Escolar Documentos

Profissional Documentos

Cultura Documentos

Patil V. P., Tathe R. D ., Devdhe S. J., Angadi S. S. and Kale S. H

Enviado por

AndriyaniTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Patil V. P., Tathe R. D ., Devdhe S. J., Angadi S. S. and Kale S. H

Enviado por

AndriyaniDireitos autorais:

Formatos disponíveis

Patil V. P. et al.

IRJP 2 (6) 2011 39-44

INTERNATIONAL RESEARCH JOURNAL OF PHARMACY ISSN 2230 8407

Available online http://www.irjponline.com

Review Article

ULTRA PERFORMANCE LIQUID CHROMATOGRAPHY: A REVIEW

1 1 2 2 3

Patil V. P. *, Tathe R. D ., Devdhe S. J. , Angadi S. S. and Kale S. H.

1

Department

2

of Pharmaceutical Analysis, Yash Institute of Pharmacy, Aurangabad, Maharashtra, India

3

Department of Pharmacology, Yash Institute of Pharmacy, Aurangabad, Maharashtra, India

Department of Pharmaceutical Chemistry, Yash Institute of Pharmacy, Aurangabad, Maharashtra, India

Article Received on: 09/04/2011 Revised on: 18/05/2011 Approved for publication: 10/06/2011

*Prof. Vandana P. Patil, Yash Institute of Pharmacy, Aurangabad-431134, Maharashtra, India.

E-mail: vandana2609@gmail.com

ABSTRACT

Ultra performance liquid chromatography (UPLC) takes advantage of technological strides made in particle chemistry performance, system

optimization, detector design and data processing and control. Using sub-2 mm particles and mobile phases at high linear velocities and

instrumentation that operates at higher pressures than those used in HPLC, dramatic increases in resolution, sensitivity and speed of analysis

can be obtained. This new category of analytical separation science retains the practicality and principles of HPLC while creating a step

function improvement in chromatographic performance. This review introduces the theory of UPLC and summarizes some of the most recent

work in the field.

KEYWORDS: UPLC, HPLC, Resolution, Sensitivity.

INTRODUCTION capillary electrophoresis due to low diffusion coefficients

UPLC refers to Ultra Performance Liquid in liquid phase, involving slow diffusion of

Chromatography. It improves in three areas: 1,2

analytes in the stationary phase. The Van Deemter

chromatographic resolution, speed and sensitivity equation shows that efficiency increases with the use of

analysis. It uses fine particles and saves time and smaller size particles but this leads to a rapid increase in

reduces solvent consumption. UPLC is comes from back pressure, while most of the HPLC system can

HPLC. HPLC has been the evolution of the packing

materials used to effect the separation. An underlying

principle of HPLC dictates that as column packing

particle size decreases, efficiency and thus resolution

also increases. As particle size decreases to less than

2.5m, there is a significant gain in efficiency and it

doesnt diminish at increased linear velocities or flow

rates according to the common Van Deemter equation.

By using smaller particles, speed and peak capacity

(number of peaks resolved per unit time) can be

extended to new limits which is known as Ultra

Performance. The classic separation method is of HPLC

(High Performance Liquid Chromatography) with many

advantages like robustness, ease of use, good selectivity

and adjustable sensitivity. Its main limitation is the lack

of efficiency compared to gas chromatography or the

IRJP 2 (6) June 2011 Page 39-

44

Patil V. P. et al. IRJP 2 (6) 2011 39-44

3 resistances than conventional particle-packed

operate only up to 400 bar. That is why short columns

4,5,6

filled with particles of about 2m are used with these columns.

PRINCIPLE

systems, to accelerate the analysis without loss of

The UPLC is based on the principal of use of stationary

efficiency, while maintaining an acceptable loss of

phase consisting of particles less than 2 m (while

load. To improve the efficiency of HPLC separations,

HPLC columns are typically filled with particles of 3 to

the following can be done:-

5 m). The underlying principles of this evolution are

i) Work at higher temperatures

governed by the van Deemter equation, which is an

ii) Use of monolithic columns

USE OF THE UPLC SYSTEM empirical formula that describes the relationship

Elevated-temperature chromatography also allows for between linear velocity (flow rate) and plate height

high flow rates by lowering the viscosity of the mobile (HETP or column efficiency). The Van Deemter curve,

phase, which significantly reduces the column back governed by an equation with three components shows

pressure. Monolithic columns contain a polymerized

porous support structure that provides lower flow that the usable flow range for a good efficiency with

small diameter particles is much greater than for larger

7,8 H=A+B/v+Cv

diameters. of disadvantages, which include a limited pH range and

tailing of basic analytes. Polymeric columns can

Where A, B and C are constants and v is the linear particles. Resolution is 70% higher than with 5 m

velocity, the carrier gas flow rate. The A term is particles and 40% higher than with 3.5 m particles. High

independent of velocity and represents "eddy" mixing. It speed is obtained because column length with 1.7 m

is smallest when the packed column particles are small particles can be reduced by a factor of 3 compared to 5 m

and uniform. The B term represents axial diffusion or particles for the same efficiency and flow rate can be three

the natural diffusion tendency of molecules. This effect times higher. The application of UPLC resulted in the

is diminished at high flow rates and so this term is detection of additional drug metabolites, superior

9,10

divided by v. The C term is due to kinetic resistance to separation and improved spectral quality.

equilibrium in the separation process. The kinetic SMALL PARTICLE CHEMISTRY

resistance is the time lag involved in moving from the The promises of the van Deemter equation cannot be

gas phase to the packing stationary phase and back fulfilled without smaller particles than those traditionally

again. The greater the flow of gas, the more a molecule used in HPLC. The design and development of sub-2 mm

on the packing tends to lag behind molecules in the particles is a significant challenge and researchers have

mobile phase. Thus this term is proportional to v. been active in this area for some time to capitalize on

Therefore it is possible to increase throughput and thus their advantages. Although high efficiency, non-porous

the speed of analysis without affecting the 1.5 mm particles are commercially available, they suffer

chromatographic performance. The advent of UPLC has from poor loading capacity and retention due to low

demanded the development of a new instrumental surface area. To maintain retention and capacity similar to

system for liquid chromatography, which can take HPLC, UPLC must use novel porous particles that can

advantage of the separation performance (by reducing withstand high pressures. Silica based particles have good

dead volumes) and consistent with the pressures (about mechanical strength, but can suffer from a number

8000 to 15,000 PSI, compared with 2500 to 5000 PSI in

HPLC). Efficiency is proportional to column length and

inversely proportional to the particle size18. Therefore,

the column can be shortened by the same factor as the

particle size without loss of resolution. Efficiency is

three times greater with 1.7 m particles compared to 5

m particles and two times greater compared to 3.5 m

IRJP 2 (6) June 2011 Page 39-

44

Patil V. P. et al. IRJP 2 (6) 2011 39-44

overcome pH limitations, but they have their own HPLC (3.0 to 4.6 mm), a consequence of frictional

issues, including low efficiencies and limited heating is the loss of performance due to temperature

capacities. In 2000, generation hybrid chemistry that induced non uniform. To minimize the effects of

took advantage of the best of both the silica and frictional heating, smaller

polymeric column worlds was introduced. Produced diameter columns (12.1 mm) are typically used for

11

using a classical sol- gel synthesis that incorporates UPLC.

carbon in the form of methyl groups, these columns are INSTRUMENTATION

Sample injection

mechanically strong with high efficiency and operate In UPLC, sample introduction is critical. Conventional

over an extended pH range. But, in order to provide the injection valves, either automated or manual, are not

kind of enhanced mechanical stability required for designed and hardened to work at extreme pressure. To

UPLC, a second generation bridged ethane hybrid protect the column from extreme pressure fluctuations,

(BEH) technology was developed. These 1.7 mm the injection process must be relatively pulse-free and

particles derive their enhanced mechanical stability by the swept volume of the device also needs to be minimal

bridging the methyl groups in the silica matrix. to reduce potential band spreading. A fast injection

Packing 1.7 mm particles into reproducible and rugged cycle time is needed to fully capitalize on the speed

columns was also a challenge that needed to be afforded by UPLC, which in turn requires a high sample

overcome. Requirements include a smoother interior capacity. Low volume injections with minimal carryover

surface of the column hardware, and re-designing the are also required to increase sensitivity. There are also

end frits to retain the small particles and resist clogging. direct injection approaches for biological samples.

12,13

Packed bed uniformity is also critical, especially if UPLC Column

shorter columns are to maintain resolution while Resolution is increased in a 1.7 m particle packed

accomplishing the goal of faster separations. In column because efficiency is better. Separation of the

addition, at high pressures, frictional heating of the components of a sample requires a bonded phase that

mobile phase can be quite significant and must be provides both retention and selectivity. Four bonded

considered. With column diameters typically used in phases are available for UPLC separations: ACQUITY

UPLCT M BEH C18 and C8 (straight chain alkyl Phenyl columns utilize a trifunctional C6 alkyl tether

columns), ACQUITY UPLC BEH Shield RP18 between the phenyl ring and the silyl functionality. This

(embedded polar group column) and ACQUITY UPLC ligand, combined with the same proprietary end capping

BEH Phenyl (phenyl group tethered to the silyl processes as the ACQUITY UPLC BEH C18 and C8

functionality with a C6 alkyl). Each column chemistry columns, provides long column lifetimes and excellent

provides a different combination of hydrophobicity, peak shape. This unique combination of ligand and end

silanol activity, hydrolytic stability and chemical capping on the 1.7 m BEH particle creates a new

interaction with analytes. dimension in selectivity allowing a quick match to the

ACQUITY UPLC BEH C18 and C8 columns are existing HPLC column. An internal dimension (ID) of

considered the universal columns of choice for most 2.1 mm column is used. For maximum resolution, choose

UPLC separations by providing the widest pH range. a 100 mm length and for faster analysis, and higher sample

They incorporate trifunctional ligand bonding throughput, choose 50 mm column. Half- height peak

chemistries which produce superior low pH stability. widths of less than one second are obtained with 1.7m

This low pH stability is combined with the high pH particles, which gives significant challenges for the

stability of the 1.7 m BEH particle to deliver the widest detector. In order to integrate an analyte peak accurately

usable pH operating range. ACQUITY UPLC BEH and reproducibly, the detector sampling rate must be high

Shield RP18 columns are designed to provide enough to capture enough data points across the peak. The

selectivities that complement the ACQUITY UPLC detector cell must have minimal dispersion (volume) to

BEH C18 and C8 phases. ACQUITY UPLC BEH preserve separation efficiency. Conceptually, the

IRJP 2 (6) June 2011 Page 39-

44

Patil V. P. et al. IRJP 2 (6) 2011 39-44

sensitivity increase for UPLC detection should be 2-3 take full advantage of the sub-2m particles. The sample

times higher than HPLC separations, depending on the manager also incorporates several technology

detection technique. MS detection is significantly advancements. Using pressure assisted sample

enhanced by UPLC; an increased peak concentration introduction, low dispersion is maintained through the

with reduced chromatographic dispersion at lower flow injection process, and a series of pressures transducers

rates promotes increased source ionization efficiencies. facilitate self-monitoring and diagnostics. It uses needle-

The ACQUITY UPLC System consists of a binary in-needle sampling for improved ruggedness and needle

solvent manager, sample manager including the column calibration sensor increases accuracy. Injection cycle

heater, detector, and optional sample organizer. The time is 25 seconds without a wash and 60 sec with a

binary solvent manager uses two individual serial flow dual wash used to further decrease carry over. A variety

pumps to deliver a parallel binary gradient. There are of micro titer plate formats (deep well, mid height, or

built-in solvent select valves to choose from up to four vials) can also be accommodated in a thermostatically

solvents. There is a 15,000-psi pressure limit (about 1000 controlled environment. Using the optional sample

bar) to organizer, the sample manager can inject from up to 22

micro titer plates. The sample manager also controls the

column heater. Column temperatures up to 65C can be

attained. To minimize sample dispersion, a pivot out

design allows the column outlet to be placed in closer

14

proximity to the source inlet of an MS detector.

For UPLC detection, the tunable UV/Visible detector is

used which includes new electronics and firmware to

support Ethernet communications at the high data rates.

Conventional absorbance-based optical detectors are

concentration sensitive detectors, and for UPLC use, the

flow cell volume would have to be reduced in standard

UV/Visible detectors to maintain concentration and

signal. According to Beers Law, smaller volume

conventional flow cells would also reduce the path

length upon which the signal strength depends. A

reduction in cross-section means the light path is

reduced, and transmission drops with increasing noise.

Therefore, if a conventional HPLC flow cell were used,

UPLC sensitivity would be compromised. The

ACQUITY Tunable UV/Visible detector cell consists of

a light guided flow cell equivalent to an optical fiber.

Light is efficiently transferred down the flow cell in an

internal reflectance mode that still maintains a 10mm

flow cell path length with a volume of only 500 ml.

Tubing and connections in the system are efficiently

routed to maintain low dispersion and to take advantage

of leak detectors that interact with the software to alert

15

the user to potential problems.

ADVANTAGES

Decreases run time and increases sensitivity.

IRJP 2 (6) June 2011 Page 39-

44

Patil V. P. et al. IRJP 2 (6) 2011 39-44

Provides the selectivity, sensitivity and dynamic UPLCs fast resolving power quickly quantifies

range of LC analysis. related and unrelated compounds.

Maintaining resolution performance. Faster analysis through the use of a novel separation

Expands scope of Multiresidue Methods. material of very fine particle size.

Operation cost is reduced. Biotransformation of new chemical entities (NCE) is

Less solvent consumption. necessary for drug discovery. When a compound reaches

Reduces process cycle times, so that more product the development stage, metabolite identification becomes

can be produced with existing resources. a regulated process. It is of the utmost importance for lab

Increases sample throughput and enables

to successfully detect and identify all circulating

manufacturers to produce more material that

consistently meet or exceeds the product metabolites of a candidate drug. Discovery studies are

specifications, potentially eliminating variability, generally carried out in vitro to identify major

failed batches or the need to re-work material. metabolites so that metabolic weak spots on the drug

Delivers real-time analysis in step with candidate molecule can be recognized and protected by

manufacturing processes. changing the compound structure.

Assures end-product quality, including final release

17

testing.

DISADVANTAGES

Due to increased pressure requires more maintenance

and reduces the life of the columns of this type. So far

performance similar or even higher has been

demonstrated by using stationary phases of size around

2 m without the adverse effects of high pressure. In

addition, the phases of less than 2 m are generally non-

regenerable and thus have limited use.

APPLICATIONS OF UPLC

Analysis of amino acids

UPLC used for accurate, reliable and reproducible

analysis of amino acids in the area of protein

characterization, cell culture monitoring and nutritional

analysis of foods.

Analysis of natural products and traditional herbal

medicine

UPLC is widely used for analysis of natural products and

herbal medicines. The main purpose of this is to analyze

drug samples arise from the complexity of the matrix and

variability from sample to sample. Purification and

qualitative and quantitative chromatography and mass

spectrometry are being applied to determine active drug

candidates and to characterize the efficacy of their

candidate remedies. UPLC provides high-quality

separations and detection capabilities to identify active

compounds in highly complex samples that results from

natural products and traditional herbal medicines.

Analysis of Levofloxacin in human plasma.

Identification of Metabolite

IRJP 2 (6) June 2011 Page 39-

44

Patil V. P. et al. IRJP 2 (6) 2011 39-44

Study of Metabonomics / Metabolomics and extra sensitivity allows peak detection for samples

Metabonomics studies are carried out in labs to generated by lower concentration incubations and sample

accelerate the development of new medicines. The pooling.

ability to compare and contrast large sample groups Bioanalysis/ Bioequivalence Studies

provides insight into the biochemical changes that For pharmacokinetic, toxicity, and bioequivalence

occur when a biological system is exposed to a new studies, quantization of a drug in biological samples is

chemical entity (NCE). Metabonomics provides a rapid an important part of development programs. The drugs

and robust method for detecting these are generally of low molecular weight and are tested

changes improves understanding of during both preclinical and clinical studies. Several

potential toxicity and allows biological matrices are used for quantitative

monitoring the efficacy. bioanalysis, the most common being blood, plasma and

ADME Screening urine.

ADME studies measure physical and biochemical Dissolution Testing

properties absorption, distribution, metabolism, For quality control and release in drug manufacturing,

elimination, and toxicity of drugs where such dissolution testing is essential in the formulation,

compounds exhibit activity against the target disease. A development and production process. In sustained-release

significant number of candidate medicines fall out of dosage formulations, testing higher potency drugs is

the development process due to toxicity. If toxic particularly important where dissolution can be the rate-

reactions or any side effect occurs in the limiting step in medicine delivery. The dissolution profile

discovery/development process, then it becomes more is used to demonstrate reliability and batch-to-batch

costly. It is difficult to evaluate candidate drugs for uniformity of the active ingredient. Additionally, newer

possible toxicity, drug-drug interactions, inhibition, and more potent formulations require increased analytical

and/or induction of metabolizing enzymes in the body. sensitivity.

Failure to properly identify these potential toxic events Forced Degradation Studies

can cause a compound to be withdrawn from the One of the most important factors that impacts the quality

market. The high resolution of UPLC enables accurate and safety of pharmaceuticals is chemical stability. The

detection and integration of peaks in complex matrices FDA and ICH require stability testing data to understand

how the quality of an API (active pharmaceutical meets, and hopefully exceeds, defined release

ingredient) or a drug product changes with time under the specifications. Continued monitoring of material stability is

influence of environmental factors such as heat, light, also a component of quality assurance and control. UPLC

pressure and moisture or humidity. Knowledge of these is used for the highly regulated, quantitative analyses

stability characteristics defines storage conditions and performed in QA/QC laboratories.

shelf life, the selection of proper formulations and Method Development / Validation

protective packaging and is required for regulatory According to FDA, validation is defined as establishing

documentation. Forced degradation or stress testing is documented evidence that provides a high degree of

carried out under even harsher conditions than those used assurance that a specific process will consistently produce a

for accelerated stability testing. product meeting its predetermined specifications and quality

Manufacturing/ QA/ QC attributes. Method development and validation is a time-

Identity, purity, quality, safety and efficacy are the consuming and complicated process: labs need to evaluate

important factors to be considered while manufacturing multiple combinations of mobile phase, pH, temperature,

a drug product. The successful production of quality column chemistries and gradient profiles to arrive at a

pharmaceutical products requires that raw materials meet robust, reliable separation for every activity. UPLC help in

purity specifications. That manufacturing processes critical laboratory function by increasing efficiency,

proceed as designed. That final pharmaceutical product reducing costs and improving opportunities for business.

IRJP 2 (6) June 2011 Page 39-

44

Patil V. P. et al. IRJP 2 (6) 2011 39-44

Impurity Profiling Compound Library Maintenance

For the drug development and formulation process, Confirming the identity and purity of a candidate

profiling, detecting, and quantifying drug substances and pharmaceutical is critical to effectively screening

their impurities in raw materials and final product chemical libraries that contain vast types of small

testing is an essential part. Impurity profiling requires molecules across a range of biological targets. Chemists

high-resolution chromatography capable of reliably and need to be sure they have synthesized the expected

reproducibly separating and detecting all of the known compound. In this high-throughput screening

impurities of the active compound. Also critical is the environment, the ability to obtain information in

ability to accurately measure low-level impurities at the multiple MS and UV detection modes in a single

same time as the higher concentration active injection is invaluable Combining fast analysis with

pharmaceutical component. UPLC System and Columns open-access software delivers the power of LC/MS to

specifically address high-throughput analysis chemists who are not analytical instrumentation

requirements while maintaining high peak resolution. specialists. A single complete system enables them

UPLC also involves the latest peak detection algorithms thoroughly screen a compound, from sample

and custom calculations to optimize data processing and introduction to end results.

reporting. It also confidently detects impurities in Open Access

compounds even at trace levels. Maximum efficiency is essential for analytical

laboratories that are constantly challenged to increase

throughput and deliver results to research chemists in

pharmaceutical discovery. UPLC and UPLC/MS

systems and software enable versatile and open

operation for medicinal chemistry labs, with easy-to-use

instruments, a user-friendly software interface, and fast,

robust analyses using UV or MS for nominal and exact

18,19,20

mass measurements.

CONCLUSION

UPLC increases productivity in both chemistry and

instrumentation by providing more information per unit of

work as it gives increased resolution, speed, and

sensitivity for liquid chromatography. The main

advantage is a reduction of analysis time, which also

meant reduced solvent consumption. The time spent

optimizing new methods can also be greatly reduced. The

time needed for column equilibration while using gradient

elution and during method validation is much shorter.

Sensitivity can be compared by studying the peak width

at half height. It was found that the sensitivity of UPLC

was much higher than that of conventional HPLC.

REFERENCES

1. Kondawar M. S; Ultra Performance Liquid Chromatography: A

Faster and Sensitive Method over HPLC; Available from:

http://www.pharmainfo.net/

2. Zhu C, Goodall DM, Wren SAC. Elevated Temperature HPLC:

Principles and Applications to Small Molecules and

Biomolecules. LCGC. 2005; 23(1):54-72.

IRJP 2 (6) June 2011 Page 39-

44

Patil V. P. et al. IRJP 2 (6) 2011 39-44

3. Michael E Swartz; UPLC: An introduction and review; ; Anal. Chem. Acta. 2004; 523:149156.

Journal of Liquid Chromatography & Related Technologies. 5. Tanaka N, Kobayashi H, Nakanishi K, Minakuchi H and

2005; 28: 1253-1263. Ishizuka N; Monolithic columns a new type of

4. Wu N, Dempsey J, Yehl PM, Dovletoglu A, Ellison A and chromatographic support for liquid chromatography; Anal.

Wyvratt J; Practical aspects of fast HPLC separations for

pharmaceutical process development using Monolithic

Columns

Chem. 2001; 73:420A429A. 1901.

6. Jerkovich AD, Mellors JS and Jorgenson J W; Uplc: An Sensitive 13. Swartz ME; Ultra Performance Liquid Chromatography

And High Throughput Analysis Over Hplc Mpy-322; (UPLC): An Introduction. Separation Science Re-Defined.

LCGC.2003; 21(7):600610. 2005; LCGC Supplement: 11.

7. Mac Nair JE, Lewis KC and Jorgenson JW; Ultrahigh-Pressure 14. Swartz ME; Ultra Performance Liquid Chromatography

Reversed-Phase Liquid Chromatography in Packed Capillary (UPLC): An Introduction, Separation Science Re-Defined.

Columns. Anal Chem. 1997; 69:983-989. 2005; LCGC Supplement: 13.

8. Mac Nair JE, Patel KD and Jorgenson JW; Ultrahigh-Pressure 15. Uttam Singh Baghel and et al; Ultra Performance Liquid

Reversed-Phase Capillary Liquid Chromatography: Isocratic and Chromatography: A Chromatography Technique; International

Gradient Elution Using Columns Packed with 1.0 mm Particles. Journal of Pharmaceutical Quality Assurance 2010; 2(1): 19-25.

Anal Chem. 1999; 71:700-708. 16. Gaikwad PV and et al; Ultra Performance Liquid

9. Wu N, Lippert JA and Lee ML; Practical aspects of ultra high Chromatography: A recent novel development in HPLC;

pressure capillary liquid chromatography; J. Chromatogr. A. Pharmacie Globale (IJCP). 2010; 2:08.

2001; A 911:112. 17. Swartz ME. UPLC: An Introduction and Review. J. Liq. Chrom.

10. Patel KN and et al; A Review: Ultra Performance Liquid 2005; 28:1253-1263.

Chromatography; International journal of biomedical research 18. Sherma Joseph, D John, Larkin and Frances H; UPLC: Ultra

and analysis. July-Aug 2010; volume 1 , issue 1:1-4. Performance Liquid Chromatography; Journal of AOAC

11. Swartz ME; Ultra performance liquid chromatography: International. 2005; May 1.

Tomorrows HPLC technology today. Lab Plus Int. 2004; 18(3): 19. Sikk P and et al; Ultra performance liquid chromatography

6-9. analysis of adenine nucleotide and creatine derivative for kinetic

12. Mc Loughlin DA, Olah TV, and Gilbert JD; A direct technique studies; Proceedings of the Estonian Academy of Sciences.

for the simultaneous determination of 10 drug candidates in 2009; 58(2):122-131.

plasma by liquid chromatography-atmospheric pressure chemical 20. Park DJ and et al; An improved UPLC method for analysis of

ionization mass spectrometry interfaced to a prospekt solid-phase Levofloxacin in human plasma; Chromatographia. 2008; 68,

extraction system; J. Pharm. Biomed. Anal. 1997; 15: 1893 August (No. 3/4): 187-192.

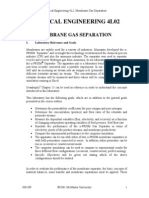

Table 1: Comparison between UPLC and HPLC16

Characteristics HPLC Assay UPLC Assay

Column 150 X 3.2 mm 150 X 2.1 mm

Particle size 3 to 5m Less than 2m

Flow rate 3.0 ml / min 0.6 ml / min

Needle wash Methanol Methanol

Injection volume 5L (Std.In 100 % MeOH) 2L(Std.In 100 % MeOH)

Column temperature 30 C 65 C

Maximum backpressure 35-40 MPa 103.5 MPa

T0 (25:75), T6.5 (25:75), T7.5 (95:5), T9

Gradient (time in min) ACN:H2O T0 (36:64), T1.1 (95:5), T1.3 (36:64)

(25:75), T10 (25:75)

Total run time 10min 1.5min

Total solvent consumption (including 0.5 Acetonitrile: 10.5 ml Acetonitrile: 0.53 ml

min of delay time in between injections) Water: 21.0 ml Water: 0.66 ml

Plate count 2000 7500

USP resolution 3.2 3.4

Delay volume 750 l 110 l

IRJP 2 (6) June 2011 Page 39-

44

Patil V. P. et al. IRJP 2 (6) 2011 39-44

UPLC mengacu Ultra Performance Liquid Chromatography. Hal ini meningkatkan di tiga bidang: resolusi kromatografi, kecepatan

dan analisis sensitivitas. Menggunakan partikel halus dan menghemat waktu dan mengurangi konsumsi pelarut. UPLC adalah

berasal dari HPLC. HPLC telah evolusi dari bahan kemasan yang digunakan untuk efek pemisahan. Prinsip yang mendasari HPLC

menyatakan bahwa ukuran kolom kemasan partikel menurun, efisiensi dan dengan demikian resolusi juga meningkat. Sebagai

ukuran partikel menurun hingga kurang dari 2.5m, ada keuntungan yang signifikan dalam efisiensi dan itu tidak mengurangi pada

peningkatan kecepatan linear atau laju aliran menurut persamaan Van Deemter umum. Dengan menggunakan partikel yang lebih

kecil, kecepatan dan kapasitas puncak (jumlah puncak diselesaikan per satuan waktu) dapat diperpanjang untuk batas baru yang

dikenal sebagai Ultra Performance. Metode pemisahan klasik dari HPLC (High Performance Liquid Chromatography) dengan

banyak keuntungan seperti ketahanan, kemudahan penggunaan, selektivitas yang baik dan sensitivitas disesuaikan. Ini Keterbatasan

utama adalah kurangnya efisiensi dibandingkan dengan kromatografi gas atau elektroforesis kapiler karena koefisien difusi yang

rendah dalam fasa cair, melibatkan difusi lambat analit dalam fase diam.

Van Deemter persamaan menunjukkan bahwa kenaikan efisiensi dengan penggunaan partikel ukuran yang lebih kecil tetapi ini

mengarah ke peningkatan pesat dalam tekanan balik, sementara sebagian besar sistem HPLC dapat beroperasi hanya sampai 400

bar.3 Itulah sebabnya kolom singkat diisi dengan partikel dari sekitar 2m yang digunakan dengan sistem ini, untuk mempercepat

analisis tanpa kehilangan efisiensi, sambil mempertahankan kerugian diterima beban. Untuk meningkatkan efisiensi pemisahan

HPLC, berikut ini dapat dilakukan: -

i) Bekerja di suhu yang lebih tinggi

ii) Penggunaan kolom monolitik

PENGGUNAAN HPLC SYSTEM

kromatografi peningkatan suhu juga memungkinkan untuk tingkat aliran tinggi dengan menurunkan viskositas fase gerak, yang

secara signifikan mengurangi kolom tekanan balik. kolom monolitik mengandung polimerisasi struktur pendukung berpori yang

memberikan resistensi aliran rendah dari columns.4,5,6 partikel-dikemas konvensional

IRJP 2 (6) June 2011 Page 39-

44

Você também pode gostar

- Patil V. P., Tathe R. D ., Devdhe S. J., Angadi S. S. and Kale S. HDocumento6 páginasPatil V. P., Tathe R. D ., Devdhe S. J., Angadi S. S. and Kale S. HNaomi Fenty Novita SimatupangAinda não há avaliações

- Review UPLCDocumento6 páginasReview UPLCepik01Ainda não há avaliações

- Ultra Performance Liquid Chromatography (Uplc) : A Modern Chromatography TechniqueDocumento23 páginasUltra Performance Liquid Chromatography (Uplc) : A Modern Chromatography TechniqueDhika RizqyAinda não há avaliações

- Ultra Performance Liquid ChromatographyDocumento8 páginasUltra Performance Liquid ChromatographyQudsia RehmanAinda não há avaliações

- UPLC: A Modern Chromatography Technique for Faster AnalysisDocumento23 páginasUPLC: A Modern Chromatography Technique for Faster Analysisburak__gulesAinda não há avaliações

- 20 UlpcDocumento23 páginas20 Ulpcsunil kaushikAinda não há avaliações

- Ultra Performance Liquid Chromatography (UPLC) - A Review: Austin Journal of Analytical and Pharmaceutical ChemistryDocumento5 páginasUltra Performance Liquid Chromatography (UPLC) - A Review: Austin Journal of Analytical and Pharmaceutical ChemistryFranklin Elard Zapana YucraAinda não há avaliações

- Comparative Study of New Trends in HPLCDocumento6 páginasComparative Study of New Trends in HPLCModAinda não há avaliações

- Uplc 2015Documento26 páginasUplc 2015Hanumant ChavanAinda não há avaliações

- Open Chemistry JournalDocumento16 páginasOpen Chemistry JournalbhavanaAinda não há avaliações

- Ultra Performance Liquid Chromatography Tomorrow's HPLC Technology TodayDocumento3 páginasUltra Performance Liquid Chromatography Tomorrow's HPLC Technology TodayxavikxavikAinda não há avaliações

- Review of Centrifugal Liquid-Liquid Chromatography Using Aqueous Two-Phase Solvent (ATPS) SystemsDocumento21 páginasReview of Centrifugal Liquid-Liquid Chromatography Using Aqueous Two-Phase Solvent (ATPS) SystemsNadeem AkramAinda não há avaliações

- RRLCDocumento26 páginasRRLCPolisetty GupthaAinda não há avaliações

- Overview of UPLC and UHPLC - Application in Pharmaceutical IndustryDocumento22 páginasOverview of UPLC and UHPLC - Application in Pharmaceutical IndustryAarti ombase100% (1)

- Fast-HPLC: University of HuddersfieldDocumento10 páginasFast-HPLC: University of HuddersfieldVishnu ShindeAinda não há avaliações

- UPLC vs HPLC AdvantagesDocumento1 páginaUPLC vs HPLC AdvantagesSARAHI MOGUEL PEREZAinda não há avaliações

- Ultra Performance Liquid Chromatography: Review ArticleDocumento11 páginasUltra Performance Liquid Chromatography: Review Articlechris ninaAinda não há avaliações

- Current Trends in UPLCDocumento15 páginasCurrent Trends in UPLCDiwya KumarAinda não há avaliações

- Improving LC-MS Sensitivity Through Increases in Chromatographic Performance: Comparisons of UPLC-ES/MS/MS To Hplc-Es/Ms/MsDocumento10 páginasImproving LC-MS Sensitivity Through Increases in Chromatographic Performance: Comparisons of UPLC-ES/MS/MS To Hplc-Es/Ms/MsgannysunAinda não há avaliações

- Columns of HPLCDocumento5 páginasColumns of HPLCvarshasunAinda não há avaliações

- HPLC TutorialDocumento5 páginasHPLC TutorialJai MurugeshAinda não há avaliações

- HPLCDocumento4 páginasHPLCAlbert BohrAinda não há avaliações

- Spectrometric TechniquesDocumento26 páginasSpectrometric TechniquesDon RajuAinda não há avaliações

- Artìculo HPLCDocumento5 páginasArtìculo HPLCleotatanAinda não há avaliações

- Chap 7 - HPLCDocumento23 páginasChap 7 - HPLCRezaul KarimAinda não há avaliações

- HPLC003 Adamas 10-2018-LRDocumento20 páginasHPLC003 Adamas 10-2018-LRchiralicAinda não há avaliações

- Lab Report 2 HPLCDocumento9 páginasLab Report 2 HPLCGissela BTAinda não há avaliações

- Column Aging Monolithes 01Documento17 páginasColumn Aging Monolithes 01Had_SnakeAinda não há avaliações

- A Review On High Performance Liquid Chromatography HPLCDocumento7 páginasA Review On High Performance Liquid Chromatography HPLCKAREN TATIANA RICO CARABALIAinda não há avaliações

- Columns and ChemistriesDocumento2 páginasColumns and Chemistrieshaha hahaAinda não há avaliações

- High Performance Liquid ChromatographyDocumento24 páginasHigh Performance Liquid ChromatographyMaame Ama Frempong100% (1)

- 4.4.4 High-Performance Liquid Chromatography (HPLC) : Using The Microscale Chromatography ColumnsDocumento2 páginas4.4.4 High-Performance Liquid Chromatography (HPLC) : Using The Microscale Chromatography ColumnsJuanAinda não há avaliações

- HPLC Related JournalDocumento5 páginasHPLC Related JournalMaruf RasselAinda não há avaliações

- Analytical Method Development and Validation For The Simultaneous Estimation of Ofloxacin and Metronidazole in Bulk and Dosage Form Using RP-HPLCDocumento12 páginasAnalytical Method Development and Validation For The Simultaneous Estimation of Ofloxacin and Metronidazole in Bulk and Dosage Form Using RP-HPLCBaru Chandrasekhar RaoAinda não há avaliações

- HPLC Mpat Sem1Documento28 páginasHPLC Mpat Sem1RAKSHA ARUNAinda não há avaliações

- Uhplc 20703007 Priya TiwariDocumento15 páginasUhplc 20703007 Priya TiwariPriya TiwariAinda não há avaliações

- Compounds Are Operated at This Range: 3.full Name of OOS & OOT ? Dercribe It With Details ? Why This Is Needed inDocumento10 páginasCompounds Are Operated at This Range: 3.full Name of OOS & OOT ? Dercribe It With Details ? Why This Is Needed inRohit SharmaAinda não há avaliações

- High-Performance Liquid Chromatography (HPLC) SystemDocumento3 páginasHigh-Performance Liquid Chromatography (HPLC) SystemJahrel DaneAinda não há avaliações

- High-Performance Liquid Chromatography (HPLC) SystemDocumento3 páginasHigh-Performance Liquid Chromatography (HPLC) SystemJahrel DaneAinda não há avaliações

- Gas-Liquid Mass Transfer in Bubble Column and Oscillatory Baf Ed Column Using Electrical Resistance Tomography (ERT)Documento5 páginasGas-Liquid Mass Transfer in Bubble Column and Oscillatory Baf Ed Column Using Electrical Resistance Tomography (ERT)rajuvadlakondaAinda não há avaliações

- Recent Applications of HPLC in Food Analysis: A Mini ReviewDocumento6 páginasRecent Applications of HPLC in Food Analysis: A Mini ReviewIjaems JournalAinda não há avaliações

- Ultra-Sensitive nanoLC-MS Using Second Generation Micro Pillar ArrayDocumento21 páginasUltra-Sensitive nanoLC-MS Using Second Generation Micro Pillar ArrayViorel_Iulian__2380Ainda não há avaliações

- 01 IntroductinDocumento57 páginas01 IntroductinPhariAinda não há avaliações

- LC by DesingDocumento12 páginasLC by DesingsudermanfitoAinda não há avaliações

- Estimation of Xipamide by Using HPLC in Pure and Pharmaceutical Dosage FormDocumento8 páginasEstimation of Xipamide by Using HPLC in Pure and Pharmaceutical Dosage FormBaru Chandrasekhar RaoAinda não há avaliações

- Original Paper Reduction in Delay Time of High-Dwell Volume Pumps in LC-MS Applications Using Short-Term Low-Ratio Split FlowDocumento7 páginasOriginal Paper Reduction in Delay Time of High-Dwell Volume Pumps in LC-MS Applications Using Short-Term Low-Ratio Split FlowOlga ĆalasanAinda não há avaliações

- High Performance Liquid Chromatography (HPLC)Documento16 páginasHigh Performance Liquid Chromatography (HPLC)Jojo ChanAinda não há avaliações

- UPLCDocumento33 páginasUPLCrat001Ainda não há avaliações

- Modernizing Acetamininophen Waters-UspDocumento11 páginasModernizing Acetamininophen Waters-UspmercedesAinda não há avaliações

- Ascentis Express 5 Micron - A Fused-Core Particle HPLC Column For Faster HPLC Separations With No Backpressure ConcernsDocumento2 páginasAscentis Express 5 Micron - A Fused-Core Particle HPLC Column For Faster HPLC Separations With No Backpressure ConcernsSuyog patilAinda não há avaliações

- HPLC separation techniquesDocumento9 páginasHPLC separation techniquesEssar MuhthaniAinda não há avaliações

- AnalysisDocumento30 páginasAnalysisSai SaiAinda não há avaliações

- Welch 2015Documento10 páginasWelch 2015Tran Minh NgocAinda não há avaliações

- HPLCC KDocumento6 páginasHPLCC Kfreskim.gashiAinda não há avaliações

- Membrane SeparationDocumento9 páginasMembrane SeparationDhananjay Kadam0% (1)

- Liquid Sample Introduction in ICP Spectrometry: A Practical GuideNo EverandLiquid Sample Introduction in ICP Spectrometry: A Practical GuideNota: 4 de 5 estrelas4/5 (6)

- Ultra-High Performance Liquid Chromatography and Its ApplicationsNo EverandUltra-High Performance Liquid Chromatography and Its ApplicationsAinda não há avaliações

- Analytical Characterization of BiotherapeuticsNo EverandAnalytical Characterization of BiotherapeuticsJennie R. LillAinda não há avaliações

- Pembahasan LainnyaDocumento77 páginasPembahasan LainnyaAndriyaniAinda não há avaliações

- 5 Erlina RustamDocumento5 páginas5 Erlina RustamPandi OiAinda não há avaliações

- 10 11648 J Ajce 20130103 12Documento7 páginas10 11648 J Ajce 20130103 12AndriyaniAinda não há avaliações

- Presentation Kimia UnsurDocumento24 páginasPresentation Kimia UnsurAndriyaniAinda não há avaliações

- Presentation Kimia UnsurDocumento24 páginasPresentation Kimia UnsurAndriyaniAinda não há avaliações

- Handbook of Instrumental Techniques For Analytical CHemistry - Fran A.Settle PDFDocumento728 páginasHandbook of Instrumental Techniques For Analytical CHemistry - Fran A.Settle PDFGuto Steinhorst100% (5)

- Presentation Kimia UnsurDocumento24 páginasPresentation Kimia UnsurAndriyaniAinda não há avaliações

- Presentation Kimia UnsurDocumento24 páginasPresentation Kimia UnsurAndriyaniAinda não há avaliações

- Presentation Kimia UnsurDocumento24 páginasPresentation Kimia UnsurAndriyaniAinda não há avaliações

- Ethics PresentationDocumento2 páginasEthics PresentationAbhinavGuptaAinda não há avaliações

- 7 Robert Boyle and Experimental Methods: © 2004 Fiona KisbyDocumento8 páginas7 Robert Boyle and Experimental Methods: © 2004 Fiona Kisbydaveseram1018Ainda não há avaliações

- Introduction to SONET and DWDM Digital Transmission StandardsDocumento35 páginasIntroduction to SONET and DWDM Digital Transmission StandardsOmar Ayoub100% (1)

- Rip Bushing PDFDocumento38 páginasRip Bushing PDFTravis Wood100% (1)

- Air Conditioner: PART No. 9380547105-02Documento4 páginasAir Conditioner: PART No. 9380547105-02Claudiu PopicaAinda não há avaliações

- QUANTUM TELEPORTATIONDocumento23 páginasQUANTUM TELEPORTATIONalkagabaAinda não há avaliações

- ZEISS CALYPSO 2021 Flyer Action Software Options ENDocumento2 páginasZEISS CALYPSO 2021 Flyer Action Software Options ENnaveensirAinda não há avaliações

- Tugas (UTS) ASPK - Andro Tri Julianda (95017019)Documento4 páginasTugas (UTS) ASPK - Andro Tri Julianda (95017019)محمد عزيرAinda não há avaliações

- UN 9252-06 Part 1-UD-AU-000-EB-00020 PDFDocumento7 páginasUN 9252-06 Part 1-UD-AU-000-EB-00020 PDFManjeet SainiAinda não há avaliações

- Phase-Field Models For The Evolution of Complex SystemsDocumento37 páginasPhase-Field Models For The Evolution of Complex SystemsMathis PlappAinda não há avaliações

- MD - Huzzatul Islam Contact Address: 01, International Airport Road, "Joar Sahara Bajar", APT # 13-F, Uttar Badda, Dhaka-1213, Bangladesh. Cell: +8801722223574Documento4 páginasMD - Huzzatul Islam Contact Address: 01, International Airport Road, "Joar Sahara Bajar", APT # 13-F, Uttar Badda, Dhaka-1213, Bangladesh. Cell: +8801722223574Huzzatul Islam NisarAinda não há avaliações

- SAP MM Purchase Info Record GuideDocumento3 páginasSAP MM Purchase Info Record GuidevikneshAinda não há avaliações

- Niche PartitioningDocumento3 páginasNiche PartitioningKhang LqAinda não há avaliações

- Katalog - Bengkel Print Indonesia PDFDocumento32 páginasKatalog - Bengkel Print Indonesia PDFJoko WaringinAinda não há avaliações

- Stanley I. Sandler: Equations of State For Phase Equilibrium ComputationsDocumento29 páginasStanley I. Sandler: Equations of State For Phase Equilibrium ComputationscsandrasAinda não há avaliações

- DLL - Mathematics 5 - Q1 - W4Documento9 páginasDLL - Mathematics 5 - Q1 - W4Avelino Coballes IVAinda não há avaliações

- A Fracture Mechanics Analysis of The Texture of Fried Potato Crust PDFDocumento7 páginasA Fracture Mechanics Analysis of The Texture of Fried Potato Crust PDFRomaric OuetchehouAinda não há avaliações

- 330 Computer Reset AddendumDocumento75 páginas330 Computer Reset AddendumA WongAinda não há avaliações

- Overhead Line Splices Automatic Copper: Splices For Metric ConductorDocumento27 páginasOverhead Line Splices Automatic Copper: Splices For Metric ConductorAzad RahmanAinda não há avaliações

- CSAT 2019 Spe3D Duguid - Andrew PDFDocumento111 páginasCSAT 2019 Spe3D Duguid - Andrew PDFdocturboAinda não há avaliações

- Unsaturated Polyester Resins: Chemistry and Technology: Piotr Penczek (U) Piotr Czub Jan PielichowskiDocumento2 páginasUnsaturated Polyester Resins: Chemistry and Technology: Piotr Penczek (U) Piotr Czub Jan Pielichowskiae0011979Ainda não há avaliações

- Grade 7 holiday assignment anagrams numbers analogiesDocumento4 páginasGrade 7 holiday assignment anagrams numbers analogies360MaRko oo.Ainda não há avaliações

- Mobil Dynagear Series Performance ProfileDocumento2 páginasMobil Dynagear Series Performance ProfileXavier DiazAinda não há avaliações

- Kadvani Forge Limitennnd3Documento133 páginasKadvani Forge Limitennnd3Kristen RollinsAinda não há avaliações

- Sheet No. 1: Roop LalDocumento6 páginasSheet No. 1: Roop LalzzzAinda não há avaliações

- Free Study PDF Download from pebexam BlogDocumento22 páginasFree Study PDF Download from pebexam Blogk_jaiswalAinda não há avaliações

- Certified Lead-Base White Metal AnalysisDocumento2 páginasCertified Lead-Base White Metal AnalysisIshmael WoolooAinda não há avaliações

- Openroads Designer User ManualDocumento112 páginasOpenroads Designer User ManualNilay BhavsarAinda não há avaliações

- Viking Tech ARG03FTC2551 - C217943Documento8 páginasViking Tech ARG03FTC2551 - C217943ALIRIO SOLANOAinda não há avaliações

- Latex WikibookDocumento313 páginasLatex Wikibookraul_apAinda não há avaliações