Escolar Documentos

Profissional Documentos

Cultura Documentos

Continuous Gas Carburising Furnace

Enviado por

Emba MadrasDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Continuous Gas Carburising Furnace

Enviado por

Emba MadrasDireitos autorais:

Formatos disponíveis

Continuous Gas Carburising Furnace

Hightemp-Dowa is an acknowledged leader in Pusher Furnace technology, enabling us to incorporate state-of-the-art facilities in Pusher Furnaces such as full automatics, pick-and-

place robot systems and SCADA.

Continuous Gas Carburisers Furnaces are endowed with a single track continuous gas carburising design enabling consistent production at low operating costs. Whats more, a

combination of the latest in sophisticated controls, including data acquisition systems, ensures high quality heat treatment.

Features

Production capacity 150kg/hr to 400kg/hr

Operating temperature up to 950oC

Sophisticated controls including SCADA & Data Acquisition can be offered

Option for Endothermic gas or Nitrogen-Methanol system as atmosphere

Option for Gas fired or Electric heating with Radiant tubes

Fully automatic, PLC controlled closed loop system

Robotic charge handling system for Press Quenching can be offered

Ability to process large numbers of different components

Modular designs for flexibility and ease of maintenance

Silicon carbide skid rails for smooth long lasting movement of charge

Pneumatically operated door systems for positive sealing

Pusher mechanism designed for heavy loads

Automatic adjustment of stroke length to compensate for thermal expansion

Guiding of quenching oil throughout the charge with baffles located inside the quench tank

Applications

Gears, Crowns, Pinions, Transmission & Axle components, Castings, Forgings and Engine components.

Metallurgical Processes

Carburising, Carbonitriding, Neutral Hardening, Annealing, Isothermal Annealing, Spherodize Annealing, Normalising, Stress Relieving, Solution Treating & Ageing.

Tempering Furnaces

HIGHTEMP offers Tempering furnaces for both low and high tempering processes. These tempering furnaces provide a reliable platform for acquiring various mechanical properties

during tempering and reduce the residual stresses during the stress relieving process. Pit Type, In-out Box Type and the Double Door Straight through Box Type are the various options

that we offer in Tempering Furnaces.

Features

Space and Energy saving

Production rate at 400oC 55 kg/hr to 4500kg/hr

Option for Electric or Gas fired heating system

Patented heating and circulation system

Application

Springs

Gears

Batch Type Integral Sealed Quench Furnace

Batch Type Integral Sealed Quench Furnaces provide the benefit of uniform heating from the sides through Radiant tube heaters located on either side. Integral Sealed Quench

Furnaces from HIGHTEMP incorporate a cast integral fan to ensure uniformity of temperature. For the furnace atmosphere, these furnaces provide the option of using Endothermic gas,

Nitrogen-Methanol or Fine Carburising Process.

Features

Straight through design

No moving parts in heating chamber

Fully automated sequentially controlled with PLC

Thyristor with PID temperature control

Carbon potential controller with proportional valve

Touch screen graphic operator panel with alarm annunciation

Multi point temperature recorder

Silicon carbide skids or heat resistant steel T-rails

Pneumatically operated doors and elevators

Turnkey project offered with process know-how

All alarms and annunciation with inter-locks for operational safety

Options for Electric / Gas fired Radiant tube heating available

Easily available low cost spares

Design facilitates minimum down-time for maintenance / replacement

Integrated and compact layout with washing, tempering and material handling equipment at economical prices

Sophisticated controls including SCADA and Data Acquisition can be offered

Applications

Bright Hardening

Carburising

Nitro Carburising

Hardening

Normalizing

Carbonitriding

Precipitation

Annealing

Hardening

Você também pode gostar

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesAinda não há avaliações

- Ipsen Atmosphere TechnologyDocumento5 páginasIpsen Atmosphere TechnologyCarlos SartoriAinda não há avaliações

- Continuous Sintering PDFDocumento1 páginaContinuous Sintering PDFKrishnanAinda não há avaliações

- Ipsen Furnace Turbo CoolingDocumento8 páginasIpsen Furnace Turbo CoolingArun KrishnaAinda não há avaliações

- Hardening and Tempering Solutions: Other Thermatool ApplicationsDocumento2 páginasHardening and Tempering Solutions: Other Thermatool ApplicationsskluxAinda não há avaliações

- Direct Fired Heaters: Convection HeaterDocumento2 páginasDirect Fired Heaters: Convection HeaterGustav MolMedAinda não há avaliações

- Thermic Fluid HeaterDocumento11 páginasThermic Fluid HeaterAtrij DeyAinda não há avaliações

- Windsor Kilns 2021Documento8 páginasWindsor Kilns 2021Wai Phyo HlaingAinda não há avaliações

- Thermal Fluid Systems BrochureDocumento3 páginasThermal Fluid Systems BrochurehasrunizraAinda não há avaliações

- Brochure Gas Turbine SGT-400 For Power Generation PDFDocumento4 páginasBrochure Gas Turbine SGT-400 For Power Generation PDFfrdnAinda não há avaliações

- ST Thermal Fluid Heating SystemsDocumento4 páginasST Thermal Fluid Heating SystemsHossam MagdyAinda não há avaliações

- I8-500a Datasheet 2021Documento4 páginasI8-500a Datasheet 2021Abdou MohAinda não há avaliações

- VAI - aroTHERM Plus Brochure - EN v7 - Final Awaiting SCOPDocumento12 páginasVAI - aroTHERM Plus Brochure - EN v7 - Final Awaiting SCOPDuncan Steven100% (1)

- RDA Induction Heating 4 PageDocumento4 páginasRDA Induction Heating 4 Pageนภดล สินธุแปงAinda não há avaliações

- Thermal Fluid Heaters: Model HHC and VHCDocumento4 páginasThermal Fluid Heaters: Model HHC and VHCRexx MexxAinda não há avaliações

- Qac CoolersDocumento12 páginasQac CoolersMiguel Angel LopezAinda não há avaliações

- Heat Treatment Processes in The Ceramics Industry: Edition 09.09 GBDocumento8 páginasHeat Treatment Processes in The Ceramics Industry: Edition 09.09 GBKosphy Arden100% (1)

- Prod Prco21g GB - 0319Documento236 páginasProd Prco21g GB - 0319Said ZubizaAinda não há avaliações

- SsDocumento8 páginasSstayefehAinda não há avaliações

- GEA - Refrigeration in Oil & Gas Industry - tcm11-33981Documento4 páginasGEA - Refrigeration in Oil & Gas Industry - tcm11-33981Dhroov SharmaAinda não há avaliações

- E50001 W410 A105 V1 4A00 - SolarbroschuereDocumento4 páginasE50001 W410 A105 V1 4A00 - SolarbroschuereWilfredo Rojo CastañoAinda não há avaliações

- Cooling & Heating: ShellmaxDocumento3 páginasCooling & Heating: Shellmaxvijaysirsat2007Ainda não há avaliações

- I.C.T Lyra-Series Reflow Oven V1.4Documento13 páginasI.C.T Lyra-Series Reflow Oven V1.4AlexanderAinda não há avaliações

- FurnacesforforgingDocumento4 páginasFurnacesforforgingVijay MenonAinda não há avaliações

- Thermal Master 500Documento2 páginasThermal Master 500cris melos0% (1)

- Biomass BrochureDocumento8 páginasBiomass BrochureParamasamy SubramaniAinda não há avaliações

- Solutions For Improved Thermal Process Performance: Field ProductsDocumento8 páginasSolutions For Improved Thermal Process Performance: Field ProductssirballesterosAinda não há avaliações

- Chamber and Tube Furnaces 0001-G-EDocumento64 páginasChamber and Tube Furnaces 0001-G-EMutsikamahwe BrianAinda não há avaliações

- Kanthal Ladle HeatingDocumento4 páginasKanthal Ladle HeatingETA THERMALAinda não há avaliações

- Teknovak Presentation PDFDocumento22 páginasTeknovak Presentation PDFSinan YıldızAinda não há avaliações

- 093.A01.2014.002 Brochure A4 Temperature-Control en V01.FINAL - RZ.RGBDocumento4 páginas093.A01.2014.002 Brochure A4 Temperature-Control en V01.FINAL - RZ.RGBD4R3 D3V1LAinda não há avaliações

- UltraGas (15-2000) TTE Technical Data Booklet - 4212948-02 - 07-15Documento45 páginasUltraGas (15-2000) TTE Technical Data Booklet - 4212948-02 - 07-15MBMAinda não há avaliações

- Vitocrossal 200-cm2 SM gw6b TDMDocumento16 páginasVitocrossal 200-cm2 SM gw6b TDMCiprian BalcanAinda não há avaliações

- Sigma Thermal Products OverviewDocumento2 páginasSigma Thermal Products OverviewfrankyAinda não há avaliações

- Water Bath HeaterDocumento4 páginasWater Bath HeaterBensmatAinda não há avaliações

- Prefab Boiler HousesDocumento2 páginasPrefab Boiler HousesSubir Kumar MandalAinda não há avaliações

- Operational Strategies For Flexing in Thermal PlantsDocumento27 páginasOperational Strategies For Flexing in Thermal PlantsSanjay NandalAinda não há avaliações

- ThermJet PCA (USA)Documento2 páginasThermJet PCA (USA)Alejandro Ignacio Araneda WordenAinda não há avaliações

- Multi Purpose IncineratorDocumento7 páginasMulti Purpose IncineratorMDLAinda não há avaliações

- SCHWING Heat-Treatment Brochure ENDocumento3 páginasSCHWING Heat-Treatment Brochure ENSinan YILDIZAinda não há avaliações

- Fired HeatersDocumento20 páginasFired HeatersCal100% (5)

- Kiln Revamping en 20180921Documento33 páginasKiln Revamping en 20180921Fernando Araujo100% (2)

- Dental English 0Documento44 páginasDental English 0Royal Academy of BrillianceAinda não há avaliações

- Tank Heating: Industrial Heat Tracing SolutionsDocumento29 páginasTank Heating: Industrial Heat Tracing Solutionsromero2kAinda não há avaliações

- SyncroTherm TIDocumento5 páginasSyncroTherm TIskluxAinda não há avaliações

- WP Tunnelofen Thermador - ENDocumento5 páginasWP Tunnelofen Thermador - ENmnenasratnarabotuAinda não há avaliações

- Krom Schroder 1Documento10 páginasKrom Schroder 1Sujanto WidjajaAinda não há avaliações

- CYTEC SpindelDocumento9 páginasCYTEC Spindel李恩杰Ainda não há avaliações

- Arotherm Plus Spec Sheet 1892564Documento12 páginasArotherm Plus Spec Sheet 1892564ErikAinda não há avaliações

- Oil Plant SolutionsDocumento10 páginasOil Plant SolutionsMarcus MihaiAinda não há avaliações

- JM Dryers Air Tropical PCM 60hz C913E BRO USDocumento12 páginasJM Dryers Air Tropical PCM 60hz C913E BRO USDeny PranowojatiAinda não há avaliações

- Thermo-Economic Analysis For The Optimal Conceptual Design of Biomass Gasification Energy Conversion SystemsDocumento29 páginasThermo-Economic Analysis For The Optimal Conceptual Design of Biomass Gasification Energy Conversion SystemsAdriana Rocio Palencia SalgarAinda não há avaliações

- Upflow/Horizontal Two-Stage Condensing Gas-Fired Furnace: TDD-D-1Documento16 páginasUpflow/Horizontal Two-Stage Condensing Gas-Fired Furnace: TDD-D-1randy_uberAinda não há avaliações

- 566 180083 Factsheet SGT A45 Online PDFDocumento2 páginas566 180083 Factsheet SGT A45 Online PDFIwan AbdurahmanAinda não há avaliações

- Thermal Fluid Heating SolutionsDocumento8 páginasThermal Fluid Heating SolutionsJosé Pedro MagalhãesAinda não há avaliações

- Encon Thermal Engineers: Answer To The Continued Need For Energy ConservationDocumento70 páginasEncon Thermal Engineers: Answer To The Continued Need For Energy ConservationAtul SaxenaAinda não há avaliações

- Jenny Gas Fired Combination Unit: Solving Individual Cleaning Problems WorldwideDocumento2 páginasJenny Gas Fired Combination Unit: Solving Individual Cleaning Problems WorldwidePawan SehrawatAinda não há avaliações

- Issct - Ijt PRSNTN June08Documento21 páginasIssct - Ijt PRSNTN June08nagtummala100% (1)

- Ultra GasDocumento12 páginasUltra Gasdonetek677Ainda não há avaliações

- 33.trane Variable Refrigerant (TVR III) - VRF - System - Mar 26, 2013 PDFDocumento15 páginas33.trane Variable Refrigerant (TVR III) - VRF - System - Mar 26, 2013 PDFchinitnAinda não há avaliações

- BMW Stock 03.12.2017Documento8 páginasBMW Stock 03.12.2017Emba MadrasAinda não há avaliações

- Points of Reflection Class 1 Class 2 Introduction To Materials Selection Atomic Structure & BondingDocumento43 páginasPoints of Reflection Class 1 Class 2 Introduction To Materials Selection Atomic Structure & BondingEmba MadrasAinda não há avaliações

- TEST1Documento4 páginasTEST1Emba MadrasAinda não há avaliações

- Utr 1Documento4 páginasUtr 1Emba MadrasAinda não há avaliações

- Quotation Format 5Documento2 páginasQuotation Format 5Emba MadrasAinda não há avaliações

- Part/Material Inputs: Injection Molding Technical Cost Model MIT - Materials Systems LaboratoryDocumento13 páginasPart/Material Inputs: Injection Molding Technical Cost Model MIT - Materials Systems LaboratoryEmba MadrasAinda não há avaliações

- Inventory Is TheDocumento16 páginasInventory Is TheEmba MadrasAinda não há avaliações

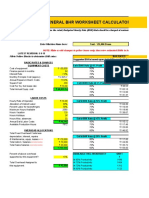

- General BHR Worksheet CalculatorDocumento2 páginasGeneral BHR Worksheet CalculatorEmba MadrasAinda não há avaliações

- Sand Casting: Low Cost Tooling Largest Casting Sizes Achievable Very Low Gas Porosity General VersatilityDocumento13 páginasSand Casting: Low Cost Tooling Largest Casting Sizes Achievable Very Low Gas Porosity General VersatilityEmba MadrasAinda não há avaliações

- Uk / India ISO en Ac-France Germany Italy Uni USA USA Japan Aa / Astm SAE LM0 LM2Documento13 páginasUk / India ISO en Ac-France Germany Italy Uni USA USA Japan Aa / Astm SAE LM0 LM2Emba MadrasAinda não há avaliações

- Child From SchoolDocumento1 páginaChild From SchoolEmba MadrasAinda não há avaliações

- 1558035837508gtwf3RUDP4SoBRDQ PDFDocumento1 página1558035837508gtwf3RUDP4SoBRDQ PDFEmba MadrasAinda não há avaliações

- Trade Terms ImprortsDocumento31 páginasTrade Terms ImprortsEmba MadrasAinda não há avaliações

- Generic Model FSA For Mine Specific Supply IPPsDocumento54 páginasGeneric Model FSA For Mine Specific Supply IPPsEmba MadrasAinda não há avaliações

- Risk - and - Issues - Analysis - QA FinalDocumento10 páginasRisk - and - Issues - Analysis - QA FinalEmba MadrasAinda não há avaliações

- We Can Change From This ..Documento20 páginasWe Can Change From This ..Emba MadrasAinda não há avaliações

- Tonnage Calc-4Documento12 páginasTonnage Calc-4Emba MadrasAinda não há avaliações

- LANXESS - Processing Data For The Injection Molder - LXS-HPM-006EN - 2017-10 PDFDocumento25 páginasLANXESS - Processing Data For The Injection Molder - LXS-HPM-006EN - 2017-10 PDFEmba MadrasAinda não há avaliações

- You Enter Information Only in The Shaded CellsDocumento9 páginasYou Enter Information Only in The Shaded CellsEmba MadrasAinda não há avaliações

- Manual CTI Technical Manual PDFDocumento39 páginasManual CTI Technical Manual PDFaricomen43% (7)

- Astm D3078 94Documento1 páginaAstm D3078 94Jusuf Hasan100% (1)

- E1-240-2014 - Foundation Engineering II Introduction To Building FoundationsDocumento21 páginasE1-240-2014 - Foundation Engineering II Introduction To Building FoundationsEfraim HaifekeAinda não há avaliações

- ASTM and Fall Cone TestDocumento2 páginasASTM and Fall Cone TestCutsilverAinda não há avaliações

- Theory of CHEMKINDocumento402 páginasTheory of CHEMKINamir1224Ainda não há avaliações

- AccesoDocumento4 páginasAccesoerazorafaelAinda não há avaliações

- System of Linear InequalitiesDocumento7 páginasSystem of Linear InequalitiesDominic SavioAinda não há avaliações

- AUC SheetDocumento26 páginasAUC SheetTanmay SagarAinda não há avaliações

- Control System Engineering EC6405 Unit I-Cont Rol Syste M Mod Elin G Part ADocumento12 páginasControl System Engineering EC6405 Unit I-Cont Rol Syste M Mod Elin G Part ASivaprakasam KarthikeyanAinda não há avaliações

- 3 Die CuttingDocumento41 páginas3 Die CuttingNarendrareddy RamireddyAinda não há avaliações

- Fan7529 Critical Conduction Mode PFC ControllerDocumento20 páginasFan7529 Critical Conduction Mode PFC ControllerPompei RusuAinda não há avaliações

- CE 350 Project2Documento22 páginasCE 350 Project2MariaEstherAlguacilRodriguezAinda não há avaliações

- Acetone ProductionDocumento8 páginasAcetone ProductionZahraa GhanemAinda não há avaliações

- Begin As Follows: To Compute An MPN and The 95% Confidence Limits On The Log of The MPN: Enter The Inoculum/tube in Column ADocumento1 páginaBegin As Follows: To Compute An MPN and The 95% Confidence Limits On The Log of The MPN: Enter The Inoculum/tube in Column AlailinayahAinda não há avaliações

- Physics - 11Documento11 páginasPhysics - 11Ishika GuptaAinda não há avaliações

- Double Integration MethodDocumento10 páginasDouble Integration Methodmau_boi16100% (1)

- Molecules 18 02328Documento48 páginasMolecules 18 02328Yamid OrtizAinda não há avaliações

- Xilinx Spartan3 Device ReliabilityDocumento118 páginasXilinx Spartan3 Device ReliabilityRaffi SkAinda não há avaliações

- MIT6 003F11 hw04 PDFDocumento14 páginasMIT6 003F11 hw04 PDFSudheer KumarAinda não há avaliações

- Kodaikanal Weir GateDocumento32 páginasKodaikanal Weir GateHarish Kumar MahavarAinda não há avaliações

- Sinumerik 810T 820T GA3 ProgrammingDocumento219 páginasSinumerik 810T 820T GA3 ProgrammingNedret BajramovicAinda não há avaliações

- Natural ColorDocumento14 páginasNatural ColorleeAinda não há avaliações

- Adv Funct Materials - 2023 - Zhang - Water Adsorption in MOFs Structures and ApplicationsDocumento32 páginasAdv Funct Materials - 2023 - Zhang - Water Adsorption in MOFs Structures and ApplicationsnemaderakeshAinda não há avaliações

- CHAPTER 1 FluidsDocumento24 páginasCHAPTER 1 FluidsIvan JadeAinda não há avaliações

- S MB Bearing CatalogueDocumento104 páginasS MB Bearing Cataloguefog900Ainda não há avaliações

- Power System Engineering MaterialDocumento6 páginasPower System Engineering MaterialAshok SainiAinda não há avaliações

- Trial MRSM SPM 2014 Physics K2 No SkemaDocumento37 páginasTrial MRSM SPM 2014 Physics K2 No SkemajeglilaAinda não há avaliações

- Material Clase 10 PDFDocumento6 páginasMaterial Clase 10 PDFStefany CorreaAinda não há avaliações

- Treatment of Anchorage of Main Bars in Reinforced Concrete by Codes of Practice - A Critical Review (Part One: Straight Bar Anchorages)Documento19 páginasTreatment of Anchorage of Main Bars in Reinforced Concrete by Codes of Practice - A Critical Review (Part One: Straight Bar Anchorages)Govind GauravAinda não há avaliações

- 7 Anthropometry and Workplace DesignDocumento22 páginas7 Anthropometry and Workplace DesignDeshanBenhurAinda não há avaliações