Escolar Documentos

Profissional Documentos

Cultura Documentos

Pilot's guide to aircraft power plant systems

Enviado por

BhaskerNegiTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pilot's guide to aircraft power plant systems

Enviado por

BhaskerNegiDireitos autorais:

Formatos disponíveis

PILOT TRAINING GUIDE POWER PLANT

Table of Contents

Introduction ....................................................................................................................... 18-1

Flat-Rated Thrust ..............................................................................................................18-1

Engine Construction.......................................................................................................... 18-2

Description .................................................................................................................. 18-2

Flow Distribution.................................................................................................... 18-2

Major Power Plant Components ........................................................................... 18-3

Engine Fuel System.......................................................................................................... 18-4

Description .................................................................................................................. 18-4

Components and Operation ........................................................................................ 18-4

Engine-Driven Fuel Pump ..................................................................................... 18-4

Fuel/Oil Heat Exchanger and Fuel Filter ............................................................... 18-4

Fuel Control Unit (FCU) ........................................................................................ 18-4

Electronic Control Unit (ECU) ............................................................................... 18-6

Fuel System Operation ......................................................................................... 18-6

Automatic Performance Reserve System ......................................................................... 18-7

Description .................................................................................................................. 18-7

Operation .................................................................................................................... 18-7

APR Test............................................................................................................... 18-7

Engine Oil System ............................................................................................................ 18-8

Description .................................................................................................................. 18-8

Components and Operation ........................................................................................ 18-8

Engine Oil Replenishment System...................................................................... 18-10

Engine Bleed Air System ................................................................................................ 18-12

Description ................................................................................................................ 18-12

Components and Operation ...................................................................................... 18-12

Engine Starting System .................................................................................................. 18-14

Description ................................................................................................................ 18-14

Components and Operation ...................................................................................... 18-15

Starter Control Valve ........................................................................................... 18-15

Air Turbine Starter (ATS) .................................................................................... 18-15

Start Sequence ................................................................................................... 18-16

Ignition System ............................................................................................................... 18-17

Description ................................................................................................................ 18-17

Operation .................................................................................................................. 18-17

Vibration Monitoring System ........................................................................................... 18-19

Description ................................................................................................................ 18-19

Operation .................................................................................................................. 18-19

For Training Purposes Only 18-i

May 03

POWER PLANT PILOT TRAINING GUIDE

N1 Fan ................................................................................................................. 18-19

N2 Core................................................................................................................ 18-19

Vibration Monitoring System Test ....................................................................... 18-19

Thrust Levers .................................................................................................................. 18-20

Description ................................................................................................................ 18-20

Operation .................................................................................................................. 18-20

Thrust Levers ...................................................................................................... 18-20

Thrust Reverser System ................................................................................................. 18-22

Description ................................................................................................................ 18-22

Operation .................................................................................................................. 18-22

Controls and Indicators ................................................................................................... 18-25

Engine Starting ......................................................................................................... 18-25

Engine Speed Controls ............................................................................................. 18-26

Thrust Levers ............................................................................................................ 18-27

Reverse Thrust ......................................................................................................... 18-28

Oil System........................................................................................................... 18-29

EICAS Primary Page ................................................................................................ 18-30

EICAS Messages...................................................................................................... 18-34

18-ii For Training Purposes Only

Jan 04

PILOT TRAINING GUIDE POWER PLANT

List of Figures

Graphic Title Figure

Flow Distribution ............................................................................................................... 18-1

Engine Fuel System - Schematic ...................................................................................... 18-2

ENGINE CONTROL Panel ............................................................................................... 18-3

ENGINE CONTROL Panel ............................................................................................... 18-4

Oil System Schematic ....................................................................................................... 18-5

Oil Replenishment System................................................................................................ 18-6

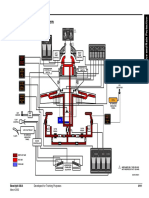

Engine Bleed Air System - Schematic .............................................................................. 18-7

Starting System - Schematic............................................................................................. 18-8

Engine Start/Ignition Panel ............................................................................................... 18-9

Ignition System ............................................................................................................... 18-10

ENGINE CONTROL Panel ............................................................................................. 18-11

Thrust Levers .................................................................................................................. 18-12

Thrust Reverser Operation ............................................................................................. 18-13

GND SPOILERS/THRUST REVERSER Panel .............................................................. 18-14

Engine Start/Ignition Panel ............................................................................................. 18-15

ENGINE CONTROL Panel ............................................................................................. 18-16

Thrust Levers .................................................................................................................. 18-17

GND SPOILERS/THRUST REVERSER Panel .............................................................. 18-18

Impending Bypass and Chip Detector Annunciators (JB-5)............................................ 18-19

N1 Indications .................................................................................................................18-20

ITT Indications ................................................................................................................18-21

N2 Indications .................................................................................................................18-22

Engine Secondary Indications ........................................................................................ 18-23

For Training Purposes Only 18-iii

May 03

POWER PLANT PILOT TRAINING GUIDE

Page Intentionally Left Blank

18-iv For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

CHAPTER 18: POWER PLANT

Introduction

The Challenger 604 is equipped with two General Electric CF34-3B high-bypass ratio

turbofan engines.

The dual-assembly engine consists of a fan rotor (N1) and a compressor rotor (N2). The

N1 rotor is comprised of a single-stage fan connected through a shaft to a four-stage

low-pressure turbine. The N2 rotor is a 14-stage axial flow compressor connected

through a shaft to a two-stage high-pressure turbine. The accessory gearbox is

mechanically driven by the N2 compressor.

Normal takeoff thrust rating is 8729 pounds per engine. During engine-out operation,

the automatic performance reserve (APR) system increases thrust on the operable

engine to 9220 pounds.

Flat-Rated Thrust

Outside air temperature and pressure altitude are determining factors in achieving

takeoff and APR power. Increases in ambient temperature or pressure altitude

adversely affect the engines ability to produce rated thrust. The CF34-3B is flat-rated

to ISA + 15C at sea level.

For Training Purposes Only 18-1

May 03

POWER PLANT PILOT TRAINING GUIDE

Engine Construction

Description

The CF34 power plant has two independently rotating major assemblies. The N1

section consists of a fan rotor that is driven through a shaft by a four-stage low-

pressure turbine. The N2 section is comprised of a 14-stage axial flow compressor, a

combustor, an accessory gearbox and a two-stage high-pressure turbine. The

compressor is driven by the high-pressure turbine.

Flow Distribution

Engine airflow passes through the single-stage fan and is divided into two airflow

paths:

Bypass Air - Air is accelerated by the single-stage N1 fan only and is ducted

around the engine nacelle. Bypass airflow produces approximately 80% of the

thrust at takeoff. Thrust reversers are used to divert the bypass air forward to assist

in airplane braking on the ground.

Core Air - Air that is accelerated by the N1 fan enters the N2 core where it is

compressed, mixed with fuel, and ignited. The resulting combustion gases are

exhausted through the high-pressure two-stage N2 turbine, which drives the N2

assembly. The exhaust gases are then discharged through the low-pressure four-

stage N1 turbine to drive the N1 fan. Jet pipe thrust produces approximately 20% of

the takeoff thrust.

IGN B

P604_18_002

N1 N2 IGN A

Bypass Air

Core Air

Flow Distribution

Figure 18-1

18-2 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

Major Power Plant Components

N1 Fan

The N1 fan is a single-stage fan that consists of 28 titanium blades. A Kevlar blanket is

wrapped around the inlet housing to contain damage from a failed fan blade. The N1

fan rpm is displayed on the EICAS primary page.

Variable Geometry (VG) Compressor

The VG system regulates airflow across the compressor by changing the position of

the compressor inlet guide vanes and the first five stages of the stator vanes. Fuel

metered by the Fuel Control Unit (FCU) is used to hydraulically change the vane

angle. The VG system optimizes the airflows angle of attack at the compressor blades

and provides compressor stall and surge protection.

Accessory Gearbox

The engine-mounted accessory gearbox is driven by the N2 compressor. The gearbox

drives the:

engine lubrication pumps

alternator that powers the N1 Control Amplifier

engine-driven hydraulic pump (Hydraulic Pump 1A or 2A)

engine-driven fuel pump

integral drive AC generator (IDG)

Mounted on the gearbox is the air turbine starter (ATS).

The N2 rpm is displayed on the EICAS primary page.

For Training Purposes Only 18-3

May 03

POWER PLANT PILOT TRAINING GUIDE

Engine Fuel System

Description

Fuel is delivered to the fuel injectors at pressures and flow rates required to maintain

the desired engine thrust. The engine fuel system, in addition to providing fuel for

combustion, is used for:

controlling and actuating the VG compressor linkage

cooling the engine oil (heat exchange)

actuating and lubricating servos within the Fuel Control Unit (FCU)

providing motive flow for the main ejector and scavenge ejector pumps

Combustion fuel can be interrupted by moving the thrust lever to SHUTOFF or by

selecting the engine FIRE PUSH switch/light. The SHUTOFF position shuts off the

fuel at the FCU. The FIRE PUSH switch/light closes the fuel shutoff valve.

Components and Operation

Engine-Driven Fuel Pump

The accessory gearbox-mounted fuel pump is comprised of three separate pumps

contained within a single housing. The engine-driven fuel pump provides high-

pressure fuel at a flow rate that exceeds the requirements of the engine at any power

setting. Fuel pump pressure is used to generate motive flow for the scavenge and main

ejectors of the aircraft fuel system.

Fuel/Oil Heat Exchanger and Fuel Filter

A fuel/oil heat exchanger is used to warm engine fuel and cool engine oil. The fuel

temperature at the fuel filter is indicated on the EICAS status page. A fuel filter is used

to remove solid contaminants from the fuel. If the filter becomes clogged, the fuel

bypasses the filter to ensure continued operation. A clogged filter is indicated by the

L(R) FUEL FILTER caution EICAS message.

Fuel Control Unit (FCU)

The fuel control unit is a hydromechanical metering device that supplies fuel in

response to mechanical inputs from the thrust levers. In addition, the FCU controls and

actuates the VG inlet guide vanes and stator vanes of the engine compressor.

During start and at low power, the FCU hydromechanically schedules the fuel.

18-4 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

N2

3500 FF 3500

VARIABLE 10 OIL PRESS 82

GEOMETRY

ACTUATOR

N1 SPEED

L FUEL FILTER FUEL CONTROL

CONTROL

UNIT

Filter

with P Engine-Driven

Indicator Pump

LEGEND

Bypass

Valve Motive Fuel

Supply

FUEL TEMP

Metered Fuel

80 ENGINE 80

20 BULK

Fuel Shutoff

Valve

Fuel Fuel/Oil Heat Mechanical

Temp Exchanger Connection

Sensor Electrical

LH ENG Connection

FIRE

Fuel PUSH Engine-Driven

Low-Pressure Pump Element

L FUEL LO PRESS Switch

Fuel

Shutoff Temperature

P604_18_006

Valve Probe

AIRCRAFT

Fuel Flow

FUEL

Note: Left Engine Illustrated Meter

SYSTEM

Engine Fuel System - Schematic

Figure 18-2

For Training Purposes Only 18-5

May 03

POWER PLANT PILOT TRAINING GUIDE

Electronic Control Unit (ECU)

When at high thrust settings, the engine is controlled by an electronic control unit

(ECU) which works in tandem with the FCU. The ECU is also referred to as the N1

control amplifier. The ECU (or N1 control amplifier) trims the FCU fuel output to

maintain a N1 speed schedule for a given thrust lever setting.

Fuel System Operation

N2 Speed Control (N1 < 79%)

At low power settings (N1 below 79%), the FCU hydromechanically controls the N2

speed. In N2 mode, the FCU adjusts N2 speed so that matched movement of the thrust

levers produces nearly matched N2 rpm for the engines. N1 speeds, fuel flows, or ITT

indications may differ between engines.

N1 Speed Control (N1 > 79%)

At takeoff, climb and cruise power settings (N1 above 79%), the N1 control amplifier

controls the engine N1 rpm. The amplifier trims the FCU fuel output to achieve the

desired N1 rpm.

With the ENG SPEED switches selected to ON, automatic switchover from N2 to N1

speed governing occurs at 79% N1. Matched movement of the thrust levers produces

nearly matched N1 rpm and nearly matched thrust between the engines.

NOTE

If an ENGINE SPEED switch is moved from ON to OFF at high

power settings, the engine will revert to N2 speed control. A rapid

increase in engine acceleration will occur and an

overtemperature limit may be exceeded.

ENG SPEED Switches

ENGINE CONTROL

TEST

ARM

A 1 TEST ON

OFF OFF

P604_18_020

TEST TE

TEST O

OFF OFF

3 2 LH RH

APR VIB ENG

SPEED

ENGINE CONTROL Panel

Figure 18-3

18-6 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

Automatic Performance Reserve System

Description

During takeoff, the APR system monitors the N1 rpm of both engines. If a significant

loss of N1 rpm is sensed on one engine, the APR system automatically increases the

thrust of the remaining engine to the APR thrust rating.

APR activation does not override thrust lever input to the FCU nor does it restrict

movement of the thrust lever.

Operation

The APR system is armed during takeoff when the APR switch is selected to ARM

and both engines N1 rpm is above 79% (N1 speed mode). This is indicated by the APR

ARM advisory EICAS message. During a normal takeoff, the advisory message is

removed five minutes after APR arming.

During takeoff, the APR system monitors the N1 rpm of both engines through the

DCUs. If an N1 rpm drop below 67.6% rpm is sensed at either engine, the system

automatically commands both engines to increase N1 speed. Only the normally

operating engine can respond, which it does by increasing the N1 fan speed by a

minimum of 2%. This increase in rpm equates to an increase of approximately 500

pounds of thrust. No roll-back in N1 rpm occurs when APR thrust has been

commanded and the APR system times-out.

When the APR system is activated, a green APR icon appears in the center of the N1

gauge of the operating engine.

APR Test

The APR TEST switches allow the system to be tested on the ground. The system can

only be tested successfully with the engines operating. Normal system test operation

results in the APR TEST 1 (2) (3) OK advisory EICAS message. If the system fails, an

APR INOP caution EICAS message is displayed.

APR Switches

ENGINE CONTROL

TEST

ARM

A 1 TEST ON

OFF OFF

P604_18_024

TEST TE

TEST O

OFF OFF

3 2 LH RH

APR VIB ENG

SPEED

ENGINE CONTROL Panel

Figure 18-4

For Training Purposes Only 18-7

May 03

POWER PLANT PILOT TRAINING GUIDE

Engine Oil System

Description

Oil from each engine nacelle tank is circulated under pressure to lubricate the engine

and accessory gearbox.

Components and Operation

The gearbox-driven main lubrication pump pressurizes the lubrication system. Oil

flows from the pump, through an oil filter, a fuel/oil heat exchanger and continues

through the engine sumps to the bearings and gearbox.

The oil is returned to the oil tank by the gearbox-driven main lubrication and scavenge

pumps. The oil passes through scavenge screens for filtering prior to the oil pumps.

The oil then flows through a chip detector and a deaerator to the tank. Maximum oil

consumption is 6.4 ounces or 0.05 US gallons/hour.

Engine oil pressure and temperature indications are presented on the EICAS primary

page. To provide system redundancy, a pressure switch and separate pressure

transmitter are used to monitor the engine oil pressure. When low oil pressure is

detected by the pressure switch, the L(R) ENG OIL PRESS warning EICAS message

is presented. If the pressure transmitter detects low oil pressure, the EICAS digital oil

pressure readout changes to red.

Chip detector and impending oil filter bypass indications are provided in the aft

equipment bay on Junction Box 5 (JB-5) but are not presented on EICAS.

Pressurized refilling of the engine oil tanks is provided by a replenishment tank system

located in the aft equipment bay. The system remotely gauges engine oil tank level and

is used to transfer oil to the engine-mounted tanks.

18-8 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

to Bearings

and Accessory

Gearbox

LEGEND

Oil Pump

Element

Differential

Pressure Scavenge

Switch/ 3500 FF 3500

Transmitter

10 OIL PRESS 82

Selector 115 OIL TEMP 115

Valve

Temperature

Sensor

Cooled

Supply

Scavenge L ENGINE OIL PRESS

Supply

ENGINE

Supply and OIL

Scavenge Pump

STORAGE

OIL TANK Fuel/oil Heat

Exchanger

Fuel

10 OIL PRESS 82

115 OIL TEMP 115

P604_18_004

1.2 FAN VIB 1.2 Oil Filter

to Other

Engine

Note: Left Engine Illustrated

REPLENISHMENT

OIL TANK

Oil System Schematic

Figure 18-5

For Training Purposes Only 18-9

Jan 04

POWER PLANT PILOT TRAINING GUIDE

Engine Oil Replenishment System

The Challenger 604 is equipped with an oil replenishment system located in the aft

equipment bay. The system consists of a replenishment tank holding approximately

6.0 U.S. quarts of oil, a pump, selector valve, and control panel.

If a low oil tank quantity is indicated during the test, the nacelle oil tanks can be filled

from the replenishment tank. Pump and selector valves, located next to the

replenishment tank, are used to transfer oil from the replenishment tank to the

applicable engine-mounted tank.

Engine Oil Replenishment Procedure

Oil levels should be checked between 15 minutes to two hours after engine shutdown.

The engines must be motored if the replenishment period is exceeded. Maximum refill

allowable is 2 U.S. quarts, then the engine must be dry-motored for at least 30 seconds

prior to adding more oil.

Oil replenishment is accomplished as follows:

1. Note the oil quantity on the oil replenishment tank gauge.

2. The system power switch is selected ON, illuminating the green ON light.

3. The ENG OIL PRESS TO TEST switch/light is activated to illuminate (test) the

green LH (RH)-FULL indications.

4. The selector valve is rotated to the L or R position as required to pump oil from the

oil replenishment tank to the associated engine oil tank

5. The selector valve is released when the pump automatically shuts off and the LH

(RH)- FULL legend illuminates. A full level is indicated by the illumination of the

respective side green light (LH FULL or RH FULL).

6. The system power switch is selected OFF.

7. Oil quantity used for each engine is noted.

18-10 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

Filter Cap

Engine Oil

ON

Replenishment

Tank

OFF Electric

Pump

ENG OIL

LH FULL

ON

RH FULL

PRESS

TO TEST

Oil Quantity

Indicator

OIL LEVEL Manual

CONTROL PANEL Selector

Valve

Note: AFT EQUIPMENT BAY

Engine oil level should be checked within 15 minutes to two hours after engine shutdown

The engines must be dry-motored if the replenishment period is exceeded.

Do not allow more than 1.9 liters (2 U.S. quarts) to flow into the engine without

dry-motoring the engine for at least 30 seconds (prior to adding more oil).

CONTROL SELECTOR CONTROL SELECTOR

PANEL VALVE PANEL VALVE

ON ON

R L R L Selector valve held to "L"

OFF OFF

position, oil pump running

ENG OIL System not ENG OIL

(LH tank being filled & RH

LH FULL Activated LH FULL

ON

RH FULL

ON

RH FULL

tank full)

PRESS PRESS

TO TEST TO TEST

ON ON

R L R L Selector valve held to "L"

OFF OFF

position, oil pump not

ENG OIL System power ENG OIL

running (LH tank is now full

LH FULL is on LH FULL

ON

RH FULL

ON

RH FULL

& RH tank full)

PRESS PRESS

TO TEST TO TEST

ON ON

R L System under test R L

OFF OFF

condition (RH & LH Selector valve

ENG OIL ENG OIL

indicator switch pressed released (both tanks

LH FULL LH FULL

ON system is functional) ON are full)

RH FULL RH FULL

PRESS PRESS

TO TEST TO TEST

ON ON

P604_18_018

R L R L

OFF Selector valve held to "R" OFF

ENG OIL position oil pump running ENG OIL System

LH FULL (RH tank being filled) LH FULL deactivated

ON ON

RH FULL RH FULL

PRESS PRESS

TO TEST TO TEST

ON

R L Selector valve held to "R"

OFF

position oil pump not

ENG OIL

running (RH tank is now

LH FULL

ON

RH FULL

full)

PRESS

TO TEST

Oil Replenishment System

Figure 18-6

For Training Purposes Only 18-11

May 03

POWER PLANT PILOT TRAINING GUIDE

Engine Bleed Air System

Description

Engine bleed air is extracted from the 7th, 10th and 14th stages of the engine

compressor and used by the airplane systems below:

7th stage: Pressurization of oil seals and the venting of engine sumps in the

lubrication system

10th stage: Pneumatic supply to the air conditioning and pressurization systems,

and engine starting

14th stage: Pneumatic supply to the engine cowl and wing anti-ice systems, or

thrust reverser systems

Components and Operation

Ducting and check valves are used to direct the flow of bleed air from the engine to the

10th- and 14th-stage bleed air manifolds. The nacelle and pylon ducts are monitored

for bleed air leakage by the engine fire and jet pipe overheat detection systems.

For additional information, refer to Chapter 9 Fire Protection and Chapter 19

Pneumatic System.

18-12 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

RW

e ing

i-Ic A

Ant nti-

ice

ing

LW

Left Right

Fuselage Fuselage

ISOL

L Wing R Wing

A/I Valve A/I Valve

L ACU R ACU

L Cowl R Cowl

A/Ice A/Ice

L T/R L 10th R 10th R T/R

PDU SOV ISOL SOV PDU

10th-Stage 10th-Stage

L Bleed R

ATS Air ATS

Ports

R 14th

14th-Stage LCV 14th-Stage

SOV

L 14th

SOV

APU

P604_18_008

External

Air Source

LEGEND

10th-Stage

Bleed Air

14th-Stage

Bleed Air

Engine Bleed Air System - Schematic

Figure 18-7

For Training Purposes Only 18-13

May 03

POWER PLANT PILOT TRAINING GUIDE

Engine Starting System

Description

The starting system consists of the starter control valve and the air turbine starter

(ATS). The air turbine starter drives the accessory gearbox, which in turn drives the N2

core section. DC electrical power and air from the 10th-stage bleed air manifold are

required to open the starter control valve and engage the air turbine starter.

The 10th-stage bleed air manifold can be pressurized by the:

APU

external air cart

10th-stage bleed air from the operating engine (crossbleed)

The following minimum bleed air pressures should be available for an engine start:

APU - 40 psi

External air start cart - 45 psi

Engine crossbleed - 60 psi (approximately 85% N2).

L(R)10th-stage bleed air manifold pressure is displayed on the EICAS status page.

CAUTION

During an engine crossbleed air start, ensure that intake

and exhaust areas of the operating engine are secure. When

starting engines in close quarters, consideration should be

given to the effects of jet blast.

Starter Starter

Control Control

L ACU

ACU R ACU

Valve Valve

10th- 10th-

STG STG

ATS ATS

L 10th 10th R 10th

SOV ISOL SOV

P604_18_003

LCV

External

Air Source APU

Starting System - Schematic

Figure 18-8

18-14 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

Components and Operation

Starter Control Valve

The starter control valve is mounted next to the air turbine starter (ATS) inside the

engine nacelle. It controls the initial rate of engine acceleration upon engagement of

the starter by regulating the amount of air supplied to the starter. The starter control

valve is controlled by the START and STOP switches on the START/IGNITION

panel.

Air Turbine Starter (ATS)

The air turbine starter (ATS) is mounted on the accessory gearbox. The ATS converts

pneumatic energy into mechanical motion. The starter mechanically engages the

accessory gearbox through a clutch, and accelerates the N2 section of the power plant.

The starter is capable of dry-motoring the engine up to approximately 28% N2 rpm.

During a normal start, the starter remains engaged until 55 % N2 to assist the engine in

accelerating to idle speed. At 55% N2 rpm, the starter control valve closes and the air

turbine starter disengages.

For subsequent starts or relights, the starter clutch does not require that engine rotation

be completely stopped before engaging the starter. The ATS may be engaged at any

rpm up to 55% N2 rpm (starter cutout speed).

Starter disengagement may be commanded at any time by pressing the engine STOP

switch/light.

L-ENG-R IGNITION

S S

T T ARM

A START START A A

R R ON

T T

ON

S S

T T ARM

STOP STOP B CONT

O O

ON

P604_18_022

P P

Engine Start/Ignition Panel

Figure 18-9

For Training Purposes Only 18-15

May 03

POWER PLANT PILOT TRAINING GUIDE

Start Sequence

Each engine has a set of START and STOP switch/lights on the ENGINE START/

IGNITION panel. When the engine START switch/light is pressed, the following

occurs:

left, right and isolation 10th-stage bleed air SOVs open

starter control valve on the associated engine opens to allow pressure from the

10th-stage manifold to engage the air turbine starter

when the starter control valve opens, a white light illuminates in the associated

START switch/light

at 55% N2 rpm, the start control valve is de-energized and the ATS disengages.

The ATS is subject to the following starter engagement limits:

START # ENGAGEMENT TIME COOLING PERIOD

1 30 seconds none

2 30 seconds none

3 & subsequent 30 seconds 5 minutes

DRY MOTORING # ENGAGEMENT TIME COOLING PERIOD

1 90 seconds 5 minutes

2 & subsequent 30 seconds 5 minutes

Starter Engagement Limitations

Table 18-1

Dry-Motoring

Dry-motoring is performed with ignition off and thrust levers at SHUTOFF.

Dry-motoring may be used for engine ground starts and engine airstarts.

18-16 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

Ignition System

Description

Two independent alternating current (AC) ignition systems are provided for each

engine. Each ignition system consists of one ignition exciter and one igniter plug.

Ignition system A is powered by the AC Essential Bus. Ignition system B is powered

by the Battery Bus through a static inverter.

Operation

There are three ignition system modes:

Normal - Prior to engine start, the ignition is armed by selecting either A or B ignition

switch/light at the START/IGNITION panel.When an ignition system is armed, the

corresponding white ARM light illuminates. Ignition is energized upon starter

engagement and is de-energized at starter cutout (55% N2). While an ignition system is

energized, the corresponding green ON light illuminates and the IGNITION A(B)

advisory EICAS message appears.

Continuous ignition - Continuous ignition may be selected by pressing the CONT

ignition switch/light at the START/IGNITION panel. Both ignitions A and B are

energized. When continuous ignition is selected, both green ON lights illuminate and

the IGNITION A/B advisory EICAS message appears.

Continuous ignition must be used during the following flight conditions:

takeoff and landings on contaminated runways

takeoff with high crosswind components (greater than 10 knots)

flight through moderate or heavier intensity rain

flight through moderate or heavier intensity turbulence

flight in the vicinity of thunderstorms

Auto-ignition (aerodynamic stall protection) - Automatic activation of continuous

ignition is based upon angle-of-attack (AOA) data. Both systems A and B are

energized by the stall warning computer and remain on until the airplane flight attitude

is corrected.

CAUTION

Activation of the Stall Protection System Test will activate

continuous ignition.

Both ignition systems A and B are disabled on the associated engine when the L (R)

ENGINE FIRE PUSH switch/light is selected. If continuous ignition was in use, the

white ON legend of the CONT switch/light will extinguish, but the green ON lights in

For Training Purposes Only 18-17

May 03

POWER PLANT PILOT TRAINING GUIDE

the switch/lights remain illuminated, and the IGNITION A/B advisory EICAS

message remains displayed (to advise the crew that continuous ignition is still active

on the unaffected engine).

L-ENG-R IGNITION

S S

T T ARM

A START START A A

R R ON

T T

ON

S S

T T ARM

STOP STOP B CONT

O O

P P ON

SPS

Both on Cont COMPUTER

A Circuit

B Circuit

P604_18_005

Ignition System

Figure 18-10

18-18 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

Vibration Monitoring System

Description

The power plant consists of two major rotating assemblies, the N1 fan and N2 core

sections. Each assembly is continuously monitored for vibration. Indications are

displayed on the EICAS primary page.

Operation

N1 Fan

N1 fan vibration is displayed as a numeric readout on the EICAS primary page as FAN

VIB. When the N1 vibration level is 2.7 mils or greater, the color of the readout

changes to amber. There is no associated caution EICAS message.

N2 Core

N2 core vibration levels are continuously monitored but are presented only when

vibration levels exceed a target value. An amber VIB icon appears in the middle of the

N2 gauge when the vibration target value is exceeded. There is no associated caution

EICAS message.

Vibration Monitoring System Test

The system is tested by selecting the VIB switch on the ENGINE CONTROL Panel to

the TEST position. In the TEST position, high vibration levels are simulated in the

electrical circuitry. The following indications appear on selection of the ENGINE VIB

test switch:

FAN VIB readouts increase to 3.6 mils, changing from green to amber, passing

through 2.7 mils

Amber VIB icons appear on the N2 dials

VIB Switch

ENGINE CONTROL

TEST

ARM

A 1 TEST ON

OFF OFF

P604_18_025

TEST TE

TEST O

OFF OFF

3 2 LH RH

APR VIB ENG

SPEED

ENGINE CONTROL Panel

Figure 18-11

For Training Purposes Only 18-19

May 03

POWER PLANT PILOT TRAINING GUIDE

Thrust Levers

Description

The thrust lever quadrant contains the thrust levers, thrust reverse levers, micro-

switches and internal locks and stops necessary to control the engines in forward and

reverse thrust.

Operation

Thrust Levers

Most functions of the thrust levers are conventional in operation. Thrust lever quadrant

settings are SHUTOFF, IDLE, and MAX POWER.

Mechanical Stop

A mechanical stop prevents the thrust levers from inadvertent movement. When the

thrust lever is at SHUTOFF, the thrust lever is mechanically locked in that position.

When the thrust lever is at idle, the mechanical stop prevents the thrust lever from

being accidentally moved to SHUTOFF. The mechanical stop is released by lifting the

idle/shutoff release latch on the thrust lever.

Friction Knobs

A friction knob allows the pilot to change the friction setting for the thrust levers.

Thrust Lever Position Measurement

Actual thrust lever positions are electrically measured by rotary variable differential

transformers (RVDTs) or sensed by microswitches that are housed within the thrust

lever quadrant. The information is provided to the N1 control amplifier, the flight

control computers (FCCs), and the data concentrator units (DCUs). Other aircraft

systems receive thrust lever position information, including:

landing gear warning system

takeoff configuration warning system

cabin pressurization

ground spoilers

Takeoff/Go-Around (TOGA) Switches

A takeoff/go-around switch is mounted on each thrust lever. When pressed, the TOGA

switch signals the flight control computers to activate flight director modes

accordingly.

18-20 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

Thrust Reverser Levers

The thrust reverse levers control the operation of the thrust reverser system. See the

thrust reverser description in this chapter for further details.

Thrust Levers, Left &

Right Engine

Takeoff/

Go-Around Switches

Thrust Reverser

Lever

Thrust Reverser

Trigger

Idle/Shutoff

Release Latches

P604_18_026

PO

W

M

ER

AX

IDL

E

SH

OF UT

F

IDL

E

Max

SH Power

OF UT

F

Idle

Thrust Lever Shutoff

Friction Adjustment

Thrust Levers

Figure 18-12

For Training Purposes Only 18-21

May 03

POWER PLANT PILOT TRAINING GUIDE

Thrust Reverser System

Description

The thrust reverser system is used to assist in stopping the aircraft on landing and

during a rejected takeoff (RTO). The system is operable on the ground only.

Operation

The thrust reversers are armed when the appropriate switches on the THRUST

REVERSER panel are selected to ARM and the respective 14th-stage bleed air shutoff

valves are opened. When armed, a L(R) REV ARMED EICAS advisory message is

displayed.

Reverse thrust is generated by blocking fan bypass airflow and redirecting it forward

through a series of cascade vanes. Bleed air from the 14th stage of the compressor

pneumatically activates a power drive unit (PDU), which mechanically moves the

engine translating cowls rearward by means of a flexible driveshaft and ballscrew

actuators. As the translating cowl moves rearward, blocker doors rotate to redirect fan

airflow forward through the cascade vanes.

Reverser deployment is accomplished by squeezing the thrust reverser triggers and

applying upward pressure on the thrust reverser levers. Thrust reverser lever

movement is initially restricted to approximately 20 degrees by a solenoid stop and a

reverse thrust lever lock. This locks the thrust lever in the IDLE position and prevents

thrust from being applied. When the translating cowl reaches full aft travel, the

solenoid stop is released, allowing the reverser lever to be operated through its full

range and reverse thrust to be applied.

During normal thrust reverser deployment, an amber REV icon appears in the engine

N1 gauge while the reverser is in transit. When the reverser is fully deployed, the REV

icon changes to green. Reverser deployment is achieved in approximately 5 seconds.

Anti-Ice Disable

On touchdown or during rejected takeoff with the wing and/or cowl anti-ice system

on, the anti-ice systems are automatically disabled while the thrust reversers are

activated. This disabling action redirects all 14th-stage bleed air to the thrust reverser

PDU to ensure proper operation.

18-22 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

Cascade Blocker Translating

Vanes Door Stowed Cowl

THRUST REVERSER

LEVER

Bypass

Airflow

Core

Airflow

Bypass

Airflow

NORMAL OPERATION

Bypass Blocker Door

Airflow Deployed

THRUST REVERSER

LEVER

Core

Airflow

P604_18_009

Bypass

Airflow

WITH REVERSER DEPLOYED

Thrust Reverser Operation

Figure 18-13

For Training Purposes Only 18-23

May 03

POWER PLANT PILOT TRAINING GUIDE

GND SPOILERS

ARM

AUTO

DISARM

L ARMED R ARMED

EMER STOW

UNLK UNLK

P604_18_023

L R

OFF OFF

THRUST

REVERSER

GND SPOILERS/THRUST REVERSER Panel

Figure 18-14

The thrust reverse system incorporates the following safety features:

In-flight protection - The reversers are locked out in flight. WOW (weight-on-

wheels) signals from the Proximity Sensing Electronics Unit (PSEU) or wheel

spin-up (from the anti-skid control unit) must be sensed in order to energize the

thrust reverser deploy relays

Flexshaft lockpin and lock cam - The reverse thrust PDU flexshaft is equipped

with a lock pin and lock cam, as well as a brake, which act to prevent

uncommanded travel of the reverser by more than 1/4 of an inch from the fully

stowed position

Auto stow - In the event of flexshaft lock cam failure resulting in uncommanded

movement of the thrust reverser away from the fully stowed position, the stow

solenoid will energize, and provided 14th-stage bleed air is available, the thrust

reverser will be returned to the fully stowed position

Automatic thrust lever retard system - An auto-retarding thrust lever

mechanism ensures that the thrust lever is at idle whenever the thrust reverser is in

transit. In flight, should a thrust reverser inadvertently deploy, the affected thrust

lever is automatically retarded to IDLE and locked to minimize asymmetric thrust

Emergency Stow - A thrust reverse emergency stow system is installed to stow an

unlocked thrust reverser. Selecting the respective UNLK switch/light on the

THRUST REVERSER panel directs 14th-stage bleed air to the PDU to stow the

unlocked reverser

NOTE

While the UNLK switch/light is selected, 14th-stage bleed air is

continuously applied to the PDU even if the reverser returns to

the stowed position.

18-24 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

Controls and Indicators

The CF 34-3B engine controls consist of the following:

Thrust levers

Thrust reversers

Engine start/Ignition panel

Engine control panel

The EICAS Primary and Secondary pages provide analog and digital engine

information and system warning/caution and advisory messages.

Engine Starting

IGNITION A (B) Switch/Lights L-ENG-R IGNITION CONTINUOUS IGNITION

(alternate-action) Switch/Light (alternate-

S S

Press - Arms associated T T ARM

action)

engine ignition system A

R

START START A

R

A Press - Manually energizes

ON

ARM Light T T ignition system A and B

Illuminated - Indicates ON ON Light

S S

associated ignition has been T T ARM

CONT

Illuminated - Indicates that

STOP STOP B

armed (IGN A (B) switch/light O

P

O

P ON continuous ignition is being

selected) supplied to both engines by

ON Light manual selection of the

Illuminated - Indicates CONT IGN switch/light or by

associated ignition is energized automatic activation by the

Note: IGN A or B switch/lights Stall Protection System

do not have to be armed for Computer

continuous ignition

L (R) ENGINE START Switch/Lights

Press momentary - Initiates engine start sequence

START Light

Illuminated - Indicates associated air turbine start (ATS) valve is open

L-ENG-R IGNITION

S S

T T ARM

A START START A A

R R ON

T T

ON

P604_18_012

S S

T T ARM

STOP STOP B CONT

O O

P P ON

L (R) ENGINE STOP Switches (momentary-action)

Press momentary - Stops the engine start sequence (acts as an ATS

cutout switch)

Engine Start/Ignition Panel

Figure 18-15

For Training Purposes Only 18-25

Jan 04

POWER PLANT PILOT TRAINING GUIDE

Engine Speed Controls

VIB Test Switch (spring-loaded to OFF)

OFF - Normal operating position

TEST :

!Performs a functional test of the vibration monitor

system

!N2 VIB icons appear

!FAN VIB reading displays 3.5 MILS

ENGINE CONTROL

TEST

ARM

A 1 TEST ON

OFF OFF

P604_18_011

TEST TE

TEST O

OFF OFF

3 2 LH RH

APR VIB ENG

SPEED

ENGINE CONTROL PANEL

APR Selector Switches L and R ENG SPEED Switches

TEST 1 (2) (3) - Tests respective APR circuit ON :

OFF - Disables APR system ! Enables N1 speed control when N1 rpm exceeds 79%

ARM - Arms APR system if both ENG SPEED ! Enables the automatic Performance Reverse (APR) system

switches are at ON OFF :

! Engine speed control is in N2 mode regardless of N1 rpm

NOTE: TEST 3 switch position is installed in a ! Disables the APR system

3-DCU configuration

ENGINE CONTROL Panel

Figure 18-16

18-26 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

Thrust Levers

Thrust Levers, Left & Right

Engine

Controls forward thrust and

acts as fuel shutoff. Takeoff/

Remains locked at idle Go-Around Switches

position during thrust Momentary pushbutton

reverser operation. switches. These Switches

are associated with Takeoff/

Note: In the event of an Go-Around mode of Flight

inadvertent thrust reverser Director system.

deployment, the thrust

reverser system will

mechanically drive the

applicable thrust lever to Thrust Reverser

the idle position. Lever

Thrust Reverser

Trigger

Idle/Shutoff

Release Latches

Lift to advance thrust

Thrust Settings

levers from shutoff to

Shutoff - Shuts off fuel to

idle positions or

engine at the FCU. Located at

PO

retard throttle levers

WE

MA

R

IDL

E rear thrust lever stop.

from idle to shutoff

Idle - Lowest forward thrust

positions. SH

OF UT Max

F

IDL

setting. Locate at idle throttle

E Power lever stop.

SH

OF UT

Max Power - Nominal forward

F Idle thrust setting. Located at

forward thrust lever stop.

Shutoff

Note: Interlocks are provided

Thrust Lever Friction to prevent inadvertent

P604_18_019

Adjustment movement of the levers from

Adjusts friction on thrust the idle to fuel shutoff positions

levers only. Rotate control (for forward flight) and from

clockwise to increase idle to reverse thrust.

friction.

Thrust Levers

Figure 18-17

For Training Purposes Only 18-27

May 03

POWER PLANT PILOT TRAINING GUIDE

Reverse Thrust

GND SPOILERS

L and R Thrust

Reverser ARMED

Switches

ARM

ARMED - Arms

AUTO

respective thrust

DISARM

reverser

OFF - Disables

respective thrust L ARMED R ARMED

reverser EMER STOW

L and R EMER STOW Switch/Lights

UNLK UNLK (alternate-action)

Press - Stows respective thrust reverser during

L R inadvertent deployment

OFF OFF

UNLK Light

THRUST Illuminated - Indicates associated:

REVERSER ! PDU unlocked,

! Flexshaft lock is released

P604_18_010

SPOILERS/THRUST REVERSER PANEL

! Thrust reverser away from the fully stowed

position, or

! in flight, the thrust reverser has moved more

than 1 1/4 away from the stowed position

GND SPOILERS/THRUST REVERSER Panel

Figure 18-18

18-28 For Training Purposes Only

May 03

PILOT TRAINING GUIDE POWER PLANT

Oil System

L & R Engine

Oil Tanks

(Chip detectors

located here)

5

JB

MASTER

CAUTION

TEST LH TEST RH RESET TEST RESET

LH RH LH RH

OIL FILTER OIL FILTER

LH RH LH RH

CHIP DETECT CHIP DETECT

P604_18_021

TEST OK

Effectivity Effectivity

A/C 5301 to 5356 per SB 604-79-00 A/C 5301 to 5356 per SB 604-79-00

MAGNETIC LATCHED LED FAULT FLAGS

FAULT FLAGS

! In view, white triangles indicate fault ! LED (red light) comes on to indicate

at applicable LH and/or RH engine fault at applicable LH and/or RH

oil system. engine oil system.

! Blank -system operational ! LED off - system operational

Impending Bypass and Chip Detector Annunciators (JB-5)

Figure 18-19

For Training Purposes Only 18-29

May 03

POWER PLANT PILOT TRAINING GUIDE

EICAS Primary Page

Takeoff N1

Readout and Bug

N1 RPM Digital and

Dial Readout

85.0 85.0

REV

N1

90.0 N1 Message Area

EICAS PRIMARY PAGE

Description Symbol Condition

Indicates fan speed in percent RPM and Takeoff N1

N1 RPM Digital and Dial readout.

Readout. Green - 0 to 98.5%

85.0 85.0

Takeoff N1 Readout and Red - 98.6

Bug (On aircraft 5301-5499 Bug range - 76 to 98.5% N1

and aircraft pre SB 604-34- N1 NOTE: Takeoff N1 readout removed automatically

031). 90.0

when airplane is at cruise altitude. Must be manually

reset for go-around.

98.8 98.8

N1 RPM is above 98.6%

N1

90.0

N1 Limit Readout and Bug 85.0 85.0

(On aircraft 5500 and Displays N1 limit for selected thrust setting

subsequent and aircraft

post SB 604-34-031) N1

90.0

CLB

Indicates selected thrust setting

Thrust Setting Display TO TO - Maximum Takeoff

CLB

CRZ

CLB - Maximum Climb

(On aircraft 5500 and MCT CRZ - Maximum Cruise

subsequent and aircraft APR MCT - Maximum Continuous Thrust

post SB 604-34-031) TGT

APR - Automatic Performance Reserve

TGT - Target (Pilot entered)

APR APR thrust has been commanded and achieved

N1 Message Area REV

P604_18_027

Thrust Reverser is in transit

REV Thrust Reverser is fully deployed

N1 Indications

Figure 18-20

18-30 For Training Purposes Only

Sept 04

PILOT TRAINING GUIDE POWER PLANT

EICAS PRIMARY PAGE

85.0 85.0

N1

90.0

650 910

HOT

ITT

Inter-Turbine Temperature (ITT) HOT Icon

Digital and Dial Readout

Description Symbol Condition

Indicates the temperature of the low pressure turbine

exhaust in C

650 650

(APR not activated scale)

Green - 0 to 899C

ITT Red - 900C

Indicates the temperature of the low pressure turbine

Inter-Turbine Temperature exhaust in C

650 650

(ITT) Digital and Dial (APR activated scale)

Readout Green - 0 to 927C

ITT Red - 928C

910 910

Indicates that ITT is above the maximum limit (900C)

ITT

650 650 Indicates that engine has a hot start; remains

P604_18_028

HOT Icon

displayed until engine is shut down and ITT reduces

HOT HOT below 220C

ITT

ITT Indications

Figure 18-21

For Training Purposes Only 18-31

May 03

POWER PLANT PILOT TRAINING GUIDE

EICAS PRIMARY PAGE

85.0 85.0

N1

90.0

750 750

ITT

90.0 90.0

VIB

N2

N2 RPM Digital and N2 Core Vibration

Dial Readout Message

Description Symbol Condition

Indicates maximum allowable compressor speed in

90.0 90.0 percent RPM

Green - 0 to 99.2%

Red - 99.3%

N2

Amber band - 0 to 77.9%

90.0 90.0 N2 RPM is above 78% and Wing Anti-Ice is

selected on.

N2

N2 RPM Digital and Dial

Readout

70.0 70.0 N2 RPM is less than 78% and Wing Anti-Ice is

selected on.

N2

99.6 99.6

N2 RPM is above 99.3%.

N2

90.0 90.0

N2 Core Vibration Message Displayed when N2 vibration is greater than 1.7 MILS

P604_18_029

VIB VIB

N2

N2 Indications

Figure 18-22

18-32 For Training Purposes Only

Jan 04

PILOT TRAINING GUIDE POWER PLANT

EICAS PRIMARY PAGE

90.0 90.0

Fuel Flow

Digital Readout

N2

Oil Pressure 3500 FF 3500

Digital Readout 82

82 OIL PRESS

Oil Temperature 115 OIL TEMP 115

Digital Readout 1.2 FAN VIB 1.2

- FUEL QTY - TOTAL 16770

FAN VIB

Digital Readout 4870 4890 4890

Symbol

2120

Description Symbol Condition

Fuel Flow Digital Readout 3500 FF 3500 Indicates fuel flow in pounds per hour (PPH)

(On aircraft 5301-5499 and

aircraft pre SB 604-34-031) 3500 FF 3500 Invalid data or fuel flow exceeds 5000 lbs/hr

3500 FF(PPH) 3500

Indicates fuel flow in pounds per hour (PPH) or

Fuel Flow Digital Readout kilograms per hour (KGH)

1590 FF(KGH) 1590

(On aircraft 5500 and

subsequent and aircraft

FF(PPH)

post SB 604-34-031) Invalid data or fuel flow exceeds 5000 lbs/hr or

2222 kg/hr

FF(KGH)

Oil pressure greater than 25 psi and less than or

82 OIL PRESS 82

equal to 115 psi

Oil pressure greater than 116 psi and less than or

120 OIL PRESS 120

Oil Pressure Digital equal to 155 psi

Readout

10 OIL PRESS 10 Oil pressure is less than or equal to 25 psi

10 OIL PRESS 10 Invalid data

Oil temperature greater than -40C and less than or

115 OIL TEMP 115

equal to 154C

Oil temperature greater than 155C and less than or

158 OIL TEMP 158

Oil Temperature Digital equal to 162C

Readout

169 OIL TEMP 169 Oil temperature is greater than 163C

115 OIL TEMP 115 Invalid data

1.2 FAN VIB 1.2 Fan vibration is 0 to less than or equal to 2.6 MILS

FAN VIB Digital Readout 3.0 Fan vibration is equal or greater than 2.7 MILS

P604_18_030

3.0 FAN VIB

. FAN VIB . Invalid data

Engine Secondary Indications

Figure 18-23

For Training Purposes Only 18-33

Jan 04

POWER PLANT PILOT TRAINING GUIDE

EICAS Messages

AURAL WARNING

MESSAGE MEANING

(IF ANY)

Left or right engine N1 or N2 or ITT above exceedance

ENGINE TRIPLE ATTENSON

level.

L ENG OIL PRESS

Oil pressure in the respective engine is less than 25 psi. ENGINE OIL

R ENG OIL PRESS

L ENG START SOV The respective start shutoff valve is not closed with that TRIPLE ATTENSON

R ENG START SOV engine running.

Either the APR has failed or it is not armed (APR to arm and N1 > 79% and both

APR INOP

eng speed switches on).

APR CMD SET APR has been inadvertently activated on both engines.

L ENG MISCOMP The engine comparator has sensed a discrepancy in the respective engine

R ENG MISCOMP parameters (N1, ITT or N2).

L FUEL FILTER

Respective fuel filter is in impending bypass mode.

R FUEL FILTER

L FUEL LO PRESS

Insufficient pressure at the respective engine pump inlet.

R FUEL LO PRESS

L REV UNLOCKED

Reverser moved away from fully stowed position without a deploy command.

R REV UNLOCKED

L REV UNSAFE

Unarmed thrust reverser received a deploy command.

R REV UNSAFE

APR ARM Aircraft in takeoff configuration, dynamic test OK.

APR TEST 1 OK

APR TEST 2 OK The respective APR circuit has passed the self-test.

APR TEST 3 OK

L ENG SOV CLSD Fuel shutoff valve is closed after activation of the respective ENG FIRE PUSH

R ENG SOV CLSD switch/light.

IGNITION A A igniters are activated, B igniters off.

IGNITION A/B Both A and B igniters are activated.

IGNITION B B igniters are activated, A igniters off.

L REV ARMED

The respective thrust reverser is armed.

R REV ARMED

DCU 1 APR FAIL

DCU 2 APR FAIL The respective DCU has failed its APR test.

DCU 3 APR FAIL

L ENG ECU FAIL

The respective engine ECU failed to respond to an APR test.

R ENG ECU FAIL

EICAS Messages

Table 18-2

18-34 For Training Purposes Only

Jan 04

Você também pode gostar

- GE CF34 Engine Training DocumentDocumento18 páginasGE CF34 Engine Training DocumentMadhan Ganesan100% (1)

- CFM56 5B SB Rev 72-1073 TSN.01 R 20200117Documento13 páginasCFM56 5B SB Rev 72-1073 TSN.01 R 20200117Irfan05Ainda não há avaliações

- Supplemental Corrosion Program for 737 Cargo Door ModificationDocumento59 páginasSupplemental Corrosion Program for 737 Cargo Door ModificationDanilo SoutoAinda não há avaliações

- Revision 12 March 31, 2013: ©2013 Gulfstream Aerospace CorporationDocumento2 páginasRevision 12 March 31, 2013: ©2013 Gulfstream Aerospace CorporationSantiago Hidalgo0% (1)

- CFM56 5B SB Rev 72-1094 TSN.00 N 20201216Documento42 páginasCFM56 5B SB Rev 72-1094 TSN.00 N 20201216Irfan05100% (1)

- Trent 800 Type CertificateDocumento7 páginasTrent 800 Type CertificateHelloWorldAinda não há avaliações

- CFM56 turbofan engines directoryDocumento5 páginasCFM56 turbofan engines directoryasdfknasfiojafAinda não há avaliações

- Pilatus Pc-Xii Initial Maintenance Training CourseDocumento442 páginasPilatus Pc-Xii Initial Maintenance Training CourseSabrina GrasielaAinda não há avaliações

- TES Engine Datapack (April 10)Documento49 páginasTES Engine Datapack (April 10)Ibraheem Sadiq100% (1)

- QRH 103Documento148 páginasQRH 103JAVIER TIBOCHAAinda não há avaliações

- PPH May2010Documento91 páginasPPH May2010Varghese AlexAinda não há avaliações

- Fokker EgpwsDocumento20 páginasFokker EgpwsHenry Blandon100% (1)

- RB211 Trent 500 Series TCDS Issue 02Documento9 páginasRB211 Trent 500 Series TCDS Issue 02makumba1972Ainda não há avaliações

- CFM56 5B SB Rev 72-1092 TSN.00 N 20201210Documento20 páginasCFM56 5B SB Rev 72-1092 TSN.00 N 20201210Irfan05Ainda não há avaliações

- FAA FSB Report for Textron Aviation HS-125 and BAE 125 Series AircraftDocumento65 páginasFAA FSB Report for Textron Aviation HS-125 and BAE 125 Series AircraftJuaco Zamb100% (1)

- Application Guides Aluminum Propeller Applications 1349891787Documento6 páginasApplication Guides Aluminum Propeller Applications 1349891787Wander GomesAinda não há avaliações

- Cessna Citation 500/501 Pilot's Technical Examination: CandidateDocumento16 páginasCessna Citation 500/501 Pilot's Technical Examination: Candidatealvaro2005100% (1)

- AIRPLANE GENERAL OVERVIEWDocumento41 páginasAIRPLANE GENERAL OVERVIEWmarcbigbossAinda não há avaliações

- GE Flight Ops Newsletter 2006Documento8 páginasGE Flight Ops Newsletter 2006Leslie WilliamsAinda não há avaliações

- Embraer ERJ145EPDocumento8 páginasEmbraer ERJ145EPTechcenter AssessoriaAinda não há avaliações

- Legacy 600 14500974Documento5 páginasLegacy 600 14500974cjtrybiecAinda não há avaliações

- Cf34-10e Colorization 011006Documento1 páginaCf34-10e Colorization 011006johala100% (1)

- JT8D Fuel SystemDocumento8 páginasJT8D Fuel SystemTrifi AJe JaenuriAinda não há avaliações

- PW500 Pilot Brief NotesDocumento32 páginasPW500 Pilot Brief NotesSonya McShark100% (1)

- Chapter 4: Powerplant: GeneralDocumento26 páginasChapter 4: Powerplant: GeneralMax powersAinda não há avaliações

- Williams Fanjet FamilyDocumento1 páginaWilliams Fanjet FamilyIon PopescuAinda não há avaliações

- G550 MTM 74Documento23 páginasG550 MTM 74stive100% (1)

- King Air BrochureDocumento40 páginasKing Air BrochureFran Garita100% (1)

- Pilatus Aircraft LTD PC 12NG JustTheFactsDocumento10 páginasPilatus Aircraft LTD PC 12NG JustTheFactsEmanuel Pop100% (1)

- Aerospace Actuators 2: Signal-by-Wire and Power-by-WireNo EverandAerospace Actuators 2: Signal-by-Wire and Power-by-WireAinda não há avaliações

- Extra 500 Maintenance Manual PDFDocumento626 páginasExtra 500 Maintenance Manual PDFOdilon Nascimento100% (1)

- CFM56 7B SB Rev 72-1050 TSN.00 N 20190613Documento15 páginasCFM56 7B SB Rev 72-1050 TSN.00 N 20190613media artupAinda não há avaliações

- D8 ATA 23 CommunicationsDocumento61 páginasD8 ATA 23 Communicationsrav100% (1)

- Hawker800XP Spec DescriptionDocumento32 páginasHawker800XP Spec Descriptiontomay77767% (3)

- Vol. 1 Auxiliary Power UnitDocumento22 páginasVol. 1 Auxiliary Power UnitRicardo GarciaAinda não há avaliações

- Acb G550 013Documento34 páginasAcb G550 013Marty SmallwoodAinda não há avaliações

- FJ33-5A Level 1Documento38 páginasFJ33-5A Level 1Maral HaghaniAinda não há avaliações

- GNS-XLS User ManualDocumento431 páginasGNS-XLS User ManualHoward Beck100% (2)

- DOCUMENT BLR-200-700 Wingtip and Winglet Installation ManualDocumento43 páginasDOCUMENT BLR-200-700 Wingtip and Winglet Installation ManualRene QueirozAinda não há avaliações

- 500 Series Technical Review October 2012Documento41 páginas500 Series Technical Review October 2012Melinda Hudson100% (1)

- 747Documento12 páginas747Lucky IsmailovAinda não há avaliações

- Ice and Rain Protection System: Beechjet 400A 4H-1Documento10 páginasIce and Rain Protection System: Beechjet 400A 4H-1Miguel Angel MartinAinda não há avaliações

- CF34-8C1/-8C5 Turbofan Technical Manual Index October 1, 2019Documento11 páginasCF34-8C1/-8C5 Turbofan Technical Manual Index October 1, 2019Oscar Alexander PérezAinda não há avaliações

- Model 250 C40BDocumento2 páginasModel 250 C40Bsnappish1Ainda não há avaliações

- 12 Ice RainDocumento10 páginas12 Ice RainBlueSkyMaster100% (2)

- A300-600 Airport Planning Guide RevisedDocumento192 páginasA300-600 Airport Planning Guide RevisedMahmoud Elbolkini100% (1)

- Atr 72Documento35 páginasAtr 72Tarik BenzinebAinda não há avaliações

- Complete DC-8 MM R36 Vol 1Documento832 páginasComplete DC-8 MM R36 Vol 1Belisario Llacchas rodasAinda não há avaliações

- 690B Systems Reference Guide PDFDocumento11 páginas690B Systems Reference Guide PDFBrian AdrianAinda não há avaliações

- A340 Flight Deck and Systems Briefing For PilotsDocumento211 páginasA340 Flight Deck and Systems Briefing For PilotsMa JoAinda não há avaliações

- Boeing 727 - 71 (Gen Fam)Documento15 páginasBoeing 727 - 71 (Gen Fam)ElLoko Martines100% (2)

- Cessna Citation X-ElectricalDocumento19 páginasCessna Citation X-ElectricalTony NicholasAinda não há avaliações

- CF34 10 CompIDMarchPrint PDFDocumento47 páginasCF34 10 CompIDMarchPrint PDFJulio Eme-ErreAinda não há avaliações

- Big Airplane Safety A Cessna 340 340a Buyers GuideDocumento12 páginasBig Airplane Safety A Cessna 340 340a Buyers Guidelolo laurent100% (1)

- B737-3 71-80 B1 e (Jun2005 CMP)Documento290 páginasB737-3 71-80 B1 e (Jun2005 CMP)mehdi100% (2)

- FLYFokker Fokker 70 Leaflet - 1Documento4 páginasFLYFokker Fokker 70 Leaflet - 1FredyBrizuelaAinda não há avaliações

- Introduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsNo EverandIntroduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsAinda não há avaliações

- Study Questions M 10.4 CAR AIR OPSDocumento2 páginasStudy Questions M 10.4 CAR AIR OPSBhaskerNegiAinda não há avaliações

- Car-M - Continuing Airworthiness Requirements - Issue 06 PDFDocumento359 páginasCar-M - Continuing Airworthiness Requirements - Issue 06 PDFsathishkesavaAinda não há avaliações

- 7b.study Questions M 10.7.2 Applicable National and International Requirements - AirworthinessDocumento2 páginas7b.study Questions M 10.7.2 Applicable National and International Requirements - AirworthinessBhaskerNegiAinda não há avaliações

- Car-Ml - Continuing Airworthiness For Light Weight Aircraft - Issue 03Documento27 páginasCar-Ml - Continuing Airworthiness For Light Weight Aircraft - Issue 03BhaskerNegiAinda não há avaliações

- EASA Form19 Part-66 Aircraft Maintenance License (AML) Application FormDocumento9 páginasEASA Form19 Part-66 Aircraft Maintenance License (AML) Application FormBhaskerNegiAinda não há avaliações

- Mod 05 - Digital Techniq QuestionsDocumento102 páginasMod 05 - Digital Techniq QuestionsKshitiz RastogiAinda não há avaliações

- Study Questions M 10.6 CAR MDocumento3 páginasStudy Questions M 10.6 CAR MBhaskerNegiAinda não há avaliações

- Mod 13Documento1 páginaMod 13BhaskerNegiAinda não há avaliações

- 7a.study Questions M 10.7.1 Applicable National and International Requirements - MaintenanceDocumento2 páginas7a.study Questions M 10.7.1 Applicable National and International Requirements - MaintenanceBhaskerNegiAinda não há avaliações

- A Study On The Technical Analysis of NSE Towards It Stocks With Reference To Indian Stock MarketDocumento8 páginasA Study On The Technical Analysis of NSE Towards It Stocks With Reference To Indian Stock MarketsettiAinda não há avaliações

- $$mod 05 Extras-1Documento102 páginas$$mod 05 Extras-1pandurang nalawadeAinda não há avaliações

- Maintain your aircraft's airworthiness with the CAA's guideDocumento81 páginasMaintain your aircraft's airworthiness with the CAA's guideBhaskerNegiAinda não há avaliações

- Essential guide to maintaining aircraft airworthinessDocumento81 páginasEssential guide to maintaining aircraft airworthinessBhaskerNegiAinda não há avaliações

- PDFViewerDocumento1 páginaPDFViewerBhaskerNegiAinda não há avaliações

- Papajohns TCenDocumento3 páginasPapajohns TCenBhaskerNegiAinda não há avaliações

- PDFViewerDocumento243 páginasPDFViewerBhaskerNegiAinda não há avaliações

- The Test of Predictive Power of "Moving Average" Indicator On Indian Stock Market Through System Design & Back Testing StrategyDocumento13 páginasThe Test of Predictive Power of "Moving Average" Indicator On Indian Stock Market Through System Design & Back Testing StrategyBhaskerNegiAinda não há avaliações

- UntitledDocumento6 páginasUntitledSujoy GhoshAinda não há avaliações

- Agusta AW109SP FM PDFDocumento1.056 páginasAgusta AW109SP FM PDFpilafAinda não há avaliações

- M13 Rev04 Unlocked PDFDocumento244 páginasM13 Rev04 Unlocked PDFBhaskerNegiAinda não há avaliações

- M13 Rev04 Unlocked PDFDocumento244 páginasM13 Rev04 Unlocked PDFBhaskerNegiAinda não há avaliações

- Training Pt6a 60 Series PDFDocumento270 páginasTraining Pt6a 60 Series PDFBhaskerNegi88% (8)

- Final EasaDocumento1 páginaFinal EasaBhaskerNegiAinda não há avaliações

- IASA Safety StandardsDocumento4 páginasIASA Safety StandardsBhaskerNegiAinda não há avaliações

- Module 5Documento73 páginasModule 5adi93% (15)

- Dgca Module 5 Hand Written Feb 2018 PDFDocumento6 páginasDgca Module 5 Hand Written Feb 2018 PDFBhaskerNegiAinda não há avaliações

- M07 Rev04 Unlocked-Compressed PDFDocumento233 páginasM07 Rev04 Unlocked-Compressed PDFBhaskerNegi100% (1)

- Dgca Module 5 Hand Written 02 Mar Jul 17 PDFDocumento6 páginasDgca Module 5 Hand Written 02 Mar Jul 17 PDF01ankuAinda não há avaliações

- Your Score: Test ResultsDocumento200 páginasYour Score: Test ResultsBhaskerNegiAinda não há avaliações

- Dgca Module 05 Part 06 PDFDocumento22 páginasDgca Module 05 Part 06 PDFBhaskerNegiAinda não há avaliações

- Ef TechnologyDocumento2 páginasEf TechnologyAdarsha SarpangalaAinda não há avaliações

- Code - Aster: Multiaxial Criteria of Starting in FatigueDocumento44 páginasCode - Aster: Multiaxial Criteria of Starting in FatigueYoyoAinda não há avaliações

- 11 Risks and Rates of Return KEYDocumento12 páginas11 Risks and Rates of Return KEYkAinda não há avaliações

- Timer Counter ArduinoDocumento8 páginasTimer Counter ArduinoKietDangAinda não há avaliações

- Acids and Bases NotesDocumento17 páginasAcids and Bases NotesNap DoAinda não há avaliações

- Flow Chart SymbolsDocumento7 páginasFlow Chart SymbolsAbhishekAinda não há avaliações

- Test 2Documento16 páginasTest 2edwardAinda não há avaliações

- Unit 6 - Quantitative Analysis NotesDocumento53 páginasUnit 6 - Quantitative Analysis Notesapi-182809945Ainda não há avaliações

- CFG Grammar: Context Free Grammar BasicsDocumento34 páginasCFG Grammar: Context Free Grammar BasicsEd MolloAinda não há avaliações

- 3-Lecture 03 Translational Mechanical System3-SDocumento23 páginas3-Lecture 03 Translational Mechanical System3-SHamza KhanAinda não há avaliações

- Chemical Equilibrium ExplainedDocumento42 páginasChemical Equilibrium ExplainedDedi WahyudinAinda não há avaliações

- The World of Chemistry Video Guide SetDocumento10 páginasThe World of Chemistry Video Guide SetrkvAinda não há avaliações

- PermutationDocumento3 páginasPermutationKhairuddin MuhamadAinda não há avaliações

- Treatment of Electroplating Wastewater Containing Cu2+, ZN 2+ and CR (VI) by ElectrocoagulationDocumento8 páginasTreatment of Electroplating Wastewater Containing Cu2+, ZN 2+ and CR (VI) by ElectrocoagulationAnonymous ZAr1RKAinda não há avaliações

- WPS PQR CompressedDocumento5 páginasWPS PQR CompressedBalaje MantravadiAinda não há avaliações

- Cost Estimation TechniquesDocumento41 páginasCost Estimation TechniquessubashAinda não há avaliações

- Eee f111 Electrical Sciences1Documento3 páginasEee f111 Electrical Sciences1aryan mittalAinda não há avaliações

- Introduction To Business Statistics: ProbabilityDocumento2 páginasIntroduction To Business Statistics: ProbabilityNghĩa PhùngAinda não há avaliações

- Paracetamol Overdose: BW 40 KG Without Fluid RestrictionDocumento2 páginasParacetamol Overdose: BW 40 KG Without Fluid RestrictionAndy TanAinda não há avaliações

- Solutions For Statistics and Probability For EngineersDocumento6 páginasSolutions For Statistics and Probability For EngineersPHAinda não há avaliações

- Ukur KadasterDocumento21 páginasUkur KadasterMuhammad NajmiAinda não há avaliações

- Harduaganj Thermal Power Plant by Geetesh SharmaDocumento66 páginasHarduaganj Thermal Power Plant by Geetesh Sharmageeteshaccurate100% (1)

- Daikin RXS-K - Technical DataDocumento21 páginasDaikin RXS-K - Technical DataPrestoneKAinda não há avaliações

- A Prediction of Water Quality Analysis Using Machine LearningDocumento6 páginasA Prediction of Water Quality Analysis Using Machine LearningmonacmicsiaAinda não há avaliações

- Viscosity Vs ConsistencyDocumento6 páginasViscosity Vs Consistencysontakke manmathAinda não há avaliações

- Fault Report - Inventory Cpf1 Vs Caño LimomDocumento37 páginasFault Report - Inventory Cpf1 Vs Caño LimomJessica RiveraAinda não há avaliações

- Auditing The Usage of Therapeutic Footwear in Diabetic Foot Patients Through Amit Jain's Extended SCC' Classification For Therapeutic FootwearDocumento6 páginasAuditing The Usage of Therapeutic Footwear in Diabetic Foot Patients Through Amit Jain's Extended SCC' Classification For Therapeutic FootwearJosé MorenoAinda não há avaliações

- Failure Mode For Gas CHromatographDocumento2 páginasFailure Mode For Gas CHromatographardi-Ainda não há avaliações

- Absorption QuestionsDocumento11 páginasAbsorption QuestionsRalph CastinoAinda não há avaliações

- Er DiagramsDocumento20 páginasEr DiagramsMatthew BloomfieldAinda não há avaliações