Escolar Documentos

Profissional Documentos

Cultura Documentos

Meter Tubes 3sec DS

Enviado por

Jose SonnetDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Meter Tubes 3sec DS

Enviado por

Jose SonnetDireitos autorais:

Formatos disponíveis

DAN-3MT-3M-08/01

May, 2002

3 Section and Flow Conditioning Plate Meter Tubes

Instruments You Can Trust

Daniel Meter Tubes are more than just fabricated pipe

with an orifice fitting. They are accurate, dependable

instruments because of Daniels dedicated approach to

quality. Extra steps taken during every phase of meter

tube design and production separate Daniel Meter

Tubes from all the rest.

The Daniel 3 section meter tube is available with any

style Senior or Junior orifice fitting, Simplex plate holder

or orifice flanges. The assembly contains an inlet spool

of the minimum length prescribed by the 14.3 standard.

The second section begins with a concentric, flange

mounted tube bundle meeting the 2000 API 14.3

requirements and a " thick spacer plate to ease tube

removal for inspection. The outer end of section 2 con-

tains the orifice flange or fitting. The third or downstream Features:

section follows and contains 2 branch connections and Dowel pin alignment, close tolerance male/female

is extra long to allow for the addition of extra branch con- flange or knock out dowel pins insure that the bores

nections in the field, if desired. The standard meter tube of sections two and three are matched without

has flanged outer ends (beveled shown). Other end offsets.

connections are available on request.

One " and one " branch connection on the

downstream for thermowell or other uses standard.

Inspection/Testing: Daniel maintains rigid inspection

procedures during manufacturing of meter tubes. Beveled, flanged or reduced ends as well as any

Micrometer and internal surface roughness readings are available weld fitting can be furnished on the ends of

recorded and supplied with each meter tube. Customer the tubes.

or third party inspectors are welcome to verify these

readings. Radiography of welds is another service that is Hydrostatically tested after manufacture.

available.

Each orifice fitting is tested for tap hole and orifice

plate seal integrity after the meter tube has been

Fabrication: Fabrication of your instrument includes pressure tested.

attaching the orifice fitting to the meter tube to make an

integral primary measuring element. For welding opera-

tions, Daniel uses automatic welding machines and rotat- Material Selection: Daniel uses special cold drawn

ing positioners. Highly skilled, "code qualified" welders seamless tubing or honed pipe in the fabrication of

are employed to turn out highest quality on each job. meter tubes. The strict requirements for internal round-

Special internal jigs and fixtures are used to insure ness and surface finish preclude the use of standard

smooth inlet and outlet surfaces without steps or offsets. commercial pipe in most cases. Daniel maintains a

All welds receive expert grinding by experienced crafts- large inventory of this special pipe to rapidly complete

men. your order.

DAN-3MT-3M-08/01

May, 2002

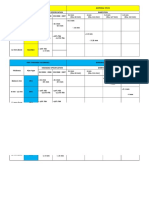

3 Section Meter Tube Catalog Numbers

2-12 with Senior Fitting 10 & 12 with Junior Fitting

Pressure Flange by Flange by Weld by Flange by Flange by Weld by

Rating Weld Flange Weld Weld Flange Weld

(Flangnek) (Flanged) (Weldnek)* (Flangnek) (Flanged) (Weldnek)*

150# 3M-011 3M-101 N/A 3M-021 3M-201 N/A

300# 3M-013 3M-103 N/A 3M-023 3M-203 N/A

600# 3M-015 3M-105 3M-185 3M-025 3M-205 3M-285

High Pressure 3 Section Meter Tubes

900# 3M-016 3M-106 3M-186 3M-026 3M-206 3M-286

1500# 3M-017 3M-107 3M-187 3M-027 3M-207 3M-287

2500# 3M-018 3M-108 3M-188 3M-028 3M-208 3M-288

2-8 with Simplex 2-12 with Orifice Flanges

Pressure Flange by

Rating Weld Weld by Weld Raised Face Weldneck

(Flangnek) (Weldnek)*

150# 3M-071 N/A N/A

300# 3M-073 N/A 3M-30RW

600# 3M-075 3M-705 3M-60RW

High Pressure High Pressure

900# 3M-076 3M-706 3M-90RW

1500# 3M-077 3M-707 3M-150RW

2500# 3M-078 3M-708 3M-250RW

*Two Section Meter Tubes When Using Weldnek Fittings

Senior and Simplex fittings are also available in 10,000 psi rating in some sizes. All units are also available with Ring

Type Joint (RTJ) flanges on request. Sizes larger than 12 available on request.

Packing/Shipping: Daniel bolts together all meter A SPECIAL NOTE: The use of factory original Daniel

tubes, when size permits, before shipment. This saves parts will assure your Senior, Junior and Simplex Orifice

the user time and field labor costs. Fittings are protect- fittings will stay within original specifications and operate

ed by heavy lumber, and the tube flanges by special-cut properly.

protectors.

Painting/Coating: The Daniel standard paint is a

basic enamel type. Special coatings such as multi-coat

offshore systems are available on request.

3-Section Meter Tube with Tube Bundle

U V D

1/2 3/4

Senior, Simplex,

Flange model tube bundle vane Junior Orifice Fitting

plus 1/2 thick spacer plate or Orifice Flange

Standard Lengths

Size U Upstream D Downstream V (vane location)

2* N/A N/A N/A

3 7-5 4-0 13 D

4 9-9 4-0 13 D

6 14-8 5-0 13 D

8 19-8 5-0 13 D

10 24-10 6-0 13 D

12 29-8 7-0 13 D

Note: Straightening vanes are not available in 2" line size (See Daniel Profiler

DAN-1852-2M)

Lengths shown are suitable for any piping configuration To specify a 3 section meter tube, use the designation

and up to .67 beta ratio. Daniel meter tubes can be sup- "3M" followed by the type orifice holding device. Ex. 4"

plied in many combinations and configurations. Any of 600# 3 section meter tube with flanged ends using a

the orifice fittings, plate holders or orifice flanges can be Senior fitting, flangneck style is specified as 4"-3M-015.

included in a meter tube. Each 3 section standard meter The same unit with a weldneck style Simplex is specified

tube is equipped with a flange mounted tube bundle as 4"-3M-705. When ordering, specify pipe schedule

straightener* in accordance with April 2000 API 14.3 and and end configuration. Larger size and custom meter

a " thick spacer to facilitate tube removal for inspection. tube designs are available on request.

Downstreams are longer than minimum required to allow

for field installation of additional branch connections if

required.

*Not available in some sizes/schedules.

The Daniel Flow Conditioning Plate three section lows and contains 2 branch connections. Other or addi

meter tube is available with any style Senior or Junior ori- tional connections can be supplied in this section on

fice fitting, Simplex plate holder or orifice flanges. The request. These meter tubes are for use in any piping con-

assembly contains an inlet spool of the minimum length figuration with beta ratios to .67. Downstream sections

determined during testing to the API 14.3 standard. The are extra long to allow for the addition of extra branch

flange union between the first and second sections con- connections in the field, if desired. The standard meter

tains the ProfilerTM and a " thick spacer plate to facilitate tube has beveled outer ends. Flanges or other end con-

tube removal for inspection. The outer end of section 2 nections are available on request.

contains the orifice flange or fitting. The third or down-

stream section fol

Flow Conditioning Plate Meter Tube Catalog Numbers

2-12 with Senior Fitting 10 & 12 with Junior Fitting

Flange by Flange by Weld by Flange by Flange by Weld by

Pressure

Weld Flange Weld Weld Flange Weld

Rating

(Flangnek) (Flanged) (Weldnek)* (Flangnek) (Flanged) (Weldnek)*

150# 3MP-011 3MP-101 N/A 3MP-021 3MP-201 N/A

300# 3MP-013 3MP-103 N/A 3MP-023 3MP-203 N/A

600# 3MP-015 3MP-105 3MP-185 3MP-025 3MP-205 3MP-285

2-8 with Simplex 2-12 with Orifice Flanges

Flange by Weld by

Pressure

Weld Weld Raised Face Weld Neck

Rating

(Flangnek) (Weldnek)*

150# 3MP-071 N/A N/A

300# 3MP-073 N/A 3MP-30RW

600# 3MP-075 3MP-705 3MP-60RW

*Two Section Meter Tube When Using Weldnek Fittings

Consult Factory for High Pressure Applications

Daniel Flow Conditioning Plate

The Daniel Flow Conditioning Plate has been tested and

shown to be in full compliance with the requirements of

API 14.3 April 2000. The Flow

Conditioning Plate both

removes swirl and

creates a fully

developed flow

profile at the

orifice. Use of

this unit allows

shortened

upstream straight

pipe lengths of 17

diameters. Beta ratio

limit is .67 as with the tube

bundle. Available in flange mounted model only. Also

available in RTJ style on request.

3-Section Meter Tube With Daniel

Flow Conditioning Plate

U D

P

1/2 3/4

Senior, Simplex,

Daniel Flow Conditioning Plate Junior Orifice Fitting

plus 1/2 spacer plate or Orifice Flange

Standard Lengths

Size U Upstream D Downstream "P" Profiler Locations

2 3-0 3-0 7.5 D

3 4-5 4-0 7.5 D

4 5-9 4-0 7.5 D

6 8-8 5-0 7.5 D

8 11-7 5-0 7.5 D

10 14-7 6-0 7.5 D

12 17-5 7-0 7.5 D

Lengths shown are suitable for any piping configuration To specify a 3 section Flow Conditioning Plate meter

and up to .67 beta ratio. Reference API 14.3, April 2000. tube, use the designation "3MP" followed by the type ori-

Daniel meter tubes can be supplied in many combina- fice holding device. Example 4" 600# 3 section meter

tions and configurations. Any Senior, Junior, Simplex or tube with beveled ends using a Senior fitting, flangneck

orifice flange can be included in a meter tube. Each Flow style is specified as 4"-3MP-015. The same unit with a

Conditioning Plate meter tube is equipped with a flange weldneck style Simplex is 4"-3MP-705. When ordering,

mounted Conditioning Plate and a " thick spacer* to specify pipe schedule and end configuration. Larger

facilitate tube removal for inspection. Upstream lengths size, higher pressure rating and custom meter tube

shown are minimum, but can be increased any amount designs are available on request.

to meet installation requirements. Downstreams are

longer than minimum to allow for field installation of addi-

tional branch connections if required.

*Not used with RTJ Style

DAN-3MT-3M-08/01

May, 2002

Orifice Fitting Styles Meter Tube End Modifications

Several common and frequently used end modifications

are shown here to illustrate

types available. Daniel

will custom build

risers, flanges,

ells, reducers and

couplings, expertly fab-

ricated to meet your

specifications. When

ordering special end

tube modfications,

please specify full

information for both upstream and

downstream tube sections.

Flanged

19 Tube Concentric Bundle

Available in either line mounted or

flange mounted styles. These

units effectively remove swirl

that has been introduced by

upstream piping

components. Individual

tubes and bundle diameter

are sized to meet the

requirements of API 14.3 April

2000. These units allow the use of

Flangnek a 29D upstream meter tube section in any piping

configuration with a .67 beta ratio limit.

Weldnek

Daniel Division Headquarters

Houston, Texas, USA, T: (713) 467-6000, F: (713) 827-3880

Calgary, Alberta, Canada, T: (403) 279-1879, F: (403) 236-1337

Stirling, Scotland - UK, Mid-East & Africa,T: +44 01786 433400, F: +44 01786 433401

Singapore - Asia Pacific, T: +65-6777-8211, F: +65-6770-8001

USA Toll Free 1-888-FLOW-001 www.daniel.com

Daniel is a wholly owned subsidiary of Emerson Electric Co., and a division of Emerson Process Management

The Daniel logo is a registered trademark of Daniel Industries, Inc. The Emerson logo is a registered trademark and service mark of Emerson Electric Co.

2002 Daniel Measurement and Control, Inc., all rights reserved. Printed in USA , DAN-3MT-5M-05/02

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Catalog Produk by List FlowmeterDocumento3 páginasCatalog Produk by List FlowmeterAhmad RifaiAinda não há avaliações

- Avk Ball Float ValveDocumento2 páginasAvk Ball Float ValveDota NgAinda não há avaliações

- BQ SewerageDocumento3 páginasBQ SewerageMuhammad Ghazali100% (1)

- Water Distribution SystemsDocumento32 páginasWater Distribution Systemsvishwas gowdaAinda não há avaliações

- Me2204 Unit Wise QuestionsDocumento18 páginasMe2204 Unit Wise QuestionsMohanraj Subramani0% (1)

- SAES-R-004 Sanitary SewersDocumento27 páginasSAES-R-004 Sanitary SewersWaqar AhmedAinda não há avaliações

- Design Report (Public Health)Documento10 páginasDesign Report (Public Health)subramanyam kumarAinda não há avaliações

- NDMC InvoiceDocumento1 páginaNDMC Invoicerchahar5963Ainda não há avaliações

- Storm Drainage Layout Plan Allen-RafaelDocumento1 páginaStorm Drainage Layout Plan Allen-RafaelVios, Allen Rafael M.Ainda não há avaliações

- Water Supply and Distribution SystemDocumento33 páginasWater Supply and Distribution SystemLeera Lee Adorablé100% (2)

- Rainwater Harvesting SystemDocumento19 páginasRainwater Harvesting SystemJaanaavi WasadeAinda não há avaliações

- Power Plant Engineering 2020Documento4 páginasPower Plant Engineering 2020Dos DosAinda não há avaliações

- PSV Back PressureDocumento2 páginasPSV Back PressureTon PhichitAinda não há avaliações

- 3.9 MM (Dia. 60 MM) 6 MM (Dia. 114 MM) 3.5 MM (Dia. 127 MM) 4.5 MM (Dia. 152 MM)Documento2 páginas3.9 MM (Dia. 60 MM) 6 MM (Dia. 114 MM) 3.5 MM (Dia. 127 MM) 4.5 MM (Dia. 152 MM)Sri HudiAinda não há avaliações

- Kaushaletal.2020 EURO MEDPublishedDocumento7 páginasKaushaletal.2020 EURO MEDPublishedAnonymous iTzCnMAinda não há avaliações

- Centrifugal Pumps - Single Impeller: Specifications Technical DataDocumento5 páginasCentrifugal Pumps - Single Impeller: Specifications Technical Dataسمير البسيونىAinda não há avaliações

- Instructions EN 2018Documento23 páginasInstructions EN 2018Athiphap SrisupareerathAinda não há avaliações

- Sustainable Water ManagementDocumento36 páginasSustainable Water ManagementHelder MbidiAinda não há avaliações

- Losses in Piping SystemDocumento5 páginasLosses in Piping SystemHemashwaryAinda não há avaliações

- API 6D-IsO 14313 23rd Edition Errata 6Documento3 páginasAPI 6D-IsO 14313 23rd Edition Errata 6adil_farooq_6100% (1)

- 01SA0S02Documento5 páginas01SA0S02raobabar21Ainda não há avaliações

- Design Response: Basiru Niang MATT NO: 220110014Documento6 páginasDesign Response: Basiru Niang MATT NO: 220110014Basiru NiangAinda não há avaliações

- Supplier Address: Note For Exact Price Please Inquire To The Given Contact PersonDocumento3 páginasSupplier Address: Note For Exact Price Please Inquire To The Given Contact PersonJohnCarloBernardoAinda não há avaliações

- Week 1 - Introduction - WatermarkDocumento40 páginasWeek 1 - Introduction - Watermark1pallabAinda não há avaliações

- Walworth Check ValvesDocumento24 páginasWalworth Check ValvesFahad RockingAinda não há avaliações

- All 115 1 Catalogo CNG 2011Documento36 páginasAll 115 1 Catalogo CNG 2011Sebastian OlayaAinda não há avaliações

- Sample of A Project Proposal - Water System ProjectDocumento4 páginasSample of A Project Proposal - Water System Projectrolandtrojas93% (226)

- Session 4B - Using Infrastructure Controls - Ziad MazboudiDocumento20 páginasSession 4B - Using Infrastructure Controls - Ziad MazboudiZiad MazboudiAinda não há avaliações

- 2021 HiMCM Problem BDocumento4 páginas2021 HiMCM Problem BLe Minh KhanhAinda não há avaliações

- ProVent IPC Comparison Manual LetterDocumento12 páginasProVent IPC Comparison Manual Letterjack j100% (1)