Escolar Documentos

Profissional Documentos

Cultura Documentos

Au Modeling Gold Ore Leaching

Enviado por

Ana Luisa Garnica SalgadoDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Au Modeling Gold Ore Leaching

Enviado por

Ana Luisa Garnica SalgadoDireitos autorais:

Formatos disponíveis

Paper 8:Paper 8 10/15/09 4:26 PM Page 51

Bellec S., Hodouin D., Bazin C., Khalesi M. R. and Duchesne C. Modelling and simulation of gold ore leaching. World Gold Conference 2009, The Southern

African Institute of Mining and Metallurgy, 2009.

Modelling and simulation of gold ore leaching

S. BELLEC*, D. HODOUIN*, C. BAZIN*, M.R. KHALESI*, C. DUCHESNE

*Department of mining, metallurgical and material engineering

Department of chemical engineering

Laval University, Quebec, QC, Canada

A leaching model for gold ore that takes into account the impact of cyanide and oxygen

concentrations as well as gold surface exposure on leaching performance is developed. Cyanide

consumption is estimated by an empirical model that is a function of ore particles size distribution

as well as cyanide, copper and sulphur concentrations. The proposed model has been validated by

data from laboratory leaching tests on the Sleeping Giant gold mine ore.

Keywords: gold leaching, modelling, exposure surface.

Nomenclature R: Oxygen efficiency

AA: Anodic surface area : Ore sulphur concentration.

AC: Cathodic surface area : Surface of gold particle available for chemical

: Ore gold concentration reaction

: Ore gold concentration before cyanidation begins : Surface of partially exposed gold grains

: Cyanide concentration in solution : Surface of totally liberated gold grains

: Ore copper concentration. : Molar rate of gold dissolution per unit of gold

surface available to reaction

dg: Length of cubic gold grain sides

: Molar rate of partially exposed gold dissolution

dp: Length of cubic ore particle sides

per unit of gold surface available to reaction

: Cyanide diffusivity

: Molar rate of dissolution for gold accessible

: Oxygen diffusivity through ore porosity expressed per unit of gold

K: Constant factor used to approximate hindered surface available to reaction

transport through pores : Percentage of ore in class of average diameter dp

: Kinetic rate constant associated to copper-bearing g: Mean of gold size distribution

minerals

: Cyanide consumption per unit of time and mass of

Kinetic rate constant associated with sulphur- liquid

bearing minerals

: Molar diffusion rate of cyanide

Kinetic rate constant associated with cyanide

: Molar diffusion rate of oxygen

diffusion

: Mass dissolution rate of partially liberated gold

: Gold molecular weight

: Mass dissolution rate of totally liberated gold

: Mass of partially liberated gold

: Mass dissolution rate of gold accessible through

: Mass of totally liberated gold

ore porosity

: Mass of gold in the liquid phase

0: Thickness of the boundary layer

: Mass of gold accessible through ore porosity

1: Distance between gold surface and bulk solution

: Mass of gold cyanide added to the leaching thank

g: Standard deviation of gold size distribution

: Total mass of liquid in the leaching thank

p: Threshold distance from the ore surface above

N: Number of totally liberated gold grains which gold grains are not accessible to chemical

: Oxygen concentration attack by cyanide.

: Proportion of inaccessible gold grains : Gold density

: Proportion of totally liberated gold grains

: Proportion of gold grains accessible through ore Introduction

porosity Leaching by cyanide solution is widely used as a separation

: Proportion of gold grains accessible at the ore method to recover gold from ores. Different processes can

surface be used to perform this chemical separation. Some rely on

MODELLING AND SIMULATION OF GOLD ORE LEACHING 51

Paper 8:Paper 8 10/15/09 4:26 PM Page 52

the exposure of gold surfaces to enhance dissolution through ore porosity is related to the hindered transport of

kinetic. In this type of process, the ore is crushed and cyanide to the reaction site.

ground to expose the surface of gold grains to a chemical Gold liberation (or accessibility) has an important impact

attack by cyanide in presence of oxygen. This chemical on leaching kinetics; therefore, it is interesting to be able to

reaction produces a soluble complex of gold cyanide which characterize it. Many authors have developed mathematical

is subsequently recovered by adsorption or cementation. models for the liberation of minerals such as those proposed

Others use an approach, called heap leaching, which by Wiegel and Li 12 , King 13, 14 , Barbery 15 , Gay 16 ,

consists of spraying a cyanide solution on a roughly Stamboliadis17. Unfortunately the applicability of those

crushed ore pile. In this approach, cyanide and oxygen models for estimation of gold exposure properties is

diffuse slowly through the pores and fractures of the ore to limited, since most of them were developed for mineral

reach gold surfaces. concentrations significantly larger than those observed for

Several authors studied gold dissolution kinetics. Some gold ores and with a non-preferential breakage assumption

considered pore diffusion transport in heap leaching which is not applicable due to gold grains ductility. Because

(Prosser1, Bouffard and Dixon2) while others addressed the of such particularities, only a few studies on the liberation

leaching problem by the concept of gold surface liberation. of gold are available. Lorenzen and Deventer18 modified

In those conditions, experimental results showed a Kings14 model by adding an empirical term that accounts

reduction of leaching kinetics as the chemical reaction for the fraction of leachable gold that is not directly

advances. To model that behaviour, many authors (Brittan3, exposed to cyanide. Wen et al. 19 developed a cubic

Nicol et al. 4 , Hodouin et al. 5 , Ling et al. 6 ) proposed exposure model to predict the proportion of exposed

mathematical equations based on the evolution of leachable inclusive gold. This section proposes a simple geometric

gold concentration. When it decreases, the chemical model to characterize the proportions of free gold grain,

reactions rates slow down. Changes in the kinetic exposed inclusive gold as well as inclusive leachable gold

mechanisms are also proposed to explain the slowing down through ore fractures or porosity.

effect. The initial reaction may be governed by diffusion Based on simple geometrical assumptions for gold grains

through boundary layers if pulp agitation is not sufficiently and ore particle shape size and distribution, it is possible to

vigorous (Brittan 7 ) while it is controlled by diffusion approximate the gold surface degree of exposure and its

through ore porosity in the later stages. Habashi8 presented accessibility through ore porosity. Those assumptions are:

a gold dissolution model based on an electrochemical Ore particle shape is approximated by cube of side

mechanism as well as cyanide and oxygen diffusivities dp

through a boundary layer. Rubisov et al. 9 applied that Gold grains are approximated by cubes of side dg

diffusion model to pure gold by adding a stoichiometric Gold grain orientation is the same as the ore particle

factor representing the number of leached gold moles per orientation; therefore the cubes edges are parallel

mole of consumed oxygen. Crundwell and Godorr 10 The space distribution of gold grain centres inside

proposed a model that considers the formation of a ore particles is uniform

passivation layer of materials on the surface of gold Gold is unbreakable, therefore fragmentation is

particles as they dissolved. De Andrade Lima and intergranular

Hodouin11 went one step further by including the effect of Total liberation of gold grains occurs when at least

particle size in the kinetic model. This indirectly takes into 50% of the volume of gold is out of an ore particle

account the liberation effect on leaching behaviour. Gold grains positioned farther than a threshold

This paper proposes a kinetic model that takes into distance (p) from the ore surface are not accessible

account the fast rate of dissolution of exposed gold surfaces to chemical attack by cyanide.

and slower one of gold accessible through ore porosity. The According to those assumptions, Figure 2 shows the

reduction of leaching kinetic is explained by the different zones where gold grains centres can be positioned.

disappearance of exposed gold surfaces as the reaction The centre position influences the degree of gold

evolves. This approach first requires a geometrical model to leachability, a property related to gold surface accessibility

describe the surface liberation phenomena. This model is to reagents.

presented and explained in Section 2. Section 3 introduces

the leaching model, while Section 4 proposes an empirical

cyanide consumption model. Finally, the model is

calibrated and validated on batch leaching tests.

Gold grain surface accessibility to reagents

Depending on their degree of accessibility, gold grains have

different leaching kinetics. When gold is directly exposed

to the surrounding phase it has a fast leaching kinetic. On

the other hand, gold attacked through ore porosity, like in

heap leaching, exhibits slow dissolution kinetics. Figure 1

shows four different classes of gold, each one having a

different leaching behaviour. One can see that gold can be

totally liberated, accessible at the ore surface or through

pores. The fourth class contains inaccessible gold which

cannot be leached. The differences in leaching behaviour of

totally liberated gold and exposed gold at the ore surface is

due to the fact that the first one offers more accessible Figure 1. Classes of gold according to their degree of accessibility

surface to cyanide. The slow kinetics of gold accessible for leaching

52 WORLD GOLD CONFERENCE 2009

Paper 8:Paper 8 10/15/09 4:26 PM Page 53

Then, the overall cathodic reaction is given by:

[8]

where R is the oxygen efficiency

According to Habashis8 model, which considers that the

chemical reaction is much faster than the reagent diffusion

rate, and Ficks law of diffusion applied to a boundary

layer, the oxygen and cyanide molar diffusion rates () at

the exposed gold surface are:

[9]

Figure 2. Accessibility of gold in an ore particle

as a function of gold grain centre positions

[10]

From geometrical considerations, it is possible to obtain where A A and A C are the surface areas of anodic and

the proportion of inaccessible ( ) and totally liberated cathodic reaction, respectively D CN and are the

gold grains ( ): diffusivities of cyanide and oxygen in the pulp phase, and

0 is the thickness of the boundary layer, which is

[1] considered as dependant on impeller rotation speed.

The dissolution kinetic of exposed gold surfaces can then

be calculated as a function of the oxygen efficiency:

[2]

[11]

The proportion of gold grains accessible through ore

porosity ( ) is obtained by subtracting the unreachable Then, the rate of gold dissolution (in moles per unit of

volume from the unexposed one: time and gold surface available to the reaction) is given by:

[3] [12]

Finally, the proportion of gold grains accessible at the ore

Where the gold surface available to the reaction is given by

surface ( ) represents the non-liberated gold present in

the exposed volume of ore, and then is obtained by: (Habashi8):

[13]

[4]

Equation [12] is adapted in the following sections to the

three classes of leachable gold grains.

Gold leaching model

The dissolution model is based on the basic electrochemical Totally liberated gold grains

and diffusion mechanisms proposed by Habashi 8. It is

modified to account for possible loss of oxygen efficiency, Since gold grains are approximated by cubes of side length

as proposed by Rubisov et al.9 who used a stoichiometric dg(t) at any time of reaction, the overall surface of totally

factor representing the number of moles of leached gold per liberated gold in a batch of ore can be calculated by:

moles of oxygen consumed, assuming that oxygen is

consumed by an intermediate reaction producing peroxide. [14]

According to Habashi8, the anodic reaction is:

where N, the number of totally liberated gold grains, is

[5] obtained by:

while the cathodic reactions are:

[15]

[6]

where is the gold density.

[7] Equation [1] can be used to approximate the proportion

of totally liberated gold grains and therefore the mass of

The overall reaction mechanism assumes that 0.25 mole material attributed to that class of gold at the beginning of

of oxygen is required to dissolve one mole of gold. The the reaction ( (0)). Finally, using Equations [12], [14]

oxygen efficiency is then maximal. However, if peroxide is and [15], one can approximate the dissolution rate of totally

-

not completely used to subsequently produce OH , its liberated gold ( ) expressed in mass of leached gold per

efficiency is reduced and oxygen consumption increases. unit of time:

MODELLING AND SIMULATION OF GOLD ORE LEACHING 53

Paper 8:Paper 8 10/15/09 4:26 PM Page 54

Based on reaction stoichiometry, the molar kinetics of

[16] gold dissolution per unit of surface can then be expressed

as:

where is the molecular weight of gold.

[23]

Exposed gold at the ore surface

Finally, by considering an average accessible surface

The kinetic behaviour of gold exposed on the ore surface is

(Nd g (t) 2 ), one can characterize the behaviour of gold

similar to the one of completely liberated gold grains. The

accessible through ore porosity expressed in mass of gold

major difference between the two classes of gold, is that the

per unit of time.

accessible surface of partially liberated gold is much

smaller. The area of these surfaces follows a distribution

dependent on the position of gold grain centers in the ore [24]

particle. However, to simplify modelling equations and

simulations algorithms, this surface is approximated by:

where (mAup(0) ) is the mass of gold accessible through ore

[17] porosity at the beginning of the reaction and obtained by

Equation [3].

Figure 3 shows an accessible gold grain at the surface of

an ore particle. It points out that, at the beginning of the Cyanide consumption model

reaction, the reagents need to diffuse through the thickness

Cyanide is consumed by several minerals to form a variety

of the boundary layer and, as the reaction progresses, the

of complexes. Copper sulphides and other minerals are

distance between the bulk solution and the gold grain

highly soluble in aqueous cyanide solutions and can form a

surface increases. Considering that the dissolution of gold is

variety of complex ions with coordination numbers between

uniform on the exposed surface, it is possible to

one and four (De Andrade Lima and Hodouin11). More

approximate this distance by:

generally, sulphide minerals are large consumers of cyanide

because they form very stable complexes (Marsden and

[18] House20).

where ( (0)) is the mass of exposed gold at the ore

surface at the beginning of the reaction and obtained using

Equation [4]. The rate of dissolution for partially exposed

gold grains expressed in moles per unit of time and gold

surface area is given by:

[19]

Expressed in mass of leached gold per unit of time, it

becomes:

[20]

Gold accessible through ore porosity

To dissolve gold accessible through ore porosity, reagents Figure 3. Distance to travel by reagents to access exposed gold

particles

have to cross the boundary layer and diffuse on a certain

distance within the ore pores (p). Diffusivity coefficients

of cyanide and oxygen differ in these two zones. The

transport through ore porosity is hindered and therefore is

slower than through the boundary layer. Figure 4 shows the

process of lixiviation for the third class of gold.

By considering that both diffusivities of reagent are

proportionally reduced by a constant factor K while

travelling trough pores and that there is a uniform

consumption of gold along the grain face parallel to the

nearest particle face, it is possible to obtain the molar

diffusion rates of cyanide and oxygen.

[21]

[22] Figure 4. Distance to travel by reagents to access gold through ore

porosity

54 WORLD GOLD CONFERENCE 2009

Paper 8:Paper 8 10/15/09 4:26 PM Page 55

It is difficult to develop a rigorous cyanide consumption Batch leaching simulation equations are obtained by

model due to the impressive variety of complexes that can writing species mass balance equations. Using the kinetic

be formed with cyanide. De Andrade Lima and Hodouin11 expressions for the three classes of gold (liberated, exposed

proposed a pseudo-homogenous empirical model to and accessible through pores) in the solid phase, one

describe the cyanide consumption process. Their model obtains:

takes into account cyanide concentration and ore particle

size. This section introduces a model which takes into

[28]

account these two variables as well as the copper ( ) and

sulphur ( ) concentrations in the ore. Cyanide

consumption ( ) per unit of time and mass of liquid for

ore particles of size dp is given by: [29]

[25]

The first term roughly corresponds to the dissolution of [30]

copper-bearing minerals (mainly chalcopyrite in the studied

example), the second one to the sulphur-bearing minerals

which produces sulphur-cyanide complexes, and the third Gold mass balance in the liquid phase is therefore obtained

one to all other cyanide consumption assumed to be by:

diffusion controlled and particle size sensitive. Cyanide

consumption by copper and sulphide is also related to the [31]

extent of surface accessibility and therefore are particle size

sensitive. This is considered in the following relationships

for estimating dissolution rate constants: where (t) is the mass of gold in the liquid phase at time

t. Cyanide balance equation is obtained using the

[26] consumption model for five ore sizes (dp) (<38 m, 38

45 m, 4575 m, 75150 m and >150 m):

[32]

[27]

These equations also contain a slowing down effect that

models the reduced leaching rate related to disappearance

of easily accessible cyanicide surfaces. As this effect is

difficult to quantify, it is empirically correlated to gold

dissolution extent, where [Au]s is the ore gold concentration

and [Au 0] s is the gold concentration prevailing before

cyanidation begins. The coefficients Kc1, Kc2, Kc11, Kc22,

1, 2, 1, 2, 1, 2, 1, 2 and 3 are parameters to be

estimated from experimental data.

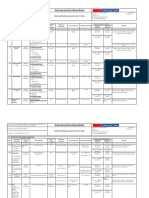

Application to batch leaching

Batch leaching tests were performed with the Sleeping

Giant gold mine ore. Twelve tests were performed on a pre-

aerated and ground ore (50% passing 38 micrometers).

Leaching was carried out at pH 11, at 50% solid, with a 600

ppm initial cyanide concentration and a saturated oxygen

concentration maintained by constant injection of O 2 .

Liquid samples were regularly collected to dose cyanide Figure 5. Leaching tests initial conditions

and gold concentrations. After each liquid sampling,

cyanide was added to the leaching tank for maintaining

cyanide concentration near its initial value. Figure 5

summarizes the twelve tests performed at four different

agitation speeds, and their initial conditions.

The equations presented in earlier sections are written for

a unique dimension of gold grain size (dg). If the gold grain

size distribution is known, these equations can be extended

to a multigrain distribution. The mineralogical properties of

the Sleeping Giant ore used for the leaching tests were

characterized and 307 gold grains were identified. Figure 6

shows the density distribution in numbers of gold grains

according to their diameter as well as an approximation of

it by a gamma distribution. This distribution coupled with

the liberation and leaching equations is used to calibrate the Figure 6. Density distribution gold grains for the Sleeping Giant

model parameters. gold mine ore

MODELLING AND SIMULATION OF GOLD ORE LEACHING 55

Paper 8:Paper 8 10/15/09 4:26 PM Page 56

Table I

Numerical values of estimated parameters

p m

g m

g m m

1

2

m

3+1

m /min

1

2

m2/min 3

m2/min

0.1200 m 1

0.1350 m 2

0.1500 m 1

0.1650 m 2

where xdp is the mass fraction of ore in class of average considered as predictions. Figures 10 and 11 respectively

diameter dp, mCN(t) is the mass of cyanide added to the compare the results predicted by the model with the

reactor at time t and m liq is the mass of liquid in the measured liquid concentrations of gold and cyanide. The

leaching tank. agitation speed of the stirrer influences the dissolution rate

of gold but not the overall gold leachability. The large

difference in final gold liquid concentration at 1600 rpm

Model calibration and other agitation speeds is due to the different initial

The model parameters were estimated using the data concentrations of gold (see Figure 5) and their respective

obtained for batch tests as well as the above simulation and proportion of inaccessible gold grains.

liberation equations. The results of only nine tests were From those results, one can see that the calibrated model

used, keeping the others for validation: the two leaching can be use to predict the leaching behaviour of a gold ore

tests at 1500 rpm as well as the 1-hour and 4-hour tests at based on its gold grain size distribution and a geometric

the three other agitation speeds. The twenty-four liberation model.

parameters characterizing the equations are estimated by a

non-linear least square regression method minimizing the Conclusions

sum of squared differences between the gold and cyanide This paper proposed a leaching model based on gold surfaces

concentrations obtained experimentally and by simulation. accessibilities and controlled by reagent diffusivities to the

In total, 164 measurements are used to approximate the reaction site. The model allows an adequate prediction of

parameters. Figure 7 summarizes the methodology used to gold dissolution and cyanide consumption for the studied ore.

calibrate the model. The model parameter estimates are The integration of the model in a steady state simulator

presented in Table I. D is the product of two parameters (R

and D O2 ). As it can be seen in the leaching kinetic

equations, those two parameters cannot be estimated

independently. g and g are respectively the mean and

standard deviation of the beta distribution used to

approximate the gold size distribution. The variation of

sigma zero with the impeller rotation speed confirms that

external diffusion is a dominant kinetic mechanism.

Figures 8 and 9 respectively compare the gold and

cyanide concentrations in the liquid phase obtained by

simulation to the experimental data for the tests at 1200,

1350, 1500 and 1650 rpm. One can see that simulated

behaviours are reasonably fitting the measured values. The

saw tooth behaviour of the cyanide consumption model is

caused by punctual addition of cyanide in the leaching

thank.

Model validation

To validate the proposed model, the three 2-hour length

cyanidation tests at 1200, 1350 and 1650 rpm are simulated

with the calibrated parameters. Since those three tests were

not used to calibrate the model, the simulations results are Figure 7. Methodology used to approximate models parameters

56 WORLD GOLD CONFERENCE 2009

Paper 8:Paper 8 10/15/09 4:26 PM Page 57

Figure 8. Comparison between simulated and experimental gold liquid concentrations

(a) Results at 1200 RPM, (b) Results at 1350 RPM

(c) Results at 1500 RPM, (d) Results at 1650 RPM

Figure 9. Comparison between simulated and experimental cyanide concentrations

(a) Results at 1200 RPM, (b) Results at 1350 RPM

(c) Results at 1500 RPM, (d) Results at 1650 RPM

MODELLING AND SIMULATION OF GOLD ORE LEACHING 57

Paper 8:Paper 8 10/15/09 4:26 PM Page 58

2. BOUFFARD, S.C. and DIXON, D.G. Evaluation of

kinetic and diffusion phenomena in cyanide leaching

of crushed and run-of-mine gold ores.

Hydrometallurgy. 2007, vol. 86, pp. 6371.

3. BRITTAN, M.I. Variable activation energy model for

leaching kinetics. International Journal of Mineral

Processing. vol. 2, pp. 321331.

4. NICOL, M.J., FLEMING, C.A., and CROMBERGE,

G. The adsorption of gold cyanide into activated

carbon: IIApplications of the kinetic model to

multistage absorption circuits. Journal of the South

African Institute of Mining and Metallurgy. 1984, vol.

2, pp. 5054.

5. HODOUIN, D., BISSONNETTE, B., and KANE, M.

An instrumented laboratory cell for gold cyanidation

modelling. Proceedings of the 22th annual meeting of

Figure 10. Comparison between predicted and experimental gold

the Canadian Mineral Processors. Ed. CIM, 1990,

liquid concentrations pp. 562574.

6. LING P., PAPANGELAKIS V.G.,

ARGYROPOULOS, S.A., and KONDOS, P.D. An

improved rate equation for cyanidation of a gold ore.

Canadian Metallurgical Quarterly. 1996, vol. 35,

pp. 225234.

7. BRITTAN M.I. Kinetic and equilibrium effects in

gold ore cyanidation. Minerals & Metallurgical

Processing. 2008, vol. 25, pp. 117122.

8. HABASHI, F. Kinetics and mechanism of gold and

silver dissolution in cyanide solution. Bulletin of the

Bureau of Mines and Geology. 1967, Bul. 59.

9. RUBISOV, D. PAPANGELAKIS, V.G., and

KONDOS, P.D. Fundamental kinetic models for gold

ore cyanide leaching. Canadian Metallurgical

Quarterly. 1996, vol. 35, pp. 353361.

10. CRUNDWELL, F.K. and GODDORR, S.A. A

mathematical model of the leaching of gold in cyanide

Figure 11. Comparison between predicted and experimental solutions. Hydrometallurgy. 1997, vol. 44,

cyanide concentrations pp. 147162.

11. DE ANDRADE LIMA, L.R.P and HODOUIN D. A

lumped kinetic model for gold ore cyanidation.

Hydrometallurgy. 2005, vol. 79, pp. 121137.

would allow studying the effectiveness of different

cyanidation flowsheets in order to minimize cyanide 12. WIEGEL, R.L. and LI, K. A random model for

consumption and maximize gold dissolution. This study will mineral liberation by size reduction. Society of

be presented in a subsequent paper. Mining Engineers. 1967, pp. 179189.

Acknowledement 13. KING, R.P. A model for the Quantitative Estimation

The authors would like to thank Mintek Lab for of Mineral Liberation by Grinding. International

mineralogical characterization of gold ore samples; Journal of Mineral Processing. 1979, vol. 6,

COREM for batch leaching tests. NSERC, COREM, pp. 207220.

IAMGOLD and AGNICO-EAGLE are also acknowledged 14. KING, R.P. The Prediction of Mineral Liberation

for their financial support and authorization to publish.

from Mineralogical Texture. XIV International

Mineral processing Congress. CIM, 1982, vol. 8,

References pp. 118.

1. PROSSER, A.P. A general model for the reaction of

several minerals and several reagents in heap leaching 15. BARBERY, G. Mineral Liberation: Measurement,

and dump leaching. Hydrometallurgy. 1986, vol. 6, Simulation and Practical Use in Mineral Processing.

pp. 7792. ditions GB. 1991.

58 WORLD GOLD CONFERENCE 2009

Paper 8:Paper 8 10/15/09 4:26 PM Page 59

16. GAY, S.L. A liberation model for comminution based leaching behaviour. International Journal of Mineral

on probability theory. Minerals Engineering. 2004, Processing. 1994, vol. 41, pp. 115.

vol. 17, pp. 525534.

19. WEN, S.B., HSIH, C.S., and KUAN, C.C. The

17. STAMBOLIADIS, E.T. The evolution of a mineral application of a mineral exposure model in a gold

liberation model by the repetition of a simple random leaching operation. International Journal of Mineral

breakage pattern. Minerals Engineering. 2008, vol. Processing. 1996, vol. 46, pp. 215230.

21, pp. 213223.

18. LORENZEN, L. and VAN DEVENTER, J.S.J. The 20. MARSDEN, J. and HOUSE, I. The chemistry of gold

interrelationship between mineral liberation and extraction. Ellis Horwood, 1992.

Steve Bellec

PhD Student, Laval University

MSc from cole Polytechnique de Montral in chemical eng.: Online data reconciliation

PhD student at Laval University in Metallurgical eng.: thesis on optimisation of gold cyanidation

process.

MODELLING AND SIMULATION OF GOLD ORE LEACHING 59

Paper 8:Paper 8 10/15/09 4:26 PM Page 60

60 WORLD GOLD CONFERENCE 2009

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1091)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Metallurgical BalancesDocumento26 páginasMetallurgical BalancesIsmaelAinda não há avaliações

- Study Notes - Aeronautical EngineeringDocumento15 páginasStudy Notes - Aeronautical EngineeringElijah MercadoAinda não há avaliações

- B. Pesic - Electrometallurgy Review PDFDocumento44 páginasB. Pesic - Electrometallurgy Review PDFAna Luisa Garnica Salgado100% (1)

- Polyurethane SDocumento13 páginasPolyurethane SWendell SanchezAinda não há avaliações

- Carbon Carbon CompositeDocumento12 páginasCarbon Carbon CompositeAnurag SinghAinda não há avaliações

- En 837-1Documento5 páginasEn 837-1Rodrigo Galdo Martínez50% (2)

- Handbook of Extractive Metallurgy III PDFDocumento288 páginasHandbook of Extractive Metallurgy III PDFPatricio Leonardo100% (1)

- Breviary Online PDFDocumento466 páginasBreviary Online PDFAna Luisa Garnica Salgado100% (1)

- PE-pH 2013 HandoutsDocumento31 páginasPE-pH 2013 HandoutsAna Luisa Garnica SalgadoAinda não há avaliações

- Chapter 1, 2, 4 Basic Television and Video Systems GrobDocumento102 páginasChapter 1, 2, 4 Basic Television and Video Systems GrobAna Luisa Garnica Salgado100% (3)

- Physical Metallurgy Principles - R.E. Reed-Hill - 2Documento468 páginasPhysical Metallurgy Principles - R.E. Reed-Hill - 2Ana Luisa Garnica Salgado0% (1)

- Text Cross Within TheDocumento475 páginasText Cross Within Theversion3Ainda não há avaliações

- Transport Phenomena in Materials Processing Poirier-GeigerDocumento336 páginasTransport Phenomena in Materials Processing Poirier-GeigerAna Luisa Garnica SalgadoAinda não há avaliações

- Example The Electorostatic Fields of A Coaxial LineDocumento10 páginasExample The Electorostatic Fields of A Coaxial LineAna Luisa Garnica Salgado100% (1)

- Transport Phenomena Data CompanionDocumento160 páginasTransport Phenomena Data CompanionAna Luisa Garnica SalgadoAinda não há avaliações

- Notes Chapter 9Documento12 páginasNotes Chapter 9Ana Luisa Garnica SalgadoAinda não há avaliações

- Ultrasonografo Simens Acuson Nx2, Nx3 EliteDocumento14 páginasUltrasonografo Simens Acuson Nx2, Nx3 EliteCarlos TrujilloAinda não há avaliações

- FLUENT Tutorial 5 - BlowerDocumento26 páginasFLUENT Tutorial 5 - BlowerKwanchai ChoicharoenAinda não há avaliações

- Nickel SulfateDocumento127 páginasNickel SulfateMayerly Giraldo AvilaAinda não há avaliações

- Shell Morlina s2 B 100Documento4 páginasShell Morlina s2 B 100PT Tunggal Karya PratamaAinda não há avaliações

- 73 Ohmrrf99Documento140 páginas73 Ohmrrf99Shajahan ShagulAinda não há avaliações

- TE - Mech - RAC - Chapter 5 - Thermodyn Propertis of Moist AirDocumento48 páginasTE - Mech - RAC - Chapter 5 - Thermodyn Propertis of Moist AirAkshay ChandoleAinda não há avaliações

- Fennis 090302Documento6 páginasFennis 090302CIVIL ENGINEERINGAinda não há avaliações

- Weather Variables Review SheetDocumento3 páginasWeather Variables Review Sheetapi-283242736Ainda não há avaliações

- Test - 6: (Science)Documento21 páginasTest - 6: (Science)ptv7105Ainda não há avaliações

- Membrane Chemicals and CleaningDocumento0 páginaMembrane Chemicals and CleaningChevronelleAinda não há avaliações

- Commercial and Public BuildingsDocumento14 páginasCommercial and Public BuildingsAnonymous S9qBDVkyAinda não há avaliações

- Reator de Alta Pressão BR - ProspDocumento16 páginasReator de Alta Pressão BR - ProspPerinto CalafangeAinda não há avaliações

- Moisture Content TestsDocumento3 páginasMoisture Content Testsghaghra bridgeAinda não há avaliações

- Lecture 2: The Chemical Basis of LifeDocumento2 páginasLecture 2: The Chemical Basis of LifeAnna ChoAinda não há avaliações

- Flushing and Disinfection 1Documento3 páginasFlushing and Disinfection 1achusanachuAinda não há avaliações

- DPP - 06 Mole Concept & Stoichiometry: Topic-Combined Mole CalculationDocumento5 páginasDPP - 06 Mole Concept & Stoichiometry: Topic-Combined Mole CalculationLakshmi BhuvanaAinda não há avaliações

- Functionalization of Indole and Pyrrole Cores Via Michael - Type AdditionsDocumento61 páginasFunctionalization of Indole and Pyrrole Cores Via Michael - Type AdditionsSilvina CancianAinda não há avaliações

- Development and Validation of Dimenhidrinat Analysis Method in Tablet With Absorbance Method and Method of Area Under Curve With Ultraviolet SpectrophotometryDocumento10 páginasDevelopment and Validation of Dimenhidrinat Analysis Method in Tablet With Absorbance Method and Method of Area Under Curve With Ultraviolet SpectrophotometryHarrizul RivaiAinda não há avaliações

- Class 12 MLM Chemistry em PDFDocumento77 páginasClass 12 MLM Chemistry em PDFkalaiarasiAinda não há avaliações

- Enantiomers PDFDocumento4 páginasEnantiomers PDFsaurabh100% (1)

- Unep Pops Pub Brochure 16newpops 201706.englishDocumento14 páginasUnep Pops Pub Brochure 16newpops 201706.englishJunnho Nick Landin RodrigezAinda não há avaliações

- Turbidity Currents and Hydraulic JumpsDocumento37 páginasTurbidity Currents and Hydraulic JumpsVenkataraju BadanapuriAinda não há avaliações

- OPI SDS 017 - v31 NPDocumento6 páginasOPI SDS 017 - v31 NPczar.eg78Ainda não há avaliações

- Btech (Agri. Engg) Mid-Examination, 2016 Fden 1202 Heat and Mass Transfer (1+1)Documento1 páginaBtech (Agri. Engg) Mid-Examination, 2016 Fden 1202 Heat and Mass Transfer (1+1)nithink100Ainda não há avaliações

- Dispex A40Documento3 páginasDispex A40elgendawyAinda não há avaliações