Escolar Documentos

Profissional Documentos

Cultura Documentos

Report

Enviado por

priyapgandhiTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Report

Enviado por

priyapgandhiDireitos autorais:

Formatos disponíveis

Automatic Drip Irrigation System

1. INTRODUCTION

1.1 Introduction

Raindrops are like liquid gold to farmers in the poorest countries of the world. Yet when

the rains do come - and in many places they come erratically or with decreasing frequency

- with no irrigation techniques available, most of that precious moisture is washed away,

unused. Land is so dehydrated that they are unable to grow enough produce even to

sustain their families, there seems to be no way out.

Practical Action is working with communities to introduce simple yet effective irrigation

systems to combat the issue. So instead of parched, dusty fields, there are life-giving

gardens brimming with hearty fruit and vegetables or sturdy columns of maize, year after

year. Even if rainfall is low or erratic, the drip irrigation system enables farmers to nourish

and grow the crops they need.

This is how it works:

A large, water harvesting tank in the village catches the rain and stores it.

A farmer fills a 20-litre drip bucket and places it one meter above the ground on

poles.

The drip bucket is attached to a long hose that criss- crosses the crop field.

Simple gravity provides enough pressure to force the water through the hose.

Water drips through the holes in the hose, directly onto the roots of the plants.

GHRCEM, Ahmednagar (E&TC Engineering) Page 1

Automatic Drip Irrigation System

100-200 plants can be grown using just one drip bucket system.

1.2 Necessity

The ultimate aim of our project is to provide the water supply to the various areas

of the field. The conventional method is to operate the manual motor/valves, by

an operator. Thus, the operator has to be alert and regular to provide the water. If

the operator is irregular or he is late due to some reason it creates major problem.

So, our system that is timer based drip irrigation system works automatically. Set

a time by keyboard its a micro controller based system.

1.3 Organization

The overall detail of project is organized in 6 chapters. Chapter 1 contains the

introduction of entire project. It includes the basic idea of the working of the

system. Chapter 2 contains the Literature survey where the history of the already

existing system is discussed. It contains all the papers we have referred for our

system. This gives us a brief idea about the improvement in the system. It gives

us a rough idea of the previous techniques and the various components used in

them. Chapter 3 contains the aim and objective of the system. It contains the

problem statement of our system. It also contains the objectives which were

observed by us and also the limitations of other systems, because of which we felt

it necessary to design the system. Chapter 4 deals with System development. It

consists of the block diagram which we have proposed for our system. It also

consists of the hardware components and their description. It includes the detail

description of all the components used along with their diagrams and operation

and their interfacing with other components. As well as it includes the technical

specifications of the various components of the system. Chapter 5 consists of the

results which we have shown for the rain sensor, level indicator and for the entire

system. Chapter 6 consists of the conclusions which we have made, and also the

advantages of our system, disadvantages of the system, the applications i.e. the

various places where it can be used, and the future improvements which can be

easily made in the system i.e. the future scope of the system and also the list of

GHRCEM, Ahmednagar (E&TC Engineering) Page 2

Automatic Drip Irrigation System

references which we have referred for the improvement and further development

of the system

GHRCEM, Ahmednagar (E&TC Engineering) Page 3

Automatic Drip Irrigation System

2. LITERATURE SURVEY

We surveyed on IEEE papers, [1] International Conference on Computation of Power,

Energy Information and Communication (ICCPEIC), published in the year 2016 titled as

Automated Plant Watering System. This paper consisted of ATmega 328 microcontroller,

which was programmed to water the plants using sprinklers through mobile

applications.In this the system was designed in such a way that it reported its current state

as well as reminded the user to add water. In this system the microcontroller was

programmed to water the plants two times per day. Next we surveyed on IEEE paper

based on Automatic Crop Irrigation System [2],which was published in the year 2015.In

this paper, GSM module was included which sends message only on registered mobile

number .This system kept notifying the farmers through an on-board LCD display and

sends the message on the farmers registered mobile number. This system also had the

capability to indicate the water level. This system included automated supply of water to

the fields according to the crop sown and the depth of indicator strip. Next we surveyed

on IEEE paper, based on 3rd International Conference on System Engineering and

Technology, published in the year 19 - 20 Aug. 2013, by Shah Alam, Malaysia [3], which

was titled as Fully Automatic Water Irrigation and Drainage System for Paddy Rice

Cropping in Malaysia. This paper consisted of water level sensors, which senses the level

of water continually in the field. This system had water level sensors which were placed in

the rice field which continuously measured the water level. This system automatically

irrigated water through entrance gate when the water level is lower than the desired level.

The entrance gate closes after the water level reaches the desired level. When the water

level in the rice field is higher than the desired level, this system either opens the exit gate

if the drain is empty, or switches on the pump if the drain is full of water .Next we

surveyed on IEEE paper based on International Journal of Advanced Engineering and

Global Technology ISSN No: 2309-4893 Vol-04, Issue-01[4] titled as Design and

implementation of Automatic Plant watering System published in the year January 2016.

In this paper the automatic system based on ARM (Advanced RISC Machine) and for

communication GSM (Global System for Mobile communication) technology was used.

This system had microcontroller based design which controlled the water supply and the

GHRCEM, Ahmednagar (E&TC Engineering) Page 4

Automatic Drip Irrigation System

field to be irrigated. This system also consisted of sensors which were present in each

field which were not activated till the water was present on the field. Once the field gets

dry sensors sense the requirement till the sensors are de-activated again. In case when

there is more than one signal for water requirement then the microcontroller will prioritize

the first received signal and irrigate the fields accordingly.

Next we surveyed on the International Journal of Modern Engineering Research (IJMER)

ISSN: 22496645 Vol. 5 Issue 4[5], published in the year April 2015, titled as

Microcontroller Based Automatic Sprinkler Irrigation System. In this system Automatic

sprinkler irrigation system was designed. This system uses a microcontroller that acts as a

decision taking unit. Microcontroller takes decision based upon the input set by a farmer

as per his requirements and water flow sensor. It controls the operation of solenoid valve

and continuously motors the run time of sprinkler water pipeline. All solenoid valves are

opened in sequence for the irrigation of the crop.

Next we surveyed on the paper based on International Journal of Agricultural Science and

Research (IJASR) ISSN 2250-0057 Vol. 3 Issue 3[6] published in the year August 2013,

titled as intelligent irrigation system. In this system Automatic irrigation system and

automatic pesticide system was designed. This system discussed the prototype design of

microcontroller based on intelligent irrigation system which allowed irrigation to take

place in zones where watering is required, while bypassing zones where adequate soil

moisture was indicated. Other feature of this prototype is pesticide sprinkling system

where the mixture is prepared in required proportion deserved by plants automatically

thereby preventing the human mistakes to maximum extent.

GHRCEM, Ahmednagar (E&TC Engineering) Page 5

Automatic Drip Irrigation System

3. AIM AND OBJECTIVE

3.1 Problem statement

Irrigation of plants is usually a very time consuming activity; to be done in a reasonable

amount of time, it requires a large amount of human resources. Traditionally all the steps

were executed by humans. Now a days, some systems use technology to reduce the

number of workers or the time required to water the plants. With such systems the control

is very limited, and many resources are still wasted.It is a challenge for farmers to

maintain their fields and manage watering of plants during shortage of water. Based on

the above background, we thought that it is necessary to implement the automated system

which will take care of plants considering all the different aspects of drip irrigation

system.

3.2 Aim

Our project aims to implement a simple system using automatic drip irrigation, which

waters the plant with minimal human intervention.

3.3 Objectives

The objective of this project was to design a small scale automated irrigation system for

indoors that would use water in a more efficiency way, in order to prevent water loss and

minimize the cost of labor.

To provide the necessary moisture for the crop development.

To ensure sufficient supply of water during droughts of short duration and

unpredictable climate.

To dissolve soil salts.

It is a way to apply agro-chemicals.

To improve the ambient condition for the vegetative growth.

GHRCEM, Ahmednagar (E&TC Engineering) Page 6

Automatic Drip Irrigation System

4. SYSTEM DEVELOPMENT

4.1 Design of the system

4.1.1 Description of blocks: -

Microcontroller: - This is used for interfacing of specific devices. In our project the role

of micro controller is to manage the events as per program. It is 8 bit CPU with 4K

internal flash memory that means the memory can be reprograms 10,000 times and thus

the same micro controller can be used, for various applications.

Timer: - The timer is going to give a facility of password to avoid unauthorized access.

As concerned with reliability and accuracy micro controller is more efficient compared to

GHRCEM, Ahmednagar (E&TC Engineering) Page 7

Automatic Drip Irrigation System

other timers. Battery backup is also used. So there will not be any effect of power failure.

We can see time of day on LCD.

Rain sensor:-

Basic NPN Transistor Switching Circuit:

Conductive probes - The probe is feedback instrument of the automated irrigation system.

It is used to measure the moisture content of the soil in which it is place permanently.

When activated it gives an electric output from a transistor.

Relay: - Relays are simple switches which are operated both electrically and

mechanically. Relays consist of an electromagnet and also a set of contacts. The switching

mechanism is carried out with the help of the electromagnet. There are also other

operating principles for its working. But they differ according to their applications.

4.2 System Software

4.2.1 Keil uvision-4 software:

Keil is based on Integrated Development environment (IDE). It consists of a code

editor, a compiler, a debugger and what you see is what you get (WYCIWYG)

editor in a single package, which is used for programming in embedded c and

generate Hex code for burning in microcontroller.

Steps for keil software:

Open the Keil IDE.

The Keil IDE main window in is divided into three areas.

i)Editor: Here .c file and and .h files are written and edited.

ii) Project explorer: It shows the project tree.

iii) Output window: Shows messages related with compiling, project building and

debugging.

Click on project->new uvision project.

choose file name , for e.g. multisensor.uvproj and its saving location

Select the device for target target1 i.e. AT89c51 and press ok.

GHRCEM, Ahmednagar (E&TC Engineering) Page 8

Automatic Drip Irrigation System

Now select yes to copy startup.s file, this is for initial configuration and right

click the target option in project window and select output->create hex file option.

Creating and writing program.

Click New and save file with name main.c .Write the program and save the

program.

Right click source group and add files to source group and select saved files to add

to the program.

Click on Build for compiling the program and see for errors in output window, if

any to correct it.

4.2.2 Flash Magic:

This software is used for burning the generated Hex file into microcontroller.

After selecting Build option, it will create hex file with same name as project name

and this file is used for burning program in flash memory of microcontroller using

flash magic.

This is done by serial communication using UART (Universal Asynchronous

Receiver/Transmitter) by connecting PC with UART0 of microcontroller using

RS232 (DB 9 cable).

Steps involved in burning:

Hex file is created.

Pc is connected with microcontroller using DB-9 and uart.

Open Flash magic and select microcontroller, select assigned COM port.

Set the Baud Rate (the baud rate of both microcontroller and pc should be same

for burning) and crystal frequency to 12 MHZ.

Select erase blocks used by hex file and verify after programming and load the hex

file and click on start to burn the hex file.

4.3 HARDWARE DESCRIPTION:-

The hardware of drip irrigation system consists of a micro controller based system, we

real clock operation and the displays are shown on 16 x 2 type alphanumeric display.

Relay board is controlled by the micro controller which operates keyboard with timer

GHRCEM, Ahmednagar (E&TC Engineering) Page 9

Automatic Drip Irrigation System

which is a works on the principle of amplitude shift Keying modulation. The matrix

keyboard is provided which is used to set the various timing inside the micro controller.

At the output of the relay driver IC a bank of four relays is there. The system works on

DC supply, which is developed on the system only. The detailed explanation regarding the

power supply is illustrated in separate chapter.

At receiver end motor/solenoid valve which operates on 230V AC and it is based on the

principle of electromagnetic indication. When the relay is switch ON it closes its contact

and provides 230V AC supply, to the motor or coil of solenoid valve. Due to this electro -

magnetic field is generated and the piston in solenoid valve is pushed backsword, and thus

the way for the flow of water is there. When the supply is cut the coil of solenoid valve is

demagnetized and the piston comes to its original position. It opposes the flow water, and

thus, the water supply is stopped.

Micro controller:-

AT 89C51 is micro controller is used. It is 8 bit CPU with 4K internal flash memory that

means the memory can be reprograms 10,000 times and thus the same micro controller

can be used, for various applications. It is having 4 different I/O ports. Out of 4 ports 3

are general purpose ports and 1 is special purpose port. This is used for interfacing of

specific devices. It also content 2, 16 bit internal timers and counters. In our project the

role of micro controller is to manage the events as per program. For programming

purpose matrix keyboard is provided. We can feed a specific password, for entering the

program mode. This will be secreted and will be familiar to the related persons only.

Thus, no other person can interfere the water distribution tank once the program is fed.

The 4 x 4 matrix is interfaced at port no 1 of micro controller AT 89C51; at port no 0

LCD is interfaced. Port no 3 is used for keyboard interfaced. The time entered by the

matrix keyboard, is stored inside the memory. The port no 2 is used for driving various

relays. As different relays are to be made on different times, the time for particular relay

is all ready set. During the passage of the time when set time for particular relay, comes

the relay is ON. After decoding the signal it is given to multiplexer where the provisions

GHRCEM, Ahmednagar (E&TC Engineering) Page 10

Automatic Drip Irrigation System

life latch hold mode and normal invert mode is provided. We can select our required

module. At the output of multiplexer ULN driver is there. It is an array of 7 Darlington

pair transistors. It drives the coil of and electromagnetic relay which in turn operates the

solenoid valve.

The details regarding the LCD interfaced and keyboard are provided as below:-

Microcontroller LCD:-

Atmels 89C51 is the central processing unit of our system. It is 8 bit ADC having 4K

flash memory and 128bytes of RAM. It has 4 input output ports out of which port 3 is a

special purpose port. Port 1, 2 and 0 are general purpose ports. But port 3 can also be

used as general purpose port if required. It is a single chip micro controller suitable to our

application. Hence it is used here. The 32 I/O lines can be used for any purpose, say

ADC, DAC, LCD, Relay, LED display interfacing. Also real time clock and serial

communication with PC. In our application we use serial interface between ADC and

micro controller. ADC and micro controller communication is already discussed.

LCD Interface:-

Interface of LCD with micro controller requires hardware as well as software

synchronization. As shown below LCD is having 16 pins for signaling and associated

VCCs and GNDs.

Pin 1 and 2 are the Vcc and GND to LCD module. Pin 3, 4 & 4 are the control signal to

LCD module from micro controller, i.e. R/S determines, whether the signal sent is

command or data. If it is then it is data and when it sends 1, it is 0 (Zero). R/W enables

GHRCEM, Ahmednagar (E&TC Engineering) Page 11

Automatic Drip Irrigation System

if 0 it reads the data, if it is 1 it writes the data. EN Enables an active data to enable

strobe. D0-D7 (P7-P14) is the data bus through which 8 bit data from micro controller

89C51 is sent to LCD. LCD accepts this data, its micro controller manages, how to write

or read in its memory or indicate on LCD display. Thus, in our case both parameters say

temperature and humidity is shown on LCD display. P15, P16 are used for the supply of

back plate LED. The LCD we used is 16 x 2 alphanumeric type means two rows

containing 16 characters in each row.

Timer:-

In market several projects are available which can be used to give timing schedules. In

market sequential timer circuit is available which a CMOS timer is. This timer can make

ON one or more electronic or electric equipment in specific sequence and turns them OFF

after some particular time. It uses a timer IC MC 7555 that is a low frequency oscillator.

It controls or adjusts the time period by VR1. This timer can be used for such an

application like our project but it is not having facility for prohibiting unauthorized

access. So we are going to give facility of password to avoid unauthorized access. As

concerned with reliability and accuracy micro controller is more efficient compared to

other timers. Battery backup is also used. So there will not be any effect of power failure.

We can see time of day on LCD which facility is not provided in above project. Another

option a system is can be long duration timer which is available. Which uses timer IC555,

it is used along with CD 4060 for giving time delay more than 30 min. it can give delay

up to 24 hrs, 12 hrs, 1.5 hrs, 45 hrs, 22.5 min.

Another long duration timer uses IC 4020 which is counter, which uses only two ICs. It

selects time with the help of switch. After completion of selected time period relay

becomes ON and get connected with the circuit. In requirement they do not requires large

delay and system is not programmable. And again it cannot have password facility to

avoid unauthorized access. The system will require less maintenance as compared to

system discussed above and will have long life than above discussed systems. Battery

backup is also used. So there will not be any effect of power failure. In 89C51 two timers

provided and also Read Only Memory (ROM) of 4 KB is provided. Random Access

GHRCEM, Ahmednagar (E&TC Engineering) Page 12

Automatic Drip Irrigation System

Memory (RAM) is 128 bytes for 89C51. This is sufficient for our project thats why we

are using 89C51 which is having low cost than 89C52. The popular AT89C51 chip has an

on chip ROM in the form of Flash memory. This is ideal for fast development since flash

memory can be erased in seconds compared to 20 minutes or more needed for 8751 and

for that reason AT89C51 is used in place of 8751 and others to eliminate the waiting time

needed to erase the chip and there by speed up the development time. In flash memory we

must erase the entire contents of ROM in order to program it again. This erasing of Flash

is done by PROM burner itself, therefore separate eraser is not required and now to

eliminate the need of PROM burner Atmel is working on version of AT89C51 that can be

programmed via the serial COM port of an IBM PC. Priority, the problem of mapping a

concept of time constraint reactions on to traditional constructs remains. We will prefer

the Assembly language.

Memory Management:-

Another problem facing the user of modern languages is the task of correctly managing

memory. Although not a problem specific to systems, the scares memory resources of

system make memory leakage on urgent and intolerable problem. One commonly

suggested solution is to lessen the Burden on the program.

Capturing of Specifications:-

Real time system is usually identified with the concept of using real time operating system

for concurrency and process management. Traditional C or C++ coding for Timer

Operating System lacks the ability to natively capture the timely behavior of a system

whereas the real time behavior of a system is often specified in terms of reaction

deadlines, the common real time operating system programming model requires the

reactions to be translated into process or threads and the deadlines to be translated into

priorities. Even if we can derive appropriate thread.

GHRCEM, Ahmednagar (E&TC Engineering) Page 13

Automatic Drip Irrigation System

Rain sensor:-

Fig: Basic NPN Transistor Switching Circuit

The difference this time is that to operate the transistor as a switch the transistor needs to

be turned either fully OFF (cut-off) or fully ON (saturated). An ideal transistor switch

would have infinite circuit resistance between the Collector and Emitter when turned

fully-OFF resulting in zero current flowing through it and zero resistance between the

Collector and Emitter when turned fully-ON, resulting in maximum current flow. In

practice when the transistor is turned OFF, small leakage currents flow through the

transistor and when fully ON the device has a low resistance value causing a small

saturation voltage ( VCE ) across it. Even though the transistor is not a perfect switch, in

both the cut-off and saturation regions the power dissipated by the transistor is at its

minimum. In order for the Base current to flow, the Base input terminal must be made

more positive than the Emitter by increasing it above the 0.7 volts needed for a silicon

device. By varying this Base-Emitter voltage VBE, the Base current is also altered and

which in turn controls the amount of Collector current flowing through the transistor as

previously discussed. When maximum Collector current flows the transistor is said to

be Saturated. The value of the Base resistor determines how much input voltage is

required and corresponding Base current to switch the transistor fully ON.

GHRCEM, Ahmednagar (E&TC Engineering) Page 14

Automatic Drip Irrigation System

Conductive probes: - The probe is feedback instrument of the automated irrigation system.

It is used to measure the moisture content of the soil in which it is place permanently.

When activated it gives an electric output from a transistor. The probes have to be

compatible with most soil types.

4.4 Technical specifications:-

1) Supply Voltage = 230 V AC, 5 V DC, 12V DC.

2) Logic = AT 89c51 based.

3) Language = Assembly.

4) Indication = 16 x 2 LCD Display.

5) Time setting = Through Matrix keyboard.

6) External memory = 24C04.

7) Memory Interface Protocol = I2C.

8) Power transformer = 0-12V, 1A.

9) Relay 12V dc electromagnetic.

10) Motor operating load capacity up to 12A.

11) Motor power rating 1/4 HP.

12) Motor speed 280 rpm.

Innovative idea of the project:-

1) Fully Programmable.

2) Not affected by power failure.

3) Completely digital control.

4.5 Data validity:

The data on the SDA line must be stable during the HIGH period of the clock. The HIGH

or LOW state of the data line can only change when the clock signal on the SCL line is

low.

START and STOP Conditions: -

1. A HIGH to LOW transition on the SDA line while SCL is HILGH is one unique

case. This situation indicates a START condition.

GHRCEM, Ahmednagar (E&TC Engineering) Page 15

Automatic Drip Irrigation System

2. A LOW to HIGH transition on the SDA line while SCL is HILGH defines a

STOP condition.

3. The master always STARTS and STOPS conditions. The bus is considered to be

busy after the START condition. The bus is considered to be free again certain

time after the STOP condition.

4. The bus stays busy if a repeated START is generated instead of a STOP

condition.

5. Detection of start and stop conditions by devices connected to the bus is easy if

they incorporate the necessary interfacing hardware. However microcontrollers

with no such interface have to sample the SDA line at least twice per clock

period to sense the transition.

4.6 Write operation:

Bytes write:

It requires 8 bit data word address following device address word and acknowledgment.

Upon receipt of this address EEPROM will again respond with a zero and the clock in the

first 8 bit data word address following receipt of the 8 bit data word.

The EEPROM will output a 0 and addressing device such as microcontroller must

terminate the right sequence with STOP condition. At this time the EEPROM enters an

internally time write T (wr).

4.7 Read operation:-

Sequential read:-

Sequential reads are initiated by either by current address of random address read. After a

microcontroller receives a data word it responds with acknowledge as long as EEPROM

receives acknowledge, it will continue to increment a data word address and serially clock

out the sequential data words.

When memory address limit is reached, the data word address will roll over and

sequential read will continue. The sequential read operation is terminated when the

microcontroller does not respond with a 0 but does generate a STOP condition.

GHRCEM, Ahmednagar (E&TC Engineering) Page 16

Automatic Drip Irrigation System

4.8 Operation:

The timer set by keyboard motor is operated cyclic type Access is obtained by

implementing a START condition and providing a device identification code followed by

a register address. Subsequent register can be accessed sequentially until a STOP

condition is executed.

When Vic falls below 1.25 x V (bat) the device terminates an access in progress and reset

the device address counter inputs to the device will not be recognized at this time to

prevent erroneous data from being written to the device from an out of tolerance system

when Vcc falls below V (bat).

The microcontroller switches into low current battery backup mode. On power up the

microcontroller switches from battery to Vcc. When Vcc is greater than (V (bat) + 0.2 V)

and recognizes input when Vcc is greater than 1.25 x V (bat).

GHRCEM, Ahmednagar (E&TC Engineering) Page 17

Automatic Drip Irrigation System

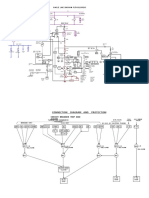

4.9 Circuit diagram

The circuit diagram consists of microcontroller, keyboard, relay, rain sensor, and level

indicator and resistor bank. The keyboard acts as an input to the system. Rain sensor

senses the level of rain fall and intensity of rain. Level indicator gives indication of levels

in the upper tank and shows levels of the water in the tank. The microcontroller gives the

signals to the respective pin numbers. Relay acts as a switch in it. The resistor bank in it is

GHRCEM, Ahmednagar (E&TC Engineering) Page 18

Automatic Drip Irrigation System

given as an additional support to the system as external supply as per the requirement of

the system and the microcontroller.

4.10 Flow chart

Start

Check whether the

tank is full

Yes Is tank full

No

No

Fill the tank by using the

lower tank

Check the rainfall level

No

Rain<4m

m

Yes

Watering of plants up to

specified duration

Stop

GHRCEM, Ahmednagar (E&TC Engineering) Page 19

Automatic Drip Irrigation System

4.11 PCB Layout

GHRCEM, Ahmednagar (E&TC Engineering) Page 20

Automatic Drip Irrigation System

5. RESULTS

At the specified time, the timer will get ON then the microcontroller will give signal to the

valve and the valve will open automatically and it will water the plants. The counter will

count for the specified duration, after the completion of the specified duration the counter

will give signal to the microcontroller indicating it to turn OFF the valve. In return the

microcontroller will give signal to the valve and the valve will turn OFF automatically. In

case, if the rain comes then the rain sensor present in the system will detect the rain and it

will inform the microcontroller. Now if this rainfall is below the threshold level then the

watering will be as usual, but if this rainfall is above the threshold level then the valve

will water the plants according to the intensity of the rain.

1. Result for working of rain sensor

GHRCEM, Ahmednagar (E&TC Engineering) Page 21

Automatic Drip Irrigation System

2. Result for working of level indicator.

GHRCEM, Ahmednagar (E&TC Engineering) Page 22

Automatic Drip Irrigation System

3. Result of entire system.

GHRCEM, Ahmednagar (E&TC Engineering) Page 23

Automatic Drip Irrigation System

5.1 Comparison between existing system and proposed system

Table 5.1 Results for comparison of existing work with our proposed system.

Sr. no. Parameters Existing work Proposed system

01 Sensors used Soil, moisture, Rain sensor

humidity & rain

sensor.

02 Mobile application Used Not used

03 Arduino board Used Not used

04 Moisture content Detected Not detected

05 Drip/water sprinkler used Both are used Only drip is used

GHRCEM, Ahmednagar (E&TC Engineering) Page 24

Automatic Drip Irrigation System

6. CONCLUSION

6.1 Conclusion

The Microcontroller based drip irrigation system proves to be a real time feedback control

system which monitors and controls all the activities of drip irrigation system efficiently.

The present proposal is a model to modernize the agriculture industries at a mass scale

with optimum expenditure. An automated irrigation was successfully designed and

assembled. It serves to reduce the consumption of water used, the human monitoring time

and labor associated with a standard method. This design uses a time feedback control to

measure the soil moisture and turn on the motor/valve on demand, in regular interval.

Such system can be manufactured at a relatively low cost using simple electronic part.

Using this system, one can save manpower, water to improve production and ultimately

profit

6.2 Advantages

1. Relatively simple to design and install.

2. This is very useful to all climatic conditions any it is economic friendly.

3. This makes increase in productivity and reduces water consumption.

4. Here we have microcontrollers so there is error free.

5. This is safest and no manpower is required. Permit other yard and garden work to

continue when irrigation is taking place, as only the immediate plant areas are wet.

6. Reduce soil erosion and nutrient leaching.

7. May be concealed to maintain the beauty of the landscape, and to reduce

vandalism and liability when installed in public areas.

8. Require smaller water sources, for example, less than half of the water needed for

a sprinkler system.

9. Weed growth is lessened.

10. Fields with irregular shapes are easily accommodated.

11. Saving of manpower

12. Soil erosion is lessened.

13. Optimal water supply to crop

GHRCEM, Ahmednagar (E&TC Engineering) Page 25

Automatic Drip Irrigation System

14. Protection against adverse weather conditions

15. It is user-friendly system.

6.3 Disadvantages

1. This is only applicable for large size farms.

2. Equipment is costlier.

3. Require frequent maintenance for efficient operation.

4. Have limited life after installation due to the deterioration of the plastic

components in a hot, arid climate when exposed to ultraviolet light.

6.4 Applications

1. Drip irrigation is adopted extensively in areas of acute water scarcity and

especially for crops and trees such as coconuts, containerized landscape trees,

grapes, bananas, eggplant, citrus, strawberries, sugarcane, cotton, maize, and

potatoes.

2. It can be used in residential gardens.

3. It can be used in homes.

4. It can be used in commercial places.

5. It can be used in agriculture.

6. It can be used in commercial green houses.

7. Drip irrigation for garden available in drip kits are increasingly popular for the

homeowner and consist of a timer, hose and emitter. Hoses that are 4 mm in

diameter are used to irrigate flower pots.

6.5 Future Directions

We can run this system using solar panel also which will save the power.

We can connect this system to computer.

GHRCEM, Ahmednagar (E&TC Engineering) Page 26

Automatic Drip Irrigation System

REFERENCES

A. Papers

[1] Lala Bhaskar, Barkha Koli, Punit Kumar, Vivek Gaur, `` Automatic Crop

Irrigation System ``, IEEE 2016.

[2] Drashti Divani, Pallavi Patil, Prof.Sunil.K.Punjabi, `` Automated Plant

Watering System ``, 2016 International Conference on Computation of Power,

Energy Information and Communication (ICCPEIC)

[3] Jagdeep, Ritula Thakur, Daljit Singh Microcontroller Based Automatic

Sprinkler Irrigation System, IJMER Apr 2015

[4] Muhammad Azman Miskam, Othman Sidek, Inzarulfaisham Abd Rahim,

Muhammad Qayum Omar and Mohammad Zulfikar Ishak, `` Fully Automatic

Water Irrigation and Drainage System for Paddy Rice Cropping in Malaysia``,

2013 IEEE 3rd International Conference on System Engineering and Technology,

19 - 20 Aug. 2013, Shah Alam, Malaysia.

[5] Jia Uddin, S.M. Taslim Reza, Qader Newaz, Jamal Uddin, Touhidul Islam, and

Jong-Myon Kim, Automated Irrigation System Using Solar Power 2012 IEEE

[6] Sami Safety, Ayoub Al-Hamadiy, Bernd Michaelisy, Usama Sayedz, An

Acoustic Method for Soil Moisture Measurement, IEEE 2004

B. Books

[7] Kenneth Ayala, The 8051 microcontroller.

[8] M. A. Mazidi, The 8051 microcontroller and embedded system.

C. Web sites

[9] http://en.wikipedia.org/wiki/www.atmel.com

[10] http://www.alldatasheets.com

GHRCEM, Ahmednagar (E&TC Engineering) Page 27

Automatic Drip Irrigation System

APPENDIX

Code

#include <REGX51.H>

#include"init_pin_PB1.h"

#include"delay.h"

#include"lcd.h"

#include"key_press.h"

//#include "i2c.h"

//#include"EPROM.h"

unsigned int sec_count=0,ms_count=0,min_count=0,Key,T1_on,T1_off;

unsignedchar

min=0,sec=0,hour=0,RUN_Mode_Flag=0,HrMin_Selection=0,HrMin1_Selection

=0;

unsigned int TON,TOFF;

/*****************************************************************

******************/

void timer0_ISR (void) interrupt 1

{

ms_count++;

if(ms_count>=14)

{

ms_count=0;

sec_count++;

sec =1;

}

if(sec_count >60)

{

sec_count=0;

GHRCEM, Ahmednagar (E&TC Engineering) Page 28

Automatic Drip Irrigation System

min_count++;

min =1;

}

if(min_count >60)

{

min_count=0;

hour =1;

}

TH0= 0x00;

TL0= 0x00;

}

/***********************************************************/

void init_timer()

{

TMOD &= 0xF0;

TMOD |= 0x01;

TH0=0x00;

TL0=0x00;

EA = 1;

ET0 = 1;

TR0 = 1;

}

/***********************************************************/

void off_timer()

{

EA = 0;

ET0 = 0;

TR0 = 0;

}

/*************************************************************/

GHRCEM, Ahmednagar (E&TC Engineering) Page 29

Automatic Drip Irrigation System

void Display_3digit_no(char a, char b,unsigned int num)

{

unsigned int Result;

unsigned char arr[3];

arr[0]= (num/100) +48;

Result= (num % 100);

arr[1]= (Result/10) +48;

arr[2]= (Result % 10) +48;

Lcd_Set_Cursor(a,b);

Lcd_Write_String(arr);

}

/*****************************************************************

****/

void Set_Programm()

{

unsigned int cnt=0,Result=0,S_Count=1;

char shift_flag=0,Time_count=0,Set_flag=0,i=0,a=0,cur_pos,b=0;

while(Time_count<2)

{

cnt=0;

Lcd_Clear();

if(Time_count==0)

{

Lcd_Set_Cursor(1,1);

Lcd_Write_String("T ON:");

}

else

{

Lcd_Set_Cursor(1,0);

Lcd_Write_String("T OFF:");

GHRCEM, Ahmednagar (E&TC Engineering) Page 30

Automatic Drip Irrigation System

}

Display_3digit_no(1,6,0);

Lcd_Set_Cursor(1,9);

Set_flag=0;

Lcd_Set_Cursor(1,9);

Lcd_Write_String(" Min");

cur_pos=8;

Lcd_Cursor_Blink(1,cur_pos);

while(Set_flag==0)

{

Key = key_press();

switch(Key)

{

case UP:

{

cnt++;

if(cnt>9) cnt=0;

a=cnt+48;

Lcd_Set_Cursor(1,cur_pos);

Lcd_Cursor_off();

Lcd_Write_Char(a);

break;

}

case SHIFT:

{

Result= (S_Count*cnt)+Result;

S_Count=S_Count*10 ;

cnt=0;

cur_pos=cur_pos-1;

if(cur_pos <6)

GHRCEM, Ahmednagar (E&TC Engineering) Page 31

Automatic Drip Irrigation System

{

Set_flag=1;

break;

}

Lcd_Cursor_Blink(1,cur_pos);

shift_flag=1;

break;

}

case ENTER:

{

Lcd_Cursor_off();

Result= (S_Count*cnt)+Result;

if(Time_count==0)

{

TON=Result;

}

else

{

TOFF=Result;

}

Result=0;

S_Count=1;

cnt=0;

Set_flag=1;

Time_count++;

break;

}}

}

}

GHRCEM, Ahmednagar (E&TC Engineering) Page 32

Automatic Drip Irrigation System

/*****************************************************************

****/

void Run_Sequantial_Timer(unsigned int Time,unsigned char Relay_Status)

{

unsigned int Run_Time;

Run_Time = Time;

init_timer();

while(1)

{

if(LEVEL_Sensor==0)

{

BUZZER=1;

}

if(LEVEL_Sensor==1)

{

BUZZER=0;

}

Display_3digit_no(1,6,Run_Time);

if( Rain_Sensor==0)

{

RELAY =0;

}

else

{

RELAY =Relay_Status;

}

if (min==1)

GHRCEM, Ahmednagar (E&TC Engineering) Page 33

Automatic Drip Irrigation System

{

min =0;

Run_Time = Run_Time-1;

if(Run_Time==0)

{

delay_ms(100);

break;

}

}

}

}

/*****************************************************************

***********/

void main()

{

Init_Port();

Lcd_Init();

Lcd_Clear();

Lcd_Set_Cursor(1,1);

Lcd_Write_String("drip irrigation");

Lcd_Set_Cursor(2,1);

Lcd_Write_String("advance");

delay_sec(3);

Set_Programm();

while(1)

{

if( Rain_Sensor==0)

{

RELAY =0;

GHRCEM, Ahmednagar (E&TC Engineering) Page 34

Automatic Drip Irrigation System

}

if(LEVEL_Sensor==0)

{

BUZZER=1;

}

if(LEVEL_Sensor==1)

{

BUZZER=0;

}

if(RUN_Mode_Flag==0)

{

if(LEVEL_Sensor==0)

{

BUZZER=1;

}

if(LEVEL_Sensor==1)

{

BUZZER=0;

}

Lcd_Clear();

Lcd_Set_Cursor(1,1);

Lcd_Write_String("T ON:");

Lcd_Set_Cursor(1,10);

Lcd_Write_String("Min");

if(TON>0)

{

Run_Sequantial_Timer(TON,1);

delay_ms(10);;

off_timer();

}

GHRCEM, Ahmednagar (E&TC Engineering) Page 35

Automatic Drip Irrigation System

else

{

Display_3digit_no(1,6,0);

delay_ms(500);

}

}

if(RUN_Mode_Flag==0)

{

if(LEVEL_Sensor=0)

{

BUZZER=1;

}

if(LEVEL_Sensor=1)

{

BUZZER=0;

}

Lcd_Clear();

Lcd_Set_Cursor(1,0);

Lcd_Write_String("T OFF:");

Lcd_Set_Cursor(1,10);

Lcd_Write_String("Min");

if(TOFF>0)

{

Run_Sequantial_Timer(TOFF,0);

off_timer();

delay_ms(10);;

}

else

{

Display_3digit_no(1,6,0);

GHRCEM, Ahmednagar (E&TC Engineering) Page 36

Automatic Drip Irrigation System

delay_ms(500);

}

}

}

}

GHRCEM, Ahmednagar (E&TC Engineering) Page 37

Você também pode gostar

- BE FinalDocumento38 páginasBE FinalpriyapgandhiAinda não há avaliações

- PrachiDocumento24 páginasPrachipriyapgandhiAinda não há avaliações

- INF4300 2011 f02 TextureDocumento15 páginasINF4300 2011 f02 TexturepriyapgandhiAinda não há avaliações

- Front PageDocumento4 páginasFront PagepriyapgandhiAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- TDS - Tassel Neo FloodDocumento1 páginaTDS - Tassel Neo Floodmurugan.ragulAinda não há avaliações

- Space Division MultiplexingDocumento1 páginaSpace Division Multiplexingx3b0Ainda não há avaliações

- A11 Electric Diagram-3Documento7 páginasA11 Electric Diagram-3Ibrahim TamerAinda não há avaliações

- Machinery Protection Devices ChapterDocumento50 páginasMachinery Protection Devices Chaptermilanstr100% (2)

- GEH-6729H Vol1 MVe UpgradeDocumento190 páginasGEH-6729H Vol1 MVe UpgradeJorge ContrerasAinda não há avaliações

- Chapter 11Documento28 páginasChapter 11gag1989Ainda não há avaliações

- APCN Series Screw Chillers: Range 45 TR To 470 TR (158 KW To 1600 KW)Documento43 páginasAPCN Series Screw Chillers: Range 45 TR To 470 TR (158 KW To 1600 KW)Ahmad Salah100% (1)

- EET455 - M2 Ktunotes - inDocumento62 páginasEET455 - M2 Ktunotes - inrajkumarAinda não há avaliações

- Electronic Warfare FundamentalsDocumento171 páginasElectronic Warfare FundamentalsChandra Sekaran100% (1)

- Precision-490-Dt - User's Guide - En-Us PDFDocumento170 páginasPrecision-490-Dt - User's Guide - En-Us PDFgdfeiu dionwdnAinda não há avaliações

- Technological Applications of SuperconductivityDocumento3 páginasTechnological Applications of SuperconductivityDaria CulaghinAinda não há avaliações

- SMT ConsumableDocumento20 páginasSMT ConsumableLam HoangAinda não há avaliações

- Circuits 1 IntroductionDocumento41 páginasCircuits 1 IntroductionKim OpenaAinda não há avaliações

- FischerDocumento1 páginaFischerJericho Morales0% (1)

- Ax Series User ManualDocumento15 páginasAx Series User ManualAl Fakhamah Lifts100% (1)

- Vacuum Switchgear Type VMX Spares ManualDocumento21 páginasVacuum Switchgear Type VMX Spares ManualAnupamAinda não há avaliações

- Ibraheem Gaffar 124002 PDFDocumento65 páginasIbraheem Gaffar 124002 PDFSriram ramsAinda não há avaliações

- 7-level cascaded H-bridge inverterDocumento17 páginas7-level cascaded H-bridge inverterKcian RanjanAinda não há avaliações

- Download-Guide To Install PDFDocumento40 páginasDownload-Guide To Install PDFTran Cong HauAinda não há avaliações

- Manish Expt2 Lab Observation Record 1Documento12 páginasManish Expt2 Lab Observation Record 1Yasir MalikAinda não há avaliações

- LC171W03 C4 PDFDocumento29 páginasLC171W03 C4 PDFAnderson Duarte100% (1)

- Advantages of Automatic Switching System Over The Manual ExchangesDocumento9 páginasAdvantages of Automatic Switching System Over The Manual ExchangesWodari HelenaAinda não há avaliações

- rr310204 Power ElectronicsDocumento5 páginasrr310204 Power ElectronicsSRINIVASA RAO GANTAAinda não há avaliações

- Feature-Automatic Transfer Scheme 3ppDocumento2 páginasFeature-Automatic Transfer Scheme 3ppJason29Ainda não há avaliações

- Phase To Earth Clearance As Per NECDocumento1 páginaPhase To Earth Clearance As Per NECYuvaraj SathishAinda não há avaliações

- Lab ManualDocumento48 páginasLab ManualA'ziz MoAinda não há avaliações

- Diagram PLTA SLJDocumento4 páginasDiagram PLTA SLJMEi Cuiet Luph-LuPhAinda não há avaliações

- ARPANET to Satellite Broadband - A History of Internet ConnectivityDocumento3 páginasARPANET to Satellite Broadband - A History of Internet ConnectivityirnairAinda não há avaliações

- Ansys q3d Extractor Brochure PDFDocumento8 páginasAnsys q3d Extractor Brochure PDFMaria Lavinia IordacheAinda não há avaliações

- DTC ECM 164.186 Eng.Documento19 páginasDTC ECM 164.186 Eng.aqidiAinda não há avaliações