Escolar Documentos

Profissional Documentos

Cultura Documentos

Technical Note TN 046 Bitumen Emulsions

Enviado por

Francisco Jesús Infante PérezDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Technical Note TN 046 Bitumen Emulsions

Enviado por

Francisco Jesús Infante PérezDireitos autorais:

Formatos disponíveis

46 Technical Note

BITUMEN EMULSIONS

1. INTRODUCTION seals involving small size aggregates (generally no more

than 7 mm, but occasionally 10 mm depending on texture

The purpose of this Technical Note is to provide an overview of surface being treated and required application rates).

for the use of bitumen emulsions in road construction and

maintenance work. A particular application for bitumen emulsions is in pin

down seals that are applied to lock down a seal that is at

2. WHAT ARE BITUMEN EMULSIONS? risk of ravelling or stripping. Such seals can be applied in

cool weather using emulsions as binders. Alternative pin

Bitumen emulsions are dispersions of ne droplets of down seals using cutback bitumen binders require the use

bitumen in water. Standard grades of emulsion comprise of signicant amounts of cutters which could increase the

approximately 60% bitumen and 40% water. Grades risk of bleeding following hot weather.

consisting of approximately 70% bitumen and 30% water

are becoming popular for sprayed seal operations. Higher Standard bitumen emulsions are sometimes used with larger

bitumen content (up to 85 - 90%) emulsions are being aggregates in multiple application seals that build up a well

developed but these are not in general use. bound surfacing with successive applications of emulsion

and smaller aggregates. Spraying temperature for standard

Bitumen emulsions are used for various applications and grade emulsion is generally 40 - 60C.

some type of emulsions include additives such as polymer or

cutter. Setting and curing of emulsion involves separation For single application seals using larger aggregates (10 mm

and removal of water leaving solid bitumen. The type and and 14 mm) the emulsion binder content is often increased

quantity of emulsier determines the setting characteristics to 65 or 70%. Such emulsions require additional heating

of the emulsion. for effective spraying (generally 80 - 90C) and are viscous

enough to avoid excessive run-off. Higher binder content

Particular procedures apply to the handling and storage of emulsions are often supplied as proprietary grades and may

bitumen emulsions and a guide is provided in Austroads/ also include polymers for improved initial adhesion and

AAPA Pavement Work Tip No.2. Emulsion Handling and enhanced performance. Manufacturer recommendations

Storage. should be sought prior to using these grades.

Bitumen emulsion can be used in almost any application 3.2 Design Application Rates

where cutback bitumen is used.

In principle, emulsion seals should be designed to produce

Advantages of bitumen emulsions include: the same residual binder application rates as for cutback

the ability to handle with minimal or no heating; and bitumen seals. Emulsion seal binders however lack the extra

the absence or signicant reduction of cutter in the volume and softer nature of cutback seal binders. These

binder. different properties mean that it may be desirable to add an

extra 0.1 - 0.2 litres/m2 to the emulsion binder application

Disadvantages of bitumen emulsions include: values when spraying emulsions in cool conditions. This

slow initial curing rates; and is to provide additional aggregate retention and assist with

higher cost. trafc embedment early in the life of the seal.

3. APPLICATIONS IN SPRAYED SEAL 3.3 Construction Factors

TREATMENTS

A signicant difference in the use of bitumen emulsion

3.1 Seal Types sealing binders and cutback bitumen is the time taken for

the emulsion to gain sufcient strength to resist uncontrolled

Standard grades of bitumen emulsion are very uid at trafc. The breaking and curing of emulsion goes through

ambient temperatures. They are applied cold and hence two stages. The rst stage, which occurs rapidly, is a

suitable for skin patching in maintenance work or sprayed breaking and adhesion of bitumen at the contact surface.

June 2006 Page 1 of 2

Technical Note 46

At this stage the binder still contains water and is very soft 3.6 Priming

(sometimes referred to as cheesy). The second stage of

curing may take several hours. During this time trafc must Standard grades of bitumen emulsion are not suitable for

be carefully controlled or excluded altogether. priming as there is almost no penetration into the pavement.

However, priming emulsions have been formulated to

The secondary curing stage will be increased in cool contain cutter to assist pavement penetration. Pavements

or damp conditions so that although emulsions can be must be moist (not wet) and penetration is generally

successfully applied in such conditions, particular care must less than that of cutback primers. Priming emulsions are

be taken before permitting release to trafc. becoming the preferred treatment in cooler winter periods,

providing appropriate precautions are addressed.

A technique that can assist in avoiding larger sized

aggregates being dislodged by trafc during the curing 3.7 Surface Enrichment

phase is the use of rack-in or dry lock treatments where

a light application of a small sized aggregate (5 mm or 7 Slow setting grades of emulsion are normally used for

mm) is used to hold aggregate in place. This material is surface enrichment to assist in emulsion running down to

usually considered sacricial and not intended to remain a the base of aggregate rather than breaking on contact with

permanent part of the seal. the surface. Bitumen emulsion surface enrichments are

more susceptible to pick-up by trafc in the uncured state

Aggregates for emulsion seals should be precoated with and therefore trafc control is important.

bitumen emulsion or plant precoated bitumen products.

Fresh diesel fuel oil and kerosene based precoating 4. OTHER APPLICATIONS

materials have been successfully used but can adversely

affect the breaking and adhesion of emulsions to aggregate. Other uses of emulsions in road construction and

The absence of precoating is considered poor practice and maintenance include:

increases the risk of inferior work except possibly with some

smaller sized aggregates. Aggregates that are used without Tack coating for asphalts;

precoating should be damp and not dry and/or dusty. Dust laying;

Manufacture of cold mix site mixed and plant mix

3.4 Primerseals stockpile mixtures for patching and paver laying;

Slurry Surfacing;

Bitumen emulsion is an effective binder for primerseals. Pavement stabilisation;

The absence of cutter makes emulsions particularly suitable Cold Recycling of Asphalt;

where it is necessary to apply a nal treatment without Crack lling; and

an extended curing period. Penetration into pavement Mulching and seeding.

surfaces may be less than that with cutback primerbinders.

Primerseals with emulsions require careful trafc control 5. ENVIRONMENTAL CONSIDERATIONS

until cured and can be damaged by rain on uncured binder.

Pavements must be damp (but not wet) to ensure even binder Particular care is required when using bitumen emulsions

coverage without pin-holes. when there is a likelihood of rain before the emulsion breaks

and the seal is cured. This is especially important when

3.5 Aggregate Precoat they are used in primerseals or primes. Environmental

management plans should include special provisions to

Bitumen emulsions can be used for precoating aggregates manage the risk of their use in such circumstances.

in all types of sprayed sealing. They must, however, be

specially formulated with a low binder content that enables 6. CONTACT OFFICERS

application of a thin uniform coating of bitumen that is

free of tackiness. Emulsion precoating is suitable for both John Esnouf Phone (03) 5434 5015

aggregates that are to be stockpiled and for those required E-mail john.esnouf@roads.vic.gov.au

for immediate use. Precoating with emulsions on site can

be messy and it is better to use plant precoating whenever Cliff Partt Phone (03) 9881 8916

possible. Plant precoated aggregates reduce contamination E-mail cliff.partt@roads.vic.gov.au

at stack sites.

GeoPave Facsimile: (03) 9881 8900

GeoPave believes this publication to be correct at the time of printing and does not accept responsibility for any consequences arising from

the use of the information herein. Readers should rely on individual judgement and skill to apply information to particular issues.

Page 2 of 2 June 2006

Você também pode gostar

- Technical Note TN 048 Differences Between Conventional HSS SAM and SAMI TreatmentsDocumento2 páginasTechnical Note TN 048 Differences Between Conventional HSS SAM and SAMI TreatmentsKarina Benavides BurgosAinda não há avaliações

- Worktips 51 Asphalt Tack CoatingDocumento2 páginasWorktips 51 Asphalt Tack CoatingDilhara WickramaarachchiAinda não há avaliações

- Additional GuideDocumento61 páginasAdditional GuideObsinet ObsinetAinda não há avaliações

- Guide 9 Bitumen Emulsions Storage and Handling PDFDocumento21 páginasGuide 9 Bitumen Emulsions Storage and Handling PDFViswalal ViswanathanAinda não há avaliações

- Bituaqua Prime Coat - Cationic & AnionicDocumento2 páginasBituaqua Prime Coat - Cationic & Anionicmuhammad aliAinda não há avaliações

- BitumenDocumento7 páginasBitumenArjun KumarAinda não há avaliações

- Tiki Tar Industries - Asphalt, Modified Bitumen Manufacturers, Bitumen Emulsion & MembraneDocumento2 páginasTiki Tar Industries - Asphalt, Modified Bitumen Manufacturers, Bitumen Emulsion & MembraneSanjay PatelAinda não há avaliações

- SentinelCem Cement H08282Documento3 páginasSentinelCem Cement H08282Saavedra NicoAinda não há avaliações

- How To Avoid Screed Failure: Contact The Flooring SpecialistDocumento7 páginasHow To Avoid Screed Failure: Contact The Flooring SpecialistSamuel WooAinda não há avaliações

- Method Statement Floor and Speciality JointsDocumento10 páginasMethod Statement Floor and Speciality JointsJamsheed Ap KadangodAinda não há avaliações

- Brochure Asphalt Surface Dressing ChipsealDocumento20 páginasBrochure Asphalt Surface Dressing ChipsealOjullaIsaac100% (1)

- Brochure Asphalt Slurry Seal Microsurfacing Global enDocumento24 páginasBrochure Asphalt Slurry Seal Microsurfacing Global enعبد الرحيم كريم حسينAinda não há avaliações

- Masterkure 106 TdsDocumento2 páginasMasterkure 106 TdsEmre ErdoğanAinda não há avaliações

- Bitumen Binder and TypesDocumento47 páginasBitumen Binder and TypesTarun Goel50% (2)

- Bitumen Binder and TypesDocumento59 páginasBitumen Binder and TypesTarun Goel100% (1)

- Barra Emulsion 57DDocumento2 páginasBarra Emulsion 57Dnadeesha100% (2)

- Expancure 90Documento3 páginasExpancure 90Amar Wadood KhanAinda não há avaliações

- Bituminous Binders - EmulsionsDocumento3 páginasBituminous Binders - EmulsionsCamilo MéndezAinda não há avaliações

- TDS Polycoat RBEDocumento2 páginasTDS Polycoat RBEMang JoseAinda não há avaliações

- Usg Plasters Hydrocal Gypsum Cements Sealers Parting Compounds Brochure en IG515Documento2 páginasUsg Plasters Hydrocal Gypsum Cements Sealers Parting Compounds Brochure en IG515aeoiuAinda não há avaliações

- Bitustick Al PDFDocumento2 páginasBitustick Al PDFRupesh GenesisAinda não há avaliações

- The Use of Bonding Agents For Portland Cement PlasteringDocumento3 páginasThe Use of Bonding Agents For Portland Cement PlasteringbatteekhAinda não há avaliações

- MasterProtect 300Documento3 páginasMasterProtect 300Gavriel NgAinda não há avaliações

- Pavement Work Tips - No 2 September 2010Documento2 páginasPavement Work Tips - No 2 September 2010Dilhara WickramaarachchiAinda não há avaliações

- Basf Mastertop 430 TdsDocumento3 páginasBasf Mastertop 430 TdsPanruti S SathiyavendhanAinda não há avaliações

- Causes and Solutions For Cracking in Grouts: Technical BulletinDocumento2 páginasCauses and Solutions For Cracking in Grouts: Technical BulletinCarlos AlvaAinda não há avaliações

- Water Based Bitumen Paint: Product InformationDocumento4 páginasWater Based Bitumen Paint: Product InformationSaad AlownAinda não há avaliações

- FPMTAGChapter7 ChipSealsDocumento30 páginasFPMTAGChapter7 ChipSealsBea LopezAinda não há avaliações

- Bituminous SurfacingDocumento4 páginasBituminous SurfacingBryan ArcaAinda não há avaliações

- Masterkure 107: Description Typical PropertiesDocumento2 páginasMasterkure 107: Description Typical PropertiesShihab AhamedAinda não há avaliações

- TDS Uni Mould Introduction and Application GuideDocumento2 páginasTDS Uni Mould Introduction and Application GuideNoor MalakAinda não há avaliações

- Expanseal 105: Construction ChemistryDocumento2 páginasExpanseal 105: Construction Chemistrymuhammad aliAinda não há avaliações

- Nivapol Polycoat CFMDocumento2 páginasNivapol Polycoat CFMAlsayed DiabAinda não há avaliações

- Gyproc Supreme 80 One Coat Gypsum PlasterDocumento3 páginasGyproc Supreme 80 One Coat Gypsum PlasterSwapnil JadhavAinda não há avaliações

- 02 - TDS - Emaco Bonding Agent PDFDocumento2 páginas02 - TDS - Emaco Bonding Agent PDFaahtagoAinda não há avaliações

- MASTERKURE 106i v5Documento2 páginasMASTERKURE 106i v5bollavaram sivaramireddyAinda não há avaliações

- Itustick Itustick: HDPE Surfaced Bituminous Waterproofing MembraneDocumento2 páginasItustick Itustick: HDPE Surfaced Bituminous Waterproofing Membraneglen cristian riveraAinda não há avaliações

- Water Retention by Concrete Curing Materials: NOTE 2-A Commercial Wood Float EquippedDocumento3 páginasWater Retention by Concrete Curing Materials: NOTE 2-A Commercial Wood Float EquippedEvert RiveraAinda não há avaliações

- Sikagrout FMDocumento2 páginasSikagrout FMKasyie AbrahamAinda não há avaliações

- Visqueen Self Adhesive Damp Proof Membrane: Description Typical PropertiesDocumento2 páginasVisqueen Self Adhesive Damp Proof Membrane: Description Typical PropertiesJAinda não há avaliações

- Datasheet File Conbextra GP PremixDocumento4 páginasDatasheet File Conbextra GP PremixLftea AdiAinda não há avaliações

- P I 2525, P I 2555 & P I 2574: Product BulletinDocumento4 páginasP I 2525, P I 2555 & P I 2574: Product BulletinvikramAinda não há avaliações

- Grout - Estogrout UW - Data Sheet - 120404Documento2 páginasGrout - Estogrout UW - Data Sheet - 120404Dana IrmawanAinda não há avaliações

- A Review of Shop Coating FailuresDocumento5 páginasA Review of Shop Coating FailuresHugo F Barrera AlvaradoAinda não há avaliações

- DS3172 Chemlok205Documento4 páginasDS3172 Chemlok205sanjiv66669Ainda não há avaliações

- Plastiseal : Rubber-Bitumen Cold Applied Joint SealantDocumento4 páginasPlastiseal : Rubber-Bitumen Cold Applied Joint SealantzeroicesnowAinda não há avaliações

- Material Selection: 3.1. Concrete ConstituentsDocumento4 páginasMaterial Selection: 3.1. Concrete ConstituentsZXCvincentAinda não há avaliações

- Consol Cosmetic: Polymer Modified Portland Cement CoatingDocumento2 páginasConsol Cosmetic: Polymer Modified Portland Cement CoatingCiput MardiantoAinda não há avaliações

- Konsol PDFDocumento2 páginasKonsol PDFCiput MardiantoAinda não há avaliações

- Masterglenium-110m Technical Data SheetDocumento3 páginasMasterglenium-110m Technical Data Sheetabukayes.abdinAinda não há avaliações

- Gel Coat Defects - Draft BulletinDocumento14 páginasGel Coat Defects - Draft BulletinnwhAinda não há avaliações

- Masterkure 181 - KsaDocumento2 páginasMasterkure 181 - KsaSHAIK ASIMUDDINAinda não há avaliações

- Cementing DesignDocumento83 páginasCementing DesignAfnan AhmadAinda não há avaliações

- Bituminous Emulsions and CutbacksDocumento22 páginasBituminous Emulsions and Cutbacksdarsu NaikAinda não há avaliações

- Polymer Dispersion Powder in Cement Based WackerDocumento12 páginasPolymer Dispersion Powder in Cement Based Wackerm_shahbaghiAinda não há avaliações

- Notes Cutback and EmulisionDocumento7 páginasNotes Cutback and Emulisiondarsu NaikAinda não há avaliações

- Expanseal Mastic: Rubber-Bitumen Cold Applied Joint Sealant UsesDocumento4 páginasExpanseal Mastic: Rubber-Bitumen Cold Applied Joint Sealant UsesKhizar HayatAinda não há avaliações

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionAinda não há avaliações

- Chapter 1: Installation Prerequisites For LinuxDocumento8 páginasChapter 1: Installation Prerequisites For LinuxFrancisco Jesús Infante PérezAinda não há avaliações

- ANSYS Quick Start Licensing Guide: Release Release 2020 R2 000404Documento8 páginasANSYS Quick Start Licensing Guide: Release Release 2020 R2 000404Francisco Jesús Infante PérezAinda não há avaliações

- Chapter 1: Installation Prerequisites For WindowsDocumento14 páginasChapter 1: Installation Prerequisites For WindowsFrancisco Jesús Infante PérezAinda não há avaliações

- ANSYS Quick Start Installation Guide: Release Release 2020 R2 000403Documento8 páginasANSYS Quick Start Installation Guide: Release Release 2020 R2 000403Francisco Jesús Infante PérezAinda não há avaliações

- CHP 11Documento104 páginasCHP 11Francisco Jesús Infante PérezAinda não há avaliações

- Colloid Mills Bulletin 4Documento4 páginasColloid Mills Bulletin 4Francisco Jesús Infante PérezAinda não há avaliações

- Water ProofingDocumento23 páginasWater ProofingSIDDHANT VERMAAinda não há avaliações

- Green Pavement 2 r1 - HRDocumento99 páginasGreen Pavement 2 r1 - HRcharml auliaAinda não há avaliações

- 25) Softening Point of BitumenDocumento5 páginas25) Softening Point of BitumenPn Ekanayaka100% (4)

- Project:SASEC Mugling-Pokhara Highway Improvement Phase I Project (SMPHIP) Contract No. SMPHIP/OCB/MAP/2 Contractor: Anhui Kaiyuan Highway and Bridge Co. LTDDocumento4 páginasProject:SASEC Mugling-Pokhara Highway Improvement Phase I Project (SMPHIP) Contract No. SMPHIP/OCB/MAP/2 Contractor: Anhui Kaiyuan Highway and Bridge Co. LTDugrasen chaudharyAinda não há avaliações

- StrippingDocumento9 páginasStrippingppalmacAinda não há avaliações

- 9 Test To Check Quality of Bitumen For Use in Road WorkDocumento4 páginas9 Test To Check Quality of Bitumen For Use in Road Workmuhammad iqbalAinda não há avaliações

- Bridge Cost by RsepsDocumento8 páginasBridge Cost by RsepsTahfimul Islam Ruhan100% (1)

- Standard Test Procedure RHD - BDDocumento348 páginasStandard Test Procedure RHD - BDgazi sharif100% (3)

- Pavement Engineering Notes 2012Documento77 páginasPavement Engineering Notes 2012Mohamed Wehliye90% (10)

- Technical Criteria Tenant MEP Works - APR'19Documento1 páginaTechnical Criteria Tenant MEP Works - APR'19Rome AdolAinda não há avaliações

- Bitumen - AsphaltDocumento36 páginasBitumen - AsphaltjohanAinda não há avaliações

- Project Estmate (Final)Documento65 páginasProject Estmate (Final)Bilal Ahmed BarbhuiyaAinda não há avaliações

- HWAYDocumento2 páginasHWAYMarc Anthony de Villa100% (1)

- Comparison Concrete and Asphalt PavementDocumento6 páginasComparison Concrete and Asphalt PavementJulius OgowewoAinda não há avaliações

- Balmerol BlucoatDocumento1 páginaBalmerol Blucoattsrinvas thadaboinaAinda não há avaliações

- Vacant PHD TopicsDocumento18 páginasVacant PHD TopicsPeeran DittaAinda não há avaliações

- Cold Recycler and Stabilizer WR SeriesDocumento70 páginasCold Recycler and Stabilizer WR SeriesNguyen Ngoc75% (4)

- Bills of Quantity For Road WorksDocumento5 páginasBills of Quantity For Road WorksFaizal Hakimi100% (1)

- Check List (Quality Auditors) - Converted1Documento65 páginasCheck List (Quality Auditors) - Converted1DeepakAinda não há avaliações

- Specification Bituminous Concrete (Asphaltic Concrete) Road PavementDocumento18 páginasSpecification Bituminous Concrete (Asphaltic Concrete) Road PavementharivennelaAinda não há avaliações

- ArrMaz Brochure 2008Documento12 páginasArrMaz Brochure 2008sukrukayaAinda não há avaliações

- Bitumen With Salt PDFDocumento9 páginasBitumen With Salt PDFbkswain2003Ainda não há avaliações

- Sika WP Shield-104 P: APP Modified Plain Finished Bituminous MembraneDocumento3 páginasSika WP Shield-104 P: APP Modified Plain Finished Bituminous MembraneSouvik DasAinda não há avaliações

- Technical Datasheet Viscosity Bitumen VG-40Documento0 páginaTechnical Datasheet Viscosity Bitumen VG-40NakkolopAinda não há avaliações

- S.O (1) .R For Building Ahmedabad District 2015-16 PDFDocumento426 páginasS.O (1) .R For Building Ahmedabad District 2015-16 PDFMehta MalayAinda não há avaliações

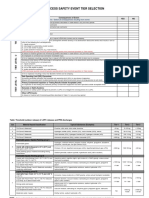

- Process Safety Event Tier SelectionDocumento2 páginasProcess Safety Event Tier SelectionsheerazaliAinda não há avaliações

- Fosroc Colpor 200: Constructive SolutionsDocumento4 páginasFosroc Colpor 200: Constructive Solutionsarwin dela cruzAinda não há avaliações

- Functions and Installation of Paving Geosynthetics: S.K. ShuklaDocumento8 páginasFunctions and Installation of Paving Geosynthetics: S.K. ShuklamojeebmashalAinda não há avaliações

- Bituminous Surfacings and Road Bases - UNOPSDocumento137 páginasBituminous Surfacings and Road Bases - UNOPSFranklinAinda não há avaliações

- Basic Notes and Interview QuestionsDocumento50 páginasBasic Notes and Interview QuestionsRaheel AliAinda não há avaliações