Escolar Documentos

Profissional Documentos

Cultura Documentos

Electrode Holders: Insulated Quick Connectors

Enviado por

Willy UioTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Electrode Holders: Insulated Quick Connectors

Enviado por

Willy UioDireitos autorais:

Formatos disponíveis

Fig. 11-27 Insulated quick connectors.

McGraw-Hill Education/DavidMoyer,

photographer

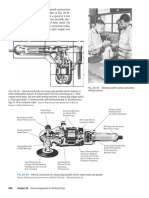

When the work is of such nature that different lengths the jaws can be replaced with new ones when they be-

of cable leads are necessary, cables may be made up in come so badly burned that they do not grip securely. The

specific lengths and equipped with cable connectors so holder should be light in weight, well-balanced, and have

that they can be quickly and easily attached to make up a comfortable grip. Although it should be easy to change

any desired length. The connector shown in Fig. 11-27 the electrode, the holder must be sturdy enough to with-

has a cam-type action that ensures a positive stop and lock stand rough usage. The current-carrying parts must be

and cannot come loose or accidentally fall apart. large enough to prevent overheating, which causes the

handle to become too hot for the welder to hold. For the

Electrode Holders same reason, the size of the holder must be in line with

the size of the welding machine; that is to say, a larger

Metal Electrode Holders electrode holder is required for a 400-ampere welding

A metal electrode holder is the device used for holding machine than for a 200-ampere machine. Most holders

the electrode mechanically. It conveys electric current are fully insulated and may be laid anywhere on the work

from the welding cable to the electrode, and it has an in- without danger of a short circuit. This is especially con-

sulated handle to protect the welders hand fromheat. venient for work in close quarters.

The jaws of the holder should be designed so that Figure 11-30 shows an electrode holder of relatively

they may grip the electrode firmly at any desired angle. new design. It holds electrodes burned to a very short

They should be made of a metal that has high electrical stub. Its twist-type locking device permits electrode-

conductivity and possesses the ability to withstand high gripping power in excess of 2,000 pounds. There is never

temperatures, Figs. 11-28 and 11-29. On many holders danger of dislodging the electrode when attempting to

break through slag to start the arc. The electrode position

is always known. There is positive contact between the

holder and electrode, thus reducing both heating up of the

holder and electrode waste. The handle is fully insulated

so that it stays cool even with high duty cycles.

Another holder is the angle-head, screw-clamp, fully

insulated holder, shown in Fig.11-31. It is available in

Fig. 11-28 A 300 amp electrode holder. This type is spring sizes of 400 and 600 amperes and takes electrodes from

loaded to grip the electrode. McGraw-Hill Education/DavidMoyer,

1

16 through 516 inch in diameter. Such holders are effi-

photographer cient and reduce costs since electrode stub loss is at a

2 3

Electrode Holder 1

1. Tip Insulator w/Screws

2. Upper Body Tong, Insulated 4

3. Spring Cup Insulator

4. Spring Set (with items 3 & 5) 5

5. Spring Flat Insulator

6. Molded Handle

8

7. Hinge Pin 9

8. Lower Body Tong

9. Oval-point Screw 1

7 6

Fig. 11-29 Exploded view of a spring type electrode holder. Adapted from Lenco dba NLC, Inc.

Shielded Metal Arc Welding Principles Chapter 11293

High welding current conductance

is ensured through aluminum-copper

alloy head.

One-ton pressure contact

provides peak conductance from Special extruded copper-alloy

the holder to the electrode. body with large cross-sectional

area.

Cable connections4 types

for no. 4 and the popular D

type for no. 6.

Entirely insulated from end to end,

assuring complete safety from

electrical shock.

Lifeguard insulation developed

after many years to resist heat,

shock, impact and outwear

all other types 3 to 1.

Fig. 11-30 Short-stub electrode holder with twist-type locking device. Source: 2010 Bernard Welding Equipment Co.

Other Electric Arc Processes

The electric arc generates the heat necessary for several

major welding processes. Chapter 18 will present the prin-

ciples of gas tungsten arc welding (GTAW), and Chap-

ter21 will present the principles of gas metal arc welding

(GMAW). Arc cutting, which utilizes much of the same

equipment as arc welding, is presented in Chapter 6.

Personal Safety Equipment

Hand and Head Shields

Fig. 11-31 This type of electrode holder has an angled head, The brilliant light caused by an electric arc contains two kinds

and it is shorter and lighter than other holders of comparable of invisible rays that injure the eyes and skin unless protection

capacity. Jackson Products is provided. One of these invisible rays is known as ultraviolet

and the other as infrared. Repeated exposure, either directly

minimum and holder maintenance is low. The screw-on or indirectly, results in painful but not permanent injury to the

head can be replaced to make a new holder. eyes. Welders speak of this as hot sand in the eyes. The rays

The holder is usually attached to the welding cable by may also produce a severe case of sunburn and sometimes in-

means of solderless connections. It is important that good fection. The rays affect the eyes at any distance within 50 feet;

contact be maintained to prevent overheating. and the skin, at any distance within 20 feet.

294Chapter 11Shielded Metal Arc Welding Principles

Fig. 11-32 The hand shield usually used by foremen and

inspectors. Fibre-Metal Products Co.

Shields protect the welder not only against harmful Fig. 11-34 Note the vertical position of the large viewing

window. Jackson Products

light rays, but also against the hot globules of metal that

the welding operation gives off, especially in the verti-

cal and overhead positions. The hand shield, Fig.11-32,

has a handle so that the person using it may hold the

shield in front of his or her face. Welding inspectors

and supervisors use this type of shield. It is not suit-

able for the welder since he or she can work with only

one hand while using it. It is impossible to manipulate

the electrode and perform other necessary operations at

the same time with the other hand.

The head shield, Figs. 11-33 and 11-34, also called a

hood or helmet, is worn like a helmet. It is attached to Fig. 11-35 An adjustable free-floating headband with adjustable

an adjustable headband, Fig. 11-35, which allows it to crown. Fibre-Metal Products Co.

be moved up or down as the wearer desires. A helmet

and safety cap combination, Fig.11-36, offers practical,

Fig. 11-33 The standard head shield or hood. Fibre-Metal Fig. 11-36 Chrome leather helmets are ideal for those hard-to-

Products Co. get-into areas. Fibre-Metal Products Co.

Shielded Metal Arc Welding Principles Chapter 11295

dependable protection when there is danger of falling or

flying objects. Both hands are free to grasp the electrode

holder and carry out accompanying operations. Partial

protection is provided for the top of the head, but the op-

erator must also wear a leather or nonflammable cap for

adequate protection. This cap should be smooth and have

no pockets or turned-up edges that will hold hot globules

of metal. Most caps have a small bill that can be posi-

tioned to give additional protection to the ear that is most

exposed to weld splatter and slag especially when weld-

ing out of position.

Both the hand shield and the head shield are constructed

of a heat-resisting, pressed-fiber insulating material. The

shields are fully molded at the top and bottom to protect

the head and neck from metal particles, fumes, and dan-

gerous light rays. They are usually black to reduce reflec- Fig. 11-37 The flip-front welding helmet permits the welder to

tion and have a window frame for holding the protective inspect and brush the weld without lifting the hood.

lens which permits the welder to look at the arc safely.

The size of the protective lens is 2 412 inches or

412 514 inches. It is colored so that it can screen out ultra-

violet rays, infrared rays, and most of the visible rays from

the electric arc. A variety of shades of color may be ob-

tained. The density of the color chosen depends on the bril-

liance of the arc, which varies with the size of the electrode

and the volume of current. The shade for welding with me-

tallic electrodes with current values up to 300 amperes is

shade no. 10. Shade no. 12 is recommended for current val-

ues beyond 300 amperes and for shielded gas arc welding.

Good quality lenses are quaranteed to absorb 99.5

percent or more of the infrared rays and 99.75 percent or

more of the ultraviolet rays present. The lenses have ab-

sorbed 100 percent of these rays as reported in tests con-

ducted by the U.S. Bureau of Standards. The purchase of

cheap filter lenses is to be discouraged.

The side of the protective glass exposed to the weld

pool is protected by a clear polycarbonate plastic cover

lens. This is to protect the more costly filter lens from

molten metal spatter and breakage.

When the clear plastic cover becomes dirty from

smoke and fumes and pitted from weld spatter, it should

be replaced. Welding with clouded glass impairs vision Fig. 11-38 An electronic filter helmet improves productivity and

and causes eye strain. Many welders prefer to protect both reduces neck strain. Jackson Products

sides of the colored lens with a clear plastic cover.

Another type of head shield is shown in Fig. 11-37.

This differs from the others only in that it is equipped The helmet in Fig. 11-38 is an autodarkening elec-

with a flip front. The holder, which contains the pro- tronic filter helmet. It is useful when working in close

tective and clear cover lenses, flips up at a touch of the quarters, doing high production work, or where inad-

finger. A clear plastic cover in the stationary section pro- vertent arc strikes must be avoided. These helmets can

tects the eyes from hot scale when inspecting hot welds have a single shade or variable shades. The filter can

and from flying particles of slag and steel during clean- switch from light to dark in less than 1/10,000 (100 mil-

ing. This type is especially useful when working in close lionths) of a second. They are battery powered and may

quarters where it is difficult to raise the helmet. have a solar battery booster.

296Chapter 11Shielded Metal Arc Welding Principles

Safety Glasses

Whenever you are in the work area, safety glasses should

be worn. The practice of wearing them, Fig. 11-39, be-

hind the hood is an important safety precaution. This

is especially true in shops where there are a number of

welders working close to each other. It is almost impos-

sible under these conditions to prevent severe arc flash

reaching the eyes without safety glasses with side shields.

Safety glasses can absorb more than 99.9 percent of harm-

ful ultraviolet rays that can cause arc burn. The lenses are

usually made of a high impact polycarbonate material and

must meet ANSI Z87.1 standards. Welding with tinted or

dark lenses should be discouraged because it causes eye-

strain due to compounding the shading of the lens. Safety

glasses also protect the welders eyes while he or she is in-

specting the recently completed weld, chipping slag, wire

brushing, and grinding.

Goggles should also be worn by helpers, foremen, in-

spectors, and others who work with welders. The goggles

should be light in weight, well ventilated, and comfort- Fig. 11-40 An apron helps protect the welder from sparks

able. In order to protect the eyes from side glare, they and heat. Northeast Wisconsin Technical College McGraw-Hill

should be provided with tented side shields, and the lenses Education/Mark A. Dierker, photographer

should have a tint.

particles. Leather overalls may be worn with leather jack-

Protective Clothing ets. High-top shoes must always be worn when welding.

Gloves are necessary to protect the hands. Gloves are The feet and legs can be further protected by the use of

made of leather or some other type of fire-resistant ma- leggings and spats. Burns on the feet are quite painful, be-

terial. Leather capes, sleeves, shoulder garments with a come infected easily, and are slow to heal. Rolled sleeves

detachable bib, and aprons protect the clothing and body and turned up trouser cuffs provide lodging places for hot

of the welder from harm, Fig. 11-40. They are really metal and should be avoided.

necessary when the welder is called upon to do vertical The clothing of choice for welders should be 100 percent

and overhead work. If much of the work is to be done cotton or wool. Cotton denim shirt and pants are popular

in a sitting position, the welder should wear overalls or attire for todays welders as shown by a student welder in

a split-type apron, because full aprons form a lap for hot Fig.11-41. The clothing should be thick enough to prevent

injurious ultraviolet rays from penetrating to the skin. Shirts

should be long sleeve and button at the cuff. Shirttails are

Fig. 11-39 Wear your safety glasses even underneath your weld- Fig. 11-41 Thick clothing prevents injurious ultraviolet rays from

ing helmet. Miller Electric Mfg. Co. penetrating to the skin. Miller Electric Mfg. Co.

Shielded Metal Arc Welding Principles Chapter 11297

tucked into the welders pants and shirts should button to

the neck. The pants should be long enough so they cover

the top of the leather boots and they should not have cuffs.

However, at times it becomes necessary to wear further

protective clothing either for welding processes and/or po-

sitions. When this is the case, the welder has many options

to choose from to protect his or her skin from sparks and

hot globules of molten metal thrown out by the arc dur-

ing the welding operation. Figure 11-42 shows a student

welder who is well protected from sparks, rays, and heat.

However, the welder can be the best judge of the protective

clothing needed for the job.

Ear Protection

Because of the noise and possibility of hot weld spatter or

slag entering the ear canal, this area must be protected.

Either full ear muffs that cover the entire ear or simple ear

Leather Cap

Helmet

Fig. 11-43 A well-protected student welder. Note the platen

table, clamps, and the position of the fume extractor for optimum

protection. Miller Electric Mfg. Co.

Shoulder

Garment

plugs can be used. A welders cap with a bill on it can be

Welding used to deflect hot material away from the ear area.

Gloves

Fume Protection

Fig. 11-42 A well-protected student welder.Note the gloves,

helmet, skull cap, safety glasses, and fire-resistant jacket. Always use proper ventilation. When welding keep your

Northeast Wisconsin Technical College. McGraw-Hill Education/ head out of the fume plume. If this is not possible, use a

Mark A. Dierker, photographer fume extractor as in Fig.11-43, or a respirator.

CHAPTER 11 REVIEW

Multiple Choice c. Heat-resisting steels

Choose the letter of the correct answer. d. All of these

1. Shielded and metal arc electrodes are available to 3. The SMAW process is used for welding .

match the and of most metals. (Obj. 11-3)

(Obj. 11-1) a. Steel

a. Ductility and fatigue b. Tin

b. Density and plasticity c. Zinc

c. Properties and strength d. All of these

d. Stress and hardness 4. SMAW power sources are known as .

2. Metals most easily welded by the SMAW process (Obj. 11-4)

are . (Obj. 11-2) a. Constant voltage

a. Carbon and low alloyed steels b. Constant potential

b. Stainless steels c. Constant current

d. Constant output

298Chapter 11Shielded Metal Arc Welding Principles

5. A transformer-rectifier can supply . 10. The clothing a welder wears should be of

(Obj. 11-5) material. (Obj. 11-9)

a. a.c. power a. Cotton

b. DCEP power b. Wool

c. DCEN power c. Nylon

d. All of these d. Both a and b

6. Arc voltage is when . (Obj. 11-6)

Review Questions

a. The voltage is being generated between the elec-

trode and the work Write the answers in your own words.

b. The machine is on but idle; no welding is being 11. Name the four basic types of arc welding machines.

done Which type is used most? (Objs. 11-1 and 11-4)

c. The machine is off 12. What is the difference between an engine-driven

d. The machine is converting to volts generator welding machine and a transformer-

7. The duty cycle is the percentage of any given rectifier welding machine? Give the general use

minutes that a machine can operate at its of each. (Obj. 11-2)

rated current without overheating or breaking down. 13. Do a.c. welding machines have more wearing parts

(Obj. 11-6) than d.c. machines? Explain. (Obj. 11-4)

a. 10 14. Are d.c. welding machines capable of welding faster

b. 20 than a.c. machines? Explain. (Objs. 11-5 and 11-7)

c. 30

15. How is the output of an arc welding machine

d. 40

indicated? (Obj. 11-6)

8. A long welding arc . (Obj. 11-7)

16. List three advantages of a.c. arc welding. (Obj. 11-7)

a. Decreases amperage

b. Increases amperage 17. Explain the use of multiple-operator systems.

c. Increases voltage (Obj. 11-7)

d. Both a and c 18. How is the current delivered to the electrode and the

9. The size of an electrode holder must be in line with work? Explain. (Obj. 11-8)

the size of . (Obj. 11-8) 19. Compare the characteristics of engine-driven gener-

a. A welding machine ator, transformer, and transformer-rectifier welding

b. An electrode machines and inverters. (Obj. 11-9)

c. A cable 20. What device is used to hold the electrode? Give a

d. All of these general description of this device. (Obj. 11-9)

INTERNET ACTIVITIES

Internet Activity A

Use a search engine to find a company that sells videos about welding. If it has pho-

tos of various frames of the video, you can see, in color, what the welding process

looks like. Make a color drawing of the process you saw and describe it.

Internet Activity B

Look on the Internet to see if you can locate helmets. Now look for a helmet that

can be used for closed-in spaces that have little or no ventilation. Report on what

you found.

Shielded Metal Arc Welding Principles Chapter 11299

Você também pode gostar

- De Leon, Jennica L. DMET 2-2 - SMAW 2Documento5 páginasDe Leon, Jennica L. DMET 2-2 - SMAW 2Mark Jaynard SerranoAinda não há avaliações

- Ex-01 Study of WeldingDocumento10 páginasEx-01 Study of WeldingAryan BhatnagarAinda não há avaliações

- Power1 Chapter-7 PDFDocumento33 páginasPower1 Chapter-7 PDFEnyewAinda não há avaliações

- Welding: IntrdutionDocumento10 páginasWelding: IntrdutionJoseph George KonnullyAinda não há avaliações

- WeldingDocumento9 páginasWeldingDebanjali MajumderAinda não há avaliações

- PT Welding ReportDocumento11 páginasPT Welding ReportK38Aryya BhattacharyaCSBSAinda não há avaliações

- Arc Guided Protection Devices: Aishwarya RaviDocumento22 páginasArc Guided Protection Devices: Aishwarya RaviAishwarya RaviAinda não há avaliações

- css10 Week 5Documento8 páginascss10 Week 5lesterAinda não há avaliações

- M&e Electrical AccessoriresDocumento11 páginasM&e Electrical Accessorirespetroyston909937100% (5)

- Arc Welding-1Documento14 páginasArc Welding-1m9966822Ainda não há avaliações

- Welding: Training Partner-Chameli Devi Group of Institutions, Indore QP Name-Welding Technician Lavel-4Documento14 páginasWelding: Training Partner-Chameli Devi Group of Institutions, Indore QP Name-Welding Technician Lavel-4Bouzaida MaherAinda não há avaliações

- Chapter 3Documento14 páginasChapter 3Siva KumarAinda não há avaliações

- Splicing - Joining Electrical ConductorDocumento35 páginasSplicing - Joining Electrical ConductorMARY ANN NUCEJAAinda não há avaliações

- Electrode Converted Into TextDocumento14 páginasElectrode Converted Into TextNeha NimbarkAinda não há avaliações

- VD4 - Catalogue - EN - 1YHA000091 - REV G 04-2021Documento56 páginasVD4 - Catalogue - EN - 1YHA000091 - REV G 04-2021Rene AlogAinda não há avaliações

- Welcome YOU: Institute of Welding & Testing TechnologyDocumento66 páginasWelcome YOU: Institute of Welding & Testing TechnologyHimanshu MishraAinda não há avaliações

- Shielded Metal Arc WeldingDocumento7 páginasShielded Metal Arc WeldingSiraj JunaidAinda não há avaliações

- Fundamentals of Thermometry Measuring The Resistance of Standard Platinum Resi Stance ThermometersDocumento19 páginasFundamentals of Thermometry Measuring The Resistance of Standard Platinum Resi Stance ThermometerslizarazojavierAinda não há avaliações

- Dara Amelia Ula-D3 TL 2a-07Documento3 páginasDara Amelia Ula-D3 TL 2a-07Dara AmeliaAinda não há avaliações

- Under Water WeldingDocumento7 páginasUnder Water WeldingMishal SalemAinda não há avaliações

- ThermocouplesDocumento7 páginasThermocouplesMustafa HidayetAinda não há avaliações

- EX-OR 1212 Phy ProjectDocumento16 páginasEX-OR 1212 Phy Projectharish balajiAinda não há avaliações

- Ficha Tecnica Fusibles HHDocumento16 páginasFicha Tecnica Fusibles HHFRANCISCOAinda não há avaliações

- Unit Ii: EE 8602 Protection & SwitchgearDocumento12 páginasUnit Ii: EE 8602 Protection & Switchgeardecibel OchomAinda não há avaliações

- Types of Electrical InsulatorDocumento7 páginasTypes of Electrical InsulatorsathyaAinda não há avaliações

- Arc Tig 135 Welder Rev 2Documento28 páginasArc Tig 135 Welder Rev 2mike jonesAinda não há avaliações

- Core Faults in Large GeneratorsDocumento14 páginasCore Faults in Large GeneratorsKhusnul TaufikAinda não há avaliações

- Shielded Metal Arc Welding Principles: Chapter ObjectivesDocumento8 páginasShielded Metal Arc Welding Principles: Chapter ObjectivesWilly UioAinda não há avaliações

- PW POS Training MMA ENDocumento1 páginaPW POS Training MMA ENShaik Nizam UddinAinda não há avaliações

- Get Grounded: Protecting Electrical Devices From Lightning TransientsDocumento13 páginasGet Grounded: Protecting Electrical Devices From Lightning Transientsdigit133Ainda não há avaliações

- Unit 3 T&DDocumento44 páginasUnit 3 T&DAish KrishAinda não há avaliações

- Shielded Metal Arc Welding (Smaw)Documento45 páginasShielded Metal Arc Welding (Smaw)Eugenio Jr. MatesAinda não há avaliações

- Ampletek DeadbreakDocumento36 páginasAmpletek DeadbreakEko SusantoAinda não há avaliações

- Broco Underwater Wet Welding Operating Instructions 2017Documento6 páginasBroco Underwater Wet Welding Operating Instructions 2017Mishal SalemAinda não há avaliações

- Lightning ArresterDocumento18 páginasLightning ArresterDinesh Prasad SenapatiAinda não há avaliações

- CB Contact ResistanceDocumento5 páginasCB Contact ResistancechandraippaAinda não há avaliações

- 2.2 Shielded Metal Arc WeldingDocumento4 páginas2.2 Shielded Metal Arc WeldingMat SerabaiAinda não há avaliações

- Substation ReportDocumento23 páginasSubstation ReportLanz de la CruzAinda não há avaliações

- Written Assesment in Splicing - Joining Electrical ConductorDocumento9 páginasWritten Assesment in Splicing - Joining Electrical ConductorMARY ANN NUCEJA100% (1)

- Low Cost and Effective House WiringDocumento17 páginasLow Cost and Effective House WiringAkachi OkoroAinda não há avaliações

- For Neli BataDocumento23 páginasFor Neli BataLanz de la CruzAinda não há avaliações

- Product CatalogDocumento17 páginasProduct CatalogPower TechAinda não há avaliações

- Different Parameters of Overhead LinesDocumento8 páginasDifferent Parameters of Overhead LinesRohan Sharma75% (4)

- Topic-Vacuum Circuit Breaker: Guided byDocumento16 páginasTopic-Vacuum Circuit Breaker: Guided byshreyaAinda não há avaliações

- Training Module Manufacture TransformerDocumento91 páginasTraining Module Manufacture TransformerSanjeev Kadian100% (2)

- TVL SMAW11 Q2 M2 ModifiedDocumento9 páginasTVL SMAW11 Q2 M2 ModifiedJennylynAinda não há avaliações

- Arc N Gas ReportDocumento25 páginasArc N Gas ReportAnahAlhabshiAinda não há avaliações

- Make Your Own High Voltage ElectromagnetsDocumento15 páginasMake Your Own High Voltage Electromagnetsapi-3715567100% (21)

- Inductive Voltage Transformers Serie UEV, UEX, UEZ 123 To 765 KVDocumento6 páginasInductive Voltage Transformers Serie UEV, UEX, UEZ 123 To 765 KVOscar Francisco Astudillo Paillamilla100% (1)

- Lightning ProtectionDocumento15 páginasLightning ProtectionEnglish words BY Utkarsh johriAinda não há avaliações

- Daily Lesson Log 2Documento8 páginasDaily Lesson Log 2Emmanuel GallidoAinda não há avaliações

- Insulator Power TrueDocumento11 páginasInsulator Power TrueGary M TrajanoAinda não há avaliações

- WWWWQQQQQQQQQQQQQQDocumento33 páginasWWWWQQQQQQQQQQQQQQrigoberto otinianoAinda não há avaliações

- Transformer Design-01Documento21 páginasTransformer Design-01Anoop BhattacharyaAinda não há avaliações

- 320102cB SMAW-B - 1Documento32 páginas320102cB SMAW-B - 1Syaifur RohmanAinda não há avaliações

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionNo EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionAinda não há avaliações

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsAinda não há avaliações

- Joint Design, Testing, and Inspection: Chapter ObjectivesDocumento9 páginasJoint Design, Testing, and Inspection: Chapter ObjectivesWilly UioAinda não há avaliações

- Mance Qualification Tests. They Are Given To Find Out: 900 Chapter 28 Joint Design, Testing, and InspectionDocumento9 páginasMance Qualification Tests. They Are Given To Find Out: 900 Chapter 28 Joint Design, Testing, and InspectionWilly UioAinda não há avaliações

- Weld Discontinuities As Indicated On Radio-Graphic Film.: Fig. 28-39A-FDocumento8 páginasWeld Discontinuities As Indicated On Radio-Graphic Film.: Fig. 28-39A-FWilly UioAinda não há avaliações

- Mance Qualification Tests. They Are Given To Find Out: 900 Chapter 28 Joint Design, Testing, and InspectionDocumento9 páginasMance Qualification Tests. They Are Given To Find Out: 900 Chapter 28 Joint Design, Testing, and InspectionWilly UioAinda não há avaliações

- Common Sensors and Units of Measure: Table 27-2Documento7 páginasCommon Sensors and Units of Measure: Table 27-2Willy UioAinda não há avaliações

- Automatic and Robotic Arc Welding Equipment: Chapter ObjectivesDocumento7 páginasAutomatic and Robotic Arc Welding Equipment: Chapter ObjectivesWilly UioAinda não há avaliações

- Dual Robot Work Cell. Note The Robots Are Mounted Overhead For Easier Access To Welding JointsDocumento7 páginasDual Robot Work Cell. Note The Robots Are Mounted Overhead For Easier Access To Welding JointsWilly UioAinda não há avaliações

- © ITW Jetline - Cyclomatic: Weld ElevatorDocumento8 páginas© ITW Jetline - Cyclomatic: Weld ElevatorWilly UioAinda não há avaliações

- Inspection and Testing: © Plumbers and Pipefitters Union, Alton, ILDocumento8 páginasInspection and Testing: © Plumbers and Pipefitters Union, Alton, ILWilly UioAinda não há avaliações

- Power Punch: © Renee BohnartDocumento7 páginasPower Punch: © Renee BohnartWilly UioAinda não há avaliações

- Assortment of Hydraulic Tools Available To The Welder.: Power Press BrakesDocumento8 páginasAssortment of Hydraulic Tools Available To The Welder.: Power Press BrakesWilly UioAinda não há avaliações

- Fig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsDocumento7 páginasFig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsWilly UioAinda não há avaliações

- Power Punch: © Renee BohnartDocumento7 páginasPower Punch: © Renee BohnartWilly UioAinda não há avaliações

- © ITW Jetline - Cyclomatic: Weld ElevatorDocumento8 páginas© ITW Jetline - Cyclomatic: Weld ElevatorWilly UioAinda não há avaliações

- Assortment of Hydraulic Tools Available To The Welder.: Power Press BrakesDocumento8 páginasAssortment of Hydraulic Tools Available To The Welder.: Power Press BrakesWilly UioAinda não há avaliações

- Laser Assisted Arc Welding: Shop TalkDocumento8 páginasLaser Assisted Arc Welding: Shop TalkWilly UioAinda não há avaliações

- General Equipment For Welding Shops: Chapter ObjectivesDocumento8 páginasGeneral Equipment For Welding Shops: Chapter ObjectivesWilly UioAinda não há avaliações

- © Plumbers and Pipefitters Union, Alton, ILDocumento8 páginas© Plumbers and Pipefitters Union, Alton, ILWilly UioAinda não há avaliações

- Laser Assisted Arc Welding: Shop TalkDocumento8 páginasLaser Assisted Arc Welding: Shop TalkWilly UioAinda não há avaliações

- Wel 23 eDocumento7 páginasWel 23 eWilly UioAinda não há avaliações

- © Plumbers and Pipefitters Union, Alton, ILDocumento8 páginas© Plumbers and Pipefitters Union, Alton, ILWilly UioAinda não há avaliações

- High Energy Beams and Related Welding and Cutting Process PrinciplesDocumento8 páginasHigh Energy Beams and Related Welding and Cutting Process PrinciplesWilly UioAinda não há avaliações

- Gas Metal Arc Welding Practice:: Jobs 24-J1-J15 (Pipe)Documento9 páginasGas Metal Arc Welding Practice:: Jobs 24-J1-J15 (Pipe)Willy UioAinda não há avaliações

- Wel 23 ADocumento8 páginasWel 23 AWilly UioAinda não há avaliações

- Wel 22 FDocumento7 páginasWel 22 FWilly UioAinda não há avaliações

- Table 23-9: Impact Requirements of The Weld Deposit According To Classification For Submerged Arc FluxDocumento8 páginasTable 23-9: Impact Requirements of The Weld Deposit According To Classification For Submerged Arc FluxWilly UioAinda não há avaliações

- Table 23-9: Impact Requirements of The Weld Deposit According To Classification For Submerged Arc FluxDocumento8 páginasTable 23-9: Impact Requirements of The Weld Deposit According To Classification For Submerged Arc FluxWilly UioAinda não há avaliações

- Wel 23 CDocumento8 páginasWel 23 CWilly UioAinda não há avaliações

- Wel 23 BDocumento8 páginasWel 23 BWilly UioAinda não há avaliações

- Wel 22 eDocumento7 páginasWel 22 eWilly UioAinda não há avaliações

- ADS80 Datasheet enDocumento2 páginasADS80 Datasheet enCarlos Eduardo Plata CabreraAinda não há avaliações

- Inspection of CastingDocumento23 páginasInspection of CastingRaghu SanthAinda não há avaliações

- Narrative ParagraphDocumento7 páginasNarrative ParagraphCedie GatmaitanAinda não há avaliações

- Casio Qv-70b - 70c SM CamaraDocumento26 páginasCasio Qv-70b - 70c SM CamaraDoru RazvanAinda não há avaliações

- Polygon: Area Fill AlgorithmsDocumento29 páginasPolygon: Area Fill Algorithmsakshayhazari8281Ainda não há avaliações

- School of English : Tense RevisionDocumento3 páginasSchool of English : Tense RevisionLau VidelaAinda não há avaliações

- Easy-To-Use, Industrial Vision System For Automated Inspection ApplicationsDocumento2 páginasEasy-To-Use, Industrial Vision System For Automated Inspection ApplicationsEmilioSolkAinda não há avaliações

- Flat Design and ColorsDocumento53 páginasFlat Design and Colorsdulex100% (9)

- April 2021Documento64 páginasApril 2021Eric SantiagoAinda não há avaliações

- Knitted Toys PDFDocumento20 páginasKnitted Toys PDFMa2rina100% (2)

- Printing FaultsDocumento2 páginasPrinting FaultsAsad ChudharyAinda não há avaliações

- Nuts & Volts 25-11 - Nov 2004Documento108 páginasNuts & Volts 25-11 - Nov 2004blahblahname100% (3)

- How To Convert A Picture To Vector in Photoshop CS5Documento3 páginasHow To Convert A Picture To Vector in Photoshop CS5Kak UmiAinda não há avaliações

- How To Fix Blurry Images On Blogger in 2 WaysDocumento2 páginasHow To Fix Blurry Images On Blogger in 2 WaysRabail KhalidAinda não há avaliações

- LIST Exam Sem2 gr.9Documento10 páginasLIST Exam Sem2 gr.9Aboud AssafAinda não há avaliações

- How To Fix Usbc VirusDocumento3 páginasHow To Fix Usbc VirusRonillo PormonAinda não há avaliações

- Ewers Fisher 1989Documento13 páginasEwers Fisher 1989Gilberto Aleman SancheschulzAinda não há avaliações

- Juan Marques Mera Puerto RicoDocumento6 páginasJuan Marques Mera Puerto RicoAlvaro HuaytaAinda não há avaliações

- Secondary SourcesDocumento23 páginasSecondary SourcesVanessaAinda não há avaliações

- MilitaryIllustrated Modeler3-18Documento68 páginasMilitaryIllustrated Modeler3-18Prplknite100% (2)

- Camera Operation and Picture Composition: Co Rned, T Ey Coming Mo User Ndly. Some CameraDocumento11 páginasCamera Operation and Picture Composition: Co Rned, T Ey Coming Mo User Ndly. Some Cameraandrei neagAinda não há avaliações

- Photographing Food Intro Course 1 9Documento14 páginasPhotographing Food Intro Course 1 9teddy1967Ainda não há avaliações

- United States District Court: Criminal ComplaintDocumento5 páginasUnited States District Court: Criminal ComplaintAnonymous VSCG498eAinda não há avaliações

- Re-Cementing Lens Elements With Canadian Balsam.Documento6 páginasRe-Cementing Lens Elements With Canadian Balsam.MalaAinda não há avaliações

- Cezanne. Words and DeedsDocumento14 páginasCezanne. Words and DeedsLarisa OanceaAinda não há avaliações

- Barch Subject Wise 7 & 8 Semester 2019 PDFDocumento21 páginasBarch Subject Wise 7 & 8 Semester 2019 PDFAnamta ZehraAinda não há avaliações

- 3d Environment HandbookDocumento39 páginas3d Environment Handbookapi-278085794Ainda não há avaliações

- GQ StyleDocumento100 páginasGQ StyleDaniel ConradieAinda não há avaliações

- LloydsRegister Thermography in Condition AssessmentDocumento15 páginasLloydsRegister Thermography in Condition Assessmentho-faAinda não há avaliações

- Masks of Nyarlathotep - Characters PDFDocumento33 páginasMasks of Nyarlathotep - Characters PDFrodolfo.medvetAinda não há avaliações