Escolar Documentos

Profissional Documentos

Cultura Documentos

Par 5.6

Enviado por

Anonymous iztPUhIi0 notas0% acharam este documento útil (0 voto)

6 visualizações1 páginaSEW

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

TXT, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoSEW

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato TXT, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

6 visualizações1 páginaPar 5.6

Enviado por

Anonymous iztPUhIiSEW

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato TXT, PDF, TXT ou leia online no Scribd

Você está na página 1de 1

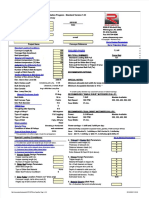

5.

6 implementation of production and construction and properties after welding

5.6.1 The general requirements in DIN 1690 Part 1

5.6.2 The choice of the filler metal is determined by the Stahlgu?sorte after co

nstructive Gegebenhei th, on the exposure and after the if appropriate intended

heat treatment after welding. Is annealed after welding, the weld must meet even

after annealing the demands on the mechanical properties of the base material.

Proven welding consumables are exemplified in Table 4.

5.6.3 The appropriate preheating temperature and intermediate between interpass

temperature depends. From Stahlgu?sor te, of the welding conditions of the wall

thickness and shape of the component With increasing internal stress level shoul

d be higher preheat who the chosen. For the cast steel according to this standar

d in wall thickness range 30 to 80 mm, the pre-and the interpass temperature are

at manual arc welding with basic must stick electrodes in the range of values ?

?according to Table 4.

Here, the interpass temperature, notwithstanding the provisions in DIN 32 524, d

efined as the tempera ture at the center of the weld bead before welding the nex

t location. The use of thermocouples to measure the colors interpass tempera tur

e is not permitted.

5.6.4 annealing after welding is in con

struktionsschwei?ungen in regard to the mechanical

Properties of the welded joints, except for the

Cast steel G17CrMo9-10 (1.7379) and GX4CrNi13-4

(1.4317) is not required. If, because of construction projects

regulations or structural reasons for a glow

the welding is concerned, should Gluhtempe

temperature at least 20 K, but no more than 50 K below the

applied annealing temperature of the casting are.

The applied annealing temperature is from Gu?stuckher

facturers specify.

Você também pode gostar

- Spheroidal Graphite (Nodular) Cast Iron:: Product Type Grade of Product Sub GradeDocumento5 páginasSpheroidal Graphite (Nodular) Cast Iron:: Product Type Grade of Product Sub GradeAnonymous iztPUhIiAinda não há avaliações

- Astm A 297Documento3 páginasAstm A 297friasdelacruz50% (2)

- PDF Design ImperialDocumento9 páginasPDF Design ImperialAnonymous iztPUhIiAinda não há avaliações

- BS 3100 1991Documento20 páginasBS 3100 1991Anonymous iztPUhIi100% (1)

- Welding Solutions: Selecting The Proper PositionerDocumento1 páginaWelding Solutions: Selecting The Proper PositionerAnonymous iztPUhIiAinda não há avaliações

- Induction Furnace Vs Electric Arc FurnaceDocumento1 páginaInduction Furnace Vs Electric Arc FurnaceAnonymous iztPUhIi100% (1)

- Elkem 10 Tundish Cover Ladle Nodularization PDFDocumento2 páginasElkem 10 Tundish Cover Ladle Nodularization PDFAnonymous iztPUhIiAinda não há avaliações

- Chance in BballDocumento12 páginasChance in BballAnonymous iztPUhIiAinda não há avaliações

- Working With The Cold Box ProcessDocumento21 páginasWorking With The Cold Box ProcessAnonymous iztPUhIiAinda não há avaliações

- Process Knowledge in FoundriesDocumento23 páginasProcess Knowledge in FoundriesAnonymous iztPUhIiAinda não há avaliações

- ISO 1940-2-1997 Mechanical VibDocumento20 páginasISO 1940-2-1997 Mechanical VibJavad Monfared100% (3)

- ISO 1940-2-1997 Mechanical VibDocumento20 páginasISO 1940-2-1997 Mechanical VibJavad Monfared100% (3)

- Steel Castings in Architecture and Engineering: Hans SchoberDocumento5 páginasSteel Castings in Architecture and Engineering: Hans SchoberAnonymous iztPUhIiAinda não há avaliações

- Sew 520Documento8 páginasSew 520Anonymous iztPUhIiAinda não há avaliações

- Solovastru Ioan L1Documento7 páginasSolovastru Ioan L1Anonymous iztPUhIiAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)