Escolar Documentos

Profissional Documentos

Cultura Documentos

Carbocoat 116 PDS

Enviado por

Kuncoro Sidi0 notas0% acharam este documento útil (0 voto)

81 visualizações2 páginascarbocoat

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentocarbocoat

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

81 visualizações2 páginasCarbocoat 116 PDS

Enviado por

Kuncoro Sidicarbocoat

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

Carbocoat 116

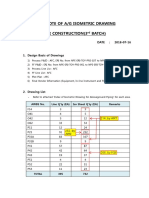

Selection & Specification Data Application Equipment Guidelines

Generic Type Modified Alkyd Primer Listed below are general equipment guidelines for the application of this product. Job site conditions

may require modifications to these guidelines to achieve the desired results.

Description Fast drying steel primer that provides corrosion

protection on structural steel. Well suited for Conventional Binks #18 or #62 gun or equal cup or pressure pot

fabrication shops that need fast cure to dry and handle Spray Fluid Nozzle: 66 or 63C

times. May be topcoated with conventional alkyds and Air Nozzle: 63PB or 66P

acrylics for color, aesthetics, or additional protection. Fluid Pressure: 10-15 psi

Air Atomizing Pressure: 60 psi

Features Fast Dry

Note: Can be electrostatically sprayed.

VOC compliant less than 250 g/l

Airless Spray Apply using a piston pump having a flow rate of 3/4

Color Gray, Red, White

GPM or higher, and able to deliver 2000-3000 psi.

Finish Flat Material Hose: 3/8" x 150 max

Dry Film 2.0 mils (51 microns) per coat Tip Size: 0.011-0.015"

Thickness High Pressure Filter: 60 Mesh

Average thickness 1.5-2.0 mils (37-50 microns)

Application Conditions

Solids Content By Volume 56% +/- 2%

Theoretical 2 2 Condition Material Surface Ambient Humidity

898 ft at 1.0 mils (22.0 m /l at 25 microns)

Coverage Rate 2 2

Minimum 35 F (2 C) 35 F (2 C) 35 F (2 C) 0%

449 ft at 2.0 mils (11.0 m /l at 50 microns) Maximum 120 F (49 C) 120 F (49 C) 120 F (49 C) 95%

This product simply requires the substrate temperature to be above the dew point. Condensation

Allow for loss in mixing and application. due to substrate temperatures below the dew point can cause flash rusting on prepared steel and

interfere with proper adhesion to the substrate. Special application techniques may be required

VOC Values As Supplied 2.08 lbs/gal (249 g/l) above or below normal application conditions. Proper airflow during curing process is critical.

According to EPA Method 24. These are nominal values and may vary

slightly with color. Product contains VOC-exempt t-butyl acetate. Check

local regulations regarding product usage.

Curing Schedule

Dry Temp. Continuous: 180 F (82 C)

Surface Temp. Dry to Handle Dry to Recoat Dry to Touch

Resistance Non-Continuous: 200 F (93 C)

& 50% Relative

Topcoats Humidity

May be topcoated with other products, as recommended by Carboline 35 F (2 C) 2 Hours 24 Hours 30.0 Minutes

Technical Service.

50 F (10 C) 90.0 Minutes 16 Hours 20.0 Minutes

77 F (25 C) 1 Hours 8 Hours 15.0 Minutes

Substrates & Surface Preparation 90 F (32 C) 45.0 Minutes 4 Hours 10.0 Minutes

Cure time based on 1.5-2.0 mils (37.5-50 microns) DFT.

Galvanized Steel NOT RECOMMENDED for galvanized steel. Allow additional drying time at lower temperature or higher humidity.

Contact Carboline Tech Service if you have additional questions.

Special Instruction This primer should be applied the same day as

cleaning to prevent re-rusting.

Spray is the preferred application method due to the Cleanup & Safety

quick drying nature of the product.

Ferrous Metal The surface should be thoroughly cleaned to remove Cleanup Clean up all tools and equipment promptly with

dirt, grease, chalk and air pollution deposits, ideally xylene, toluene, or VOC exempt solvent. Flush spray

by power washing. For aggressive environments, in equipment with the same cleaning solvent.

order to obtain adhesion, a Commercial Blast (SSPC- Safety Read and follow all caution statements on this

SP6. For noncorrosive environments, depending on product data sheet and on the MSDS for this product.

the condition of the steel, the surface preparation shall Employ normal workmanlike safety precautions. Keep

be either SSPC-SP2 Hand Tool Cleaning, SSPC-SP3 container closed when not in use.

Power Tool Cleaning, or SSPC-SP11 Power Tool

Cleaning, or SSPC-SP6 Commercial Blast Cleaning.

Mixing & Thinning

Mixing Power mix to a uniform consistency.

Thinning Thinning is not normally required. Can use up to 5%

by volume thinner 242 E. Material is ready to spray.

October 2015 0295

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company

to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Page 1 of 2

Carbocoat 116

Packaging, Handling & Storage

Shelf Life 24 months

Shipping Weight 1 Gal Kit - 14 lbs (6.35 kgs)

(Approximate) 5 Gal Kit - 68 lbs (30.85 kgs)

Storage 40 - 110F (4- 43C)

Temperature & 0-100% Relative Humidity

Humidity

Flash Point 50F (10C) setaflash

(Setaflash)

Storage Store Indoors.

October 2015 0295

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company

to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Page 2 of 2

Você também pode gostar

- Pipe ManualDocumento17 páginasPipe Manualrosarr1976Ainda não há avaliações

- Analisis Sifat Korosi Galvanik Berbagai Plat Logam Di Laboratorium Metalurgi Politeknik Negeri BatamDocumento4 páginasAnalisis Sifat Korosi Galvanik Berbagai Plat Logam Di Laboratorium Metalurgi Politeknik Negeri BatamFahmi Eka BudianAinda não há avaliações

- Gantry CraneDocumento20 páginasGantry Cranekushaljp8989Ainda não há avaliações

- Analisis Sifat Korosi Galvanik Berbagai Plat Logam Di Laboratorium Metalurgi Politeknik Negeri BatamDocumento4 páginasAnalisis Sifat Korosi Galvanik Berbagai Plat Logam Di Laboratorium Metalurgi Politeknik Negeri BatamFahmi Eka BudianAinda não há avaliações

- Batch 3Documento1 páginaBatch 3Kuncoro SidiAinda não há avaliações

- Type Steam TrapDocumento1 páginaType Steam TrapKuncoro SidiAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- NATO Obsolescence Management PDFDocumento5 páginasNATO Obsolescence Management PDFluisAinda não há avaliações

- Rolling TechnologyDocumento4 páginasRolling TechnologyFrancis Erwin Bernard100% (1)

- Agency Procurement Request: Ipil Heights Elementary SchoolDocumento1 páginaAgency Procurement Request: Ipil Heights Elementary SchoolShar Nur JeanAinda não há avaliações

- 1 - DIASS Trisha Ma-WPS OfficeDocumento2 páginas1 - DIASS Trisha Ma-WPS OfficeMae ZelAinda não há avaliações

- Rwamagana s5 Mathematics CoreDocumento4 páginasRwamagana s5 Mathematics Coreevariste.ndungutse1493Ainda não há avaliações

- The Chulalongkorn Centenary ParkDocumento6 páginasThe Chulalongkorn Centenary ParkJack FooAinda não há avaliações

- 4BT3 9-G2 PDFDocumento5 páginas4BT3 9-G2 PDFNv Thái100% (1)

- S P99 41000099DisplayVendorListDocumento31 páginasS P99 41000099DisplayVendorListMazen Sanad100% (1)

- Dash8 200 300 Electrical PDFDocumento35 páginasDash8 200 300 Electrical PDFCarina Ramo LakaAinda não há avaliações

- Atoll 1400Documento2 páginasAtoll 1400David M. SeoaneAinda não há avaliações

- Previous Papers GPSC Veterinary Officer AHI Advt. No. 33 2016 17 Date of Preliminary Test 08 01 2017 Subject Concerned Subject Que 101 To 300 Provisional Key PDFDocumento18 páginasPrevious Papers GPSC Veterinary Officer AHI Advt. No. 33 2016 17 Date of Preliminary Test 08 01 2017 Subject Concerned Subject Que 101 To 300 Provisional Key PDFDrRameem Bloch100% (1)

- Region: South Central State: Andhra PradeshDocumento118 páginasRegion: South Central State: Andhra PradeshpaulinAinda não há avaliações

- 6 - European Cluster Partnership For Excellence - European Cluster Collaboration PlatformDocumento5 páginas6 - European Cluster Partnership For Excellence - European Cluster Collaboration PlatformDaniela DurducAinda não há avaliações

- Financial Management of Public Sector Unit (PSU) - NotesDocumento23 páginasFinancial Management of Public Sector Unit (PSU) - Notesbiz19100% (1)

- April 8/91: All GroupsDocumento33 páginasApril 8/91: All Groupsreza mirzakhaniAinda não há avaliações

- DLL in Health 7 3rd QuarterDocumento2 páginasDLL in Health 7 3rd QuarterJuna Lyn Hermida ArellonAinda não há avaliações

- Categories of Cargo and Types of ShipsDocumento14 páginasCategories of Cargo and Types of ShipsVibhav Kumar100% (1)

- Carte EnglezaDocumento112 páginasCarte EnglezageorgianapopaAinda não há avaliações

- Chemistry II EM Basic Learning MaterialDocumento40 páginasChemistry II EM Basic Learning MaterialMAHINDRA BALLAAinda não há avaliações

- Understanding Culture Society, and PoliticsDocumento3 páginasUnderstanding Culture Society, and PoliticsVanito SwabeAinda não há avaliações

- Albert-Einstein-Strasse 42a, D-63322 Roedermark, Germany Tel.: 0049 (0) 6074-7286503 - Fax: 0049 (0) 6074-7286504Documento19 páginasAlbert-Einstein-Strasse 42a, D-63322 Roedermark, Germany Tel.: 0049 (0) 6074-7286503 - Fax: 0049 (0) 6074-7286504Ilias Asimakis100% (1)

- You're reading a free preview. Pages 4 to 68 are not shown in this preview. Leer la versión completa You're Reading a Free Preview Page 4 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 5 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 6 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 7 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 8 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 9 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 10 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 11 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 12 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 13 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 14 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 15 is notDocumento9 páginasYou're reading a free preview. Pages 4 to 68 are not shown in this preview. Leer la versión completa You're Reading a Free Preview Page 4 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 5 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 6 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 7 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 8 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 9 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 10 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 11 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 12 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 13 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 14 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 15 is notFernando ToretoAinda não há avaliações

- Under Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisDocumento13 páginasUnder Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisMahmud RahmanAinda não há avaliações

- Chapter 2Documento69 páginasChapter 2Lizi CasperAinda não há avaliações

- DR Afwan Fajri - Trauma - Juli 2023Documento82 páginasDR Afwan Fajri - Trauma - Juli 2023afwan fajriAinda não há avaliações

- دور أخلاقيات الأعمال في تحسين أداء المنظماتDocumento14 páginasدور أخلاقيات الأعمال في تحسين أداء المنظماتChaima LaifaAinda não há avaliações

- A Tall Order - Cooling Dubai's Burj Khalifa: FeatureDocumento2 páginasA Tall Order - Cooling Dubai's Burj Khalifa: FeatureMohsin KhanAinda não há avaliações

- Chapter 08 MGT 202 Good GovernanceDocumento22 páginasChapter 08 MGT 202 Good GovernanceTHRISHIA ANN SOLIVAAinda não há avaliações

- PPT-QC AcDocumento34 páginasPPT-QC AcAmlan Chakrabarti Calcutta UniversityAinda não há avaliações

- 2008 Kershaw CatalogDocumento38 páginas2008 Kershaw CatalogDANILA MARECHEKAinda não há avaliações