding and write

a report on your findings. You may want to try the American Welding Societys

Web site: www.aws.org.

12 Chapter 1 History of Welding

Você também pode gostar

- Spot Welding Interview Success: An Introduction to Spot WeldingNo EverandSpot Welding Interview Success: An Introduction to Spot WeldingAinda não há avaliações

- English For Welding 1Documento188 páginasEnglish For Welding 1MOSES7 WISE100% (1)

- Research Paper On Welding CareerDocumento8 páginasResearch Paper On Welding Careerfvgh9ept100% (1)

- Welding Thesis StatementDocumento5 páginasWelding Thesis Statementhcivczwff100% (1)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsAinda não há avaliações

- Aws WJ 201203 PDFDocumento146 páginasAws WJ 201203 PDFnidhinchandranvsAinda não há avaliações

- Weld Like a Pro: Beginning to Advanced TechniquesNo EverandWeld Like a Pro: Beginning to Advanced TechniquesNota: 4.5 de 5 estrelas4.5/5 (6)

- Welding Common QuestionsDocumento2 páginasWelding Common QuestionsNell Sabas AdolfoAinda não há avaliações

- Chapter 1 - OccupationsDocumento4 páginasChapter 1 - OccupationsAnonymous dh6DITAinda não há avaliações

- Underwater Welding Research PapersDocumento5 páginasUnderwater Welding Research Papersfvfj1pqe100% (1)

- Welding Research Paper OutlineDocumento4 páginasWelding Research Paper Outlinecapz4pp5100% (1)

- Pipe Welding ProceduresDocumento257 páginasPipe Welding ProceduresKhaeril Anwar100% (1)

- 5 Ways To Increase Welder EfficiencyDocumento18 páginas5 Ways To Increase Welder EfficiencyXavier BloombergAinda não há avaliações

- Flux Cored and MIG Pipe WeldingDocumento59 páginasFlux Cored and MIG Pipe Weldingcentaury2013Ainda não há avaliações

- Welding, Soldering, and Brazing WorkersDocumento5 páginasWelding, Soldering, and Brazing Workersyared BeleteAinda não há avaliações

- Rough Draft Reasearch PaperDocumento10 páginasRough Draft Reasearch Paperapi-646141712Ainda não há avaliações

- PipeWeldingProcedures PDFDocumento257 páginasPipeWeldingProcedures PDFstudent_bl94% (17)

- Welder ResumesDocumento10 páginasWelder ResumesAbdlHameed FareedahAinda não há avaliações

- Weld Carbon Steel PipeDocumento14 páginasWeld Carbon Steel PipeAdrienne Bates100% (2)

- CastingDocumento3 páginasCastingBogdan PopescuAinda não há avaliações

- Module 1 SMAW 11 12 Q2 1Documento13 páginasModule 1 SMAW 11 12 Q2 1Marc CadalinAinda não há avaliações

- Welding Term PaperDocumento5 páginasWelding Term Paperc5rzknsg100% (1)

- The Importance of Visual Welding InspectionDocumento4 páginasThe Importance of Visual Welding Inspectionhekayat71Ainda não há avaliações

- ASM005.002 Topical Guide # 6-WeldingDocumento13 páginasASM005.002 Topical Guide # 6-WeldingArnab GoswamiAinda não há avaliações

- AWS Welding Journal May 2013Documento134 páginasAWS Welding Journal May 2013ferrero68Ainda não há avaliações

- Thesis On Welding TechnologyDocumento7 páginasThesis On Welding Technologyfjn3d3mc100% (3)

- GRADE 12 SMAW MODULE 4A 1st QuarterDocumento20 páginasGRADE 12 SMAW MODULE 4A 1st QuarterClare GarcesAinda não há avaliações

- Welders Research PaperDocumento7 páginasWelders Research Paperafeaqzhna100% (1)

- Literature Review of Arc WeldingDocumento4 páginasLiterature Review of Arc Weldingaflskdwol100% (1)

- 12 - SMAW W 3 - Essentials of WeldingDocumento10 páginas12 - SMAW W 3 - Essentials of WeldingNelPalalon100% (1)

- Welding Procedures Final OutputDocumento16 páginasWelding Procedures Final OutputJeremi BajarlaAinda não há avaliações

- A Shielded Metal Arc Welding Expert System: Knowledge EngineeringDocumento9 páginasA Shielded Metal Arc Welding Expert System: Knowledge EngineeringariefefendiAinda não há avaliações

- Shielded Metal Arc Welding: Mild Steel I (E7018)Documento41 páginasShielded Metal Arc Welding: Mild Steel I (E7018)greatsteelAinda não há avaliações

- Welding, Soldering, and Brazing WorkersDocumento10 páginasWelding, Soldering, and Brazing WorkersversleAinda não há avaliações

- Shielded Metal Arc Welding: Grade 10Documento23 páginasShielded Metal Arc Welding: Grade 10Jessel Mejia OnzaAinda não há avaliações

- Shielded Metal Arc Welding: Grade 10Documento23 páginasShielded Metal Arc Welding: Grade 10Jessel Mejia OnzaAinda não há avaliações

- Aramco Specific Evaluations For WeldingDocumento6 páginasAramco Specific Evaluations For WeldingTrived MahankaliAinda não há avaliações

- Welding Thesis PDFDocumento7 páginasWelding Thesis PDFjackiehintonwashington100% (2)

- Design of Welding Fixtures and PositinersDocumento9 páginasDesign of Welding Fixtures and PositinerstalhamiAinda não há avaliações

- Underwater WeldingDocumento4 páginasUnderwater WeldingdhmbasAinda não há avaliações

- MODULE 8 SMAW 11 12 Q2 X 1Documento29 páginasMODULE 8 SMAW 11 12 Q2 X 1Marc Cadalin100% (1)

- Literature Review WeldingDocumento6 páginasLiterature Review Weldingxjcwzfrif100% (1)

- Caparo Maruti LTD.: Project Report ON Pressing & Welding TechnologyDocumento44 páginasCaparo Maruti LTD.: Project Report ON Pressing & Welding TechnologyNitesh YadavAinda não há avaliações

- Orbital WeldingDocumento4 páginasOrbital WeldingDhruv BhatiaAinda não há avaliações

- Resistance Welding ThesisDocumento5 páginasResistance Welding Thesisdwt3zbkq100% (2)

- 054 - Welding Engineering BookletDocumento8 páginas054 - Welding Engineering BookletAnonymous 8s5BkZAjAinda não há avaliações

- Welding Report (Basic)Documento15 páginasWelding Report (Basic)kurttaufiqhakimiAinda não há avaliações

- Literature Review On Mig WeldingDocumento5 páginasLiterature Review On Mig Weldingeldcahvkg100% (1)

- 342 Unlocking The Hidden Cost of WeldingDocumento2 páginas342 Unlocking The Hidden Cost of WeldingVivek JainAinda não há avaliações

- TVL - SM 11 - w8Documento4 páginasTVL - SM 11 - w8CrisTopher L CablaidaAinda não há avaliações

- Manufacturing TechnologyDocumento26 páginasManufacturing TechnologyParas kapoorAinda não há avaliações

- Welding Procedure - 1Documento4 páginasWelding Procedure - 1Vipin GuptaAinda não há avaliações

- Introduction To Piping Engineering: Gerald H. May, P.EDocumento46 páginasIntroduction To Piping Engineering: Gerald H. May, P.EdcsamaraweeraAinda não há avaliações

- Welding Course WorksopDocumento7 páginasWelding Course Worksopiyldyzadf100% (2)

- S K Bagchi - Weld Failure in Oil & Gas IndustriesDocumento6 páginasS K Bagchi - Weld Failure in Oil & Gas IndustriesathulpcucekAinda não há avaliações

- 1.0 Title: Shield Metal Arc Welding (SMAW)Documento13 páginas1.0 Title: Shield Metal Arc Welding (SMAW)Exo NadiAinda não há avaliações

- Welding Report.Documento12 páginasWelding Report.Haikal SubriAinda não há avaliações

- 5 - PDFsam - Designing Fillet Welds For Skewed T-Jointsâ - Part 1 - The James F ...Documento1 página5 - PDFsam - Designing Fillet Welds For Skewed T-Jointsâ - Part 1 - The James F ...mechfreeAinda não há avaliações

- Joint Design, Testing, and Inspection: Chapter ObjectivesDocumento9 páginasJoint Design, Testing, and Inspection: Chapter ObjectivesWilly UioAinda não há avaliações

- Mance Qualification Tests. They Are Given To Find Out: 900 Chapter 28 Joint Design, Testing, and InspectionDocumento9 páginasMance Qualification Tests. They Are Given To Find Out: 900 Chapter 28 Joint Design, Testing, and InspectionWilly UioAinda não há avaliações

- Dual Robot Work Cell. Note The Robots Are Mounted Overhead For Easier Access To Welding JointsDocumento7 páginasDual Robot Work Cell. Note The Robots Are Mounted Overhead For Easier Access To Welding JointsWilly UioAinda não há avaliações

- Automatic and Robotic Arc Welding Equipment: Chapter ObjectivesDocumento7 páginasAutomatic and Robotic Arc Welding Equipment: Chapter ObjectivesWilly UioAinda não há avaliações

- Common Sensors and Units of Measure: Table 27-2Documento7 páginasCommon Sensors and Units of Measure: Table 27-2Willy UioAinda não há avaliações

- General Equipment For Welding Shops: Chapter ObjectivesDocumento8 páginasGeneral Equipment For Welding Shops: Chapter ObjectivesWilly UioAinda não há avaliações

- Power Punch: © Renee BohnartDocumento7 páginasPower Punch: © Renee BohnartWilly UioAinda não há avaliações

- High Energy Beams and Related Welding and Cutting Process PrinciplesDocumento8 páginasHigh Energy Beams and Related Welding and Cutting Process PrinciplesWilly UioAinda não há avaliações

- Laser Assisted Arc Welding: Shop TalkDocumento8 páginasLaser Assisted Arc Welding: Shop TalkWilly UioAinda não há avaliações

- Fig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsDocumento7 páginasFig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsWilly UioAinda não há avaliações

- Inspection and Testing: © Plumbers and Pipefitters Union, Alton, ILDocumento8 páginasInspection and Testing: © Plumbers and Pipefitters Union, Alton, ILWilly UioAinda não há avaliações

- © Plumbers and Pipefitters Union, Alton, ILDocumento8 páginas© Plumbers and Pipefitters Union, Alton, ILWilly UioAinda não há avaliações

- © Pipefitters Union, St. Louis, MO © Pipefitters Union, St. Louis, MODocumento8 páginas© Pipefitters Union, St. Louis, MO © Pipefitters Union, St. Louis, MOWilly UioAinda não há avaliações

- Complete Short Circuit CycleDocumento8 páginasComplete Short Circuit CycleWilly UioAinda não há avaliações

- Gas Metal Arc Welding Practice:: Jobs 24-J1-J15 (Pipe)Documento9 páginasGas Metal Arc Welding Practice:: Jobs 24-J1-J15 (Pipe)Willy UioAinda não há avaliações

- Table 23-9: Impact Requirements of The Weld Deposit According To Classification For Submerged Arc FluxDocumento8 páginasTable 23-9: Impact Requirements of The Weld Deposit According To Classification For Submerged Arc FluxWilly UioAinda não há avaliações

- Gas Metal Arc and Flux Cored Arc Welding Principles: Chapter ObjectivesDocumento8 páginasGas Metal Arc and Flux Cored Arc Welding Principles: Chapter ObjectivesWilly UioAinda não há avaliações

- NEW Electroweld Pricelist - APR 25 2022Documento7 páginasNEW Electroweld Pricelist - APR 25 2022ernst gencayaAinda não há avaliações

- Laser Hybrid Welding of A Lean Duplex Stainless Steel: Elin M. Westin Anna FellmanDocumento10 páginasLaser Hybrid Welding of A Lean Duplex Stainless Steel: Elin M. Westin Anna FellmanAdam Al AufaAinda não há avaliações

- ECSS Q ST 70 39C1May2015Documento72 páginasECSS Q ST 70 39C1May2015Michael FlachAinda não há avaliações

- WeldSkill 155 - 185 Operating ManualDocumento88 páginasWeldSkill 155 - 185 Operating ManualBarry ThomasAinda não há avaliações

- Weldinghuide Eng BohlerDocumento515 páginasWeldinghuide Eng BohlerJorge VasquezAinda não há avaliações

- GMAW Transfer ModesDocumento3 páginasGMAW Transfer Modestuna61Ainda não há avaliações

- Met 03 Weldability - Welding of C-MN, LA Steels - CIDocumento24 páginasMet 03 Weldability - Welding of C-MN, LA Steels - CIRaghu vamshiAinda não há avaliações

- SSM Su 5003 BDocumento84 páginasSSM Su 5003 Bresp-ectAinda não há avaliações

- TIG MIG Welding Lab ReportDocumento6 páginasTIG MIG Welding Lab ReportSaad Saleem50% (2)

- What Is Fusion Welding - TWI PDFDocumento6 páginasWhat Is Fusion Welding - TWI PDFFarid Ahmed KhwajaAinda não há avaliações

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Documento2 páginasPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldAinda não há avaliações

- Railway Internship Training Report Mechanical DepartmentDocumento29 páginasRailway Internship Training Report Mechanical DepartmentAbhay JainAinda não há avaliações

- Weld Consumable CalculatorDocumento7 páginasWeld Consumable Calculatormed chabaneAinda não há avaliações

- Engineer Guide Summary DEC 2020Documento25 páginasEngineer Guide Summary DEC 2020AMALENDU PAULAinda não há avaliações

- InTech-Welding of Aluminum Alloys PDFDocumento25 páginasInTech-Welding of Aluminum Alloys PDFCortesar ManuAinda não há avaliações

- OK Autrod 5356: Mig/Mag Wires (Gmaw) Aluminum WiresDocumento2 páginasOK Autrod 5356: Mig/Mag Wires (Gmaw) Aluminum WiresDavisTranAinda não há avaliações

- Electric Arc WeldingDocumento15 páginasElectric Arc WeldingvikneshAinda não há avaliações

- Thermo MechanicalDocumento216 páginasThermo MechanicalBabu NarayananAinda não há avaliações

- Agricultural Crops Production NC II CGDocumento28 páginasAgricultural Crops Production NC II CGRenato Nator100% (4)

- GIS 36-107 Integral Cladding Weld Overlay and Limited LooseDocumento17 páginasGIS 36-107 Integral Cladding Weld Overlay and Limited LooseMarkoJovicin100% (5)

- Bhel-2 Block ReportDocumento45 páginasBhel-2 Block ReportdeepakneedsloveAinda não há avaliações

- Welding 6TH SemDocumento15 páginasWelding 6TH SemIshan VermaAinda não há avaliações

- Process - 14 Arc Welding - MODULE 14Documento52 páginasProcess - 14 Arc Welding - MODULE 14sskiitbAinda não há avaliações

- Saf FroDocumento101 páginasSaf FrolkarolinoAinda não há avaliações

- RT Level L FINALDocumento80 páginasRT Level L FINALSaad AfzalAinda não há avaliações

- OK Autrod 19.40Documento1 páginaOK Autrod 19.40joao guilhermeAinda não há avaliações

- History of WeldingDocumento10 páginasHistory of WeldingGracie O. ChingAinda não há avaliações

- API - 510 Points To Remember - 6Documento3 páginasAPI - 510 Points To Remember - 6EswaranAinda não há avaliações

- Welding FundamentalsDocumento44 páginasWelding FundamentalsDhinasuga DhinakaranAinda não há avaliações

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneNo EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneNota: 4.5 de 5 estrelas4.5/5 (5)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNo EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNota: 4.5 de 5 estrelas4.5/5 (27)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNo EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessAinda não há avaliações

- Laws of UX: Using Psychology to Design Better Products & ServicesNo EverandLaws of UX: Using Psychology to Design Better Products & ServicesNota: 5 de 5 estrelas5/5 (9)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsAinda não há avaliações

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNo EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNota: 4.5 de 5 estrelas4.5/5 (2)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionNo EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionAinda não há avaliações

- 507 Mechanical Movements: Mechanisms and DevicesNo Everand507 Mechanical Movements: Mechanisms and DevicesNota: 4 de 5 estrelas4/5 (28)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsNo EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsNota: 4 de 5 estrelas4/5 (5)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableNo EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableAinda não há avaliações

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceNo EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceNota: 4 de 5 estrelas4/5 (19)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNo EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNota: 4 de 5 estrelas4/5 (10)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesNo EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesAinda não há avaliações

- Design for How People Think: Using Brain Science to Build Better ProductsNo EverandDesign for How People Think: Using Brain Science to Build Better ProductsNota: 4 de 5 estrelas4/5 (8)