Escolar Documentos

Profissional Documentos

Cultura Documentos

05 DP DP Coupler

Enviado por

Isai AnguianoDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

05 DP DP Coupler

Enviado por

Isai AnguianoDireitos autorais:

Formatos disponíveis

Automation and Drives

DP/DP coupler for linking DP systems

SITRAIN

IK-PBSYS / DP/DP Coupler Page 1 03/2007

Siemens AG 2007 - Subject to change without prior notice

Contents Page

Application and operating principle of the DP/DP coupler ................................................................. 2

Data communication principle .......................................................................................................... 3

Properties of the DP/DP coupler ...................................................................................................... 4

Setting the PROFIBUS address with STEP7 ...................................................................................... 5

Configuring the DP/DP coupler ...................................................................................................... 6

DP/DP coupler configuration in network 1 ....................................................................................... 7

DP/DP coupler configuration in network 2 ....................................................................................... 8

S7 program in network 1 (DP master 1) ............................................................................................ 9

S7 program in network 2 (DP master 2) ............................................................................................ 10

Activating the "Data validity" diagnosis ............................................................................................... 11

Diagnosis of DP/DP coupler malfunctions ........................................................................................ 12

Diagnosis of DP/DP coupler malfunctions, LEDs SF and BF ......................................................... 13

Diagnosis with system function SFC13 .............................................................................................. 14

Exercise 1: Connect 2 DP networks using the DP/DP coupler .......................................................... 15

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 1 DP/DP Coupler

Automation and Drives

Application and operating principle

of the DP/DP coupler

SITRAIN

IK-PBSYS / DP/DP Coupler Page 2 03/2007

Siemens AG 2007 - Subject to change without prior notice

Field of application The DP/DP coupler is used to link two PROFIBUS DP networks together and to

transfer data from the master of one network to the master of the other network.

The maximum length of data that can be transferred is 244 bytes input data

and 244 bytes output data.

Configuration You can configure the DP/DP coupler using either STEP 7 or a configuring tool

that links in the DP/DP coupler with the help of a GSD file. You can use STEP 7

to set the length of input and output data required.

The output data of one side of the DP/DP coupler are transferred as the input

data of the other side and vice versa.

You enter these input/output data areas as slots with identifiers

in STEP 7.

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 2 DP/DP Coupler

Automation and Drives

Data communication principle

SITRAIN

IK-PBSYS / DP/DP Coupler Page 3 03/2007

Siemens AG 2007 - Subject to change without prior notice

Data communicationThe example above shows that both networks are independent of one another.

This means that you set one unique PROFIBUS address for each PROFIBUS DP

network.

In the diagram below, this is PROFIBUS address 3 in network 1 and PROFIBUS

address 50 in network 2.

In addition, it is possible to work with a different baud rate in each network.

Network 1 fills the output buffer slower than it is read by Network 2.

Network 2 therefore reads identical data several times consecutively.

This applies conversely in the direction from network 2 to network 1. The output

buffer is overwritten several times before it is read by network 1. The most

recently written data are therefore always available.

Note You must ensure that the input and output areas of both networks are mutually

coordinated.

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 3 DP/DP Coupler

Automation and Drives

Properties of the DP/DP coupler

SITRAIN

IK-PBSYS / DP/DP Coupler Page 4 03/2007

Siemens AG 2007 - Subject to change without prior notice

Properties The properties of the DP/DP coupler are:

Data transfer of up to maximum 244 bytes of input data and 244 bytes of

output data, of which 128 bytes is consistent

Up to 16 I/O areas for exchanging data; when one side fails the outputs on the

other side are held at the previous value

Support for DP V1 with complete and uniform diagnostics

PROFIBUS addresses can be set either via a switch on the DP/DP coupler or

with STEP 7 (or with another configuring tool)

Different baud rates and PROFIBUS addresses can be set on each side of the

DP/DP coupler

Electrical isolation between the two DP networks

Power supply on both sides

Slave address settings and diagnostics

The slave addresses for the two slaves are set independently of one another by

DIP switches on top of the unit. Addresses 1 to 124 can be set

Please ensure that the addresses set on the hardware correspond to the

parameters assigned during configuration.

Subsequent changes to the slave addresses are not effective until the power

has been switched off and on again.

Diagnosis The "Diagnosis" DIP switch provides an additional display of the data validity

within the I/O data area.

It has no effect on the normal diagnostic message frames of the DP/DP coupler.

You can set the "Diagnosis" DIP switch to specify whether the validity of data is

indicated by a defined bit within the configured I/O area.

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 4 DP/DP Coupler

Automation and Drives

Setting the PROFIBUS address with STEP7

DP/DP coupler

for network 1

SITRAIN

IK-PBSYS / DP/DP Coupler Page 5 03/2007

Siemens AG 2007 - Subject to change without prior notice

PROFIBUS address

In the delivery condition, the PROFIBUS address "126" is stored in the non-

volatile memory of the DP/DP coupler.

Procedure 1.Set the "ADDR" DIL switch to "ON". This means that the PROFIBUS address

will be read out of the non-volatile memory in the DP/DP coupler.

2.Switch on the 24 V power supply (or power supplies) for the DP-DP

coupler. LED(s) ON1 and/or ON2 light up.

3.Connect the PG/PC via a PG cable to the DP network or to the DP/DP coupler.

4.Open the STEP 7 hardware configuration and configure the DP/DP coupler

5.Select the configured DP/DP coupler

6.Change to PLC PROFIBUS Assign PROFIBUS address. The window

"PROFIBUS address" appears.

7.Enter the configured PROFIBUS address and confirm with "OK".

The PROFIBUS address is transferred to the DP/DP coupler and

stored in the non-volatile memory of the DP/DP coupler.

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 5 DP/DP Coupler

Automation and Drives

Configuring the DP/DP coupler

DP/DP coupler

for network 1

IO modules

SITRAIN

IK-PBSYS / DP/DP Coupler Page 6 03/2007

Siemens AG 2007 - Subject to change without prior notice

Notes

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 6 DP/DP Coupler

Automation and Drives

DP/DP coupler configuration in network 1

Address area for

data exchange with

network 2

Properties in

network 1

SITRAIN

IK-PBSYS / DP/DP Coupler Page 7 03/2007

Siemens AG 2007 - Subject to change without prior notice

Notes

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 7 DP/DP Coupler

Automation and Drives

DP/DP coupler configuration in network 2

2. Address area for data exchange

with network 2

Address area for

data exchange with

network 1

Properties in

network 2

SITRAIN

IK-PBSYS / DP/DP Coupler Page 8 03/2007

Siemens AG 2007 - Subject to change without prior notice

Notes

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 8 DP/DP Coupler

Automation and Drives

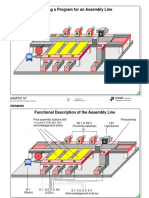

S7 program in network 1 (DP master 1)

SITRAIN

IK-PBSYS / DP/DP Coupler Page 9 03/2007

Siemens AG 2007 - Subject to change without prior notice

Notes

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 9 DP/DP Coupler

Automation and Drives

S7 program in network 2 (DP master 2)

SITRAIN

IK-PBSYS / DP/DP Coupler Page 10 03/2007

Siemens AG 2007 - Subject to change without prior notice

Notes

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 10 DP/DP Coupler

Automation and Drives

Activating the "Data validity" diagnosis

When the "Diagnosis" DIL switch is set, a

"1" is stored in the first configured

INPUTbyte in EW62 = I 62.0 when the

other side of the DP/DP coupler is

operating correctly. In the event of an

error, there is a "0" here.

SITRAIN

IK-PBSYS / DP/DP Coupler Page 11 03/2007

Siemens AG 2007 - Subject to change without prior notice

Diagnosis The "Diagnosis" DIP switch provides an additional display of the data validity

within the I/O data area. It has no effect on the normal diagnostic message

frames of the DP/DP coupler.

You can set the "Diagnosis" DIP switch to ensure that the validity of data is

indicated by a defined bit within the configured I/O area.

If one of the masters is not active or if, for example, due to a fault on an interface

of the DP/DP coupler, no data transfer takes place, this must be signaled to the

other master so that it can reject the data read over the coupler. The validity of

the data can either be determined using the slave diagnostics or, when the data

validity display is active, it can be directly evaluated within the data.DIP switch at

"1": The first bit in the LSB byte (low byte in the data unit), i.e. the first

configured input byte, is used to indicate data validity. This can be evaluated in

the user program. If the bit has the value "1", all the DP/DP coupler data are valid.

Note It is important to note that when this function is used, the I/O bit from the user

program is overwritten with the validity display.

Example:

- Network 1: 16-byte inputEW 60, i.e. I 60.0 =1 for valid data exchange

- Network 2: 16-byte input EW 50, i.e. I 50.0 =1 for valid data exchange

The first bit in the 16-byte input block of network 1 and the first bit in the 16-byte

input block of network 2 display the data validity. Value equal to 1: Data valid

Value equal to 0: Data invalid

DIP switch at "0": Within the I/O data, there is no indication of the data validity. The LSB byte can be

used for normal I/O data.

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 11 DP/DP Coupler

Automation and Drives

Diagnosis of DP/DP coupler malfunctions

SF 1: Group fault in PROFIBUS DP network 1 (red)

SF 2: Group fault in PROFIBUS DP network 2 (red)

BF 1: Bus fault in PROFIBUS DP network 1 (red)

BF 2: Bus fault in PROFIBUS DP network 2 (red)

ON 1: 24 V power supply for DP/DP coupler network 1 (green)

ON 2: 24 V power supply for DP/DP coupler network 1 (green)

SF 1: Group fault in PROFIBUS DP network 1 (red)

SF 2: Group fault in PROFIBUS DP network 2 (red)

BF 1: Bus fault in PROFIBUS DP network 1 (red)

BF 2: Bus fault in PROFIBUS DP network 2 (red)

SITRAIN

IK-PBSYS / DP/DP Coupler Page 12 03/2007

Siemens AG 2007 - Subject to change without prior notice

Notes

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 12 DP/DP Coupler

Automation and Drives

Diagnosis of DP/DP coupler malfunctions,

LEDs SF and BF

SF 1:

Group fault PROFIBUS DP network 1 (red)

SF 2:

Group fault in PROFIBUS DP network 2 (red)

BF 1:

Bus fault PROFIBUS DP network 1 (red)

BF 2:

Bus fault PROFIBUS DP network 2 (red)

SITRAIN

IK-PBSYS / DP/DP Coupler Page 13 03/2007

Siemens AG 2007 - Subject to change without prior notice

Notes

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 13 DP/DP Coupler

Automation and Drives

Diagnosis with system function SFC13

SITRAIN

IK-PBSYS / DP/DP Coupler Page 14 03/2007

Siemens AG 2007 - Subject to change without prior notice

Diagnosis with SFC13

The figure above contains an example of a DP/DP coupler malfunction. The

figure below shows an example display indicating

correct operation of the DP/DP coupler.

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 14 DP/DP Coupler

Automation and Drives

Exercise 1 : Connect 2 DP networks using

a DP/DP coupler

SITRAIN

IK-PBSYS / DP/DP Coupler Page 15 03/2007

Siemens AG 2007 - Subject to change without prior notice

Task description: Your task is to connect 2 physically separate DP systems via the DP/DP coupler.

Define the data of network 1 as output data and process them in network 2 as

input data.

Procedure: 1.Change the name of your hardware station to "Network_1", copy your system

to the clipboard and paste it in again under the name Network_2".

As a result you should have one station called network_2 and one called

network_1 in your project.

3.Change the system network_2 in such a way that it is linked to an independent

PROFIBUS network. After step 2, your project should also contain two

PROFIBUS networks.

4.Now insert the DP/DP coupler type in the "Hardware configuration tool using

the hardware catalog.

5.Configure an output area in network_1 and an input area in network_2.

Download the modified hardware stations to the relevant CPU.

6.Change your S7 program, if necessary, to ensure that output data are

generated and input data are processed.

SITRAIN training for IK-PBSYS

Automation and Industrial Solutions Page 15 DP/DP Coupler

Você também pode gostar

- 03 - Integrated PROFIBUS InterfaceDocumento27 páginas03 - Integrated PROFIBUS InterfaceIsai AnguianoAinda não há avaliações

- 01 PROFIBUS TechnologyDocumento27 páginas01 PROFIBUS TechnologyIsai AnguianoAinda não há avaliações

- 09 - CP342 5 DP MasterDocumento18 páginas09 - CP342 5 DP MasterIsai AnguianoAinda não há avaliações

- 02 Transmission Media PROFIBUSDocumento22 páginas02 Transmission Media PROFIBUSIsai AnguianoAinda não há avaliações

- Serv1 - 11e - Introduction To Profibus DP and HmiDocumento28 páginasServ1 - 11e - Introduction To Profibus DP and HmiAhmed KhairiAinda não há avaliações

- PRO1 09E Introduction HMIDocumento24 páginasPRO1 09E Introduction HMILộc QuangAinda não há avaliações

- 12 Apendix Open Process ControlDocumento26 páginas12 Apendix Open Process ControlIsai AnguianoAinda não há avaliações

- 07 - Checking The Electrical Bus CableDocumento23 páginas07 - Checking The Electrical Bus CableIsai AnguianoAinda não há avaliações

- Rewiring A User Program: Simatic S7Documento16 páginasRewiring A User Program: Simatic S7Neagoe CristianAinda não há avaliações

- 0 IK-PBSYS Cover15 V201Documento1 página0 IK-PBSYS Cover15 V201Isai Anguiano33% (3)

- Digital Operations: CMP IDocumento34 páginasDigital Operations: CMP INeagoe CristianAinda não há avaliações

- PRO1 02E Training UnitsDocumento11 páginasPRO1 02E Training UnitsLộc QuangAinda não há avaliações

- PRSERV - 05E - SW Commissioning and TroubleshootingDocumento12 páginasPRSERV - 05E - SW Commissioning and TroubleshootingNeagoe CristianAinda não há avaliações

- Documenting, Saving, Archiving: Simatic S7Documento22 páginasDocumenting, Saving, Archiving: Simatic S7Neagoe CristianAinda não há avaliações

- Siemens Automation Training CoursesDocumento22 páginasSiemens Automation Training CoursesNeagoe CristianAinda não há avaliações

- PRO1 10E Introduction MicromasterDocumento20 páginasPRO1 10E Introduction MicromasterLộc QuangAinda não há avaliações

- 06 - Hmi Panels and Profibus DPDocumento23 páginas06 - Hmi Panels and Profibus DPIsai AnguianoAinda não há avaliações

- S7 Automation SolutionsDocumento25 páginasS7 Automation SolutionsNeagoe CristianAinda não há avaliações

- Hardware Commissioning ChecklistDocumento33 páginasHardware Commissioning ChecklistChihebJmaaAinda não há avaliações

- SITRAIN-S5 Upload-Step by StepDocumento12 páginasSITRAIN-S5 Upload-Step by StepJorge_Andril_5370Ainda não há avaliações

- S120 Safety FCT Man 0620 en-USDocumento432 páginasS120 Safety FCT Man 0620 en-USNick RivieraAinda não há avaliações

- SITRAIN Training For: Automation and Industrial SolutionsDocumento41 páginasSITRAIN Training For: Automation and Industrial SolutionsIsmael Gracia100% (1)

- Serv2 02e HW Sw-CommDocumento32 páginasServ2 02e HW Sw-CommMarinel Moraru50% (2)

- Sce 031 100 FC Programming s7 1200 r1709 enDocumento54 páginasSce 031 100 FC Programming s7 1200 r1709 enandersonAinda não há avaliações

- Wincc ScriptsDocumento16 páginasWincc ScriptsntrimurthuluAinda não há avaliações

- Creating an Assembly Line ProgramDocumento24 páginasCreating an Assembly Line ProgramNeagoe CristianAinda não há avaliações

- PRO1 13E Organzation BlocksDocumento14 páginasPRO1 13E Organzation BlocksLộc QuangAinda não há avaliações

- Tia-Pro1 en 01 V14Documento517 páginasTia-Pro1 en 01 V14Mario Edgar Pérez PinalAinda não há avaliações

- 663Documento9 páginas663Ali Padaryam100% (1)

- SCE - EN - 040-020 - R1209 - Startup S7-SCLDocumento30 páginasSCE - EN - 040-020 - R1209 - Startup S7-SCLBen Hur FabriAinda não há avaliações

- PROFIBUS Diagnostic Bundle for SIMATIC S7Documento10 páginasPROFIBUS Diagnostic Bundle for SIMATIC S7Marius Nicusor PopescuAinda não há avaliações

- SCE - EN - 051-300 PID Control S7-1200 - R1709Documento50 páginasSCE - EN - 051-300 PID Control S7-1200 - R1709Nguyễn Duy ThànhAinda não há avaliações

- 00 - Register 20 deDocumento1 página00 - Register 20 deahijado motaAinda não há avaliações

- SISTRAIN PRO3 02E FBs Multi Instances - 2 PDFDocumento32 páginasSISTRAIN PRO3 02E FBs Multi Instances - 2 PDFSam eagle goodAinda não há avaliações

- PRO1 02E Training UnitsDocumento10 páginasPRO1 02E Training UnitsMarinel MoraruAinda não há avaliações

- Configuracion Sinamics PCS7 PDFDocumento21 páginasConfiguracion Sinamics PCS7 PDFAlvaro AvilaAinda não há avaliações

- SIMATIC PROFINET System Description PDFDocumento182 páginasSIMATIC PROFINET System Description PDFChen CYAinda não há avaliações

- University Training Docu-Ments For SIMATIC PCS 7: Siemens Automation Cooperates With Education - 02/2020Documento32 páginasUniversity Training Docu-Ments For SIMATIC PCS 7: Siemens Automation Cooperates With Education - 02/2020vijikeshAinda não há avaliações

- 19 Exercises V8.1.0 en PDFDocumento56 páginas19 Exercises V8.1.0 en PDFMaritza AntonioAinda não há avaliações

- 05 Bico TechnologyDocumento0 página05 Bico TechnologyLuis Fernando CuaspudAinda não há avaliações

- Click and Start M340 EN - V1 - ModifiedDocumento71 páginasClick and Start M340 EN - V1 - Modifiedshaikhsajid242Ainda não há avaliações

- Sce 092 300 Opc Ua s7 1500 r1807 en - Compressed PDFDocumento48 páginasSce 092 300 Opc Ua s7 1500 r1807 en - Compressed PDFOmkar Deshpande100% (1)

- Tia Portal V17 Technical HighlightsDocumento50 páginasTia Portal V17 Technical HighlightsSérgio SilvaAinda não há avaliações

- Graphic Screens (1) : Simatic HmiDocumento120 páginasGraphic Screens (1) : Simatic HmiHenrique XavierAinda não há avaliações

- PROFIsafe Safety Concept DSDocumento46 páginasPROFIsafe Safety Concept DSSyariefAinda não há avaliações

- Serv1 06e HW ComDocumento16 páginasServ1 06e HW ComNeagoe CristianAinda não há avaliações

- IK-TIAPN 01E Communication With SIMATICDocumento18 páginasIK-TIAPN 01E Communication With SIMATICenrique laicaAinda não há avaliações

- PRO2 - 11E - Solution SuggestionsDocumento61 páginasPRO2 - 11E - Solution SuggestionsmikeAinda não há avaliações

- 00 Register 15 enDocumento1 página00 Register 15 enmnhtvmAinda não há avaliações

- Communication Profibus-Fms: Automation and DrivesDocumento1 páginaCommunication Profibus-Fms: Automation and DrivesVictor YosafatAinda não há avaliações

- 05 EPOS eDocumento36 páginas05 EPOS eBernardo GroismanAinda não há avaliações

- TIA Openness GettingStartedAndDemo V14SP1 enDocumento35 páginasTIA Openness GettingStartedAndDemo V14SP1 enjoneschnAinda não há avaliações

- 02 IK IESYS e Introduction To Industrial EthernetDocumento32 páginas02 IK IESYS e Introduction To Industrial EthernetHernando AlborAinda não há avaliações

- 02 - 012-001 Firmware Update With SIMATIC S7-1500-En PDFDocumento33 páginas02 - 012-001 Firmware Update With SIMATIC S7-1500-En PDFJerryAinda não há avaliações

- SITRAIN Profibus FMSDocumento144 páginasSITRAIN Profibus FMSerick_thadeuAinda não há avaliações

- Technical Slides TIA Portal V15 enDocumento131 páginasTechnical Slides TIA Portal V15 enen_deepak100% (2)

- 03 Integrated PROFIBUS InterfaceDocumento27 páginas03 Integrated PROFIBUS InterfaceDenisAinda não há avaliações

- 03 Integrated PROFIBUS InterfaceDocumento27 páginas03 Integrated PROFIBUS InterfaceDenisAinda não há avaliações

- UniSP SM Profibus AUG Iss1Documento67 páginasUniSP SM Profibus AUG Iss1irmarin81100% (1)

- HA389815Documento28 páginasHA389815Hayden Lovett100% (1)

- 12 Apendix Open Process ControlDocumento26 páginas12 Apendix Open Process ControlIsai AnguianoAinda não há avaliações

- 08 - PROFIBUS DP DiagnosticsDocumento44 páginas08 - PROFIBUS DP DiagnosticsIsai AnguianoAinda não há avaliações

- 07 - Checking The Electrical Bus CableDocumento23 páginas07 - Checking The Electrical Bus CableIsai AnguianoAinda não há avaliações

- Mitsubishi F700 Drive PDFDocumento335 páginasMitsubishi F700 Drive PDFIsai AnguianoAinda não há avaliações

- 13 Apendix PROFIsafe Safety IntegratedDocumento21 páginas13 Apendix PROFIsafe Safety IntegratedIsai AnguianoAinda não há avaliações

- 14.2 Apendix 05 Distributed IODocumento56 páginas14.2 Apendix 05 Distributed IOIsai AnguianoAinda não há avaliações

- 06 - Hmi Panels and Profibus DPDocumento23 páginas06 - Hmi Panels and Profibus DPIsai AnguianoAinda não há avaliações

- 14.1 Apendix 04 PROFIBUS PDFDocumento34 páginas14.1 Apendix 04 PROFIBUS PDFIsai AnguianoAinda não há avaliações

- 11 - S7 Communication ServicesDocumento18 páginas11 - S7 Communication ServicesIsai AnguianoAinda não há avaliações

- 10 - Field Data Link ConnectionsDocumento36 páginas10 - Field Data Link ConnectionsIsai AnguianoAinda não há avaliações

- DSDocumento4 páginasDSsamirbergonziAinda não há avaliações

- 04 Intelligent SlavesDocumento25 páginas04 Intelligent SlavesIsai AnguianoAinda não há avaliações

- Hart IngDocumento724 páginasHart IngIsai AnguianoAinda não há avaliações

- G120 CU230P-2 List Manual LH9 0414 EngDocumento764 páginasG120 CU230P-2 List Manual LH9 0414 EngKaren InisAinda não há avaliações

- Lapp Group PDFDocumento40 páginasLapp Group PDFIsai AnguianoAinda não há avaliações

- 0 IK-PBSYS Cover15 V201Documento1 página0 IK-PBSYS Cover15 V201Isai Anguiano33% (3)

- IR TXN Data Sheet (IR 333)Documento7 páginasIR TXN Data Sheet (IR 333)Justin JoseAinda não há avaliações

- SIMATIC NET PROFIBUS System Course Folder V2.0.1Documento1 páginaSIMATIC NET PROFIBUS System Course Folder V2.0.1Isai AnguianoAinda não há avaliações

- DSDocumento4 páginasDSsamirbergonziAinda não há avaliações

- Balluff Network-Catalog D14Documento268 páginasBalluff Network-Catalog D14Isai AnguianoAinda não há avaliações

- IR TXN Data Sheet (IR 333)Documento7 páginasIR TXN Data Sheet (IR 333)Justin JoseAinda não há avaliações

- AB EsencialDocumento356 páginasAB EsencialIsai AnguianoAinda não há avaliações

- PLC5 Quick Intruction ManualDocumento169 páginasPLC5 Quick Intruction ManualRashedul HaqueAinda não há avaliações

- Sensores Inductivos PDFDocumento38 páginasSensores Inductivos PDFIsai AnguianoAinda não há avaliações

- AB ClemasDocumento90 páginasAB ClemasIsai AnguianoAinda não há avaliações

- Flutter Libraries: MDG Season of Code 2019Documento6 páginasFlutter Libraries: MDG Season of Code 2019Black ReaperAinda não há avaliações

- IoT Based Health Monitoring SystemDocumento11 páginasIoT Based Health Monitoring SystemakashlogicAinda não há avaliações

- How To Smart Home PDF orDocumento79 páginasHow To Smart Home PDF orAndrei Horhoianu100% (1)

- Domino Admin Help 7Documento1.910 páginasDomino Admin Help 7rakesh_kambleAinda não há avaliações

- Arduino: An Open Electronics Prototyping Platform: David A. MellisDocumento11 páginasArduino: An Open Electronics Prototyping Platform: David A. Mellissmeneses741Ainda não há avaliações

- Data Recording Setup Guide: Commandbatch V1.7.5.0 & Later 10/14/08Documento12 páginasData Recording Setup Guide: Commandbatch V1.7.5.0 & Later 10/14/08Aly AbdelhamedAinda não há avaliações

- Presentasi Gom PlayerDocumento8 páginasPresentasi Gom PlayerSupriyantoAinda não há avaliações

- A00-211 DumpsDocumento20 páginasA00-211 DumpsShivam Sahni33% (6)

- AWS Private Links: Wednesday, June 9, 2021 5:32 PMDocumento2 páginasAWS Private Links: Wednesday, June 9, 2021 5:32 PMRajan Babu SAinda não há avaliações

- Pioneer DEH-P3700MP - Radio CD-MP3 Operation ManualDocumento133 páginasPioneer DEH-P3700MP - Radio CD-MP3 Operation ManualDharma InitiativeAinda não há avaliações

- Cloud Computing Chapter 10Documento42 páginasCloud Computing Chapter 10ghar_dashAinda não há avaliações

- Operations Support System - .Documento4 páginasOperations Support System - .Dipesh JainAinda não há avaliações

- Service Manual T.MSD309Documento16 páginasService Manual T.MSD309Carlos GonçalvesAinda não há avaliações

- EPC Feature ListDocumento18 páginasEPC Feature Listelectrico services0% (1)

- Data Layer Design: Architecting With Google Cloud Platform: Design and ProcessDocumento47 páginasData Layer Design: Architecting With Google Cloud Platform: Design and ProcessDaniel ReyesAinda não há avaliações

- Raid 5Documento26 páginasRaid 5Ritu ShrivastavaAinda não há avaliações

- Computer Networking & Data Communication LECTURE NOTESDocumento150 páginasComputer Networking & Data Communication LECTURE NOTESSachin KumarAinda não há avaliações

- Timeprovider 5000 Ieee 1588 Grand Master Clock: User'S GuideDocumento306 páginasTimeprovider 5000 Ieee 1588 Grand Master Clock: User'S GuideAnonymous iTW5NPqHAinda não há avaliações

- Getting Started Guide for PIPE CLASS COMPONENT SoftwareDocumento20 páginasGetting Started Guide for PIPE CLASS COMPONENT SoftwareshamoojeeAinda não há avaliações

- COURIER MANAGEMENT SYSTEMDocumento53 páginasCOURIER MANAGEMENT SYSTEMgovindarajnAinda não há avaliações

- Dot NET Concepts PrakashDocumento160 páginasDot NET Concepts Prakashnarayana_j100% (4)

- Xbox 360 Power Supply SchematicDocumento3 páginasXbox 360 Power Supply SchematicMeysam Khosravi100% (1)

- SC835 Chassis Series: User'S ManualDocumento82 páginasSC835 Chassis Series: User'S Manual--Ainda não há avaliações

- Spec Precn m2300 enDocumento2 páginasSpec Precn m2300 ensilverkurgAinda não há avaliações

- Flexi WCDMA BTS and Module OverviewDocumento52 páginasFlexi WCDMA BTS and Module OverviewLelik GhhAinda não há avaliações

- SSO PeopleSoft Portal with Active DirectoryDocumento19 páginasSSO PeopleSoft Portal with Active DirectoryShashank TilwankarAinda não há avaliações

- Module - InternetDocumento18 páginasModule - InternetNinerz LacsamanaAinda não há avaliações

- WCF FundamentalsDocumento39 páginasWCF FundamentalsAmit TiwariAinda não há avaliações

- Comparing WebRatio and Symfony frameworks for teaching web designDocumento18 páginasComparing WebRatio and Symfony frameworks for teaching web designKarla OlivaAinda não há avaliações

- Sap Bods DetailsDocumento2 páginasSap Bods DetailsKrishna PrasadAinda não há avaliações