Escolar Documentos

Profissional Documentos

Cultura Documentos

Design and Simulation of Go Kart Chassis

Enviado por

IJIRSTDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Design and Simulation of Go Kart Chassis

Enviado por

IJIRSTDireitos autorais:

Formatos disponíveis

IJIRST International Journal for Innovative Research in Science & Technology| Volume 3 | Issue 10 | March 2017

ISSN (online): 2349-6010

Design and Simulation of Go Kart Chassis

Amberpreet Singh Ankur Deol

UG Student UG Student

Department of Mechanical Engineering Department of Mechanical Engineering

Chandigarh University, Ghuran, India Chandigarh University, Ghuran, India

Gagandeep Singh Amit Grewal

UG Student UG Student

Department of Mechanical Engineering Department of Mechanical Engineering

Chandigarh University, Ghuran, India Chandigarh University, Ghuran, India

Akashdip Singh Sembhi

UG Student

Department of Mechanical Engineering

Chandigarh University, Ghuran, India

Abstract

This paper is focused in importance of simulation in designing approach. The static test are created in this paper. The designed

frame has been investigated in a variety of altered circumstances to predict that whether the frame will endure during and after the

impact or fail in crash or hitting condition or in working condition. The outcomes from these simulated result show that the frame

should indeed be safe sufficient in the range of worst case of crash or hitting situations.

Keywords: FEA Simulation of Go kart Frame in ANSYS, Finite Element Analysis, Frame Simulation in ANSYS, Go kart

Chassis Analysis, Solid Works

_______________________________________________________________________________________________________

I. INTRODUCTION

Go-kart is just a type of open-wheel car .It comes in all shapes size and customs. From motorless models to high-powered racing

machines, some like Superkarts are being able to beat racing cars or motorcycles on long circuits. Karting is commonly perceived

as the stepping stone to the larger ranks of motorsports .Karts may differ usually in speed or power and some (known as Superkarts)

can reach speeds exceeding 260 kilometers per hour (160 mph), while recreational go-karts governed or meant for everyone might

be limited to lower speeds.

The frame of a vehicle providing safety and seating arrangement of driver and including other sub-systems of the vehicle. We

have designed a such frame good in the terms the safety and aesthetics. This paper is focused on various impact conditions like

Front Impact

Rear Impact

Side Impact,

Theses there cases are the worst case and have maximum impact energy created during impact.

II. ABBREVIATIONS

Finite element analysis (FEA), Initial Graphics Exchange Specification (IGES), (AISI) the American Iron and Steel Institute.

III. ANALYSIS METHODOLOGY

Once cad modeling of the frame structure is done by using solid works, then this design is checked by Finite Element Analysis

method. We have used ANSYS (workbench) software for FEA RESULT. We have first import the solid works file model in

ANSYS (work bench by) IGES Model format, then specified the properties of material, define the cross-section of tube created

component, then create 3D meshing, and them applied load and constrained. The final analysis is shown in ANSYS. We have to

minimum deformation and stresses and target to minimum weight of chassis the flow chat of entire process is shown in fig 1.

All rights reserved by www.ijirst.org 74

Design and Simulation of Go Kart Chassis

(IJIRST/ Volume 3 / Issue 11/ 013)

Fig. 1: Analysis Methodology

Cad model Different View

Fig. 2: CAD model Different View

IV. MATERIAL USED

We have decided to Aisi 1020 due availability and cost factor of our budget. This material was selected due to its virtuous

Combination of all of the typical qualities of Steel like strength, ductility, AISI 1020 steel can be largely utilized in all industrial

sectors in order to enhance weldability or machinability properties. we used circular pipes of diameter 25mm with thickness of 1.4

mm. Circular section is selected on the basis that it reduce the weight by diligent tube area

Some of mechanical properties are as following:

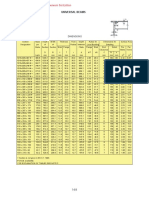

Table 1

Material Used

Sr. No. Property

1 Modulus of elasticity (GPa) 205 GPa

2 Yield strength (MPa) 350 MPa

3 Density 7.83g/cm3

4 Tensile strength (MPa) 420 MPa

5 Poisson ratio 0.290

All rights reserved by www.ijirst.org 75

Design and Simulation of Go Kart Chassis

(IJIRST/ Volume 3 / Issue 11/ 013)

V. FINITE ELEMENT ANALYSIS

After finalizing the material and cross section the thickness and shape of material we start Structural analysis of the chassis was

done along with design optimization until a convincing design with sufficient result was produced. The static structural analysis

was done in ANSYS Workbench under different conditions. The finite element method (FEM) is a numerical technique or method

for finding approximate solutions of prescribed problem.

VI. MESHING

Meshing is done by default setting in ANSYS as shown in fig 3.

Fig. 3: Meshing is done by default setting in ANSYS

VII. FRONT IMPACT

By assuming that weight of kart including the vehicle +mass of driver is 120 kg impact force is calculated based on a G of 4. F=

ma we get 120*9.81*4 that is equal to 4708.8N (approximate) which is applied on the front nodes from front of chassis of vehicle.

By assuming the worse condition of crash or hit.

Fig. 4: Stress in chassis in front impact

Fig. 5: Deformation of chassis in front impact

All rights reserved by www.ijirst.org 76

Design and Simulation of Go Kart Chassis

(IJIRST/ Volume 3 / Issue 11/ 013)

VIII. SIDE IMPACT

By assuming that weight of kart including the vehicle +mass of driver is 120 kg impact force is calculated base on a G of 2.5. F=

ma we get 120*9.81*2.5 that is equal to 2943N (approximate) which is applied on the side nodes from side of chassis of vehicle.

Fig. 6: Total deformation in side impact

Fig. 7: Stress in side impact

IX. REAR IMPACT

By assuming that weight of kart including the vehicle +mass of driver is 120 kg impact force is calculated base on a G of 2.5 F=

ma we get 120*9.81*2.5 that is equal to 2943N (approximate)which is applied on the rear nodes from fornt of chassis of vehicle

All rights reserved by www.ijirst.org 77

Design and Simulation of Go Kart Chassis

(IJIRST/ Volume 3 / Issue 11/ 013)

Fig. 8: Total deformation in rear impact

Fig. 9: Stress in rear impact

X. CONCLUSION

Sr. No Impact Stress (MPa) Displacement (mm)

1. Front 258.16 1.45

2. Side 23.06 .04

3. Rear 268.18 1.96

So three of the stresses i.e. front, side, rear are very less than the yield stress of the material so our design is safe

REFERENCES

[1] www.ijamejournals.com/pdf/FEM%20Analysis%20of%20BAJA%20Chassis.pdf

[2] https://www.youtube.com/watch?v=QA5MBzoOHkQ

[3] https://www.youtube.com/watch?v=GgZERsildDk

[4] https://www.youtube.com/watch?v=WXEKD-tcB-I

[5] Huei-Huang Lee - Finite Element Simulations with ANSYS Workbench 12 - [fervidhope.blogspot.com]

All rights reserved by www.ijirst.org 78

Você também pode gostar

- A Review Paper On Design of Go Kart IJSTDocumento4 páginasA Review Paper On Design of Go Kart IJSTbb8814137Ainda não há avaliações

- Ijaerv14n9spl 101Documento8 páginasIjaerv14n9spl 101Roberto OliveiraAinda não há avaliações

- Design and FEA of Go Kart Chassis: Bhosale Nagesh Baburao Deshmukh Mahesh BhaskarDocumento4 páginasDesign and FEA of Go Kart Chassis: Bhosale Nagesh Baburao Deshmukh Mahesh BhaskarShanker PandeyAinda não há avaliações

- Ijaerv14n9spl 101Documento8 páginasIjaerv14n9spl 101harendrasinh0810Ainda não há avaliações

- A Review Paper On Design and Analysis of A Go-Kart ChassisDocumento3 páginasA Review Paper On Design and Analysis of A Go-Kart ChassisDuzzysAinda não há avaliações

- Irjet V5i4566 PDFDocumento4 páginasIrjet V5i4566 PDFPushkar MishraAinda não há avaliações

- Quad Bike Design and Simulation: A Pre - Manufacturing MethodologyDocumento5 páginasQuad Bike Design and Simulation: A Pre - Manufacturing MethodologyerpublicationAinda não há avaliações

- Ijst 2020 502Documento9 páginasIjst 2020 502Prateek MahapatraAinda não há avaliações

- Deign Report in Formula StudentDocumento7 páginasDeign Report in Formula StudentAhmed ElgamlAinda não há avaliações

- Design, Analysis, Fabrication and Testing of A Formula Car ChassisDocumento10 páginasDesign, Analysis, Fabrication and Testing of A Formula Car ChassisSavalia HardikAinda não há avaliações

- Materials Today: Proceedings: T. Safiuddeen, P. Balaji, S. Dinesh, B.Md. Shabeerhussain, M.R. GiridharanDocumento18 páginasMaterials Today: Proceedings: T. Safiuddeen, P. Balaji, S. Dinesh, B.Md. Shabeerhussain, M.R. GiridharanCésar BermúdezAinda não há avaliações

- Design, Analysis and Optimization of Race Car Chassis For Its Structural PerformanceDocumento7 páginasDesign, Analysis and Optimization of Race Car Chassis For Its Structural PerformanceSammmAinda não há avaliações

- Fabrication and Manufacturing of Go-Kart: With Effective Time Saving, For BeginnerDocumento4 páginasFabrication and Manufacturing of Go-Kart: With Effective Time Saving, For BeginnerAnonymous 1grFXHMGAinda não há avaliações

- Icndme 14273Documento9 páginasIcndme 14273FS18ME046 MAYUR NikamAinda não há avaliações

- Modal Analysis, Fatigue Analysis and Optimization of Tractor Drop Arm Using FEMDocumento12 páginasModal Analysis, Fatigue Analysis and Optimization of Tractor Drop Arm Using FEMIJRASETPublicationsAinda não há avaliações

- Design and Manufacturing of Motorsports PDFDocumento10 páginasDesign and Manufacturing of Motorsports PDFVaisakhan.A.SAinda não há avaliações

- Designing of The Rack and Pinion Gearbox For All TDocumento7 páginasDesigning of The Rack and Pinion Gearbox For All THigor SufiattiAinda não há avaliações

- Modelling and Analysis of Drilling Jig For MountinDocumento5 páginasModelling and Analysis of Drilling Jig For MountinHarsha MetiAinda não há avaliações

- Irjet V9i3222Documento7 páginasIrjet V9i3222sinare amolAinda não há avaliações

- Design and Analysis of Go Kart Chassis Ijariie4300 PDFDocumento7 páginasDesign and Analysis of Go Kart Chassis Ijariie4300 PDFDeepak RameshAinda não há avaliações

- Formula SAE Chassis System Design, Optimization & Fabrication of FSAE Spaceframe ChassisDocumento39 páginasFormula SAE Chassis System Design, Optimization & Fabrication of FSAE Spaceframe ChassisInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Structural and Material Analysis of An Automobile Wheel Rim Using AnsysDocumento6 páginasStructural and Material Analysis of An Automobile Wheel Rim Using Ansysnadimduet1Ainda não há avaliações

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocumento16 páginasIjesrt: International Journal of Engineering Sciences & Research TechnologySai Krishna SKAinda não há avaliações

- Frame Design and Analysis of Electric Formula One Car A ReviewDocumento7 páginasFrame Design and Analysis of Electric Formula One Car A ReviewIJRASETPublicationsAinda não há avaliações

- .Design and Analysis of A Shock Absorber by Varying Spring Materials - Analysis Using Fea TechniqueDocumento9 páginas.Design and Analysis of A Shock Absorber by Varying Spring Materials - Analysis Using Fea TechniqueManjunath ReddyAinda não há avaliações

- Design and Simulation of Linear SteeringDocumento6 páginasDesign and Simulation of Linear SteeringIJRASETPublicationsAinda não há avaliações

- Design and Analysis of Two Stage Reduction Gearbox For All Terrain VehiclesDocumento6 páginasDesign and Analysis of Two Stage Reduction Gearbox For All Terrain VehiclesKunal KoreAinda não há avaliações

- Design and Finite Element Analysis of Four Wheel Drive Roll Cage IJERTV11IS020152Documento8 páginasDesign and Finite Element Analysis of Four Wheel Drive Roll Cage IJERTV11IS020152Kenneth C.LinojAinda não há avaliações

- Design and Analysis of A Ladder Frame ChassisDocumento10 páginasDesign and Analysis of A Ladder Frame ChassisJuan Sebastian CameroAinda não há avaliações

- Upgradation in Hydraulic Press Machine Arun V. Javir, Niranjan N. Manchekar, Rahul D. BelekarDocumento9 páginasUpgradation in Hydraulic Press Machine Arun V. Javir, Niranjan N. Manchekar, Rahul D. BelekarddAinda não há avaliações

- Traveler Seat AnalysisDocumento4 páginasTraveler Seat AnalysisJournalNX - a Multidisciplinary Peer Reviewed JournalAinda não há avaliações

- Analysis of FSAEDocumento4 páginasAnalysis of FSAEPriyesh SinghAinda não há avaliações

- Detailed Design Calculations & Analysis of Go-Kart VehicleDocumento15 páginasDetailed Design Calculations & Analysis of Go-Kart VehicleBhanu Pratap SinghAinda não há avaliações

- Design and Analysis of Flywheel Geometries and MaterialsDocumento6 páginasDesign and Analysis of Flywheel Geometries and Materialsjaison jacobAinda não há avaliações

- Design, Analysis and Optimisation of ATV Spaceframe Chassis: Delhi Technological UniversityDocumento12 páginasDesign, Analysis and Optimisation of ATV Spaceframe Chassis: Delhi Technological UniversityKoushal SinghAinda não há avaliações

- Design and Analysis of Alloy Wheel For Multi-Purpose VehicleDocumento5 páginasDesign and Analysis of Alloy Wheel For Multi-Purpose VehicleRohitash ThakurAinda não há avaliações

- Analysis and Modification of Screw Jack Body Using Finite Element AnalysisDocumento4 páginasAnalysis and Modification of Screw Jack Body Using Finite Element AnalysisIJSTEAinda não há avaliações

- Design and Structural Analysis of An Off Road VehicleDocumento7 páginasDesign and Structural Analysis of An Off Road Vehiclegauravme198306Ainda não há avaliações

- A Project Stage I Seminar On "Design Optimization of Two Wheeler (Bike) Chassis"Documento18 páginasA Project Stage I Seminar On "Design Optimization of Two Wheeler (Bike) Chassis"Prakash KatdareAinda não há avaliações

- BMT Chassis Structural AnalysisDocumento14 páginasBMT Chassis Structural AnalysisPriyaprasad PandaAinda não há avaliações

- Design and Analysis of Fixed Brake Caliper Using Additive ManufacturingDocumento9 páginasDesign and Analysis of Fixed Brake Caliper Using Additive ManufacturingIJRASETPublicationsAinda não há avaliações

- Abstract:: Design Report For Baja Saeindia 2018Documento10 páginasAbstract:: Design Report For Baja Saeindia 2018AndhdAinda não há avaliações

- Design and Analysis of Shock AbsorberDocumento11 páginasDesign and Analysis of Shock AbsorberInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Comparative Analysis of Frontal Car Bumper During Impact: Bhavesh A. BohraDocumento9 páginasComparative Analysis of Frontal Car Bumper During Impact: Bhavesh A. BohraarthurAinda não há avaliações

- Baja Design ReportDocumento9 páginasBaja Design ReportAkhilAinda não há avaliações

- Fatigue Analysis and Optimization of Upright of A FSAE VehicleDocumento6 páginasFatigue Analysis and Optimization of Upright of A FSAE Vehiclepreetham saiAinda não há avaliações

- Panda 2016Documento14 páginasPanda 2016ranim najibAinda não há avaliações

- GRDJEV06I070016Documento7 páginasGRDJEV06I070016maximAinda não há avaliações

- Design and Analysis of Student Race Car ChassisDocumento7 páginasDesign and Analysis of Student Race Car ChassiscoyalAinda não há avaliações

- Design Analysis of The Chassis For The Go-KartDocumento7 páginasDesign Analysis of The Chassis For The Go-KartGong68Ainda não há avaliações

- Design, Analysis and Weight Optimization of LMV Shaft by Using AL + GF CompositeDocumento7 páginasDesign, Analysis and Weight Optimization of LMV Shaft by Using AL + GF CompositeIJRASETPublicationsAinda não há avaliações

- Irjet V6i4748 PDFDocumento6 páginasIrjet V6i4748 PDFsumit sharmaAinda não há avaliações

- Fabrication of All-Terrain VehicleDocumento5 páginasFabrication of All-Terrain VehicleIJRASETPublicationsAinda não há avaliações

- CAD Lab Project UNITENDocumento5 páginasCAD Lab Project UNITENSyafiq FauziAinda não há avaliações

- Sae Baja India 2010 Design Report - VAJRADocumento8 páginasSae Baja India 2010 Design Report - VAJRAgobajasaeindia100% (3)

- Design and Analysis of Go-Kart ChassisDocumento6 páginasDesign and Analysis of Go-Kart ChassisInternational Journal of Innovations in Engineering and ScienceAinda não há avaliações

- Go KartDocumento2 páginasGo KartVivek Singh100% (1)

- Design and Structural Analysis of Scissor Jack Using ANSYS WorkbenchDocumento5 páginasDesign and Structural Analysis of Scissor Jack Using ANSYS WorkbenchAjith manjuAinda não há avaliações

- Effi Cycle Design 3Documento8 páginasEffi Cycle Design 3RohitAinda não há avaliações

- Experimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061Documento7 páginasExperimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061IJIRSTAinda não há avaliações

- Study On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)Documento10 páginasStudy On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)IJIRSTAinda não há avaliações

- The Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemDocumento9 páginasThe Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemIJIRSTAinda não há avaliações

- Postprocessing of Compacted Images Through Consecutive DenoisingDocumento4 páginasPostprocessing of Compacted Images Through Consecutive DenoisingIJIRSTAinda não há avaliações

- Experimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandDocumento6 páginasExperimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandIJIRSTAinda não há avaliações

- Manganese: Affecting Our Environment (Water, Soil and Vegetables)Documento7 páginasManganese: Affecting Our Environment (Water, Soil and Vegetables)IJIRSTAinda não há avaliações

- Development of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalDocumento7 páginasDevelopment of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalIJIRSTAinda não há avaliações

- Patterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduDocumento10 páginasPatterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduIJIRSTAinda não há avaliações

- Satellite Dish Positioning SystemDocumento5 páginasSatellite Dish Positioning SystemIJIRST100% (1)

- Physico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduDocumento3 páginasPhysico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduIJIRSTAinda não há avaliações

- Induction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationDocumento7 páginasInduction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationIJIRSTAinda não há avaliações

- Vibration Analysis of Composite Leaf Spring by Finite Element MethodDocumento7 páginasVibration Analysis of Composite Leaf Spring by Finite Element MethodIJIRSTAinda não há avaliações

- Multi-Physics Based Simulations of A Shock Absorber Sub-SystemDocumento7 páginasMulti-Physics Based Simulations of A Shock Absorber Sub-SystemIJIRSTAinda não há avaliações

- Arduino-UNO Based Magnetic Field Strength MeasurementDocumento4 páginasArduino-UNO Based Magnetic Field Strength MeasurementIJIRSTAinda não há avaliações

- Custom ROMDocumento3 páginasCustom ROMIJIRSTAinda não há avaliações

- Reconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewDocumento3 páginasReconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewIJIRSTAinda não há avaliações

- Currency Recognition Blind Walking StickDocumento3 páginasCurrency Recognition Blind Walking StickIJIRSTAinda não há avaliações

- Impact of Different Soils and Seismic Zones On Varying Height of Framed StructuresDocumento8 páginasImpact of Different Soils and Seismic Zones On Varying Height of Framed StructuresIJIRSTAinda não há avaliações

- Efficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeDocumento6 páginasEfficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeIJIRSTAinda não há avaliações

- Performance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointDocumento5 páginasPerformance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointIJIRSTAinda não há avaliações

- Development of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesDocumento4 páginasDevelopment of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesIJIRSTAinda não há avaliações

- Experimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesDocumento7 páginasExperimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesIJIRSTAinda não há avaliações

- Rock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)Documento5 páginasRock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)IJIRSTAinda não há avaliações

- Analysis of Agent Oriented Software EngineeringDocumento5 páginasAnalysis of Agent Oriented Software EngineeringIJIRSTAinda não há avaliações

- Intelligent Irrigation SystemDocumento5 páginasIntelligent Irrigation SystemIJIRSTAinda não há avaliações

- Comparative Study of Inner Core, Peripheral and RC Shear Wall SystemDocumento8 páginasComparative Study of Inner Core, Peripheral and RC Shear Wall SystemIJIRSTAinda não há avaliações

- Women Protection Mechanism With Emergency Communication Using Hand Waving PatternDocumento5 páginasWomen Protection Mechanism With Emergency Communication Using Hand Waving PatternIJIRSTAinda não há avaliações

- Literature Review For Designing of Portable CNC MachineDocumento3 páginasLiterature Review For Designing of Portable CNC MachineIJIRSTAinda não há avaliações

- Infiltration, Permeability, Liquid Limit and Plastic Limit of SoilDocumento12 páginasInfiltration, Permeability, Liquid Limit and Plastic Limit of SoilIJIRSTAinda não há avaliações

- InternshipDocumento9 páginasInternshipAyanokoji kunAinda não há avaliações

- Physics FormulasDocumento20 páginasPhysics Formulasbrandon100% (1)

- What Is Needed in Transformer Models?Documento12 páginasWhat Is Needed in Transformer Models?brunoscarpaAinda não há avaliações

- P201: Handbook of Structural Steelwork 3rd Edition: Universal BeamsDocumento44 páginasP201: Handbook of Structural Steelwork 3rd Edition: Universal Beamsmbhanusagar.keynesAinda não há avaliações

- Design and Analysis of Composite Drive ShaftDocumento4 páginasDesign and Analysis of Composite Drive ShaftmustafaAinda não há avaliações

- Reuse of Waste Glass in Building Brick Production: Waste Management & Research June 2009Documento7 páginasReuse of Waste Glass in Building Brick Production: Waste Management & Research June 2009leAinda não há avaliações

- Design of Brick Drain Wall and Base CalculationsDocumento8 páginasDesign of Brick Drain Wall and Base CalculationsNitesh SinghAinda não há avaliações

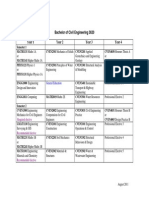

- Module Listing AY1415 Updated ADocumento28 páginasModule Listing AY1415 Updated ADarren PhuaAinda não há avaliações

- 3620 2013Documento2 páginas3620 2013Jnrules123Ainda não há avaliações

- Fundamental of ExtrusionDocumento28 páginasFundamental of Extrusion6014649Ainda não há avaliações

- Design Rivet1Documento8 páginasDesign Rivet1Narendra PalandeAinda não há avaliações

- Intro Hardness PDFDocumento2 páginasIntro Hardness PDFCali Tamagnini100% (1)

- M1101-Lec. 08 - Heat Transfer PDFDocumento29 páginasM1101-Lec. 08 - Heat Transfer PDFMohamed MahdiAinda não há avaliações

- Assessment of Microestructure Degradation of Creep Exposed Boiler SteelsDocumento4 páginasAssessment of Microestructure Degradation of Creep Exposed Boiler SteelsdantegimenezAinda não há avaliações

- Ancorsteel® 4300 PDFDocumento3 páginasAncorsteel® 4300 PDFJoydip JoydipAinda não há avaliações

- Principal of DPTDocumento5 páginasPrincipal of DPTAkshith SulliaAinda não há avaliações

- Ecr Glassflake: Micronised Grade GF007CDocumento1 páginaEcr Glassflake: Micronised Grade GF007Capde06Ainda não há avaliações

- API 571 2nd 2011 Unlocked - 051Documento1 páginaAPI 571 2nd 2011 Unlocked - 051nguyenAinda não há avaliações

- PENGARUH SUDUT POTONG DAN KECAMATAN POTONG TERHADAP MESIN BUBUTDocumento5 páginasPENGARUH SUDUT POTONG DAN KECAMATAN POTONG TERHADAP MESIN BUBUTDonnie Hafiz Prasetya RitongaAinda não há avaliações

- Mru DiodeDocumento18 páginasMru DiodeShanmuganathan ShanAinda não há avaliações

- Bonding of Contemporary Glass Ionomer Cements To Different Tooth Substrates Microshear Bond Strength and Scanning Electron Microscope StudyDocumento7 páginasBonding of Contemporary Glass Ionomer Cements To Different Tooth Substrates Microshear Bond Strength and Scanning Electron Microscope StudyAini Dwi HandiniAinda não há avaliações

- Strength of MaterialsDocumento4 páginasStrength of MaterialsAllyanna Elise DiamAinda não há avaliações

- DC Generator: 1. CommutationDocumento6 páginasDC Generator: 1. CommutationElsa WatsonAinda não há avaliações

- M-55 6u2846193 Marine Growth Preventing SystemDocumento21 páginasM-55 6u2846193 Marine Growth Preventing SystemJosip Zohil100% (1)

- P15 Tests ElectromagnetismDocumento5 páginasP15 Tests ElectromagnetismAshleyAinda não há avaliações

- Calvert CV For Material ScientistDocumento2 páginasCalvert CV For Material ScientistkaylagatorAinda não há avaliações

- A3 14 (SC) 01 (B)Documento184 páginasA3 14 (SC) 01 (B)bpd21Ainda não há avaliações

- From The Arrhenius To The Clausius-Clapeyron Equation: Igor NovakDocumento2 páginasFrom The Arrhenius To The Clausius-Clapeyron Equation: Igor NovakJonathanAinda não há avaliações

- Significance of Coordination Compounds in Daily LifeDocumento4 páginasSignificance of Coordination Compounds in Daily LifeMalaika YousafAinda não há avaliações